Masterclass : Pirelli 33kV Fluid Filled Oil Cable Jointing

Published 26 May 2021

uploaded by Chris Dodds – Sales Marketing Manager at Thore & Derrick

All Images Courtesy : Andrew Brezovszky (EHV Cable Jointer).

In a previous Guest Blog Andrew taught us the theoretical formula and then demonstrated the practical skill required in calculating and installing premoulded sleeves when jointing 110kV Extra High Voltage cable.

Today, Andrew leaves the classroom for the cable trench and provides a new Masterclass in “old-skool” oil cable jointing.

This contrasts perfectly with his modern day classic, XLPE Masterclass : 110kV Cable Preparation & Termination Using Prysmian Outdoor Sealing Ends

The 2 Masterclasses demonstrate the true depth of experience and craftmanship accumulated over decades that world class cable jointers hold – the ability to joint all cable types, whether oil, paper or XLPE with professional Certification across all manufacturers whether Pfisterer, ABB, Tyco, Brugg, 3M or Taihan.

Due to the polymeric dominance of modern cable manufacturing many of the “traditional” jointing skills are no-longer taught in the jointing schools. This is reinforced by cable accessory manufacturers making technological revolutions in the design of cable joints and terminations, such as 3M QS4 Cold Shrink.

Increasingly at 11kV and 33kV voltages cable joints and terminations are now designed to simplify the installation process – while this is not a deliberate attempt to “de-skill” cable jointing it inevitably leads to a slimmer skill-set requirement for todays MV jointer.

This series of Photographs is an enthralling counterpoint to the daily stream of “polymeric posts” on our Blog.

Pictured : 33kV Fluid Filled 3 Core Cable, 0.5 Square In.(cca 325sqmm) Copper Conductor PAPVC (Aluminium Sheathed). Made by Pirelli Cables. Pirelli transferred ownership to Goldman Sachs Capital Partners and is now called Prysmian Cables & Systems Limited.

Pictures show the process of cable excavation, preparation and jointing. The sequence also shows site set-up with 2 separate scaffolding for the cable joint bays, fencing, generator, lighting tower, oil trailer, shipping container for jointing tools and materials.

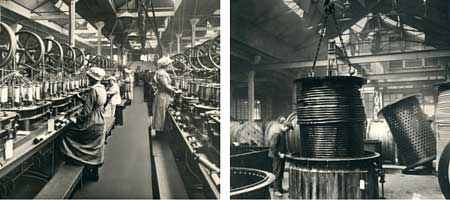

Pictured : In 2014, Prysmian (formerly Pirelli Cables) celebrated 100 years in Southampton UK. Cable Braiding Machine and Lowering Paper Cables Into A Vacuum.

New 33kV cable supported by cable rollers and jacks pulled in from drum and installed

Platforms Erected – 33kV cable ready for cut and cap

Cable Cut & Cap Plumbed Onto Drum – oil lines reconnected after final flush

Flow Board & Oil Trailer – the supply is set and ready for cutting the cable the next morning

Cables Cut, Flushed From Filing & Impurities – the 33kV aluminium cable sheath is removed with great care so the cores and insulation are not damaged. The cable gland is then plumbed onto the cable sheath.

33kV Cable Preparation- after more cable preparation work the 33kV cable cores are set, measured and cut to length

Sorry – doing the sweating left me with no hands, so that’s the final product

Ferruling – 33kV cable ferrules cleaned up

Chamfered 33kV Cores Ready For Taping – the white tape isn’t insulation tape 😉 just saying!

Cores Taped

Cores Taped

Installing Screening Layer

Padding

33kV Can Installed

33kV Outer Joint Box Installed

Pirelli – all jointing materials, cable, taping paper supplied by Pirelli

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.