Jointing 44kV High Voltage Submarine Cables Using 3M Cold Shrink Splices

Published 06 May 2021

Images Courtesy of: Douglas Page (Instructor & Cable Splicer at Hydro One Training and Development Services).

HV Cable Splicers: Douglas Page & Jeff Silliphant.

Application: 3M 44kV Cold Shrink Submarine Cable Joint (Single Core 250 MCM).

Location: Lake Couchiching, Ontario. Canada.

Please note aspects of the installation were unable to be photographed as 4 hands were required simultaneously to be cable jointing and no stand-in photographer was available.

Let’s start Cable Jointing….

1. The cable splicing barge comes alongside the buoy marker for a previously installed cable and pulls it up onto the barge, secures it, and anchors all four corners of the barge.

2. The “reel” barge backs up and connects to the cable splicing barge and anchors all four corners, the cable is pulled to the cable splice point and secured.

3. Both 44kV cables are prepared to manufacturers specifications, in this case they were prepared using Speedy Systems high voltage cable preparation tools not hand tools.

4. All of the 3M Cold Shrink Cable Termination kit parts are slid on the appropriate sides and the cable is crimped together.

5. 3M supplied silicon grease is applied by the HV cable splicers – we believe it was changed to colour red to determine if it was actually used in the event of a future cable splice failure.

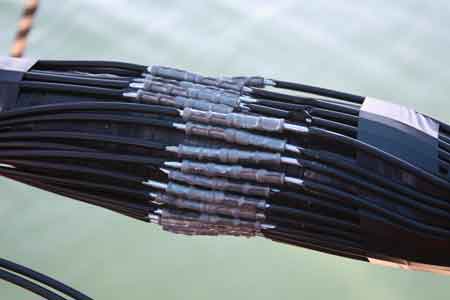

6. Inner 3M Cold Shrink cable splice body is cold shrink installed without the requirement for a heat source associated with the jointing of cables using heat shrink cable terminations. Aligned with marker tapes previously installed, then the concentric neutrals are brought back across the cable splice.

7. In this situation the high voltage splicing design was to have the neutrals individually crimped to each other, a soft mastic bed is made for the crimp sleeves to lie in to prevent damage to the insulation shield.

8. After the neutrals are all crimped and the shaped into their final position for the cable splice.

9. Once shaped they are evenly spread out and held in place to prevent hang up points for installation of the outer jacket 3M Cold Shrink tube.

10. Very important, the cable jacket is abraded, then two rows of multiple layers of aqua-seal mastic is installed, then the outer jacket is cold shrunk on.

11. To enhance the water-blocking ability of the cable joint the HV cable splicer applies extra wraps of 3M mastic tape.

12. After the outer jacket is installed and sealed using mastic and tape then the submarine armour is wrapped back around the high voltage cable .

13. The submarine cable armour wires are then individually crimped together using Burndy crimping tools and then wrapped in mastic and tape.

14. The entire 3M Cold Shrink cable splice is covered in three layers of 3M Armorcast, (installed wet and sets solid). Then all anchors are pulled, the barges stay attached and the cable barge travels the route, paying off the cable to the end of the reel.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.