Jointers Blogs

A Photoblog: 138kV Southwire Cable Pull & Termination by Allteck Contractors

December 15th, 2020This Article was originally published in September 2015.

Andy O’Malley and Jimmy Nicklin have been jointing cables together for more than a decade.

Andy is a 420kV Cable Jointer and EHV Cable installation  Supervisor while Jimmy Nicklin is an HV/EHV Cable Jointer, Splicer and acknowledged oil cable expert up to 500kV.

Supervisor while Jimmy Nicklin is an HV/EHV Cable Jointer, Splicer and acknowledged oil cable expert up to 500kV.

Both are employed by Allteck, international leaders in the design, construction, maintenance and upgrade of overhead and underground high voltage electric power utilities.

The following sequence of site installation photographs demonstrate the high skill levels deployed by the Allteck team in the cable pulling, termination and installation of a Southwire Canada 138kV cable system.

Southwire Company is North America’s leading manufacturer of wire and cable used in the distribution transmission of electricity.

Together, Allteck and Southwire Canada deliver power 24-7-365.

We all take electric power, heat and light for granted. Until we suffer blackout.

Let us offer thanks to those who power our homes and businesses through the simple act of flicking a switch.

To the Splicers and Linemen who face sleepless nights, dizzying heights, atrocious weather and the constant threat of electric shock.

To the pioneering Cable Manufacturers striving to advance technology and improve the reliability of power systems, whether underground or overhead.

Thank you Allteck and Southwire Canada.

Images Courtesy : Andy O’Malley & Jimmy Nicklin

Installation Credit : Andy O’Malley, Jimmy Nicklin & Allteck Crew

Jetset Jointers – Head in the clouds but feet firmly on the ground. Flying into Ontario the Allteck Team will be talking through the “game plan” for the 138kV Southwire cable installation. Working at high voltage and high height is high risk. “Great Safety is Great Business” is Allteck’s maxim and No.1 core value.

Sub-Zero – Sharp chill in the air and a hard ground frost with the dawn sun reflecting on the frozen ice as the Allteck Team arrive at the job site.

Getting Started – cable jacket scraping is key stage of EHV cable preparation.

Lift-Off – cable pulling commences with completion of the cable chute.

Heave-Ho – cables pulled up monopole ready for scaffolding and then terminating.

Tools of the Trade – cable jointers must hold the correct cable jointing tools to strip and remove cable jacket, cable insulation and cable semi-conductive screens from high voltage cables.

Cable Jointing – high voltage cable stalk positioned and sealed.

If The Cap Fits – hard hat swapped out for baseball cap worn for critical parts of the job once the cable oversheath has been removed as it is critical to not damage the cable insulation.

Wiping Down – a highly skilled stage of cable termination

A Master Craftsman – Jimmy Nicklin (Allteck) showing the world how to “wipe”.

Stripping Off – removal of semi-con screen using Hivotec CP90 jointers tool.

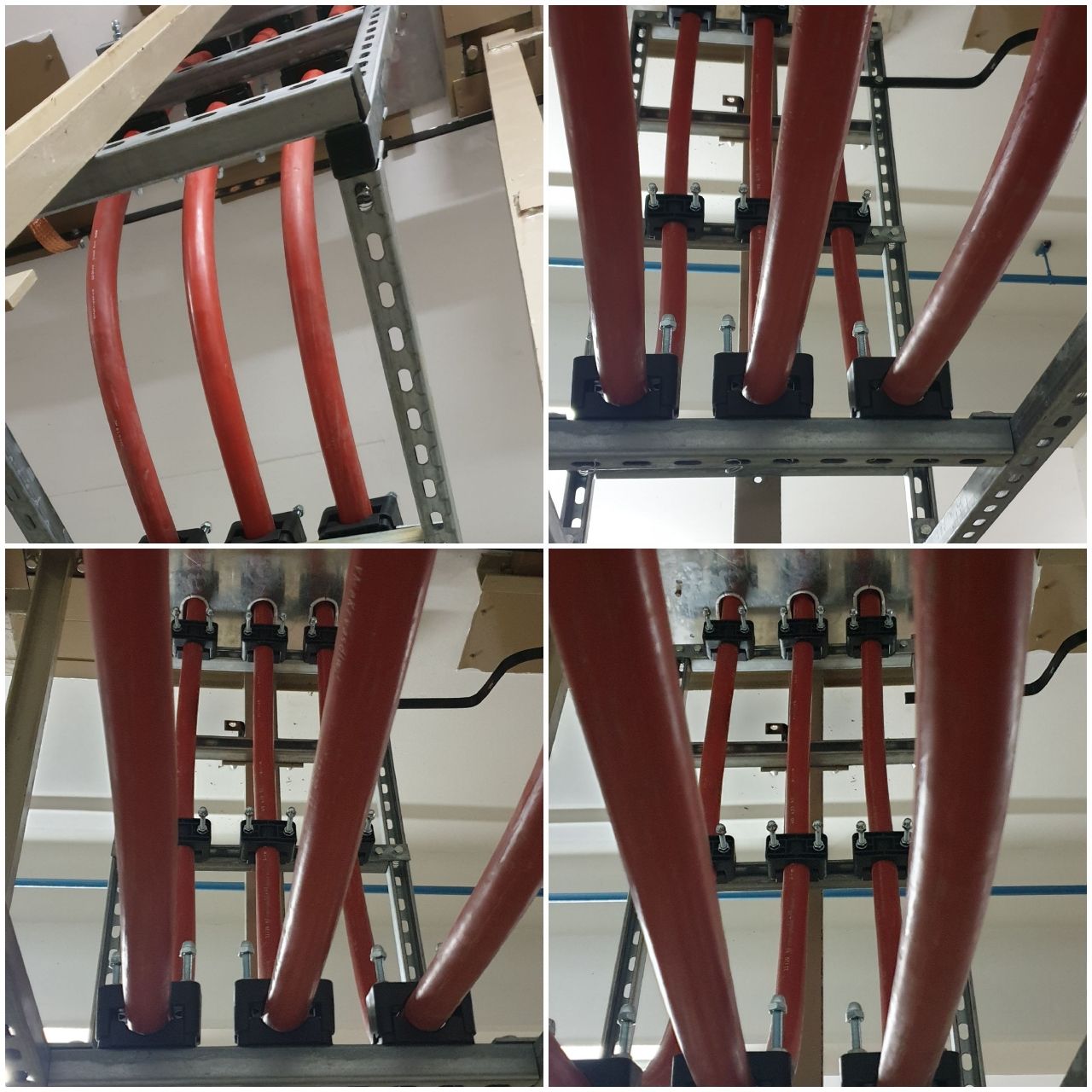

No Cheating On Cleating – installing transmission cable cleats to retain the 138kV cable in the event of short-circuit condition (as if). Southwire cable supported by Southwire cable cleats installed by Allteck crew.

Mission Accomplished – completed NKT ODSE 138kV Cable Termination

Why Specify Southwire?

138kV Southwire Cable Specification & Benefits

- Compressed Round or Compacted Segmental Conductor

- Corrugated Metallic Sheath or Copper Laminate Sheath

- True Triple Extrusion

- Super Clean XLPE Cable Insulation

- Insulation Thickness 650 mils-850 mils

Conductor Material & Size

The choice of the conductor material, copper or aluminium, is a matter of customer preference and required current carrying capacity. For larger loads, copper is the most common option. When both copper and aluminium conductors can satisfy power system requirements, the more economical solution will be a function of the metal and the cable components costs in effect.

Insulation Thickness

Cables referred to by “Traditional Wall” insulation (850 mils) follow the traditional insulation wall practice referenced in ICEA standard S-108-720 appendix F as still specified by a number of customers and utilities. For cables with a radial moisture barrier, “Southwire(SW) Standard Wall” thicknesses of 650 mils in accordance with AEIC specification CS9 are recommended. For applications requiring smaller cable diameters, cables with reduced insulation thickness are available upon request within the stress limits in AEIC specification CS9.

Cable Sheath Material

Copper and aluminium corrugated sheaths offer the best mechanical and moisture protection for HV cable. In addition, copper will provide better short circuit performance and improved connectability. Another option is Southwire composite laminate sheaths in both copper and aluminium that offer excellent protection against moisture ingress.

Cable Jacket

Southwire standard outer jacket is extruded LLDPE with a co-extruded outer semi conductive polyethylene layer for jacket integrity testing. Halogen Free Fire Retardant (HFFR) compounds are available upon request for installations in cable trays and ventilated troughs.

Southwire is one of the world’s leading manufacturers of Wire and Cable, Tools, Components and Assembled Solutions.

“We Want To Produce The Best Wire Products”

Southwire is one of the world’s leading developers, manufacturers and suppliers of building wire and utility cable, as well as the cable tools used in their installation. As such, Southwire are continually improving their products, studying how they’re used in the field and assessing the needs of their customers to find new and better ways to solve the problems facing the industry.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

High Voltage Cable Joints

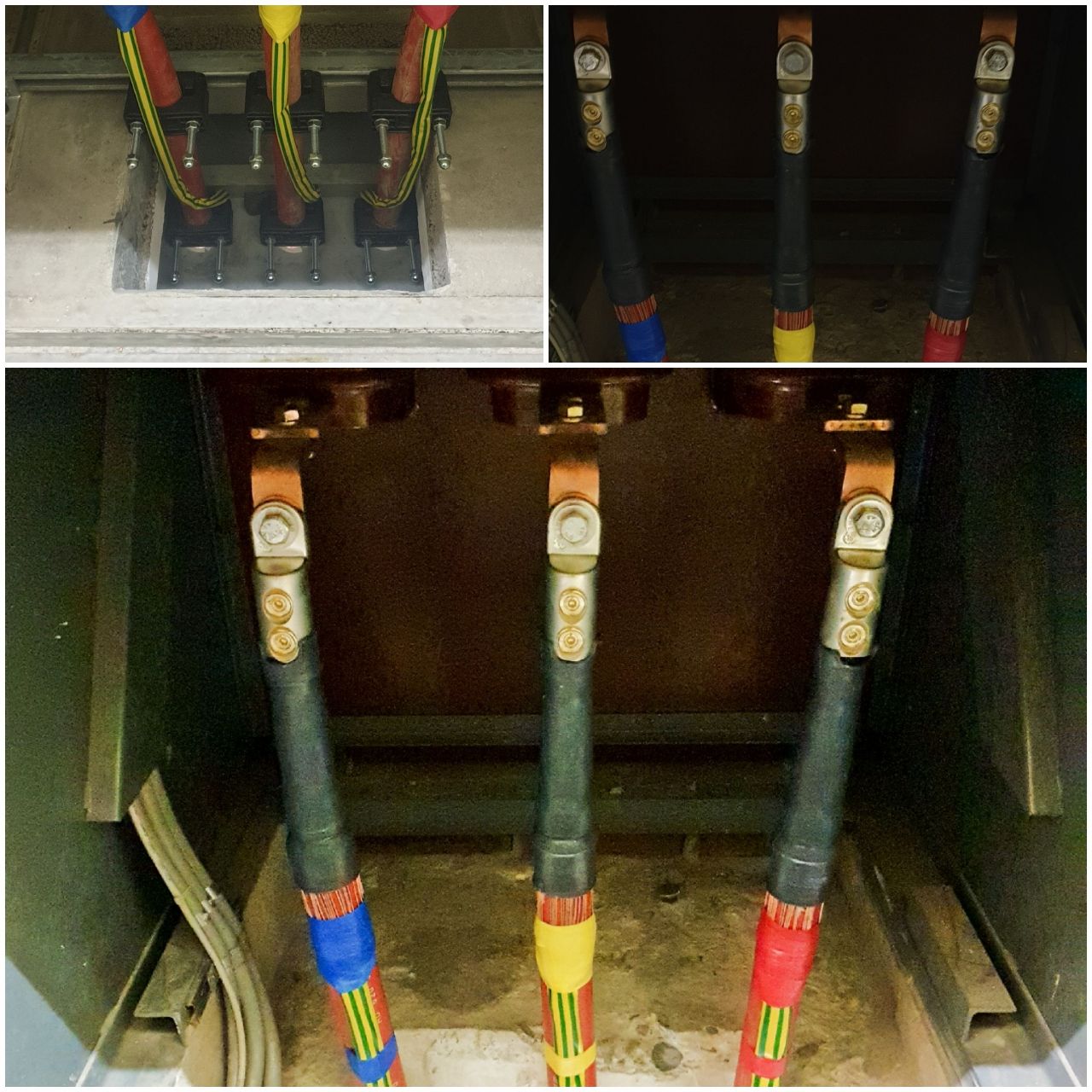

December 9th, 2020Images Courtesy of: Ace David – Owner & Founder of David Laag en Middenspannings Montage (David Low & High Voltage Installation), Rotterdam, South Holland, Netherlands.

Pictured: The brand of cable accessories are Cellpack Compax CKM straight-through high voltage joints and Lovink LoviSil M105 (polymeric/paper (1-core) joints. Voltage of the cable is 10kV – the high voltage power cable circuit length is almost 4km of cables (400sqmm). The cable jointers used Intercable tools to carry out the cable preparation of the HV cables prior to jointing.

➡ Cellpack Compax CKM are plug-in type cable joints and are the only cable joints with a metallic connector pre-installed inside of the body of the joint.

High Voltage Joints

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Array Cables | High Voltage Cable Termination & Testing for Wind Farms

December 8th, 2020

Cable Terminations for Array Cables | Thorne & Derrick Stockist of 3M ColdShrink | Nexans Euromold | Pfisterer CONNEX up to 66kV

NEWS from HV3 Solutions Limited

by John Harrison | Director

HV3 Solutions have completed the High Voltage Cable Testing on Triton Knoll Windfarm.

All 90 Array Cables have had a full suite of tests including: LRM, TDR, VLF & PD.

The windfarm has the capacity to produce 857MW of sustainable clean energy which will power more than 700,000 homes. We as a company would like to take this opportunity to thank all employees and subcontractors who helped us achieve this huge milestone.

As this year comes to a close, we are gearing ourselves up for a very busy 2021 within the Onshore & Offshore Windfarm sectors.

Electrical High Voltage Cable Testing

& Fault Finding

HV3 are an established company of electrical engineers based in Hampshire, operating throughout the UK. Specialising in the testing/fault finding on HV/LV networks and new connections – company policy is to meet the customer’s needs and is supported by a wealth of experienced and competent staff.

4 vans carry the most up-to-date Cable Fault Location & VLF Testing Equipment available. All operators are fully trained and provide this service to the highest possible standards. Cable Fault Location services are available at short notice on a nationwide basis for the following:

- Cable Fault Location & Pinpointing

- VLF Testing up to 66kV rms

- Sheath Fault Location & Testing

- PD /TD Testing

- OTDR Fiber Testing

- Array Cable Terminations

Contact HV3 High Voltage Solutions

Unit 4, Salterns Lane Industrial Estate . Salterns Lane . Fareham . Hampshire . PO16 0SU tel 01329 826 881

Image: Daniel Whitnall

Further Reading

Thorne & Derrick are Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable

LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

See how T&D support, supply and service the Renewable Energy industry.

MV HV Cables 11kV 33kV 66kV | Cable Joints, Terminations & Connections

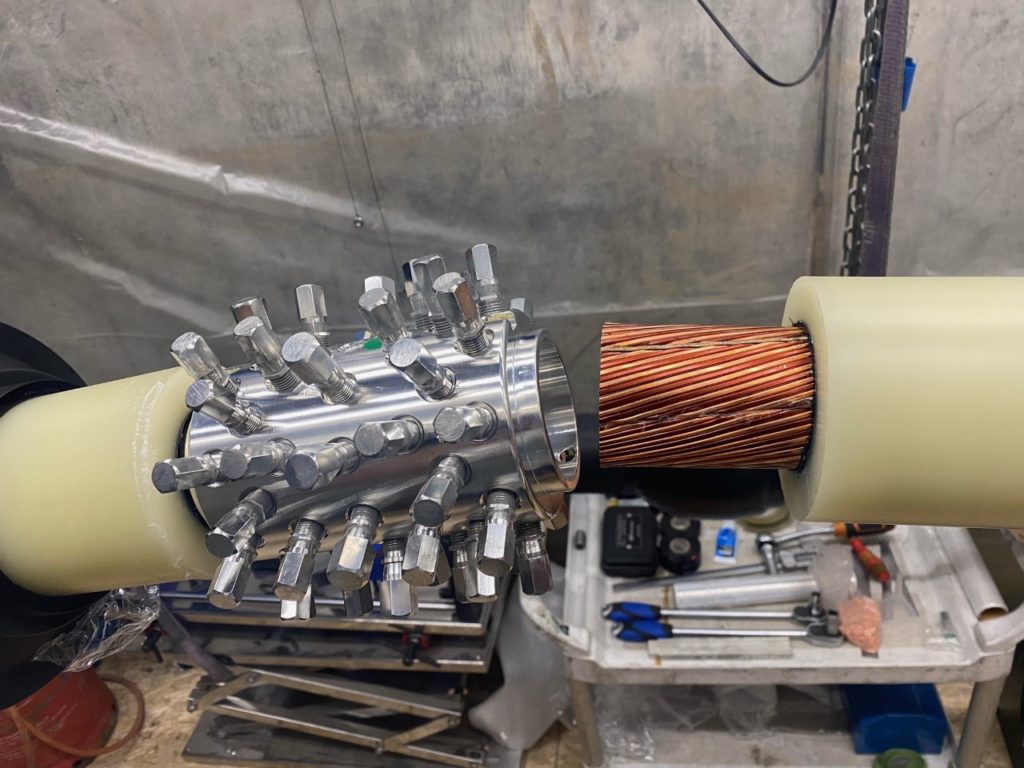

LS 220kV Cross Bonded Joint XLPE 2500sqmm Copper

November 25th, 2020Meet Richie Rice

Competent Master Craftsman | EHV Jointer

Richie Rice has a wealth of experience in the EHV Cable Sector and is expert and advanced skilled working on XLPE, HVDC Light XLPE, Oil/Gas Filled Cable Systems from Jointing & Terminating to VLF/ Sheath Testing. Certified from some of Europe’s leading manufacturers of GIS/ODSE Terminations & Straight / Sectionalised / Cross Bonded Joints up to 275kV.

Competent & Certificated by leading manufacturers of Cold Applied, Heat Shrink, Taped Joints & Terminations MV HV.

Supervision of Cable Installations overseeing all aspects of Works & Commissioning are carried out to client’s specifications – working in the Offshore Renewable Industry on Export & Array Cabling including Jointing/Terminating & Testing on power systems up to 155kV. Trained and Certified for VLF Testing of High Voltage Cables (XLPE) up to 120kV.

Contact [email protected] | or Connect via LinkedIn.

Technical Jointing Note: The paper beddings are not remove from the inner segment of the cable conductor – LS use copper particles between the cores compressed by 10no shear bolts that transfers current through these particles and this is why papers are not removed as is standard process where connectors are used for current transfer. This copper particle technique saves the cable jointer from opening cores and removing papers and the water blocking tapes – this is a significant benefit especially on Milliken Conductors.

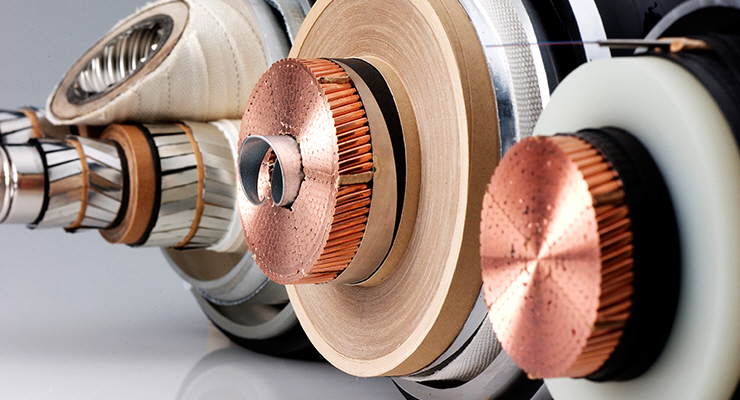

LS Cable & Systems

Extra-high voltage cables require the power network to go underground due to continuous increase of energy demand, larger transmission capacity, reliability of energy supply, safety and aesthetic issues. Among these cables, XLPE insulation cables are used widely due to their ease of handling, simpler jointing connectivity and maintenance, outstanding electrical features and other benefits.

XLPE Cables

The basic material for XLPE is polyethylene, which is chemically transformed to cross-linked polyethylene (XLPE) through the cross-link reaction of organic peroxides. The cross-link method for polyethylene was developed in the United States during the 1950’s and has since been continuously developed for application to higher voltage cables. Higher voltages are increasingly being required and now 500kV XLPE cables have already been commercialized by LS Cables.

Thorne & Derrick

Joints & Terminations

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Raychem Terminations for Medium Voltage Power Connections

November 24th, 2020Image Courtesy of: John Perrott (Director of Power at AIS)

Pictured Below: Raychem Terminations

Jointer: Ernie Briones

Accurate Infrastructure Solutions

Accurate Infrastructure Solutions is a dynamic contracting and consultancy business with expertise across a multitude of industries, including:

Offshore Support – quickly and reliably meeting all client’s short, medium or long-term, technical and general support requirements via ‘virtual’ / ‘remote’ assistance from qualified, globally experienced professionals based in AIS’s Philippines offices.

Construction – providing skilled construction professionals and solutions within the civil, commercial, residential, infrastructure, and engineering industries by way of labour only or full contract basis.

Power – providing skilled, qualified, & experienced tradesman & professionals as well as full contract solutions to the power industry within the civil, generation, transmission, distribution sectors.

Recruitment – bringing together end to end domestic & international recruitment and mobilisation solutions within any industry by offering diverse & flexible methods of engagement.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.