BASEC | Cable Quality LV HV

BASEC Medium Voltage Approval Scheme & The Importance Of Surveillance Testing To Protect The Cable Industry

November 1st, 2022

Medium Voltage Cables Approval Scheme

BASEC are collaborating on knowledge and content sharing with Thorne & Derrick.

T&D have been Specialist Distributors of Medium Voltage Cable Accessories since 1985 and understand the criticality of specifying and supplying Type Tested products to international standards to ensure the safety, reliability and longevity of MV power systems.

The meteoric rise in demand for digitalisation coupled to the Green Energy revolution has further fuelled industry need for MV power – if electrical power is the lifeblood of a data centre or a wind farm then cables are the main arteries.

T&D together with BASEC have a shared passion and objective to enhance electrical safety through the education and encouragement of industry stakeholders to specify and buy accredited, tested and certified MV Cables & Cable Accessories, whatever the industry.

Medium Voltage (MV) cables are used in critical applications where major failures and injuries may occur. Regulatory bodies and governments’ specific safety requirements and compliance are vital in eliminating safety-critical system failure. Product quality is usually measured through the material tests of products.

Manufacturers must conduct tests following methods specified within international or industry standards to demonstrate compliance with their materials.

Understanding material properties enables manufacturers to use materials suitable for specific end-user applications. Maintaining the quality and reliability of the finished products is also essential.

BASEC certification includes mandatory annual material testing of cable compounds. This way, a BASEC certified manufacturer can demonstrate that the same compound formula has been used. If the manufacturer changes the materials, BASEC can pick this up in surveillance testing. For the continuity of quality, routine surveillance is needed regularly to check whether the materials used are identical or not.

As technology develops and continuous innovations in material knowledge take shape, the manufacturer may need to maintain alternative formulas and suppliers for their cable design. Additionally, global material shortage reinforces this requirement.

BASEC can list those suppliers and formulas under BASEC certificates to support manufacturers and provide peace of mind to end-users. With continuous surveillance testing and audits twice a year combined with an unannounced visit to the manufacturer at random and take samples for testing.

BASEC Medium Voltage Approval Scheme

BASEC MV Surveillance Scheme vs Non BASEC Scheme

With an increased demand for energy, medium voltage networks need to provide constant power for industries and end-users. To ensure reliable network operation, continuously maintaining quality MV and HV cable products is essential.

The market typically has been primarily a singular test report, in other words, an initial Type Test or Factory Acceptance Test (FAT) at the manufacturer. It is not uncommon to encounter 5 year and older Type Test reports demonstrating their compliance onsite.

Technological developments and economic reasons each year pressure manufacturers to seek alternative designs and suppliers. The old Type Test report only demonstrates the compliance of MV cable for that single batch which is not a good indicator for today’s energy network and end-user. Although the FAT test is performed in each batch on request by the client/purchasers, it is not done in a controlled environment.

The accuracy of the test results can be questionable. The cables must be validated by an independent third party and accredited body like BASEC.

For high quality and continuous operation, BASEC provides MV cable approval to comply with local and international standards and meet end-user specifications. This protects the end-user from failure and extra maintenance costs. BASEC approved cable tests are carried out regularly – mechanical, electrical, construction and material Testing take place annually and are used in projects to operate safely for extended periods.

By certifying cables with BASEC, cables are subject to rigorous recurring tests and audits.

Thanks to these annual surveillances and testing cables direct from the market, end-users and contractors ensure their systems’ reliability by specifying BASEC approved cables in their projects.

By doing the above surveillance, BASEC can certify a range of cables as specified in the standards, saving costs when getting the approval instead of testing each cable individually. Providing the cables pass the initial type tests and are under surveillance schemes such as BASEC approval.

The importance of accredited lab testing vs manufacturer own type tests and what this means to the market and users for safety

By accredited to ISO/IEC 17025 through an independent, impartial accreditation body, laboratories demonstrate their technical competency, laboratory quality, performance, reliability, and efficiency to ensure the accuracy of the test results. There is always the risk that unaccredited test laboratories can produce different test results.

This can be a result of equipment use, environmental factors, staff competency, and uncalibrated and unmaintained types of equipment. To avoid these different results and to ensure the test’s accuracy, ISO/IEC 17025 accreditation must be followed by labs as a regulating reference.

As mentioned above, in-house generated manufacturer test reports are more prone to uncertain human and equipment errors. BASEC’s ongoing surveillance scheme continuously checks the cables’ conformity to ensure the quality has not dropped from the first set of initial Type Testing. This gives the manufacturer product approval for a cable; before they can mark it with the BASEC Quality Mark. When placed on the market, this then gives purchasers confidence in the ongoing quality and conformity of the product.

BASEC has an independent cable laboratory accredited by UKAS against ISO/IEC 17065 for Product Certification, against ISO/IEC 17025 for Testing, and ISO/IEC 17021-1 for Quality Management Systems Certification and Environmental Management Systems Certification.

BASEC labs are recognized under the European Accreditation Multilateral Agreement (EA MLF), the International Laboratory Accreditation Cooperation (ILAC), and the International Accreditation Forum (IAF), as well as being UKAS Accredited.

Testing your cables at BASEC accredited labs provides you with validated test results globally. Cables tested and approved by BASEC accredited to ISO/IEC 17025 are placed on the market and can be specified in projects confidently.

To read the original article please click here – https://www.basec.org.uk/news/2022/9/7/basec-medium-voltage-surveillance-scheme-vs-non-basec-scheme-the-importance-of-cable-material-testing/

About Basec

BASEC is a global leader in cable testing and certification services for power, energy, data/signal cables and ancillary products, alongside quality management systems.

Operating independently for over 45 years, the BASEC mark is trusted for quality, clarity and impartiality.

BASEC’s teams of highly skilled engineers, technicians and auditors possess extensive in-depth commercial, industrial and technical experience. As a result, BASEC has a reputation for professional and rigorous assessment processes which ultimately lead to the issuing of our highly respected product certifications and test reports.

In addition, BASEC offers a number of supporting services for cable makers, traders and users, including management system certification, bespoke type testing, impartial investigation of conformity issues and testing and reporting in the event of disputes. Furthermore, Certificates of Assessed Design are available for innovative cable products.

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – this includes 3M Cold Shrink, Nexans Euromold and Pfisterer CONNEX Cable Accessories for Medium Voltage Power Systems.

We service businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

JTS by Nexans | A modern generation of MV Cable Joints have been developed by Nexans for the UK utility and contracting industry – the primary application of JTS Joints is for the jointing of 11kV 24kV and medium voltage power cables up to 33kV/42kV.

Prysmian’s Medium Voltage Power Cables BASEC Approved

October 20th, 2020Medium Voltage MV Power Cables

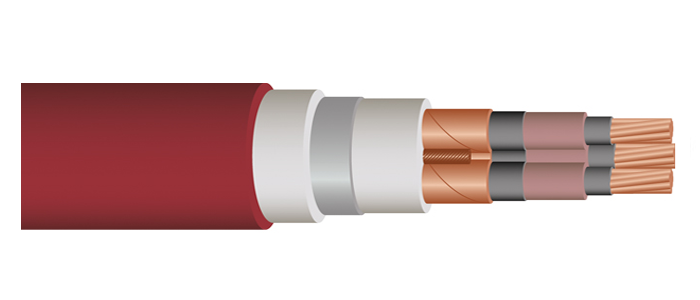

Medium voltage power cables manufactured by Prysmian have been accredited by the British Approvals Service for Cables (BASEC) as meeting the requirements of BS 6622 and BS 7835.

The cables’ third-party accreditation will give designers and installers of a wide range of power distribution networks additional assurance in the quality and safety of Prysmian Medium Voltage (MV) power cable from 6.6 kV right up to 33 kV.

The accreditation covers Prysmian’s MV cables with XLPE insulation and PVC sheaths manufactured to British Standard BS 6622, and Prysmian’s MV power cables with a low smoke zero halogen extruded outer sheath (LSOH), manufactured to British Standard BS 7835.

British Standard Cables

These British Standard cables are available from Prysmian with stranded copper or aluminium conductors, XLPE with either bonded or strippable screens, copper taped, as single core with aluminium wire armour or three-core with galvanised steel wire armour.

The company has been manufacturing cables in Britain for all voltages for over 100 years and MV cable at its Wrexham factory since it opened over 50 years ago. The cable’s accreditation by BASEC after over five decades of production serves to highlight the quality and performance inherent in Prysmian cable from the outset.

“Certification by BASEC, is confirmation that Prysmian has led the way in cable technology and quality for many years,” says Martin Boorman, Prysmian’s National Sales Manager. “Engineers and network owners can now have even more confidence in our UK manufactured MV cables,” he adds.

BASEC

BASEC is an independent certification body for the cable industry. It is accredited by the United Kingdom Accreditation Service to provide certification to National, European and International cable product standards. The tests were undertake n in BASEC’s dedicated UK testing laboratory, or were witnessed by BASEC engineers, to certify the MV power cable’s conformity to the British Standards.

MV HV CABLES

Contact T&D for medium voltage cables to IEC 60502-2 international standards including N2XS2Y / NA2XS2Y, NA2XS(F)2Y RE, NA2XS(F)2Y RM and NA2XS(F)2Y RM cable – should you require specification or technical support about 11kV-33kV cable accessory and installation requirements or advice on the terminating, jointing or duct sealing at MV-HV please call us.

T&D also distribute Medium & High Voltage Electrical Safety Equipment including insulating matting, voltage detectors, phase comparators, insulating gloves and life saving intervention kits to ensure the safe installation of MV-HV power cables into electricity substations working at 11kV/33kV up to 400kV transmission grid networks.

11kV 33kV MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors | Cold Shrink & Heat Shrink

FREE to ENROL | Cable Quality Seminar By BASEC

September 5th, 2019What’s the value of quality to you?

- uploaded by Chris Dodds – Thorne & Derrick Sales & Marketing Manager

| Date: Wednesday, 23rd October 2019 |

| Time: 10:00-15.30 |

| Venue:Tratos |

| Location: L34, Randles Rd, Knowsley, Prescot L34 9HX |

Cable Quality is often overlooked when building specification decisions are made, which can result in costly damage and potential loss of life.

BASEC has been in the business of independently testing and certifying cable products and their manufacturing facilities, to internationally recognised standards, for over 45 years.

With a rigorous programme of auditing, inspection and testing their goal is to ensure the cable you specify, source and install is compliant, safe and fit-for-purpose.

The Cable Quality Seminar is designed for anyone and everyone who is working to deliver projects which include cable installations.

Understanding the implications of poor-quality cable and increased awareness of independent cable verification is paramount to your project’s success.

Join us at Tratos to learn how BASEC, recognised instantly in the worldwide cable industry, can help you to be compliant.

Do not miss your opportunity to build your awareness of cable quality.

Register below to attend our event for free now.

CLICK TO Enrol Here >>>>>

Simply Click Here & Scroll to foot of the BASEC webpage to Register Online & Free>

Itinerary

- 10:00 – Registration

- 10:30 – The value of independently verified cable

- 11:00 – BASEC introduction and technical capability

- 12.15 – Lunch

- 13.30 – Tratos Laboratory Tour

- 15.30 – Close

The British Approvals Service for Cables (BASEC) is a recognised sign of assurance of independent cable testing and approval. As an independent body, BASEC has for nearly 40 years been a mark of reassurance to those specifying cable.

About Tratos

Tratos is a cable manufacturer, leader in Electrical, Electronic and Fibre Optic cable technology.

- LV Low Voltage Cables – Energy

- MV Medium Voltage Cables – Energy

- HV High Voltage Cables – Energy

- Fire Resistant Cables

- High Temperature Cables

- Marine Cables

- Mining & Tunneling Cables

- Oil & Gas Cables

- Overhead Conductor Cables

- Reeling Cables

- Submarine Cables & Umbilicals

Tratos serves worldwide markets, creating bespoke solutions where necessary and manufacturing to an exceptionally high standard.

For 50 years Tratos major clients have included electrical contracting and manufacturing organisations and electricity distributors all over the world.

Working with them has resulted in the most comprehensive range of cables for all their clients.

News: Tratos is the first to achieve BASEC approval for medium voltage cables.

Thorne & Derrick

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

New Testing and Certification Scheme Launched for YY, SY, CY Control Cables

September 3rd, 2019

-

Blog Written By BASEC | 6 of 10 Articles

Thorne & Derrick collaborate with BASEC to advocate the importance of electrical safety and educating industry stakeholders about specifying and buying accredited, tested and certified cables and cable accessories.

We would like to thank BASEC for allowing us to republish a selection of articles aimed to protect and inform the electrical sector – together we promote compliance with industry standards, specifications and ultimately confidence in end installations to provide LV MV HV Cable Quality.

In response to direct demands from the marketplace, BASEC has launched a certification scheme to encourage standardised and consistent levels of quality for control cable product ranges, known as YY, SY, CY.

Cable Testing

As an authority and preferred testing and certification partner to the worldwide cable industry, BASEC is regularly contacted to support and advise on control cable products comparability and application.

Our new scheme offers the cable industry and its users a way to improve and evidence the levels of quality and safety that the products manufactured, specified or sourced hold. There is presently no referenceable standard in existence, hence the reason these cable products are often a debated hot topic.

The scheme comprises of 6 BASEC specifications BA 1411, BA 1413, BA 1415 for PVC composition and BA 1412, BA 1414, BA 1416 for LSHF composition.

Control cables are found in a vast array of industries, across many industrial and everyday applications. These cable products are flexible, interconnecting and used to measure, control or regulate equipment on assembly or production lines, as well as supporting their associated computer units and work processes.

The new certification scheme is relevant to cable products up to and including 300/500 V, with a maximum conductor operating temperature of 70°C. Standards EN 50525-1 and EN 50565-2, where applicable, will be referenced in conjunction with the control cable scheme document.

BASEC is known within the industry for rigorous certification, factory auditing and testing schemes, which work continuously to improve quality and safety of cable products at manufacturing source. It is with this in mind, that the scheme has been developed, offering an all-inclusive testing programme for this widely used and barely regulated range of cable products. The below summary provides an insight into the depth of the testing which will be undertaken, which will in turn raise the levels of consistent quality in the market.

Cable testing schedule summary

- Electrical testing

- Voltage testing on complete cable and cores

- Resistance testing of conductor, insulation in normal and long-term scenarios and surface of sheath

- Transfer impedance on copper screened variants

- Constructional and dimensional tests

- Compliance with constructions

- Thickness measurements of insulation and sheath

- Overall dimensional checks

- Mean value and ovality

- Material and mechanical tests on insulation and sheath

- Properties before aging

- Properties after aging

- Tensile strength

- Elongation at break

- Loss of mass

- Heat shock testing

- Pressure at high temperature

- Bending and elongation at low temperature

- Impact testing at low temperature

- Complete cable mechanical strength

- Fire testing

- Single vertical cable flame propagation, to check flame spread characteristics

In 2016, a BASEC original scheme specification BA 1200 developed for single core fire resistant cables, based on market demand, was incorporated as a BS standard.

Now BS 8592 as we know it today.

Our longstanding tenure as a leading testing and certification provider and technical authority leads us to expect this new control cable scheme to hold the same potential – a vehicle to increase standardised levels of quality and safety.

Cable Quality Seminar

BASEC run a number of FREE Cable Quality Seminar’s across the country suitable for anyone and everyone who is working to deliver projects which include cable installations.

Do not miss your opportunity to build your awareness of cable quality.

Click here to register now.

Middle East Electricity 2020, Dubai

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

When Quality Matters: Early Indicators Of Error

September 3rd, 2019

-

Blog Written By BASEC | 8 of 10 Articles

Thorne & Derrick collaborate with BASEC to advocate the importance of electrical safety and educating industry stakeholders about specifying and buying accredited, tested and certified cables and cable accessories.

We would like to thank BASEC for allowing us to republish a selection of articles aimed to protect and inform the electrical sector – together we promote compliance with industry standards, specifications and ultimately confidence in end installations to provide LV MV HV Cable Quality.

In today’s market construction contracts can be very challenging in terms of the scope of works but equally in terms of risk management. Large amounts of cable are required for a range of applications, with various requirements for control, power supply and distribution.

No two cables perform the same role, as specific materials are required for installations dependent on environmental conditions, and achieving a consistent mix of materials for the same cable products can sometimes be difficult.

Contracts will typically be vetted by your legal department in conjunction with those working for all the parties involved in the project. It is, however, not uncommon for the risk profile to sit with you, the contractor, but this depends based on the specific terms and conditions you may have agreed. It is certain your risk management strategy starts with sound practices including appropriate planning and preparation, expertise in execution and, of course robust health and safety procedures.

Indemnity provisions will also typically feature within your contract or sub-contracts, which again serve to manage the risk. The costs of rectifying cable faults and the consequences of error can be hugely disproportionate to the sub-contract values, and this can pose a significant challenge should major faults arise, in a worst-case scenario.

Ensuring the products you specify and procure are to the highest levels of quality, safety and compliant with recognised industry standards is the first line of defence in terms of risk mitigation. Whilst any contracts must afford protection, prevention through the proper channels is far better than any cure.

Maintenance Engineers Checking Cable Installations

The responsibility for ensuring quality cable is specified and installed does not simply fall to the electrical installer. As a contractor, you too are responsible for cable installation, and you could be found liable for any faults that occur. This could, in turn, have a negative impact on your business and may even result in the loss of key customers.

While it is likely that your first concern when it comes to cables, is ensuring that they meet the relevant regulations and standards, simply specifying a cable that meets a recognised standard does not guarantee it will be suitable for the project or application. The materials may not be suitable for the conditions the cable will be installed into, which could result in the cable needing to be repaired or replaced shortly after installation.

The cost of buying cable is often a key consideration that makes specifying cheap cable tempting, but as with any item of importance, the cost of quality is almost always higher. Purchasing cheap cable that may not be compliant or suitable for application can create serious risks to health and safety. A further consideration in this decision can be the origin of the cable product.

A defect in a non-approved product is most likely to become evident during the installation or worse still, during commissioning or operation. Failures in cable can come in a range of guises, however sheath damage is probably the most common and this type of damage can occur during the manufacturing processes of spooling and un-spooling.

Other cause of failure could be related to mechanical damage, which is associated with movement of product, and, of course, faults within manufacturing or specification which can, in worst cases, render the product unusable. There are several obstacles involved in accessing and recovering a failed cable, that has already been installed, which is a far more onerous process than planning the original installation.

These obstacles can include things like, having to break or drill into concrete footings under which a problematic cable could be laid or having to access high ceilings or confined wall spaces as just a few examples.

Rectifying these sorts of issues can cost many times the value of the original purchase and installation in terms of the direct cost of gaining access alone.

Cable faults commonly arise from the use of poor-quality materials, right at the start of manufacturing process. These problems may not be detected, until it is too late, if at the product testing stages only specific characteristics are assessed.

Engineer Operating Plant Machinery

A clear way to manage risk is to insist on the use of certified products. When cable is independently tested by a third-party approvals and certification body like BASEC, all aspects of the cable make-up and materials are assessed as part of a three-year certification programme.

The cables are sampled from production and tested several times a year to ensure they maintain consistent levels of quality, but also to verify that they meet all of the required or relevant standards.

Cables are rigorously tested to determine their suitability for operation in challenging conditions, and performance is assessed through electrical, material, mechanical, chemical and fire testing. Assessing all of these criteria is essential to verifying cable quality because some cable products could pass certain tests but fail others.

The conductor resistance test is one of the most frequently required tests that all of the British, European and international standards mention. This test assesses the amount and quality of conductor material in a cable’s cores.

The purpose of this test is to verify that the cable’s current carrying capacity is in line with the rating for that product and that it will, ultimately, operate safely within the parameters specified in the installation.

This test, however, does not assess the performance of a cable when it is exposed to, expected or unexpected, environmental conditions such as flames, chemicals or extreme temperatures.

Testing a range of characteristics, therefore, provides a more accurate reflection of the quality and safety of a product, which also leads to confirming its suitability for the required application. BASEC certification is amongst the most diligent and rigorous in the market, designed to ensure that cable carrying the BASEC mark has been comprehensively tested.

The success of a construction project is often measured on completion, whether it has been delivered on time and to budget. Cable quality should be specified highly and sourced right at the start of the project, to ensure that time and money are onside. This will help to avoid the allure of a low price when budgets are dwindling at the end of the project. Using quality cable has the potential to save contractors a significant amount of time and money in the long term, if errors are detected early-on in the specification process.

Independent testing enables defects to be recognised before a cable product enters the supply chain and ends up in the hands of the installation team, ensuring that it will be safe and fit-for-purpose.

Even more importantly, third-party approved cable product certification provides assurance that cables will be safe in the event of an emergency. When approached from this perspective cable quality should be front of mind for specifiers and purchasers.

BASEC exists to promote quality cable throughout the world as is the preferred testing and certification partner to the worldwide cable industry. The BASEC mark can be relied upon by end users, when quality matters, it builds confidence in the product and manufacturing source for many years to come.

Cable Quality Seminar

BASEC run a number of FREE Cable Quality Seminar’s across the country suitable for anyone and everyone who is working to deliver projects which include cable installations.

Do not miss your opportunity to build your awareness of cable quality.

Click here to register now.

Middle East Electricity 2020, Dubai

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV