DIN Standard – Crimping & Compressing Aluminium Cable Lugs & Connectors

Published 04 Sep 2018

DIN Standard – Crimping & Compressing Aluminium Cable Lugs & Connectors

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Thorne & Derrick International, based in the UK, are leading suppliers of cable crimp lugs and associated crimping tools for Low, Medium & High Voltage Cables and Power Systems – this series of articles by Klauke discusses the theory and practise of installing compression type cable lugs and connectors.

Klauke cable lugs and crimping tools are used by Jointers, Linesmen, Panel Builders and Electrical Engineers to install underground cables and overhead line conductors on power, transmission and distribution networks including LV MV & HV systems, 11kV-33kV.

➡ Download 2018 Klauke Cable Lugs catalogue and see the complete range of tools for cutting and crimping cables.

In this Article we cover the following:

- Hexagonal crimping: the most common type of crimp for cable lugs and connectors

- Indent crimps – the traditional electrical cable crimp profile

- Intensive indent crimping – permanent and “deep acting” connection will be achieved

- Quad point crimps: centric force application and no crimping dies are needed

- Gastight oval crimps are being used predominantly in aggressive environments

Aluminium Cable Lugs & Crimping According To DIN

Best Practise for Installation

Material properties of aluminium cable are very different from those of copper cables and conductors. For safe electrical connections, solely compression cable lugs or connectors manufactured from aluminium are to be used. In addition, due to certain specific material properties the installation procedure has to be carefully observed.

The advantages of aluminium are increasingly coming to the fore in LV MV HV power distribution applications, due to the lower material weight and simple handling.

Power utilities tend to install more and more aluminium cables, for instance medium/high voltage ring main units for urban power supplies.

In principle, it is recommended to use solely high quality aluminium compression cable lugs with tube dimensions according to DIN Standard & DIN 46329 and aluminium connectors with tube dimensions according to DIN 46267 Part 2. Products of renowned cable lug and connector manufacturers such as Klauke are made from premium electrolytic aluminium alloy.

- DIN 46329 Cable Lugs – Compression Connections, Ring Type, For Aluminium Conductors. Standard by Deutsches Institut Fur Normung E.V. (German National Standard), 07/01/1983.

The barrier design with oil stop prevents leakage of oil from the paper insulated conductor.

These cable lugs feature a constant material thickness, exact diameter and a correct fit which ensures simple installation and absolute safety. Standard cross sections range from 10sqmm up to 500sqmm.

Installation of compression cable lugs and connectors for aluminium conductors is very different from installation of copper conductors. Failure of vital installation procedures can lead to a severe lack of safety and power outages.

Special sized cross sections are available up to 1000sqmm, for instance for subsea cables with high transmission capacities in the onshore and offshore wind and renewable energy sectors. Aluminium compression cable lugs feature a barrier design (according to DIN 46239) which allows installation on oil impregnated, paper insulated cables and consequently provides a firm water/oil block.

Aluminium Conductors & Cables

Aluminium conductors are available in four different types which in some cases require special installation procedures. These are as follows – should you require technical guidance, clarification or advice on crimping of aluminium cables and correct cable lugs and relating tools to use please do not hesitate to contact us:

- RE = Solid Round Conductors

- SE = Solid Sector Conductors

- RM = Round Stranded Conductors

- SM = Sector Stranded Conductors

Different types of aluminium conductors

These abbreviations can be found on aluminium compression cable lugs to make sure the correct cable lug is used with the appropriate aluminium conductor.

All markings on aluminium compression cable lugs are in conformity with those on copper cable lugs and indicate the manufacturer, dimensions and type of product.

For example marking “KL 18 10-70 /rm/sm 95 re/se” denotes:

- KL: manufacturer (in this case Klauke)

- 18: die set code

- 10: metric bolt size (bolt M 10)

- • 70: nominal cross section of conductor in sqmm

- rm/sm: for round stranded and sector stranded conductors

- 95: nominal cross section of conductor in sqmm

- RE/SE: for solid round conductors and solid sector conductors

Important: The nominal cross sections of SE and RE conductors are always one cross section size above the cross sections of SM and RM aluminium conductors.

This is due to solid conductors having a smaller diameter than their stranded equivalent type. Special attention should be given to the crimp tool and die set code.

For a professional installation the crimping dies of the appropriate crimping tool must be matched with the code of the cable lugs. Die codes on crimping dies are mirror-inverted – after the crimping operation the die code is clearly visible for quality control and documentation.

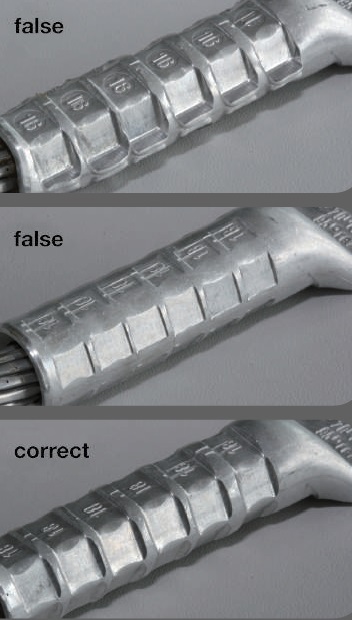

Imprint of die code “18” on the cable lug (above) indicates the crimping die used. Completed crimp (below) with marking “18” on the cable lug refers to the correct crimping die.

For a professional installation hexagonal crimping dies (according to DIN 48083 Part 4) are recommended.

Over compression (above) is the result of a crimping die which is too small, whilst under compression (middle) is caused by the use of a crimping die which is too large. The picture below shows a correct crimp using an appropriate crimping die.

The visible signs of a correctly crimped lug are the same for copper connectors as they are for aluminium.

In order to achieve a professional installation – with no over or under-crimping – the use of the appropriate cable crimping tool is essential.

An incorrect installation can result in increased joint resistance and even in fire.

To avoid such consequences Klauke recommends to use the same manufacturers tool as the lug or connector. This ensures a Matched Crimping System.

For instance the specific dies for aluminium cables have a crimping ‘bite’ width of 7mm, which is 2mm wider than for copper lugs and connectors.

The contact surface (bite width) of crimping dies for aluminium cable lugs (left) are 2 mm wider than their copper equivalent (right).

The reason for this is that wider compression areas result in better conductivity and therefore compensate for the poorer electrical properties of aluminium. In order to determine the different dies required Klauke manufacture the aluminium dies in silver and the copper dies in a yellow gold colour.

Compound for Aluminium Connectors

Cable lugs and connectors for aluminium are supplied with a special compound within the barrel.

Compounds with additives like corundum generate a “grinding effect”.

During crimping, this compound destroys the non-conductive oxide layer on the aluminium in the crimping area increasing the contact properties and ensuring the correct electrical connection. In addition the cable lug compound prevents entry of oxygen and consequently avoids any further oxidation.

The compound seals the joint and prevents oxidation.

To maintain the functional properties brand-name cable lugs are sealed with a plastic plug to prevent the compound from drying out and leaking from the cable lug.

Plastic plugs prevent compound from drying-out and leaking during storage.

Compounds for aluminium connectors contain additives such as corundum, a material similar to sand, which exhibits high resistance and hardness, temperature stabilising properties and extreme wear and corrosion resistance. A grinding effect is generated during crimping which cracks the hard oxide layer on the cable.

In addition, the compound aids the dynamic friction between the cable conductor and sleeve, which prevents jamming of materials and helps to provide a clean contact surface. When used on stranded conductors, the oxide inhibitor compound is distributed between the individual wires or cable strands during the crimping process and seals them against oxygen and moisture ingress.

It is also important to understand that aluminium crimp connections installed using compound perform much better when subjected to high current loads than those without compound.

To guarantee a safe connection, at high or low loads, Klauke recommends compression cable lugs and connectors with compound.

Installation of Aluminium Compression

Cable Lugs & Connectors

In order to accommodate the special characteristics of aluminium material, the following five installation steps are essential:

- Remove insulation of aluminium conductor

- Clean the blank conductor ends with a wire brush to remove an oxid film and to provide a clean surface

- Insert the conductor into the cable lug or connector to the recommended length

- Some compound will emerge from the mouth of the cable lug or connector which is now hermetically sealed to prevent further oxidation of the conductor

- Start the hexagonal crimping operation with a suitable crimping tool

- Important: Sector shaped conductors need to be pre-rounded with appropriate crimping dies

- Remove any excess compound emerging from the lug or connector

Please note: All DIN compression cable lugs show markings on the outside of the lug barrel for the correct crimp position and consequently number of crimps required. This is dependent on if the installer is using narrow or wide crimping dies.

Markings on the cable lugs indicate number and position of crimps as per manufacturers recommendation.

Always crimp in the direction of the conductor.

Start the first crimp at the lug end and progress towards the conductor to ensure that compacted material expands in this direction.

Aluminium & Copper Cable Lugs

A further important technical issue is the correct method of connecting aluminium and copper conductors – contact us for the jointing, connection and splicing of dissimilar conductor cables.

Further Reading

Review other Blogs in this series of articles about Cable Lugs, Crimping Cables & Tools:

Cable Lugs – Crimping Applications & Standards

Copper Cable Lugs For Special Applications

Indent Crimping Of Cables – Benefits & Limitations

Cable Lugs & Crimps – Hexagonal v Indent Methods of Crimping

Cable Lugs & Crimping Using The Hexagonal Crimp Method

Copper & Aluminium – Crimping CU-AL Cables

Electrically Driven Crimping Tools For High Volume Applications

LV MV HV Cable Accessories & Substation Electrical Equipment

Thorne & Derrick are Specialist Distributors of leading manufacturers of Cable Accessories, Jointing & Installation Equipment.

LV MV HV cable accessories used to joint, terminate, connect, cleat and gland power cables to air and gas insulated substations, transformers, switchgear and overhead line networks.

Hover over our Interactive Electricity Grid to learn more about our product ranges.

LV 600/1000V ◊ MV 11kV 33kV ◊ HV 66kV 132kV

|

|

|

|

|

|

|

|

|

|

Substation & Overhead Line Electrical Safety Equipment

Manufactured by CATU Electrical to enable the safe construction, maintenance and repair of underground cables and overhead lines network up to EHV (400kV).

T&D - CABLES ♦ JOINTS ♦ TERMINATIONS ♦ CONNECTORS ♦ GLANDS ♦ CLEATS ♦ CRIMPS & LUGS ♦ DUCT ♦ SEALS ♦ ARC FLASH PPE

EARTHING ♦ FEEDER PILLARS ♦ JOINTERS TOOLS ♦ CABLE CUTTING & CRIMPING TOOLS ♦ COLD SHRINK ♦ HEAT SHRINK ♦ FUSES

Further Reading

-

Klauke – Cable Lug & Connectors – Tools Crimping Cutting Section 1

Size: 11.50 MB

Klauke – Cable Lug & Connectors – Tools Crimping Cutting Section 1

Size: 11.50 MB

-

Klauke – Cable Lug & Connectors – Tools Crimping Cutting Section 2

Size: 7.91 MB

Klauke – Cable Lug & Connectors – Tools Crimping Cutting Section 2

Size: 7.91 MB