Jointers Blogs

World First | EHV 1,100kV GIS Tested By Standard Lighting Impulse Voltage

March 9th, 2021

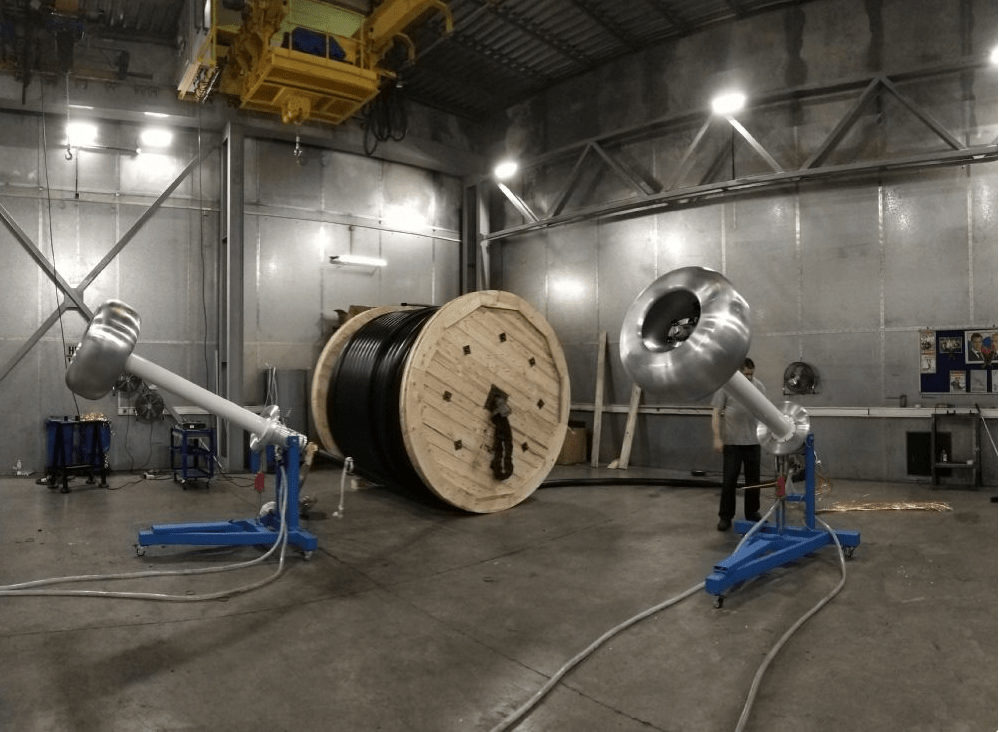

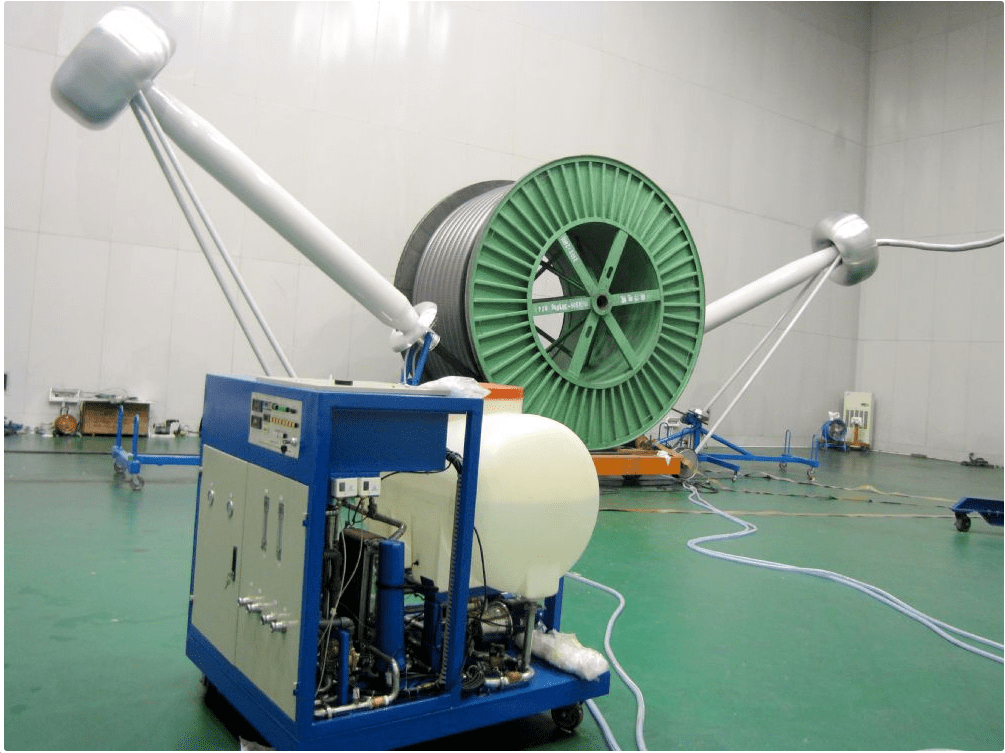

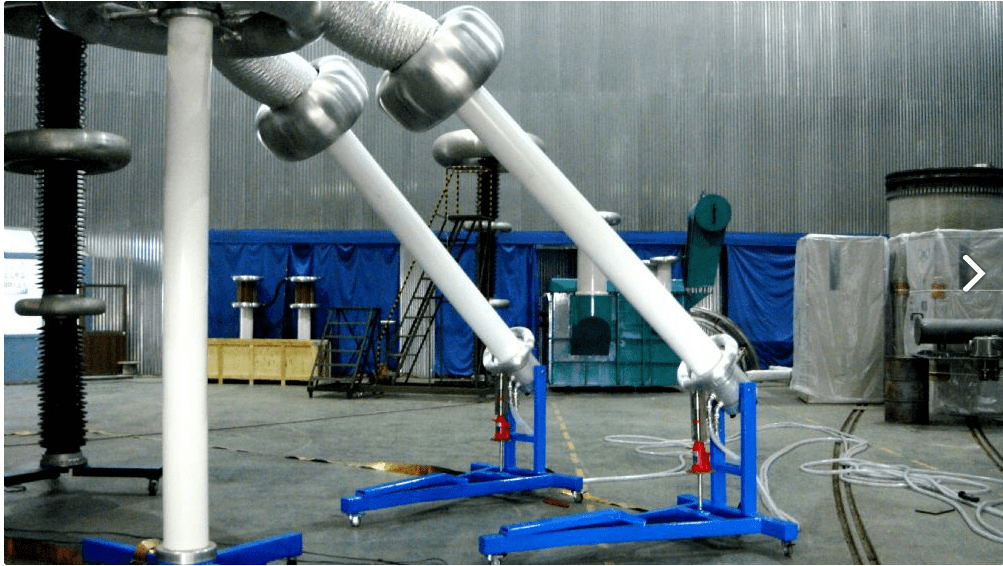

PowerHV have successfully performed onsite Lighting Impulse Voltage Testing on 1100kV GIS by 3,000kV 300kJ SF6 insulated impulse voltage generator.

It is the first time in the world that EHV GIS was tested by Standard Lighting Impulse Voltage on site. This time, the standard Lighting Impulse Voltage Test is mainly made on 1100kV GIS already installed as part of first phase project, including bushing, isolating switches, busbars, grounding switches.

YangZhou Power Electric Co., Ltd. is the subsidiary company of the Yangzhou Xinyuan Electric, Co., Ltd –  PowerHV are world leading High Voltage Testing specialists for switchgear, transformers and cable accessories including (cable joints and terminations).

PowerHV are world leading High Voltage Testing specialists for switchgear, transformers and cable accessories including (cable joints and terminations).

➡ See also: Insulating Gloves | Insulating Sticks | Substation Life Saving Kits | Transmission Line Earthing Equipment | Insulated Matting

High Voltage Cable Accessories Testing

Cable End Termination for 220kV Power Cable

800kV Water Termination and Water Condition Unit

350kV Water Termination

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Sicame LV Resin Mains Cable Joint – 3 Core PILC to Hybrid With Service Branch & PILC Joints

March 9th, 2021Image Courtesy of: Gavin Duke (LV 11kV 33kV UKPN Cable Jointer)

Pictured: 2 x .3 Imperial PILC (Paper Insulated Lead Covered) cable jointed to 185sqmm Hybrid with 2 x 35sqmm 3 Phase Services and 1 x 35sqmm Single Phase Service Cable Branched.

2 x 35sqmm 3 Phase Cable to .0225 Imperial 4 Core PILC straight joints and 1 x 35sqmm Single Phase to .0225 2 Core PILC Joint. These cable joints were installed to replace 2 faulted “T Joints”.

Video : Locating & Repairing An Overhead Line Fault By UKPN

T&D are Main Distributors and Stockists for the Sicame Key Product Groups – Mechanical Connectors for Straight Service Joints, Service/Mains Branch Joints, Single Service Joints, Double Service Joints, Mains Service Breech Joints, CNE Joints, Mains Straight Joints, Mains Breech Joints and Termination Lugs.

T&D are UK Distributors for Sicame.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Prysmian Click Fit 132kV EHV Cable Joints

March 9th, 2021Images Courtesy of: David Young (HV Cable Jointer)

Pictured: Prysmian 132kV Click Fit Cable Joint. Connector pressed on, semi-conductive screen glassed and groove cut in for shield.

T&D are distributors for Prysmian Cable Components which includes their range of Bicon cable joints, cable cleats, cable glands and jointer tooling for LV, MV and HV cables.

Prysmian 132kV

- 132kV XLPE Cable 630mm² Cu/Pb

- 132kV XLPE Cable 1000mm² Cu/Pb

- Composite Outdoor Cable Terminations

- Single Core Transition Cable Joints

- Three Core Transition Cable Joints

- Link Boxes

- Bonding Lead

- CFJ-145 Click-Fit Straight Joint 138kV

- CFJX-145 Click-Fit Straight Joint With Sheath Interruption 138kV

- CFJ-145-T Click-Fit Size Transition Joint 138kV

- CFJX-145-T Click-Fit Transition Joint With Sheath Interruption 138kV

Click Fit Cable Joints

Click-Fit joints are used in the high voltage power grids, connecting all combinations of cables with minimum effort and in less time than conventional joints.

The pre-moulded, factory tested Click-Fit joints over a fail-safe connection every time. Click-Fit joints can be split into four main categories – sectionalised and un-sectionalised (symmetrical joint and asymmetrical joints type to connect two different extruded cables), transition joints for extruded to paper cable connections and branch (Y) joints.

Click-Fit joints are highly reliable cable connection assemblies designed to connect any extruded high voltage cable and able to cover a broad range of applications. Also Click-Fit technology allows for pre-fabrication of the XLPE cable prior to disconnection of the circuit, thus reducing network down time.

Further Reading

Prysmian’s Medium Voltage Power Cables BASEC Approved

11kV Prysmian Float Fit Cable Terminations (SSE) Terminated Into 11kV/33kV Transformer

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Water Treeing in High Voltage Cables | A 230kV HPPT Termination Repair

March 2nd, 2021

This series of excellent photographs taken from site have been kindly provided by: Douglas Page | Instructor & Cable Splicer at Hydro One Training and Development Services

As Ontario’s largest transmission and distribution electricity provider, Hydro One is committed to providing homes and businesses across the Canadian province with safe, affordable and reliable electricity.

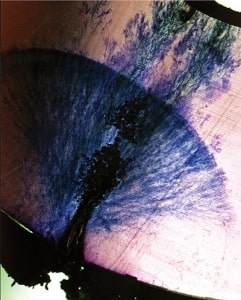

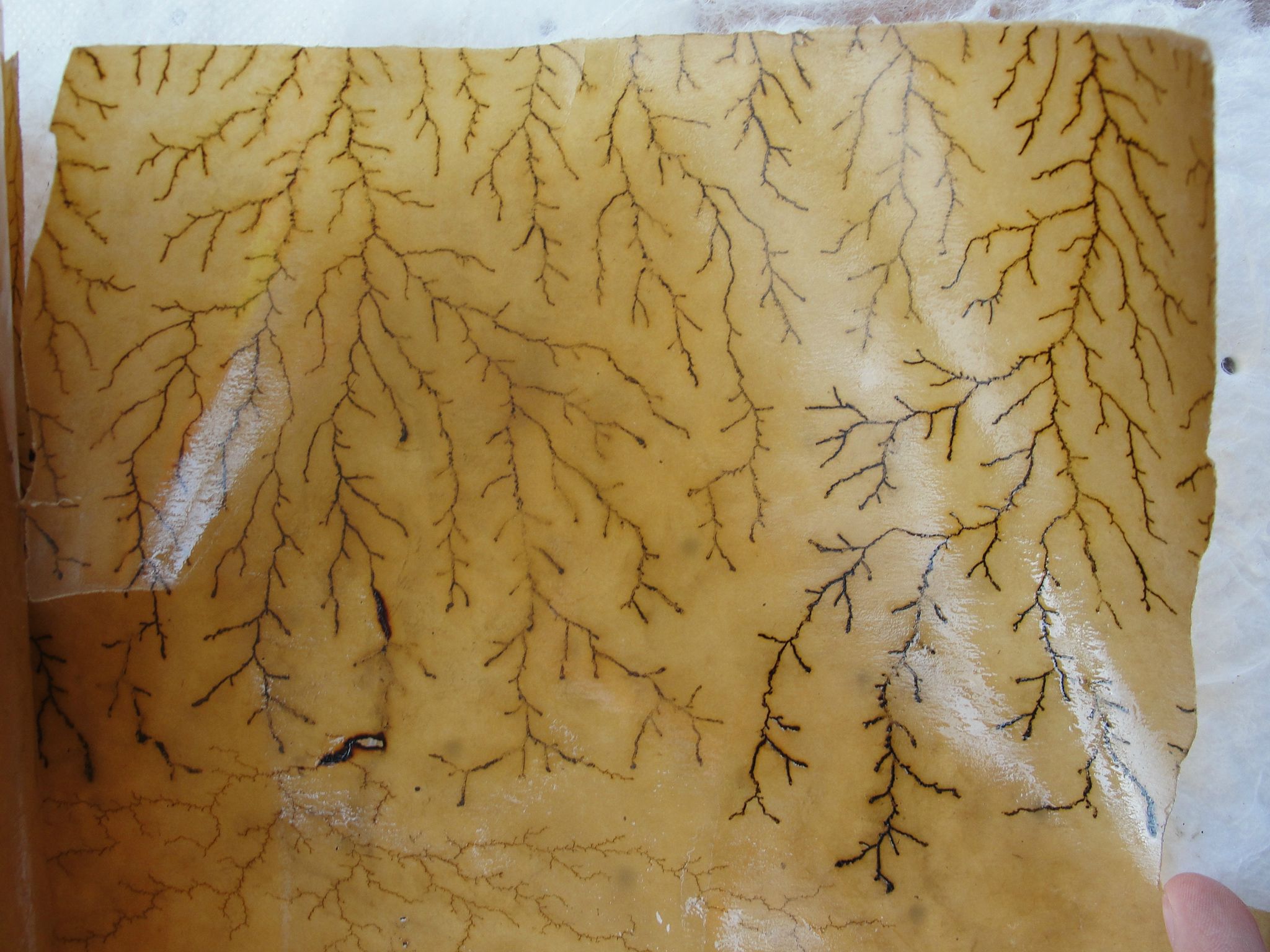

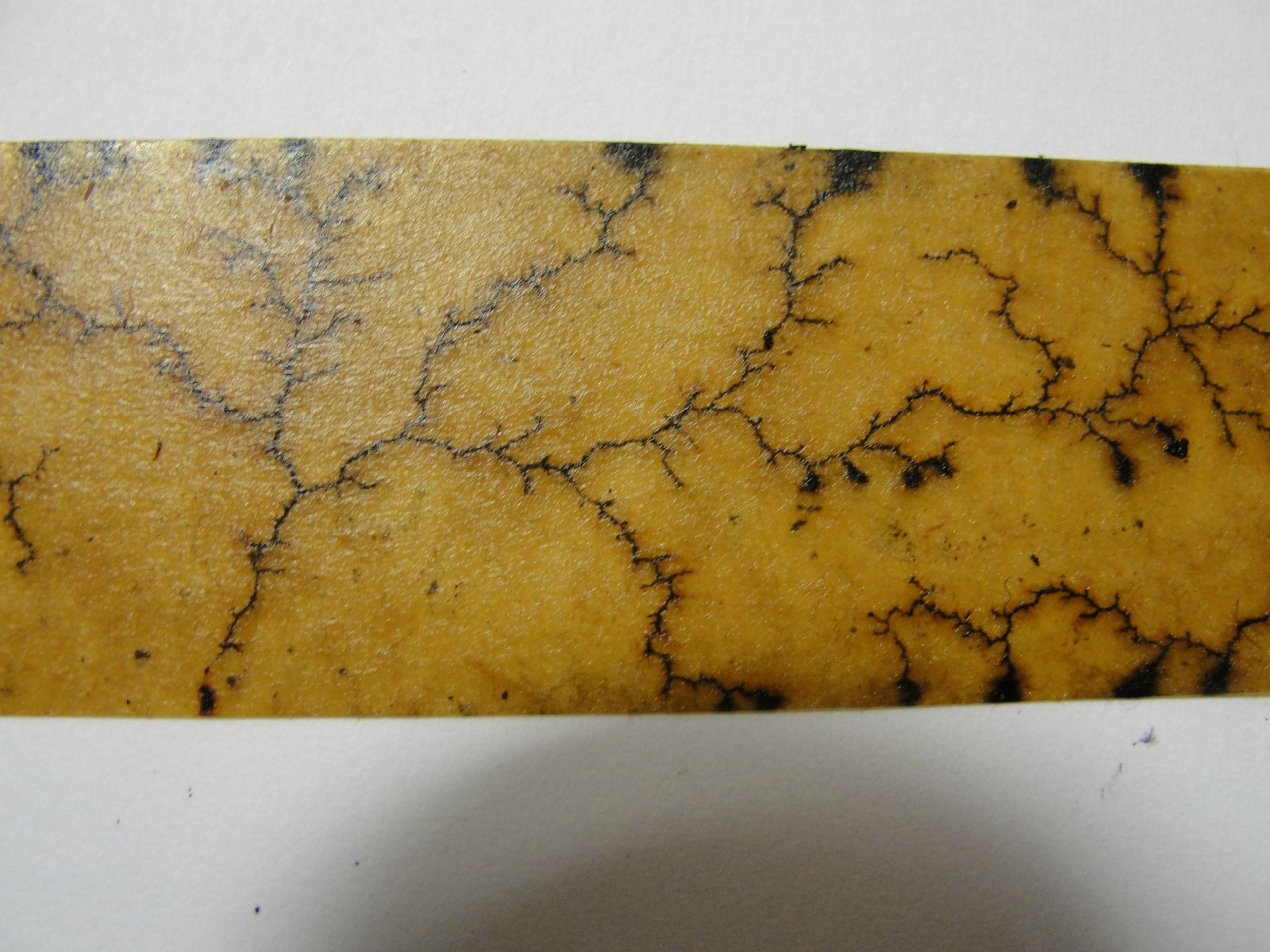

Water Treeing

Water treeing is one of the major causes of premature failure of medium, high and extra high voltage power cables. Water-trees increase cable insulation losses and in some cases can initiate electrical trees that lead to breakdown. High voltage cables are exposed to water and moisture in general condition. Water action on cable insulation systems causes changes in their properties and creates such water-trees.

The electrical degradation process of ‘treeing’ in cable polymers occurs in the presence of electrical stress and moisture. This is acknowledged as a serious cause of non-mechanical insulation degradation and cable failures.

The water tree issue is considered by most people as solved and indeed due to improvements in the design, the manufacturing process and the insulation compound the growth of water trees in new cables has been drastically reduced.

Water tree retardant cross-linked polyethylene power cables (TR-XLPE) have extended medium voltage primary distribution cable reliability and lifetime.

Longer-life TR-XLPE cables have been successfully installed by North American utilities for over 25 years using advanced performance XLPE insulations on ‘wet’ designs for underground distribution systems.

Water-treeing and the expected remaining lifetime of aged cables on high voltage power networks provides serious challenges and requires a high-skilled response by HV cable splicers – asset managers often have to maintain and service kilometres of first generation cable requiring traditional cable jointing and repair skills that are often no longer taught in today’s modern utility jointing schools.

Accelerated aged tests conducted on new cables in laboratory conditions by CIRED have concluded, ” bow-tie trees seem to represent an image of contaminants present in the insulation and vented trees seem to be related to the impurity content of the semi-conductive layer.”

Further reading: New Test Results With 3kHz Accelerated Growth Of Water Trees In Medium Voltage Power Cables (2011).

Water-Treeing

Images Courtesy: Douglas Page

The following sequence of images convey water-treeing or arcing inside a high voltage cable termination. This a 230kV HPPT (High Pressure Pipe Type) Cable Termination or (Pothead). These images show the importance of routine oil sampling, which detected acetylene in the samples, which in turn indicates arcing or burning.

The cable splicers froze the cable below the pothead, removed the porcelain and found a high voltage cable very near failure. Then the cable splicers basically removed everything that been damaged and rebuilt the cable first, then rebuilt the stress cone. It was later found that a rubber gasket had a small imperfection that allowed contaminants (moisture debris) into the pothead, which as it accumulated had created a conductive path on and in the paper insulation, which would eventually have lead to cable failure.

The following images portray the process described above.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

132kV Prysmian Oil Filled Stop Joint & 132kV Straight Joint

March 2nd, 2021

Pictured : 132kV Prysmian Oil Filled Stop Joint & 132kV Straight Joint

Image : Simon Chapman (Cable Jointer – Balfour Beatty plc).

Prysmian HV Cable Accessories – Overview

- Straight Joints

- Stop Joints

- Outdoor Terminations (ODSE)

- SF6 – Immersed Terminations (SF6-OISE)

- Transition Joints

Prysmian Group

T&D are Distributors for the Prysmian Components range of cable joints, terminations, cleats, glands and lugs for use on LV, 11kV and 33kV cable networks.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.