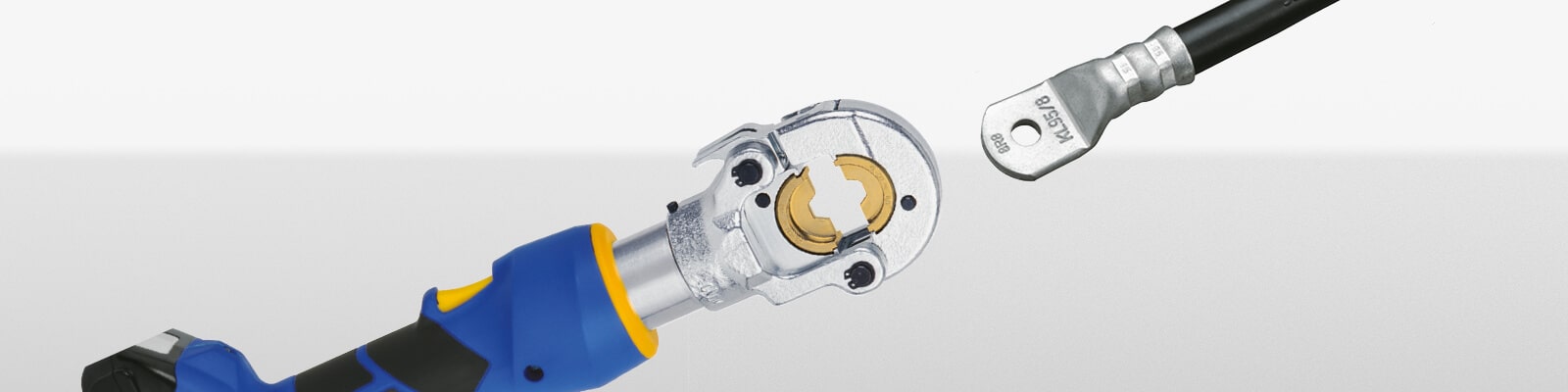

Hexagonal Crimping For Aluminium & Copper Cable Conductors

Published 02 May 2023

For aluminium and copper: hexagonal crimping according to DIN 48083 Part 4

Thorne & Derrick are leading suppliers of cable lugs and associated crimping tools from Klauke for Low, Medium & High Voltage Cables – this includes battery operated crimping tools with hexagonal crimping dies.

Hexagonal crimping is one of the more traditional crimping profiles. It is most frequently used in practice, as it is suitable for both copper and aluminium conductors. With this crimping profile, the single strands are deformed over a large horizontal area.

Hexagonal crimping is typically used for copper compression cable lugs according to DIN 46235 and aluminium compression cable lugs according to DIN 46329. This crimping profile can also be used to crimp solid cables with full tension.

Hexagonal crimps can be found in panel building industries as a manufacturer specific crimp and also as a DIN standard lug crimp for example in utilities (aluminium and copper conductors including 11kV and 33kV power cables).

The major benefit of hexagonal crimping relates to the central application of force, which is applied in equal measure from all sides and has an effect over a large contact surface. The individual stranded wires of the conductors are deformed as a whole in equal measure without being damaged.

The result is good mechanical stability and a secure connection.

Due to the consistent crimping involved, hexagonal cable crimping is also suitable for the medium and high-voltage range.

manufacturer-dependent hexagonal crimping

In addition to standardised hexagonal crimping, manufacturer-dependent hexagonal crimping is also allowed in the copper sector for conductor classes according to DIN 60228, Class 2. This crimping has been specifically developed for tubular cable lugs. As a result, it is essential you always revert to a manufacturer-specific system.

Freedom of Choice: Wide or Narrow Cable Crimping

Wide and narrow crimping is available depending on the tool selected. This will primarily depend on the cross-section and power of the tool in question. It is possible, for example, to use narrow crimping to crimp a 300 mm² tubular cable lug with a six-tonne battery-powered hydraulic tool. However, this will require several crimpings, something that will of course involve additional time. Therefore, you must take care that you make the right selection when purchasing a tool and ensure it is matched to the range of applications.

Compression cable lugs according to DIN, Cu

- For round conductors, e.g. according to DIN EN 60228 Cl. 1, 2, 5 and 6

- For non-tension copper cables, e.g. according to DIN 48201-1

- For pre-rounded multi-stranded sector shaped conductors

- With code number for clear tool assignment

- Cable lugs to DIN 46235

Klauke Compression cable lugs according to DIN, Copper

Compression cable lugs according to DIN, Al

- For non-tension connections of aluminium conductors to DIN EN 60228 and aluminium cables to DIN EN 50182

- For pre-rounded sector shaped conductors

- Cable lugs to DIN 46329

- Filled with contact grease for optimum transfer resistance

Klauke Compression cable lugs according to DIN, Aluminium

CRIMPING CABLES, LUGS & TOOLS

Thorne & Derrick distribute Cable Lugs & Cable Connectors to terminate, splice and joint LV MV HV cables – this includes copper, aluminium and bi-metallic connectors and a complete range of crimping tools for specific use on all Low, Medium & High Voltage cable types.

➡ Associated Brands & Products | Klauke | Cembre | Pfisterer Sicon | Cable Crimping & Cable Cutting Tools