Cembre B35-50MDE Battery Crimping Tool (up to 150sqmm cables)

Cembre B35-50MDE Battery Crimping Tool (up to 150sqmm cables)

Cembre B35-50MDE

LV-HV Cable Crimping Tools | Distributed from Stock | Approved Cembre Supplier | UK & Export Sales

*This product is now obsolete and has been replaced by B450ND-BVE battery crimping tool

Cembre B35-50MDE battery crimping tool is an 18.0V cordless hydraulic crimping tool which can be operated with one hand and is balanced for greater control.

The head rotates by 180º for ease of use within confined spaces and has a robust moulded body which is highly resistance to damage. Additionally the crimping tool is extremely quiet with minimal vibration.

The B35-50MDE battery crimping tool is fitted with a maximum pressure valve and an Li-Ion 18.0V 2.0Ah high power battery which has LED indicators to display the remaining battery charge.

Cembre’s B35-50MDE crimping tool can be fitted with many crimping dies common to 50kN and are supplied with a spare battery, battery charger and plastic carrying case.

18 volt cordless hydraulic crimping tool to accept ’50’ style die sets 4sqmm-95sqmm and ‘L-50’ style die sets 120sqmm & 150sqmm available with wrist strap, spare battery, battery charger, battery adapter and a plastic carrying case.

Cembre B35-50MDE crimping tool

Specification

- Crimping Force: 35kN

- Rated Operating Pressure: 390 bar (5,600 psi)

- Dimensions: Length 387mm, Width 133mm, Height 81mm

- Cable Crimper Weight: 2.6kg

- Oil: AGIP ARNICA 22 or ESSO INVAROL EP22 / equivalent (Approved by Cembre)

Cembre crimping tools should be cleaned daily (or after use) with a clean cloth removing any residue in particular particles close to pivots and moveable parts. Every six months it is essential check the oil level in the reservoir. If necessary fill oil level to the top lip and remove any excess air from the reservoir.

For storage and protection the Cembre B35-50MDE tool is supplied in a robust carrying case for storage of the crimping tool.

- Dimensions 465x315x116 mm

B35-50MDE Crimping Tool Main Applications

| LV Cable Lugs Splices | “C” Sleeve Connectors | Insulated Terminals | End Sleeves |

| 150sqmm | 35sqmm | 50sqmm | 95sqmm |

B35-50MDE Dimensions

| Cable Crimping Force | Length | Height | Width | Weight |

| 35kN | 387mm | 133mm | 81mm | 2.6kg |

Cembre B35-50MDE Battery Crimping Tool

User Instructions

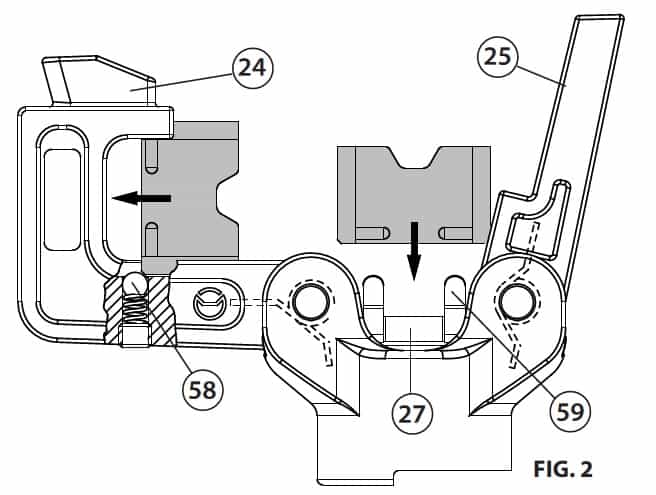

Preparation

- With the Cembre crimping tool in the rest position and without battery, proceed as follows:

- Select the appropriate Cembre die set for the connector

- Open the latch and release the upper die holder

- Insert one die into the upper die holder and one die into the lower die support

- Close the crimp tool latch

- Insert the conductor in the connector

- Position the connector between the dies and ensure the correct location of the crimp

Ensure that the latch and the upper die holder are fully secured, otherwise damage may occur during tool operation.

Die Advancement

- Grip the Cembre tool firmly and comfortably and press operating button to activate the motor pump and advance the lower die. To halt the advancement, release the operating button and the motor will cut out.

- Make sure the dies are exactly positioned on the desired crimp point otherwise re-open dies and reposition the connector.

Compression

- By keeping the operating button pressed, the motor continues to operate: the ram will gradually move forward until the two dies touch. It is recommended to keep operating until the maximum pressure valve is activated and a “click” is heard.

- The motor will continue to operate after the maximum pressure relief valve has activated. No further crimping force is applied, the oil is bypassed and returned to the reservoir.

Release of Dies

- Press the pressure release button, the ram will retract and open the Cembre dies.

Head Rotation

- For ease of operation the tool head can rotate through 180º, allowing the operator to work in the most comfortable position.

- Warning: Do not attempt to rotate the crimp tool head when the hydraulic circuit is pressurised.

Replace of Dies

- To replace the Cembre dies, open the head and extract them from their seats.

Battery Status

- The battery is equipped with LED indicators that indicate the remaining battery life at any time by pressing the adjacent button.

- 4 LEDs illuminated: Fully charged

- 2 LEDs illuminated: 50% capacity

- 1 LED flashing: Minimum charge, replace the battery.

Insertion / Replacement of Battery

- To replace the battery, remove it by pressing the release button, then insert the new battery, sliding it into the guides until it locks.

Cembre B35-50MDE Battery Crimping Tool

Technical Specification

| Type Of Action | Crimp |

| Force Developed | 35kN |

| Battery Material | Li-Ion |

| Battery Voltage | 18V |

| Battery Current | 2Ah |

| Length | 387mm |

| Height | 133mm |

| Width | 81mm |

| Weight | 2.6kg |

Order Code – Cembre B35-50MDE

Cembre B35-50MDE tool features battery condition display, pressure release button, ergonomic switch and automatic slot-in battery.

LV- HV Cable Crimping Applications

The Cembre B35-50MDE cordless hydraulic crimping tool with new 18V Li-Ion battery has the following crimp ranges:

- LV Lugs & Splices – up to 150sqmm cable conductors

- Insulated Terminals – up to 50sqmm cable conductors

- End Sleeves – up to 95sqmm cable conductors

- “C” Sleeve Connectors – up to 35sqmm cable conductors

Cembre B35-50MDE Battery Crimping Tool & Carry Case

➡ For Cembre electrical connections, see Cable Crimps, Lugs & Connectors

Contact T&D to discuss crimping cables at MV-HV, including 11kV-33kV, to ensure correct Cembre tool, lug/splice and die set selection.

Full range of battery cable cutting tools also available.

CRIMPING DIE SET GUIDE FOR CEMBRE B35-50MDE

Cembre provides a matched crimping system to ensure secure LV MV HV electrical connections (lugs and splices) manufactured from copper or aluminium in accordance with CE Marking and international standards – includes a full range of nest, indentor and die sets compatible with their hydraulic and battery crimping tools, all manufactured by Cembre.

Cembre Copper Tube Connectors & Cable Lugs

| Copper Conductor sqm | Connector | Hexagonal Crimp | Indent Crimp | |||||

| Low Str | Flex | Terminal Lug | Through Connector | Die Set | No of Crimps* | Nest | Indentor | No of Crimps* |

| 4-6 | A1-M | L1-M | ME1-50 | 1 | MA1-50 | PA1-50 | 1 | |

| 10 | A2-M A2-P12 |

L2-M | ME2-50 | 1 | MA2.3-50 | PA5-50 | 1 | |

| 16 | A3-M A3-P14 |

L3-M | ME3-50 | 1 | 1 | |||

| 25 | A5-M A5-P16 |

L5-M | ME5-50 | 1 | MA5-50 | 1 | ||

| 35 | 25 35 |

A7-M A7-P20 |

L7-M | ME7-50 | 1 | MA7-50 | PA10-50 | 1 |

| 35 | A9-M | ME9-50 | 1 | MA9-50 | 1 | |||

| 50 | 50 | A10-M A10-P25 |

L10-M | ME10-50 | 2 | MA10-50 | 1 | |

| 50 | A12-M | ME12-50 | 2 | MA12-50 | PA19-50 | 1 | ||

| 70 | 70 | A14-M A14-P30 |

L14-M | ME14-50 | 2 | MA14-59 | 1 | |

| 70 | A17-M | ME17-50 | 2 | MA17-50 | 1 | |||

| 95 | 95 | A19-M | L19-M | ME19-50 | 2 | MA19-50 | 1 | |

| 95 | A20-M | ME20-50 | 2 | MA20-50 | 1 | |||

| 120 | 120 | A24-M | L24-M | ME24L-50 | 2 | MA24-50 | PA24-50 | 1 |

| 120 | A29-M | ME29-50 | 3 | |||||

| 150 | 150 | A30-M | L30-M | ME30L-50 | 3 | |||

Cembre Copper “C” Connectors

| Copper Conductor sqmm | Connector | Die Set | No of Crimps | |

| Run | Tap | |||

| 10 | 10-1.5 | C10-C10 | MC10 | 1 |

| 16 | 16-1.5 | C16-C16 | MC25 | 2 |

| 25-16 | 10-1.5 | C25-C10 | ||

| 25 | 25-16 | C25-C25 | ||

| 40-35 | 16-1.5 | C35-C16 | MC35 | 2 |

| 40-35 | 40-25 | C35-C35 | ||

| 50 | 25-10 | |||

Cembre Nylon Insulated Copper Conductors

| Copper Conductor sqmm Flexible | Terminal Lug | Die Set | No of Crimps | ||

| 10 | ANE2-M | ANE2-P12 | ANE2-U | MN2RF-50 | 1 |

| 16 | ANE3-M | ANE3-P14 | ANE3-U | MN3RF-50 | 1 |

| 25 | ANE5-M | ANE5-P16 | MN5RF-50 | 1 | |

| 25-35 | ANE7-M | ANE7-P20 | MN7RF-50 | 1 | |

| 35 | ANE9-M | MN7RF-50 | 1 | ||

| 50 | ANE10-M | MN10RF-50 | 1 | ||

| 50 | ANE12-M | MN12F-50 | 1 | ||

Cembre End Sleeves

| Copper Conductor sqmm Flexible | Connector | Die Set |

| 16 | PKE16 | MTT16-50 |

| PKC16 | ||

| KE16 | ||

| 25 | PKE25 | MTT25-50 |

| PKC25 | ||

| KE25 | ||

| 35 | PKC35 | MTT35-50 |

| KE35 | ||

| 50 | PKC50 | MTT50-50 |

| KE50 | ||

| 70 | KE70 | MTT70-50 |

| 95 | KE95 | MTT95-50 |

➡ See Cable Jointing Tools for a complete range of LV-HV-HV Tools to enable outer sheath removal, insulation removal and screen stripping from power cables operating typically at 11kV, 33kV, 66kV, 132kV and up to 400kV.

Alroc Tools – Cable Jointing Tools (MV HV)