Subsea Cable Protection

Subsea Cable Protection Systems – Disconnection & Removal | Part 3 of 5

September 16th, 2019Subsea Cable Protection Systems

♦ Republished by Chris Dodds with Kind Permission of Greg Campbell-Smith ((Director Sales and Business Development at First Subsea)

First Subsea is the world’s leading developer of subsea connection technology, supplying, installing and decommissioning.

Subsea power cables on offshore wind farms are typically protected by means of burial.

This is a well proven means of cable protection used in other offshore industries.

However, at either end of offshore wind array cables they transition from burial, up through the water and into the wind turbine foundation. This free spanning section of cable is susceptible to what can be substantial wave and current loads.

These loads introduce movement and bending into the subsea cable which, without cable protection, can lead to over-bending, over-tensioning, fatigue and abrasion damage.

This exposed subsea cable is traditionally ‘protected’ by means of a relatively expensive and complex proprietary Cable Protection System (CPS).

Our 3rd Article on Cable Protection Systems looks at how subsea cables can be disconnected and removed, focusing on removal times and costs.

Disconnection of the CPS is not a regular occurrence offshore, after a successful installation there should be little reason to disconnect unless the system has experienced accidental damage, premature failure due to design, manufacture or higher than expected loading.

Problems during installation may require disconnection, such as, pinch points in I-Tube, winch capacity exceeded due to friction losses, incorrectly sized pull-in accessories and obstructions in entry holes.

A common misconception is the CPS is removed if the cable is faulty. Typically, the cable is disconnected and passed back through the system and the new cable is threaded back.

First Subsea CPS is a proven removable system. In a recent project an installation issue occurred that required the CPS to be removed. The disconnection process, remedial work and re-connection took less than 12 hours.

Quite some time you may think, but when you consider alternative systems require removal by subsea sawing or risk damaging the structure when removing. First Subsea CPS will save minimum €40,000 vessel, diving/ROV time. Client “it was an invaluable feature that got us out of a bind”

➡ If you would like a copy of the report, please contact Chris Dodds [email protected]

- Subsea Cable Protection Systems Installed On Offshore Wind Farm | Part 1 of 5

- Subsea Cable Protection & Laying Costs | Part 2 of 5

- Subsea Cable Protection Systems, Damage Prevention & Fixed WTG | Part 4 of 5

- Subsea Cable Protection Systems Design For Installation | Part 5 of 5

LV, MV & HV CABLE JOINTING, EARTHING, SUBSTATION & ELECTRICAL EQPT

Thorne & Derrick are Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems – we are highly customer responsive and absolutely committed to providing a world-class service.

We have an International Distribution Agreement with Nexans Power Accessories UK to supply their Heat Shrink and Cold Applied ranges of 11kV/33kV/66kV joints and terminations and Euromold brand of separable connectors.

Since 1985, we have established an international reputation based on Service, Integrity and Trust – contact us.

t: 0191 410 4292 | e: [email protected] | www.powerandcables.com

We provide expert technical support and supply from a multi-million pound stock holding:

- Cable Joints, Terminations & Connectors Earthing & Lightning Protection

- Cable Accessories – Lugs, Glands

- Circuit Protection & Fuses

- Cable Cleats & Clamps Electrical Safety Equipment

- Cable Pulling & Laying Equipment

- Arc Flash Protection & Clothing

- Cable Duct Seals & Transit Systems Surge Arresters & Bushings

Further Reading:

- Arc Flash Clothing & Protection For Safe Windfarm & Wind Turbine Working

- Jointer Training Courses – 11kV 33kV 66kV MV HV Cable Jointer Competency Training

- Sealing Cables In Offshore Substations – A Roxtec CPD

Subsea Cable Protection & Laying Costs | Part 2 of 5

September 16th, 2019Subsea Cable Protection Systems

♦ Republished by Chris Dodds with Kind Permission of Greg Campbell-Smith ((Director Sales and Business Development at First Subsea)

First Subsea is the world’s leading developer of subsea connection technology, supplying, installing and decommissioning.

Subsea power cables on offshore wind farms are typically protected by means of burial.

This is a well proven means of cable protection used in other offshore industries.

However, at either end of offshore wind array cables they transition from burial, up through the water and into the wind turbine foundation. This free spanning section of cable is susceptible to what can be substantial wave and current loads.

These loads introduce movement and bending into the subsea cable which, without cable protection, can lead to over-bending, over-tensioning, fatigue and abrasion damage.

This exposed subsea cable is traditionally ‘protected’ by means of a relatively expensive and complex proprietary Cable Protection System (CPS).

Our 2nd Article on Subsea Cable Protection Systems focuses on Subsea Cable Protection & Laying Costs.

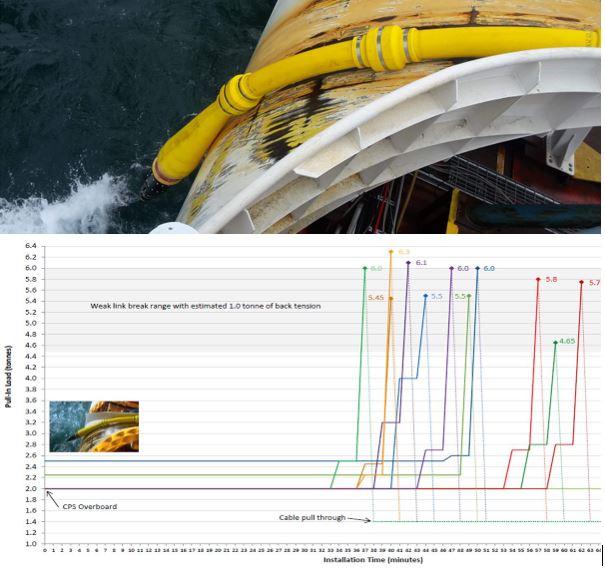

As part of our product awareness feature on Cable Protection Systems we look at the time taken to install, focusing on the critical path timings, that impact on the installation costs.

Cable lay construction vessels command market rates in excess of €150,000 a day, due to their ability to reel, carry and deploy cable using dynamic positioning, this figure excludes crew/fuel.

Most large cable lay vessels have the ability to pre-assemble and prepare the cable protection system on the runway off the critical path as they perform other operations, so the deck preparation times which take on average an hour have been discounted.

The critical path clock for the CPS product starts as it is deployed over the chute located at the stern of the vessel. The graph shown below shows the times for a number of cable pull ins with a crew new to our system. Our quickest time was 38 minutes from overboarding to connection.

After the first few pull-ins the team averaged 45 mins. From first hand observations on another CPS we saved over an 1hr on critical path.

Saving an hour on critical path, could provide a saving of €7,000, small change you may think. Think again Typically 150 CPS per project could save over €1,000.000 When selecting CPS consider the overall CAPEX not just the product cost.

➡ If you would like a copy of the report, please contact Chris Dodds [email protected]

- Subsea Cable Protection Systems Installed On Offshore Wind Farm | Part 1 of 5

- Subsea Cable Protection Systems – Disconnection & Removal | Part 3 of 5

- Subsea Cable Protection Systems, Damage Prevention & Fixed WTG | Part 4 of 5

- Subsea Cable Protection Systems Design For Installation | Part 5 of 5

LV, MV & HV CABLE JOINTING, EARTHING, SUBSTATION & ELECTRICAL EQPT

Thorne & Derrick are Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems – we are highly customer responsive and absolutely committed to providing a world-class service.

We have an International Distribution Agreement with Nexans Power Accessories UK to supply their Heat Shrink and Cold Applied ranges of 11kV/33kV/66kV joints and terminations and Euromold brand of separable connectors.

Since 1985, we have established an international reputation based on Service, Integrity and Trust – contact us.

t: 0191 410 4292 | e: [email protected] | www.powerandcables.com

We provide expert technical support and supply from a multi-million pound stock holding:

- Cable Joints, Terminations & Connectors Earthing & Lightning Protection

- Cable Accessories – Lugs, Glands

- Circuit Protection & Fuses

- Cable Cleats & Clamps Electrical Safety Equipment

- Cable Pulling & Laying Equipment

- Arc Flash Protection & Clothing

- Cable Duct Seals & Transit Systems Surge Arresters & Bushings

Further Reading:

- Arc Flash Clothing & Protection For Safe Windfarm & Wind Turbine Working

- Jointer Training Courses – 11kV 33kV 66kV MV HV Cable Jointer Competency Training

- Sealing Cables In Offshore Substations – A Roxtec CPD

Subsea Cable Protection Systems Installed On Offshore Wind Farm | Part 1 of 5

September 16th, 2019Subsea Cable Protection Systems

♦ Republished by Chris Dodds with Kind Permission of Greg Campbell-Smith ((Director Sales and Business Development at First Subsea)

First Subsea is the world’s leading developer of subsea connection technology, supplying, installing and decommissioning.

Subsea power cables on offshore wind farms are typically protected by means of burial.

This is a well proven means of cable protection used in other offshore industries.

However, at either end of offshore wind array cables they transition from burial, up through the water and into the wind turbine foundation. This free spanning section of cable is susceptible to what can be substantial wave and current loads.

These loads introduce movement and bending into the subsea cable which, without cable protection, can lead to over-bending, over-tensioning, fatigue and abrasion damage.

This exposed subsea cable is traditionally ‘protected’ by means of a relatively expensive and complex proprietary Cable Protection System (CPS).

Our 1st Article on Subsea Cable Protection Systems and how they provide real time cost savings offshore.

First Subsea Cable Protection System was recently installed on an Offshore Wind Farm in the Southern North Sea and received commendations from the Developer and Installation Contractor alike.

“The engagement system worked very well, 100% connection, quick and efficient installation times” We will be posting several articles on LinkedIn over the next few weeks detailing how we have made Cable Protection easier, quicker, consistent whilst ensuring the cable is fully protected from fatigue and environment challenges over its lifetime offshore.

➡ If you would like a copy of the report, please contact Chris Dodds [email protected]

- Subsea Cable Protection & Laying Costs | Part 2 of 5

- Subsea Cable Protection Systems – Disconnection & Removal | Part 3 of 5

- Subsea Cable Protection Systems, Damage Prevention & Fixed WTG | Part 4 of 5

- Subsea Cable Protection Systems Design For Installation | Part 5 of 5

LV, MV & HV CABLE JOINTING, EARTHING, SUBSTATION & ELECTRICAL EQPT

Thorne & Derrick are Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems – we are highly customer responsive and absolutely committed to providing a world-class service.

We have an International Distribution Agreement with Nexans Power Accessories UK to supply their Heat Shrink and Cold Applied ranges of 11kV/33kV/66kV joints and terminations and Euromold brand of separable connectors.

Since 1985, we have established an international reputation based on Service, Integrity and Trust – contact us.

t: 0191 410 4292 | e: [email protected] | www.powerandcables.com

We provide expert technical support and supply from a multi-million pound stock holding:

- Cable Joints, Terminations & Connectors Earthing & Lightning Protection

- Cable Accessories – Lugs, Glands

- Circuit Protection & Fuses

- Cable Cleats & Clamps Electrical Safety Equipment

- Cable Pulling & Laying Equipment

- Arc Flash Protection & Clothing

- Cable Duct Seals & Transit Systems Surge Arresters & Bushings

Further Reading:

- Arc Flash Clothing & Protection For Safe Windfarm & Wind Turbine Working

- Jointer Training Courses – 11kV 33kV 66kV MV HV Cable Jointer Competency Training

- Sealing Cables In Offshore Substations – A Roxtec CPD