Jointing & Connecting Submarine Cables

Published 20 May 2021

Images Courtesy of: Steven Onley – Submarine Cable Project Manager at 33Below Pty Ltd and Matthew Shields – Technical Director & Marine Engineer at Vocus Communications.

Steven Onley has 30 years of experience in submarine cable marine installation, covering all facets from contract bidding to system handover, including all offshore operations such as survey, shore ends, jointing, main lay, plough burial, PLIB and repairs as well as office-based project management. Services provided:

- Desktop Studies

- Route Surveys

- Route & Cable Engineering

- PLGR/RC

- Cable Transfers

- Shore End Landings (Direct & Pre-laid)

- Main Lay & Burial

- Post Lay Inspection & Burial (ROV)

- Cable Repairs

- Land Cable

- Procedures & Reporting

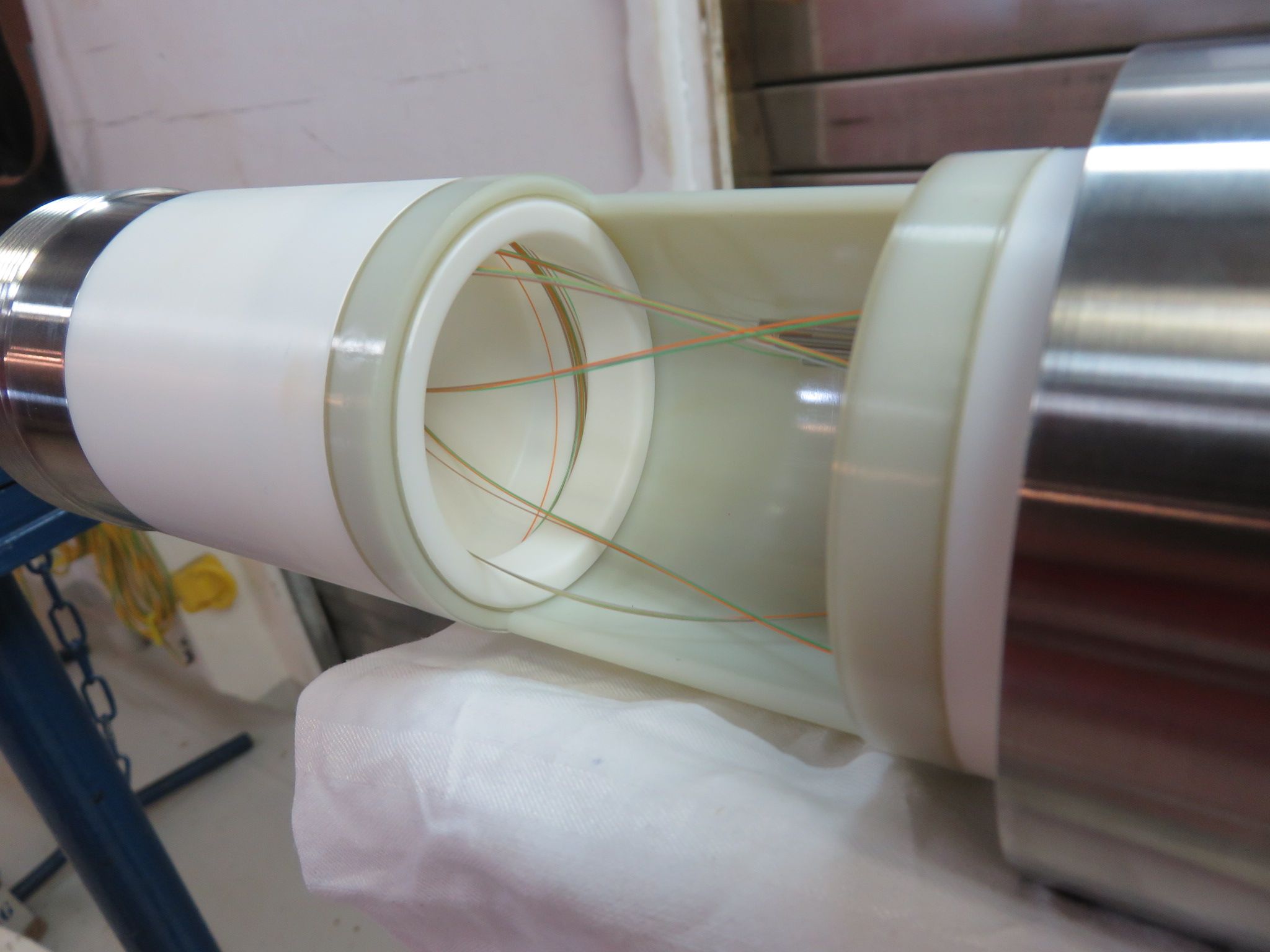

Pictured: Jointing & Connecting Submarine Cables

Steven explains ‘How do you connect submarine cable? It is not quite as simple as just making a fibre splice. Cables may only have 6-12 fibres in them, but a cable joint may take a team of 4 cable jointers as long as 18 hours to complete.

As well as making a low loss splice (<0.1dB), we need to reinstate the mechanical strength of the cable (>8 tonnes min breaking load, depending on the cable type), and also the high voltage electrical insulation (up to 12kV DC). This takes some very specialised skills.

An added complication is that each supplier like ASN or SubCom has their own proprietary method of jointing their cable. It would be impractical for repair ships to be equipped with a complete set of every supplier’s equipment, so the suppliers created the Universal Joint Consortium. A UJ (Universal Joint) kit can connect almost any type of cable to any other type of cable, regardless of supplier. Thanks to Mathew Shields for some of these photos, showing an ASN (Alcatel Submarine Networks) cable joint’

Further Reading

- Jointing 44kV High Voltage Submarine Cables Using 3M Cold Shrink Splices

- How To Remove Bitumen From Subsea Cables & Umbilicals Using Socomore Wipes

- Splicing, Wiping & Laying Submarine Cable In San Francisco Bay (1936)

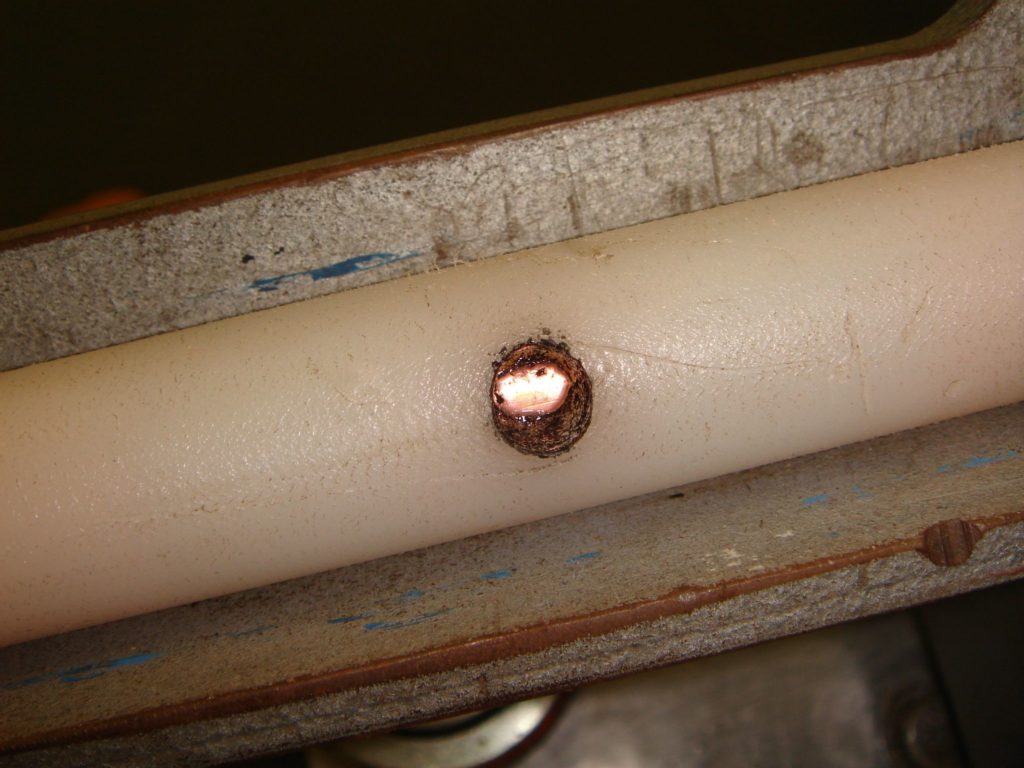

This is what can happens when there is a small scratch or contamination in the cable insulation. Submarine cables are usually powered with several thousand volts DC, which can cause a blow-out of the plastic insulation.

This example is only small (<10mm across – white cable is 21mm diameter) but it was quite spectacular when it arced as it ran along the deck while powered. You can see the burn marks around the edges as the plastic melted.

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Accessories, Jointing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV.

Stocking & Supplying | Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Jointing Tools | Cable Pulling Eqpt | Earthing & Lightning Protection | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Euromold MV HV | Cable Terminations, Connectors, Elbows & Joints