Blog

Trace Safe | Which Trace Safe is Best for Your Application?

January 7th, 2020

-

uploaded by Chris Dodds - Thorne & Derrick Sales/Marketing Manager

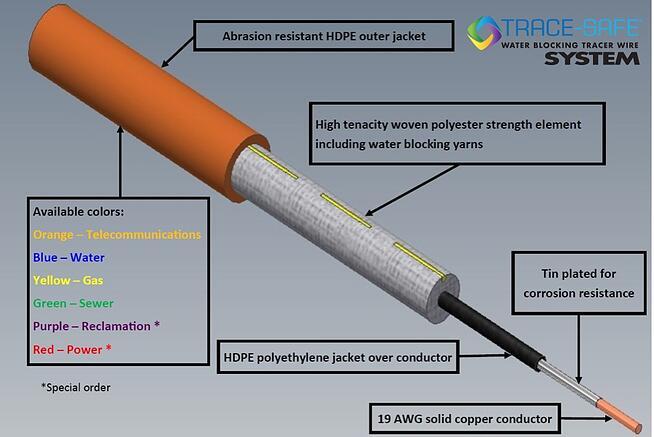

NEPTCO revolutionised the tracer wire market when it introduced Trace Safe, the world’s first tracer wire that incorporated water blocking technology to protect the solid copper conductor from water ingress. There are two distinct products that incorporate many of the same features but there are key differences.

While both products are available in all standard utility colors and have an HDPE outer jacket, water blocking yarns, HDPE wire insulation and a tin coating over the solid copper conductor; the key difference is the strength rating of each product.

Trace Safe gets its strength from the water blocking polyester core that surrounds the solid copper 19 AWG conductor.

The core is made from high tenacity polyester yarns, like those found in car tyres, that are treated with a super absorbent powder.

If the outer jacket is damaged, the super absorbent powders swell up like a baby diaper to prevent any moisture from meeting the solid copper conductor. This helps to ensure a long lasting reliable tracer wire.

Trace-Safe is the only water-blocking tracer wire on the market manufactured by NEPTCO

The amount of core material is the distinguishing difference between the 1800 lb. RT products and 600 lb. TST products. Less core material lowers the cost of the TST products but each product has distinct applications that it is best suited for.

The RT products have an overall rated strength of 1800 lb. and are ideal for horizontal directional drilling applications.

RT products can be attached directly to the drill shaft and pulled back along with the conduit and does not need to go inside the duct. The super tough jacket combined with the 1800 tensile strength means that RT Trace Safe can withstand the rigours and tensions generated during pull back.

The TST products have an overall rated strength of 600 lb. and are ideal open trench, micro trench and nano trenching or can be pulled back alongside dielectric cables inside the duct.

Trace-Safe

Trace Safe is a system which use no strip wire connectors.

Each connector comes with a TST adapter so no matter which wire is used the same connectors will work in any situation.

Trace-Safe and TST adapter

So, which Trace Safe is best for you?

It depends on the application.

For directional drilling applications always choose the RT products, for everything else, the TST products.

For simplicity, some utilities prefer to stock only one wire and choose the RT products because of its universal utility.

However, others are more explicit and will only use RT for directional drilling situations.

Consider the application and be sure to always use the Trace Safe connectors to complete the system.

Further Reading

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

How to Trace & Locate Non-Metallic Underground Gas, Water Sewer Pipelines

January 7th, 2020

Manufacturers of TRACE-SAFE

-

uploaded by Chris Dodds - Thorne & Derrick Sales/Marketing Manager

Water Blocking Utility Locating System

Detecting, Locating & Tracing Underground Pipes

NEPTCO is a global leader in the manufacturing of materials used for the Detection & Pulling of Cables for a wide variety of commercial and industrial applications.

In this Blog, Thorne & Derrick discuss how Trace-Safe provides the ideal solution for all your tracer wire needs including locating non-metallic underground gas and water sewer pipelines.

Trace-Safe® is the only water-blocking tracer wire on the market.

Its unique characteristics protect its solid copper conductor from corrosion. It enables precision locating utilising a 19AWG conductor.

Water blocking reinforced tracer wire for the Trace-safe utility locating system.

Double insulated metallic conductor enables reliable and accurate locating of all-dielectric cables, gas lines, sewer lines or water pipes.

NEPTCO’s cut resistance Trace-Safe® product ensures reliability, locates on frequencies of 9.5, 38, 80, and 512 KHz and outperforms competitive tracer wire products. The product is available in two versions: Trace-Safe and Trace-Safe Trench tracer wires.

Trace-Safe is the strongest tracer wire on the market and eliminates the need to use two or more standard tracer wires for directional drilling applications.

♦ Further Reading Trace Safe | Which Trace Safe is Best for Your Application?

Trace-Safe Water Blocking Tracer Wire System

Features & Benefits

- Water-blocked tracer wire for anti-corrosion

- Four layers of protection to guard against water penetration

- Provides superior locate accuracy for telecom, gas, water, sewer and reclamation applications

- Light-duty and heavy-duty versions available for open trench or directional drilling applications

- Simple to use connectors ensure consistent, reliable splices

- High strength, lightweight and flexible tracing system

- Sequential footage or meter markings

- Passes meter water head test

- Corrosion-resistant conductor compatible with any locating equipment

- Two high density polyethylene jackets

- Abrasion, moisture and UV resistant

- No strip universal connectors ensuring consistent reliable connections every time

Trace-Safe Utility Locating System

Properties

- Break strengths: 1800 and 610lbs (818/181kg) nominal

- RT1800 weight: 20lbs. per 1,000 feet (29 kg/km)

- TST600 weight = 11lbs. per 1,000 feet (16.4kg/km)

- High tenacity polyester fibers with super absorbent powders

- Conductor diameter: .0356″ nominal (19 AWG) (.9mm)

- RT1800 outer jacket thickness = .030″ (.762mm)

- TST600 outer jacket thickness = .025″ (.635mm)

- Inner jacket thickness = .006″ (.152mm)

- Conductor tensile strength: 38,500 psi nominal

- UL 1581 rated to 600 volts CE standards

- Dielectric constant 2.29 @ 1MhZ

Colours available:

Orange – Telecommunications

Red – Telecommunications, (AUS/NZ)

Blue – Water

Yellow – Gas

Green – Sewer

Trace-Safe Water Blocking Tracer Wire System

| Item Number | Product Code | 1800 LB Description | Package | Reel Dimensions | Wt/lbs | Rls/Skid |

| Telecommunications | ||||||

| 44087 | RT1800W | Orange – TRACE-SAFE | 500 ft | Fl. 10.5″ x W 7.75″ | 11 | 45 |

| 42410 | RT1800W | Orange – TRACE-SAFE | 1,000 ft | FI. 12″ x W 12″ | 24 | 36 |

| 44088 | RT1800W | Orange – TRACE-SAFE | 1, 500 ft | FI. 13.25″ x W 17″ | 60 | 18 |

| Gas Transmission & Distribution | ||||||

| 44089 | RT1801W | Yellow – TRACE-SAFE | 500 ft | Fl. 10.5″ x W 7.75″ | 11 | 45 |

| 41741 | RT1801W | Yellow – TRACE-SAFE | 1,000 ft | FI. 12″ x W 12″ | 24 | 36 |

| 44092 | RT1801W | Yellow – TRACE-SAFE | 1,500 ft | FI. 13.25″ x W 17″ | 60 | 18 |

| Water Transmission & Distribution | ||||||

| 44093 | RT1802W | Blue – TRACE-SAFE | 500 ft | Fl. 10.5″ x W 7.75″ | 11 | 45 |

| 41740 | RT1802W | Blue – TRACE-SAFE | 1,000 ft | FI. 12″ x W 12″ | 24 | 36 |

| 44097 | RT1802W | Blue – TRACE-SAFE | 1, 500 ft | FI. 13.25″ x W 17″ | 60 | 18 |

| Sewer | ||||||

| 44098 | RT1803W | Green – TRACE-SAFE | 500 ft | Fl. 10.5″ x W 7.75″ | 11 | 45 |

| 42408 | RT1803W | Green – TRACE-SAFE | 1,000 ft | FI. 12″ x W 12″ | 24 | 36 |

| 44099 | RT1803W | Green – TRACE-SAFE | 1, 500 ft | FI. 13.25″ x W 17″ | 60 | 18 |

| Item Number | Product Code | 400 LB Description | Package | Reel Dimensions | Wt/lbs | Rls/Skid |

| Telecommunications | ||||||

| 61859 | TST600W | Orange – TRACE-SAFE TRENCH | 1,000 ft | Fl. 12 x W 10.25″ | 12 | 36 |

| 61861 | TST600W | Orange – TRACE-SAFE TRENCH | 1,500 ft | Fl. 12 x W 10.25″ | 27 | 36 |

| 62360 | TST600W | Orange – TRACE-SAFE TRENCH | 2,000 ft | Fl. 12 x W 16.25″” | 56 | 18 |

| Gas Transmission & Distribution | ||||||

| 61873 | TST601W | Yellow – TRACE-SAFE TRENCH | 1,000 ft | Fl. 12 x W 10.25″ | 12 | 36 |

| 61875 | TST601W | Yellow – TRACE-SAFE TRENCH | 1,500 ft | Fl. 12 x W 10.25″ | 27 | 36 |

| 62361 | TST601W | Yellow – TRACE-SAFE TRENCH | 2,000 ft | Fl. 12 x W 16.25″” | 56 | 18 |

| Water Transmission & Distribution | ||||||

| 62244 | TST602W | Blue – TRACE-SAFE TRENCH | 1,000 ft | Fl. 12 x W 10.25″ | 12 | 36 |

| 62246 | TST602W | Blue – TRACE-SAFE TRENCH | 1,500 ft | Fl. 12 x W 10.25″ | 27 | 36 |

| 62245 | TST602W | Blue – TRACE-SAFE TRENCH | 2,000 ft | Fl. 12 x W 16.25″” | 56 | 18 |

| Sewer | ||||||

| 62358 | TST603W | Green – TRACE-SAFE TRENCH | 1,000 ft | Fl. 12 x W 10.25″ | 12 | 36 |

| 62357 | TST603W | Green – TRACE-SAFE TRENCH | 1,500 ft | Fl. 12 x W 10.25″ | 27 | 36 |

| 62356 | TST603W | Green – TRACE-SAFE TRENCH | 2, 000 ft | Fl. 12 x W 16.25″” | 56 | 18 |

MULEGLIDE Cable Blowing & Cable Pulling Lubrication

NEPTCO‘s long-lasting silicone cable blowing/pulling lubricant called MULEGLIDE is an ideal LV, MV & HV cable lubricant, available as low-viscosity Underground Cable Blowing Lubricant or MV HV Underground Cable Pulling Lubricant, which allows for swift and safe underground cable installation.

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

NEW Online Platform | Expert Project Intel for the UK Power T&D Industry

January 3rd, 2020

-

uploaded by Natalie Lundie | Supply Chain: Marketing Lead at Thorne & Derrick International

Thorne & Derrick are pleased to announce they have partnered with Power Transmission Distribution working together to promote products, Blogs and latest company news on their website and social media accounts.

Their Platform offers expert coverage and breaking news from the MV HV Electrical Power Transmission & Distribution Industry. After 6.5 million views in under 18 months on LinkedIn they decided to launch their own website.

A dedicated team with a wealth of experience provide information through several sources within National Grid that now features on their dedicated website:

- Scottish Power

- Scottish & Southern Energy

- UKPN

- Western Power Distribution

- Stakeholders

- Developers

This includes news and updates on the latest substation projects including HVDC, GIS, AIS and GIB construction / refurbishments – the Platform also covers nuclear and the renewable sector with windfarms and Green Energy updates as well as research news on contractors and all the authorities dominating these markets.

From the latest breaking news, technological advances to project activities, Power Transmission Distribution has an experienced and well-respected team of editors, columnists and correspondents that will keep the industry well informed.

- National Grid Tender £160 Million – Data Center Strategy and Transformation

- Smith Brothers Wins (ICP) Contract

- Hinkley Connection Project January 2020

- Plans For A Solar Farm at Connagh’s Quay

Who’s it for? Whether you are a, SAP, Site Manager, Commissioning Engineer, Tender Manager, SHEQ Consultant, Electrical Engineer, Wireman, M&E Electrical Contractor, CEO or Managing Director – this is the place to find the latest developments in the Power Transmission & Distribution sector and for all the latest news within National Grid in the UK.

Advertise online with Power Transmission Distribution

Working with an experienced editorial team Power Transmission Distribution can provide professional advertisement that will be strategically placed to gain maximum exposure.

A dedicated team of Search Engine Marketers that will make sure that your product is promoted correctly ensuring the highest possible search engine rankings, cutting through the internet clutter and targeting the people who research, recommend and purchase your products and services on a daily basis.

They also format their advertising for full screen computer display and also smart phone applications automatically.

Feel free to contact PTD to take advantage of the advertising packages that we have are on offer to suit your requirements.

Please contact:

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Upskilling To EHV – Training Opportunities For Cable Jointers With G&W Electric

December 20th, 2019T&D are frequently asked to provide advice and training recommendations to ambitious cable jointers intending to up-skill from MV-HV (6.6kV, 11kV, 33kV) to EHV transmission and distribution voltage levels (typically 132kV, 230kV, 400kV).

So, we decided to ask G&W Electric (USA), a leading global supplier of electric power equipment – since 1905 G&W have manufactured world-class transmission and distribution cable accessories including cable terminations and cable splices for XLPE, PILC, low and high pressure, fluid and gas filled, self-contained and pipe type cable systems.

“We have training programmes to certify Cable Jointers to install G&W cable splicing and terminating products. We usually carry out such training in our headquarter, Bolingbrook, IL, USA. Based on the resume/experience of the cable jointer, we will design a specific program on all of our extruded cable accessories (usually 230kV, outdoor termination, GIS/GUS termination and cable joint), which can last 1-2 weeks. After the jointer training, we will issue certificate (with or without G&W supervision on site). For those certified with supervision, we will go to the site with the jointer during the real project. If the cable jointer’s work meets our requirement, we will update the certificate without supervision. For anyone interested in our training program, they can reach me at [email protected],” replied Kai Zhou (Product Development Engineer at G&W Electric Co.).

Overview of G&W Cable Accessories

In 1905 G&W introduced the first disconnectable cable terminating device.

Over 100 years later, G&W continues to create technical innovations that have improved performance and reliability. With over 100 years experience, G&W is the name you can trust for quality cable accessories. With sales representation worldwide, G&W has a proven track record for success. G&W cable accessories are designed to accommodate cables from all manufacturers and can be created to accommodate any customer cable system. The optional mechanical shrink feature offers an easier and faster installation while reducing possible damage during installation. G&W also offers installation supervision and installation training, which can be customised to suit the audience.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

ABB EHV 275kV Cable Sealing Ends & GIS Cable Terminations

December 2nd, 2019

Images Courtesy: Richard Mason – EHV Jointer for Onshore & Offshore work up to 245kV (SMSTS) – Global Cabling Services Ltd

GCS Jointing

GCS Jointing is a trading name of Global Cabling Services Ltd and was founded in 2015 when Richard Mason (Director GCS Jointing – Global Cabling Services Ltd), decided to leave a major power utilities contractor after many years of quality service. Richard is an EHV Jointer with over 25 years of experience – with a practical approach to HV EHV projects the work GCS undertake is often installed and supervised on site by Richard personally. GCS Jointing is recognised as a specialist HV and EHV Cable Jointing and Cable Installation Sub-Contractor within the onshore and offshore utilities, oil-gas and clean energy industries.

Cable Sealing Ends

Cable Sealing Ends

The cable termination consists of an insulator installed on a box body made of aluminium castings. The box body consists partly of insulating material, which provides an insulated installation for high voltage power cables. The base part is to be installed on a supporting bracket. For 420kV a corona shield and a post insulator kit PIU 420 B/G are included with the cable sealing end. The elecrical stress control component is a premolded rubber stress cone. The insulator has sheds of short-long type and is filled with synthetic insulating oil.

The composite insulator design includes grey silicone rubber sheds and a fiberglass reinforced epoxy resin hollow core. It is light-weight and less sensitive for outer damages. The porcelain insulators are available in brown on request. A bolt clamp in the top fitting is used to connect the conductor to the top bolt. Top bolt and bolt clamp are included in the kit. For the maximum permitted diameter over the cable oversheath and the diameter over prepared XLPE cable insulation – the cable sealing end provides a fixed connection point once lifted into place to secure the cable termination.

Skilled Cable Jointers

Workmanship and Competency in the installation of MV HV cable accessories, including Joints and Terminations, is regarded as critical to the performance and reliable of power cable systems – skilled workmanship during installation by the Jointer is very important when considering and reducing the risk of future cable failures. When preparing HV cable several layers need to be removed or treated without damaging other layers, this requires the highest levels of skills, training and knowledge about how to handle specialist Jointers tools for this application. Knowledge about the critical steps in cable accessory assembling provides the best foundation for successful and safe installation.

ABB

ABB pioneered high voltage gas-insulated switchgear (GIS) more than 50 years ago and is a global leader offering a full-range product portfolio with voltage levels from 72.5kV to 1200kV matching current and future requirements for modern switchgears and power grids.

As a market leader in high voltage GIS technology, ABB has a global installed base of more than 35,000 bays. In a power system, switchgear controls, protects and isolates electrical equipment to boost the reliability of power supply.

GIS is a compact metal encapsulated switchgear consisting of high voltage components such as circuit-breakers and disconnectors.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.