Earth Tape – The Manufacture of Copper Earthing Tapes

Published 31 May 2018

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

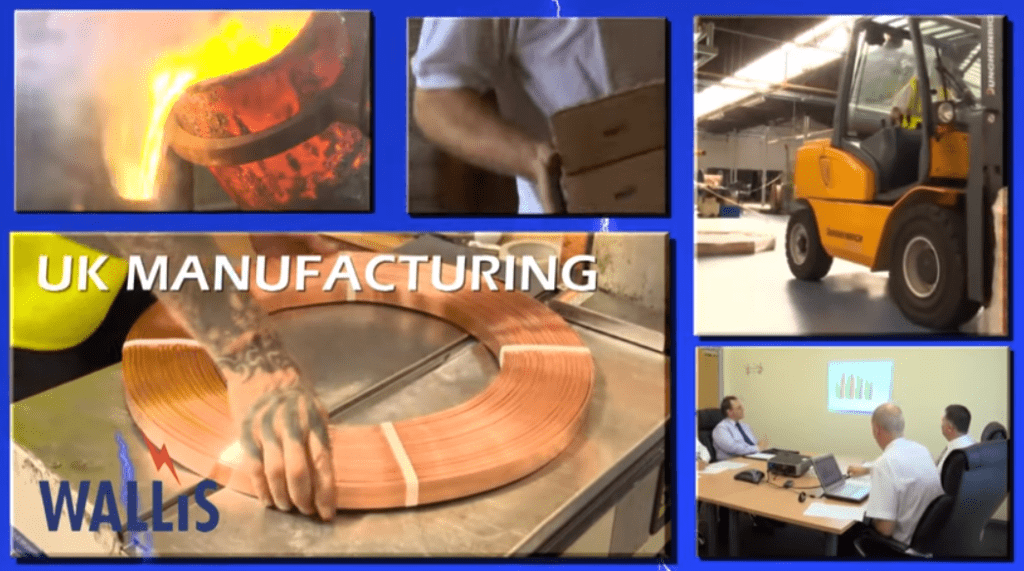

Thorne & Derrick, are UK distributors, stockists and suppliers for AN Wallis Copper Earthing & Lightning Protection Systems – we were recently invited to visit their UK based location in Nottingham to understand and learn more about the manufacturing processes for copper earth tapes.

In this post we provide a selection of photographs taken during the AN Wallis factory tour – all copper earthing products are manufactured according to BSI ISO 9001:2008 and BSI OHSAS 18001:2007.

Since 1946 AN Wallis earthing products including earth tapes, earth rods, earth bars and earth mats manufactured from high conductivity copper have provided Earthing & Lightning Protection to LV MV HV Network Assets including primary/secondary substations, overhead line towers and power cable systems from 11kV/33kV up to 400kV.

Copper is a chemical element with symbol Cu (from Latin: cuprum) and atomic number 29 – a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a reddish-orange colour.

Earth Tape

A panoramic photograph of the AN Wallis production facility and factory where the earth tapes are manufactured from raw material into finished product – earthing tapes in bare copper form or with optional PVC covering and coloured are manufactured in a range of tape thicknesses and widths to achieve the required cross sectional area.

AN Wallis extensive copper feed stocks enable fast turnaround of major earthing project requirements for the global electrical power and utility industry – the 17,000 square feet manufacturing facility and extensive raw material copper holding ensures short lead times with “off the shelf” deliveries or quick turnaround manufacturing of all earth tapes.

1 Earth Tape Manufacturing

2 Raw Material Copper Feed Stocks

The raw material is supplied in solid copper conductor form – note the circular form of the feed stock which must be processed via the manufacturing machinery into the flat tape copper configuration. The Conform machine processes the copper into flat tape form and can be pre-set to optional dimensions. Weekly maintenance checks of the Conform machine include a general clean down, gearbox oil level check, hub cooling oil check, hub cooling water check and ensuring no water or hydraulic pipes are leaking.

3 Copper Earth Tapes

The circular copper conductor is fed from coil into the Conform machine – the conductor is conformed from circular to flat configuration producing a range of flat copper earth tapes from 12.5mm to 50mm widths. Computer software, such as CDEGS, can be used to calculate the power system earthing and grounding. Asset managers must calculate the level of site protection required depending on the cross section area of conductor required to provide effective earthing and lightning protection.

Methods to improve high voltage substation earthing and grounding with supporting measurements of earth resistance and computational models to simulate the possible Ground Potential Rise (GPR) due to injected current surges are a key consideration in providing effective lightning and earthing protection.

4 Processing Circular Form Copper Into Flat Earth Tape

Here the circular copper conductor is shown entering the Conform machine – in the “On” mode the motors and pumps feed the copper conductor into the Conformer via the machine wheel. Adjustable settings enable the manufacture of an extensive range of widths and thicknesses of copper tape.

5 Copper Earth Tapes

From this angle the photograph shows the complete AN Wallis manufacturing process for copper earth tape. The finished copper earth tape has now been conformed by machine to a flat tape design from the circular copper feed stock – this production run is manufacturing 50mm wide x 6mm thick copper earth tape, a UK utility standard for medium/high voltage substation earthing. The copper earth tape is annealed and produced with radiused edges for safe site handling by installers.

Wallis copper tapes are marked “Wallis U.K.- BS EN 13601”.

BS EN 13601 2013 is the current British standard covering Copper, Copper Alloys, Copper Rod, Bar & Wire for electrical purposes. The copper tapes are available embossed or inscribed with the client owners name as a copper theft deterrence measure.

6 Aluminium Earth Tapes

AN Wallis manufacture aluminium earth tape also at their Nottingham factory – lower cost than copper but with reduced conductivity the range of aluminium earth tapes are also available from stock.

7 Large UK Stocks Of Copper Earth Tapes

AN Wallis manufacture and hold the largest UK stocks of copper earth tapes – T&D, the UK’s largest supplier of AN Wallis products provide internationally competitive prices, delivery and technical support. A complete supporting range of copper clamps are available to secure and install the earth tapes to building infrastructures.

Full range of Earth Tapes

About AN Wallis

AN Wallis & Co Ltd has over 70 years experience in the design and manufacture of Lightning Protection, Earthing & Low Voltage Electronic Surge Protection products – a broad range of technical and earthing design services are provided including full design of structural lightning protection systems, design of substation earthing systems, soil resistivity tests, commissioning and project consultation.

AN Wallis has grown steadily and is a recognised world leader in the manufacture of quality Earthing, Lightning Protection, LV Surge Protection and Exothermic Welding products.

The Earthing Product range includes copper tape conductors, earth bars, copper earth plates, DC fixings clips, earth rods produced from solid copper, copper bond and stainless steel. Air terminals, earth rod clamps, inspection pits concrete and heavy duty polymer, earth rod seals, low resistance soil conditioning agents and also CU-NNECT exothermic welding products.

Thorne & Derrick distribute the complete range of Copper Earthing Products manufactured by AN Wallis to UK and overseas projects and competitive prices from extensive stocks – this includes earthing products for MV HV EHV substation projects including:

- Neasdon Depot Substation London Underground / Enterprise Rail

- Sleaford 132kV Substation EON / Enterprise

- Iver 132kV Substation/Windfarm SSE Scottish & Southern / Enterprise

- Swansea 400kV Substation National Grid / Electricity Alliance West

- Cardiff East 400kV Substation National Grid / Electricity Alliance West

- Sundon 400kV Substation National Grid / Electricity Alliance West

The products also provide Earthing & Lightning Protection for railway traction substations, distribution substations, overhead line towers, solar farms, STOR sites, data centres, hospitals and hazardous area sites.

-

Further Reading

Underground Cable Photo Album 1890-1940 – Western Power Distribution (WPD)

Copper Earthing Tape & Rods Protecting 33kV Substation & Transformer Bund

Portable Earthing – Short Circuiting Kits For HV Substations & Overhead Lines

Thorne & Derrick

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Earthing & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.