Medium Voltage Cable Accessories – Best Practice Guide

Cables | MV Paper Insulated v MV Polymeric Insulated Cables

January 9th, 2020MV Paper Insulated

Until the 1980s, most of the MV cables installed by utilities and industry were paper-insulated type in which the insulation over the conductor(s) is built up by applying multiple layers of special cellulose paper. This paper insulation has to be impregnated with insulating oil or compound to exclude air and impart good electrical properties. A common feature of all paper cables is a metallic sheath, normally extruded lead or aluminium, enclosing the paper-insulated core(s). The main purpose of the metallic sheath is to give the paper insulated cores complete protection from the environment outside the cable.

Figures 1, 2 and 3 show examples of 3-core cables with lead sheaths and steel tape or wire armour. The three common constructions are:

- ‘Belted’, with an overall lead or aluminium sheath enclosing the three cores (Figure 1). This construction is common only with cables of rated voltage 12 kV and below,

- ‘H’ (‘screened’), with a metallic foil screen covering each core, and an overall lead or aluminium sheath (Figure 2),

- ‘HSL’, with a lead sheath covering each core (Figure 3).

These three cable types each require their own accessory designs, so it is important to identify the cable construction details in order to select the right joint or termination.

Figure 1 – 12kV ‘belted’ paper-insulated cable with overall lead sheath and steel tape armour

Figure 2 – ‘H’ type or ‘screened’ 36kV paper-insulated cable with overall lead sheath and steel wire armour

Figure 3 – ‘HSL’ 24kV paper-insulated cable with individual lead sheaths and overall steel tape armour

MV Polymeric Insulated Cables

In most European countries, paper insulated cables have been superseded by cables with extruded polymeric (plastic) insulation in place of paper. The insulation material in these modern cables is either crosslinked polyethylene (XLPE) or ethylene propylene rubber (EPR).

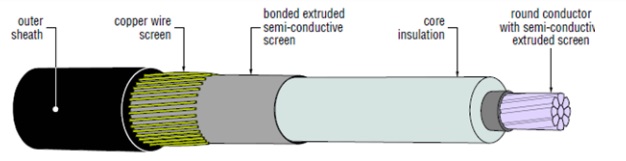

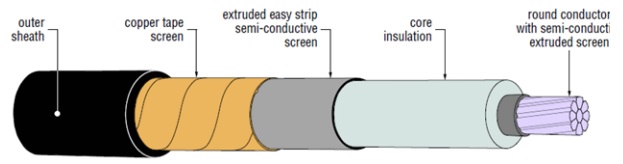

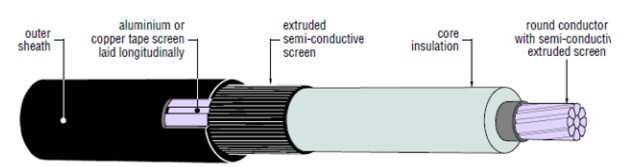

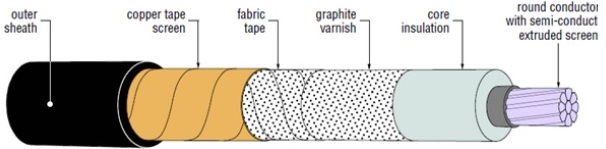

Figures 4 to 9 show typical single-core polymeric cables, though there are other design variations of cables for special applications. Similar design variety applies to 3-core cables, of which Figure 10 is one example. Figure 11 is an example of a 3-core bundle comprising 3 single-core cables supplied twisted together.

All these cables have an extruded polymeric outer sheath, usually PVC or polyethylene, and some form of metallic screen, typically copper wires or tapes, or longitudinally-applied aluminium or copper foil laminate. In addition, or sometimes in place of these screens, there may be an armour layer comprising steel tape or wire, or aluminium wire.

For protection against moisture entry, some cables are made with an extruded lead or aluminium sheath, and there may also be water-swellable tapes (Figure 9) or powder to prevent water passing along the cable under the sheath.

What is important for the installer is that he is aware of the function of each of the cable components and knows, with the help of the installation instruction, what to do with each of them as part of the procedure to prepare the cable ends.

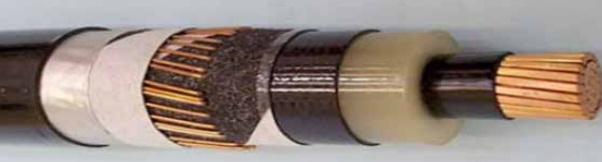

At the heart of all modern MV polymeric cables is a three-layer extrusion comprising:

- Inner conductive layer applied over the conductor (conductor screen);

- Insulation (XLPE or EPR) of defined thickness according to cable rated voltage;

- Outer conductive layer applied over the insulation (insulation screen).

The outer conductive layer is often referred to as the ‘semicon screen’. An alternative insulation screen, typical of earlier designs of polymeric cables, is a conductive (graphite) paint layer covered by a conductive fabric tape (Figures 7 and 8).

The different types of insulation screen; bonded, strippable and paint & tape, each require different methods and different jointing tools for their correct removal as part of the accessory installation procedure.

Figure 4 – Single-core cable with bonded or strippable insulation screen and copper wire earth screen

Figure 5 – Single-core cable with bonded or strippable insulation screen and copper tape earth screen

Figure 6 – Single-core cable with aluminium or copper tape laminate earth screen bonded to the outer sheath

Figure 8 – Single-core cable with conductive paint & tape insulation screen and copper tape earth screen

Figure 9 – Single-core 36 kV cable with XLPE insulation, bonded insulation screen, copper wire earth screen, waterswellable tapes and PVC outer sheath

Figure 10 – Typical 3-core 12 kV cable with copper tape earth screens and steel wire armour

Figure 11 – Single-core cables supplied twisted together to form a 3-core bundle

Although it is many years since paper cables were installed as standard, there is still a demand for ‘transition joints’ to connect new polymeric cables into existing paper cable networks owned by electricity utilities. The requirements for correct handling and preparation of paper cables and polymeric cables are quite different, as will be seen in later sections.

Further Reading

- The Installation Site | MV Cable Joints & Cable Terminations

- First Steps | MV Joints, Jointers & Initial Considerations

- Cable Preparation | Jointing & Terminating Aspects of MV Cable Preparation

- Conductor Connectors | Crimp v Mechanical Connectors with Joints & Terminations

- Earth Bonding | Joints & Terminations & Overheating Prevention

- MV Cable Accessory Technologies | Heat Shrink, Cold Shrink & Push-on

- MV Cables & Causes of MV Cable Failures

- MV Cables | Electric Field & Stress Control

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV