Care & Maintenance Of Separable Cable Connectors For High Voltage Power Systems

Published 07 Jun 2018

-

Uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Thorne & Derrick International, were recently asked by an installer of MV HV Power Cables & Systems to comment on the condition and service performance of some screened separable connectors into medium/high voltage switchgear. The contractor had suffered a succession of switchgear cable termination failures and there was uncertainty about trouble-shooting the root cause – whether poor workmanship from the cable jointers or improper routine maintenance were the main cause. The contractor understood that the MV-HV terminal of the separable connector, pictured below Interface C bushing, should be treated once or maximum twice a year with silicone grease.

As Main Stockists & Distributors for the Nexans Euromold range of cable joints, terminations and connectors for high voltage power systems we decided to ask their Technical Manager for a response.

Reply from Mick Dawn – Nexans Technical Manager (Nexans Power Accessories NPA)

These are not Nexans connectors, they are Tyco separable connectors. However, I will comment on the silicone grease suggestion as it would also be relevant to Nexans and other manufacturers of MV HV screened separable connectors. There is no reason to “treat” the contact within the separable connector with grease. In fact, Nexans expressly state in our installation instructions that lubricant is not present on threaded parts as this may interfere with achieving the correct torque. The purpose of the contact is the safe transfer of electrical power between the MV-HV cable and the electrical equipment and applying grease will not facilitate any improvement in that operation and may well contribute to failure as grease between current carrying components may well lead to a high resistance contact and considerable heat generation. If the separable connector has failed then this could be down to any number of factors and if necessary a fault investigation can be carried out and generally a rational explanation can be deduced as most of the connector will still be available for examination. Even if there has been significant heat damage due to poor connection then it is usually still possible to determine a cause of failure.

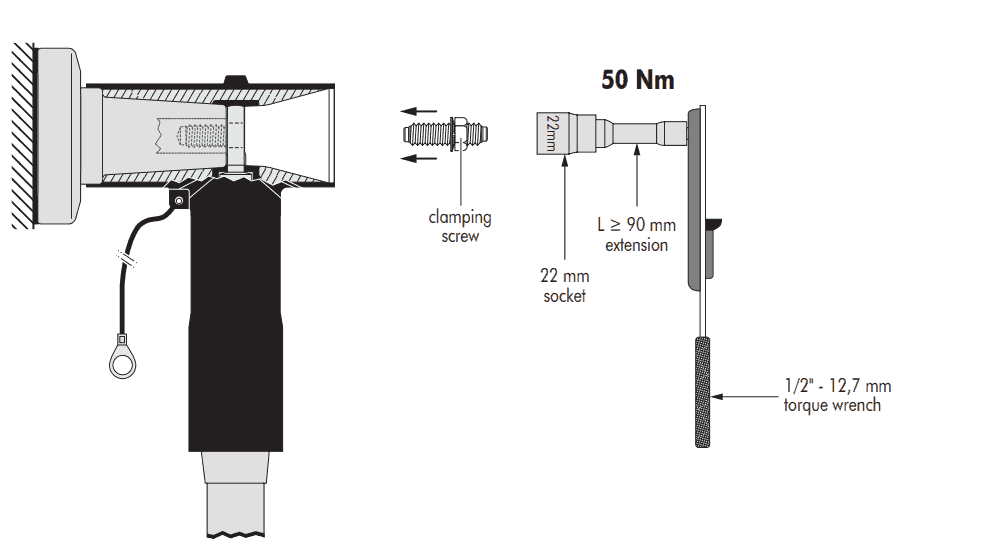

➡ The following image taken from Nexans Connectors – Installation Instruction Separable Tee Connectors (Type C Interface) Document

The image shows the insertion of the clamping screw into the threaded hole of the bushing. A torque wrench is used by the jointer with a socket wrench 22 and tighten exerting 50 Nm (5 kgm or 36,9 foot-pounds) of torque. In order to achieve the correct applied torque ensure that there is no lubricant on the threaded parts.

Nexans Connectors – Type C Bushings

Thorne & Derrick MV HV Joints | Terminations | Connectors

Thorne & Derrick

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Further Reading

-

Nexans Connectors – Installation Instruction Separable Tee Connectors (Type C Interface) Size: 204.79 KB