Cable Jointing – An Art or Science?

Published 26 Mar 2021

Both.

Whether lashing in a Straight 6 resin joint to power a domestic shower or jointing 110kV cables to energise Brisbane, the cable jointer must concentrate during all stages of cable stripping, measurement and joint installation.

Make an error with your measure, flirt with failure.

Of course cable failures keep cable jointers busy.

But self-inflicted cable failures caused by bad jointing and the “jointer” will soon be hanging up his crimper.

Quick joke. What’s the difference between a Jointer and a Doctor? A Doctor buries his mistakes – a jointer digs his up! Tumbleweed rolls through Blog.

Cable failures caused by poor jointing are costly.

Reputation damage plus consequential losses incurred by a power cut then multiplied by cost of the supply restoration as a formula is simply incalculable.

However, the ability to understand and apply complex mathematical formulae is a required staple of an EHV jointers skill-set.

Andrew Brezovsky is amongst many other things an EHV jointing legend and social media megastar. I suggest you Connect with Andrew on LinkedIn now – but don’t forget to hit the back button and rejoin us for a lesson in advanced cable jointing.

Cable Jointing Science

In todays lesson, Andrew considers the importance of the theoretical formula and the practical skill required in calculating and installing premoulded sleeves when jointing 110kV cable.

Removing the semi-conducting screen and installing the premoulded cable joint sleeve is a critical stage of jointing 110kV cables.

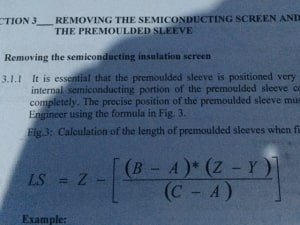

“So the calculation of the length of the premoulded sleeves when fitted is relying on the length of the mould, inner bore diameter of the tube, insulation diameter and the inner bore of the mould,” says Andrew.

Therefore, referring to the featured image above the calculation for the length of the premoulded sleeves is as follows:

- LS = length of cable joint mould when landed

- Z = overall length of mould as supplied

- A = inner bore diameter

- C = diameter of PVC tube

- Y = diameter of sleeve on PVC tube

- B = cable insulation diameter

Cable Jointing Art

“Here are a few shots from the mould loading process. The mould is being forced onto that PVC tube with the machine and silicone oil used as cable lubricant. The landing position is calculated individually for every cable joint to the point of a millimetre. You have to be good with your maths as the formula as you now know is complicated,” informs Andrew.

Images by EHV Cable Jointer : Andrew Brezovszky (EHV Cable Jointer – Energex Australia).

Images by EHV Cable Jointer : Andrew Brezovszky (EHV Cable Jointer – Energex Australia).

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.