Cable Sock Damage | How To Ensure Safe & Reliable Cable Sock Performance

Published 03 May 2022

Cable Sock Damage & Maintenance

Cable Sock Inspection & Maintenance

How Can You Tell If They Are Safe To Use?

Inspecting a cable sock is crucially important to ensure safe cable pulling operations, maximum grip strength and grip longevity.

There are a number of variables that can weaken a cable sock that are not immediately obvious on visual inspection. However, there are some important and simple checks that you can do routinely to mitigate product wear, deterioration and potential accidents from happening.

When inspecting a sock, it is critical to know the potential damage and trouble spots. Below is a summary of the types of damage you need to be aware of prior to beginning any pulling project with your cable pulling socks.

Cable Sock Safety

Safety is Thorne & Derrick & Slingco’s primary concern. The products Slingco manufacture are safety critical and therefore they have their own fully certified test facility. This allows them to comprehensively test all socks prior to release from design. They design and manufacture to the highest specifications and test to destruction so you can be confident when using a Slingco product.

If you are in doubt about the serviceability of your cable sock, use a new sock! Thorne & Derrick carry large UK stock of cable socks so lead times are short.

The following are some of the types of damage you should be aware of prior to beginning a cable pulling project with your cable socks. If these are observed, replacement of sock should be considered.

DAMAGED PULLING EYE

The eye of the cable sock is very important. If any damage is found, replace sock immediately. Causes of eye damage include:

• Pulling loads at an angle as opposed to straight line pulling

• Misuse and wear from excessive use

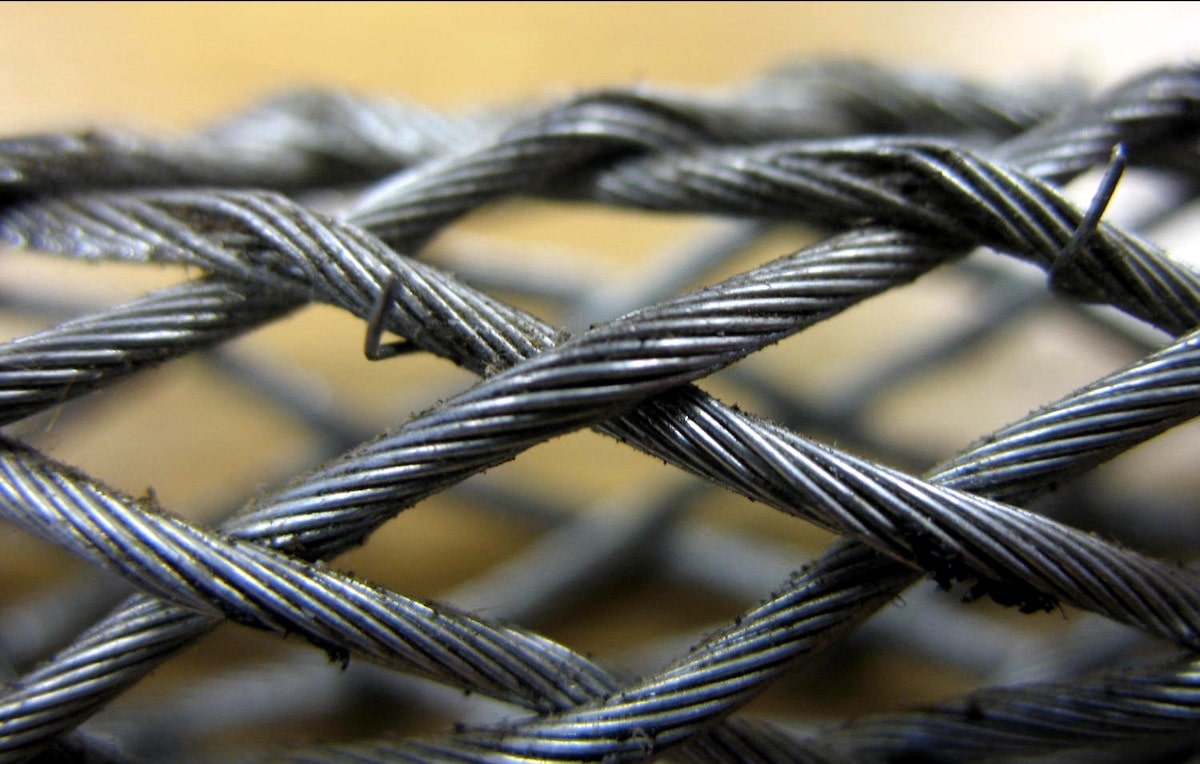

FRAYED WIRES

Frayed wires cause the cable sock to weaken significantly. The more wires damaged, the weaker the sock. Causes of fraying are:

• Excessive abrasion while cable is being pulled

• Becoming stuck or snagging during a pulling operation

Rusted Wire

Rust will weaken the strands of wire that make up the sock. If excessive rust is identified, replace sock. Causes of rust are:

• Socks left in moist conditions or stored damp after water exposure

• Water with high salinity content will cause rusting more rapidly

Bent & Broken Wires

Bent and broken wires have the same effect as fraying and cause the cable sock to weaken significantly. Causes of this type of damage are :

• Excessive abrasion while cable is being pulled

• General wear and tear over time

EFFECTS OF TORSIONAL BUILD UP

The most important factor when using a cable sock to pull wire is to eliminate torsion, or twisting of the cable grip assembly. It is important, when stringing high tension wires for electrical transmission and distribution, to use the proper components to eliminate torsion.

If wires are likely to develop torsion during a pull, line pulling swivels enable the torque to be released, which otherwise could cause damage to the wire or sock.

Advantages of Slingco Swivels include:

- Reduce torsion strain

- Are quality tested and inspected

- Come in bull-nose or rounded style

- Can be matched-up with Slingco’s heavy duty cable socks

Using a cable sock alongside the Slingco swivels to eliminate torsion is crucial

CABLE SOCKS & SUPPORT

ASSESSMENT OF SUITABILITY

There are many factors that must be taken into account when assessing the suitability of a sock for a proposed application, and when trying to calculate the working load limit.

These include:

- Size of cable sock in relation to size/shape of gripped object

- Stability of object(s) when gripped

- Sock surface of object(s)

- Resistive force of object(s)

- Anticipated path of movement, including possible obstructions

- Approximate breaking strength of the cable sock

- Condition of sock

- Suitability and compatibility of any attachments used

- Environment/operating conditions

- Persons at risk

➡ Please note: Slingco socks must be double steel banded securely before being pulled.

CABLE Sock SAFETY INFORMATION

- Ensure that the sock mesh fits the cable correctly

- Ensure that the cable fits up to the mid-point of the protective shoulder

- Clamp the ends of the cable sock when attaching the cable. Slingco recommend between 1.25” and 2.25” from the end of the sock – SECURE CLAMPING MUST BE USED ON SLINGCO SOCKS

- Never modify or attempt to repair any sock

- Ensure proper maintenance of the sock

- Check the condition of the sock, and that it is the correct size for the intended application – do not exceed the rated capacity

- Cable socks that are worn, bent, or otherwise damaged should not be used

- Cable socks are only to be used for temporary installations

- Pulling devices should only be attached via the pulling eye

- Cable socks must only be fitted and used by trained competent person(s)

➡ Slingco cable socks must not be used to their approximate breaking strength. A sensible Safety Factor must always be used. If in doubt contact the manufacturer or distributor that supplied sock.

CABLE SOCKS & PULLING PRODUCTS LV MV HV

Thorne & Derrick distribute a complete range of Cable Pulling Products to support the safe installation of LV, MV & HV cables into underground ducts, conduits and trenches – this includes products to enable safe cable drum handling, lifting and support for cables operating at LV, 11kV/33kV medium voltage (MV), 66kV/132kV high voltage (HV) and EHV transmission and distribution cables up to 400kV.

We service the Power Transmission & Distribution industry in the wind, solar, rail, oil/gas, data centre, battery storage and utility sectors.

This includes standard Pulling, Laying & Stringing Products for underground cables, subsea umbilicals and overhead line conductors and also innovations such as Catchblock – a patented overhead line catenary roller system that guarantees that, if a conductor breaks during the stringing process, there will be no need to obtain road or rail possession. This also means reduced need for scaffolding, reduced risk of an accident and an overall more efficient operation.

➡ See Also Further Reading

- Cable Laying, Installation & Support Products | MV HV Windfarm

- Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

- NOF Members Thorne & Derrick and Slingco Ltd Supporting Cables in the Offshore Wind Industry

Earlier this year, Thorne & Derrick welcomed Phil Day from Slingco Limited, the world-leading manufacturer of cable pulling and support socks, swivels, cable protectors, wire rope assemblies and accessories. Phil provided an Offshore Wind focussed company presentation to our Sales Team (pictured left-to-right Sarah Henderson, Carl Cox, Jonathan Hewitt, Phil Day, Jeff Jhanke, Natalie Lundie and Chris Dodds.

Cable Rollers | Duct Rods | Cable Jacks | Cable Lubricant | Duct Seals | Cable Duct