Cable Rollers

Cable Rollers | Pulling Cables into Trenches

➡ Cable rollers are used to support and guide LV, MV & HV cables into open trenches without damaging cable sheaths and incurring overbending stresses on power cables, typically at LV (1000 volts), MV (11kV/33kV), HV (66kV) and EHV (132kV-400kV) voltages.

Heavy duty cable rollers with zinc plated steel frames are used by medium/high voltage cable laying contractors for placement of power cables directly into the bottom of cable trenches – rollers and cable support guides available for ladder rack, gantry and cable tray applications of armoured and unarmoured LV-HV cables.

Overview of Cable Roller Product Range

- TRP76 Narrow Roller

- HSP125 Steel Cable Roller

- HBSP125 Bridge Roller

- CR1 Angle Corner Roller

- CR2 Skid Roller

- CR4 Triple Corner Roller

- CR5 Horizontal Roller

- CR6 Vertical Roller

- DR1 Draw off Roller

- VR1 “V” Roller

- SR5 Suspension Roller

Cable Rollers

For Open Trench Laying Of LV MV HV Cables

Utilities recommend cable rollers should always be used when pulling cables.

Cable rollers move easily on their free running spindles increasing cable support, labour productivity and site safety for cable pulling teams.

- Straight Horizontal Cable Runs

Rollers are generally placed into the trench to prevent the LV-HV cable from incurring damage to the sheath from trench debris or aggregate. The spacing of cable rollers depends on the cable type being installed and the pulling tension along the route.

A leading roller should be used to support the cable over the entire drum width immediately before being fed or pulled into the trench. Slide corner rollers are used on bends and “hoop” type straight cable rollers along horizontal cable run sections.

Trench rollers available to handle up to 125mm diameter cables for standard LV, 11kV and 33kV cable pulls into underground trench – narrow trench rollers with 76mm diameter available for LV armoured (XLPE SWA) applications.

Rollers with inverted skid plates can be used to prevent the cable rising into obstructions.

At cable duct entries a bell mouth should be attached at each end with rollers positioned to give central access into the bell mouth.

Straight Cable Rollers – HSP125 up to 125mm diameter cables | LV MV HV

High Voltage Cable Pulling Installations

Cable rollers provide correct levels of support and stability to ease the installation of medium/high voltage cables into cable trenches – here 3 x cable drums of 33kV power cables await laying into the trench with both standard rollers and lead-in types positioned to commence and handle the 33kV cable pull.

- Bends & Corners In Cable Routes

Rollers with skid plates of a radius greater than the cable minimum dynamic bending radius should be used on all bends.

Before commencement of cable pulling, initial tension of the cable should be taken up to remove the slack out of the bond wire – cable rollers along the trench route should be visually checked for sharp edges or projections and adjusted to line up with the taut bond and a final check should then be made to ensure that utility or cable services which may be abraded by the cable during installation are suitably protected.

When final cable roller positions are confirmed and all other services are suitably protected the cable pull can be started.

Medium Voltage & Substation Cables

Cable Rollers | here is a substation site installation of 11kV medium voltage Triplex power cables pulled and laid effectively into an underground cable trench using a cable roller system

Corner Rollers With Skid Plates – CR2 up to 75mm diameter cables | LV MV HV

Array Rollers for Overhead Conductors

This innovative cable conductor installation system eliminates the need for a lifting system – array rollers replace standard running blocks with a new type of proven roller, featuring an adjustment that allows the conductor to be raised and lowered directly into the suspension shoe. As a result, operation times and the need for large amounts of pulling or stringing equipment are substantially reduced. The use of the Array Roller has already been proven on the National Grid network, delivering substantial efficiencies when removing or replacing suspension fittings on standard suspension arrangements. With a time saving of 80%, roll-out across the network should deliver reduced overall project timescales.

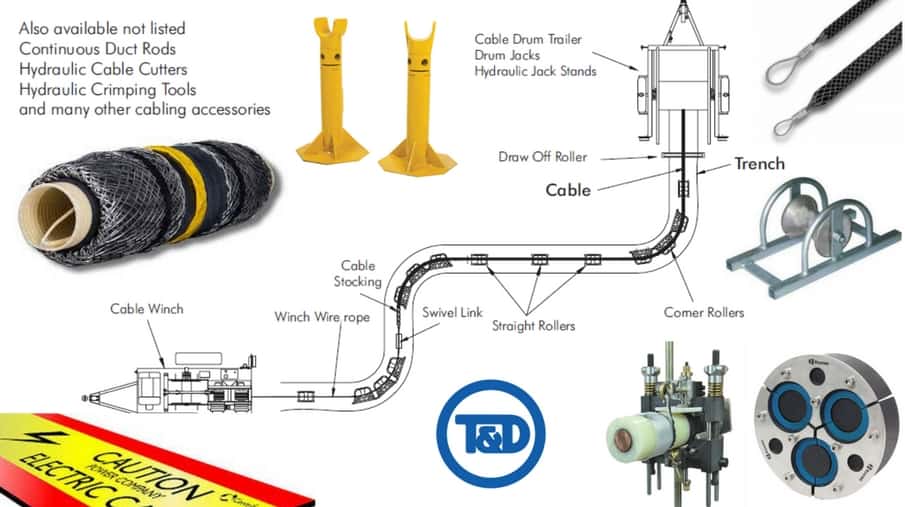

Typical Cable Pulling Layout – Open Trench

Cable Pulling & Laying Products lv mv hv

Complete range of LV, MV and HV cable pulling products for installation into trench or duct including LV, 11kV/33kV medium voltage (MV), 66kV/132kV high voltage (HV) and EHV transmission and distribution cables up to 400kV.

Pit Lifter Equipment | Ancillaries to Support Cable Installations

- S001072 Heavy Duty Manhole Key

- S001073 4″ Manhole Key

- S001463 Replacement Hook

- S003000 20″ Pit Lifter

- S003001 D Pit Lifter

- S003002 No.2 Pit Lifter

- S003031 Lifting Key 9758

- S003575 Carriageway Key

- S007906 4 Way Utilities Key

- S007907 4 Way Pit Lifter

Cable Rollers | Drum Lifting Jacks | Duct Rods | Cable Socks | Lubricant | Duct Seals | Cable Duct