Cable Cleats – Costs v Quality

Published 09 Oct 2019

Ellis Patents Cable Cleats

Cable Cleats

-

uploaded by Chris Dodds | Thorne & Derrick Sales Marketing Manager

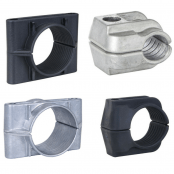

Ellis Patents based in the UK are world leading manufacturers of cable cleats and cable clamps used to clamp and support LV-MV-HV cables – this includes 11kV-33kV medium/high voltage power cables in single, trefoil or bundled formation.

Ellis Patents are global leaders in the innovation and manufacture of nylon cable cleats, aluminium cable cleats and stainless steel cable cleats – Ellis satisfy the operational requirements of the construction, oil, gas, rail, utilities, wind energy and power generation industries.

Stephen Walton Technical Director Ellis Patents

Stephen Walton, Technical Director of the world’s leading cable cleat manufacturer, Ellis Patents, recently bought a home in need of complete renovation. While pondering how he could extend the number of hours in a day in order to get the project finished, he also found himself asking the age old question – ‘Why don’t they build them like they used to?’

“Taking on a renovation project probably isn’t the most sensible thing I’ve ever done; especially when you consider I have a challenging full-time job and a rapidly growing son. But my wife and I had been in the same house for ten years, and it was fair to say we’d outgrown it.

We could have bought a brand new house on a nearby development, but instead we opted for a 1930’s property that needed fully refurbishing.

Why? Well, in my experience buildings today are built for a price, and not for the long term – a view that has been backed up by many of the tradesfolk who have been to the new house, and have all commented on the build quality of it compared to today’s new build homes.

I realise this sounds like I’m teetering on the edge of a grumpy old man rant about how things were better in the old days, but I’m not. I believe we live in the most exciting of times, and that the technology we have access to enhances our lives in a myriad of ways – whether at home, work, play or anywhere in between.

But advances in technology don’t necessarily mean improvements. In the 1930s, houses were built in a robust way as the mentality was different. Yes, cost was an issue, but longevity was key. Over the following 90 years industry mastered the art of producing products that will survive the required life span, but no more.

Described as the bathtub curve, this approach has been developed so costs can be cut to the bone, while products will only last as long as absolutely necessary. Some consider this is efficient, but for me it’s a clear case of going too far in the pursuit of margin.

The Hackitt Report, which was commissioned following the Grenfell Tower tragedy, takes a hard hitting attitude towards bathtub building methods; citing a lack of responsibility and commitment to safety in the industry.

The report insists on major change, in particular that systems as a whole are considered, rather than individual manufacturers testing their own products in isolation, which is very much accepted current practice.

Earlier in my career I worked in the subsea oil and gas industry, and during that time the Gulf of Mexico Macondo incident led to the kind of sweeping change that Dame Hackitt want to see.

The industry had become complacent and a series of failures contributed to the disaster. Post Macondo, documentation requirements increased significantly, and many more FMECA reports were needed.

Applauding what the subsea, oil and gas industry has achieved is easy, but a great deal of that has been down to exceptional internal housekeeping.

In contrast, the task the construction industry has been set requires wholesale change from manufacturers up – and once again that brings the bathtub curve back into play.

At Ellis we design, manufacture and supply cable cleats that are tried, tested and trusted around the world. We rigorously short-circuit test all of our cleats to ensure they will do the job they are designed for – that is to keep powerful electrical cables secured in short-circuit situations. And we don’t stop there.

We offer project specific testing, so that those specifying and installing our cleats do so safe in the knowledge that they are perfectly suited for that particular project. And still we don’t stop.

We are called in with increasing regularity by the likes of Siemens, Balfour Beatty and National Rail, to design bespoke solutions to solve problem installations or help consign health and safety issues to history.

Over the years we’ve banged the drum about the importance of cable cleats; reacted to a veritable flood of cheap and unsafe markets by focusing on the vital importance of correct specification; celebrated the introduction of British, European and International standards governing the use of cleats; and welcomed the arrival of others to into the market who read from the same hymn sheet as we do.

What this has all meant is that today I can confidently state the vast majority of cable cleats specified and installed in any major project, virtually anywhere in the world, are selected because of their proven quality as opposed to being selected solely on price. A position that certainly means the bathtub curve has been smoothed over.

But moving forward will this victory for quality over cost be enough? And if not, where does the responsibility for whole system testing fall? Individual manufacturers coming together to test and sell whole project solutions as opposed to their own, often highly specialised, products? Specifiers? Contractors? Installers?

Sitting in the stripped down shell of my 1930s refurbishment project, I feel whole system testing is a step too far. This house was built at a time when buildings were built to last, and the quality of products used during construction were deemed far more important than their cost.

If, post Hackitt, the building industry can return to those days – and thus shelve the cheap and often unsafe products that have been responsible for so much heartache –; then the question we’ll be asking in years to come will no longer be “why don’t we build them like we used to?”, but “why didn’t we always build them like this?”

Ellis Patents Cable Cleats

Further Reading

- IEC 61914 – Cable Cleats & Short Circuit Protection Calculations

- Fire Resistance & Cable Cleats – Surviving Fire, Flame & Extreme Heat

- Triplex Cleats – Selection Guide for Cleating 11kV BS7870 Part 4.10 Cables

- Stainless Steel Cable Cleats – Preventing Galvanic Corrosion Of Cable Fixings

- Ellis Patents Cable Cleats & Cable Basket Tray for Securing High Fault Level Cables

- Stainless Steel Cable Cleats v Ties – The Myths Debunked By Ellis Patents

Thorne & Derrick

T&D are Specialist Distributors to UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and HV Jointing Contractors of an extensive range of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt – this includes 11kV/33kV/66kV joints, terminations and connectors for both DNO and private network applications.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

➡ Read: Thorne & Derrick Announce Distribution Agreement & Contract With Nexans

Further Reading

-

Ellis Patents – The Black Book Guide To Cable Cleats

Size: 1.44 MB

Ellis Patents – The Black Book Guide To Cable Cleats

Size: 1.44 MB