Cable Pulling Calculation Example From Southwire

Published 11 Jun 2021

Cable Pulling Example from Southwire Manual in Cableizer

-

Special thanks to Damian Aegerter at Braavos GmbH / cableizer.com

for the kind permission to republish

Cable Pulling

The 2nd of this blog series features the following cable pulling example from Southwire is an extract from their public document titled ‘Power Cable Installation Guide’, published in 2005. The cable pulling calculation example is found on pages 23ff in the section ‘Typical calculation for cables in conduit‘.

This example validates our cable pulling module and has been added to our test cases, ensuring that the cable pulling calculation won’t unexpectedly and unnoticeably change.

Cable selection

In the Cable tab of the cable pulling module the cable is selected, which in the example is a THHN single-conductor 4/0 AWG copper cable. In the Cableizer cable editor, standard conductor cross-sections A_c can be selected either in mm2 or in AWG/kcmil. Typical values of conductor diameters d_c for this cross section can conveniently be selected for AWG sizes up to 2000 kcmil from UL 1581 and beyond from ASTM B8-11 standards.

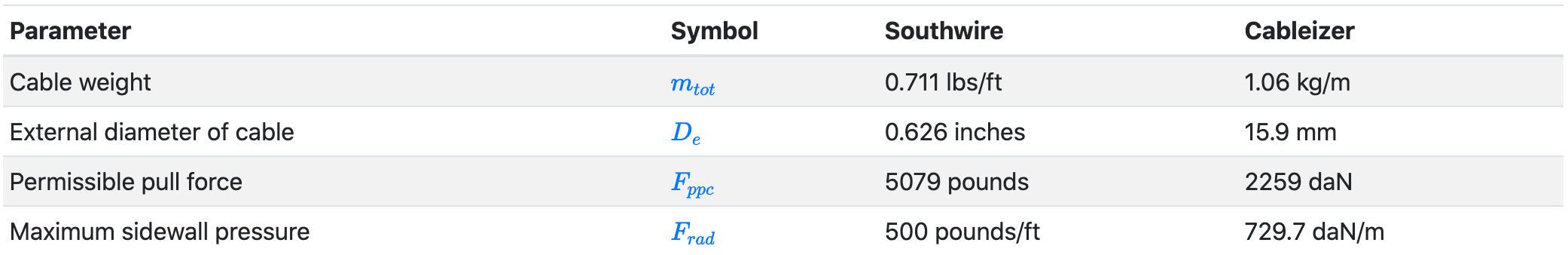

In Cableizer, all inputs/outputs are currently only supported in metric units so we converted them for this example. The following table shows the corresponding inputs regarding the cable selection for the Southwire example with cable weight m_tot and external diameter of cable D_e, which covers the case where three identical unbound cables are pulled together. Permissible pull force F_ppc and maximum sidewall pressure F_rad have been manually set to the same values as in the Southwire installation guide.

Conduit selection

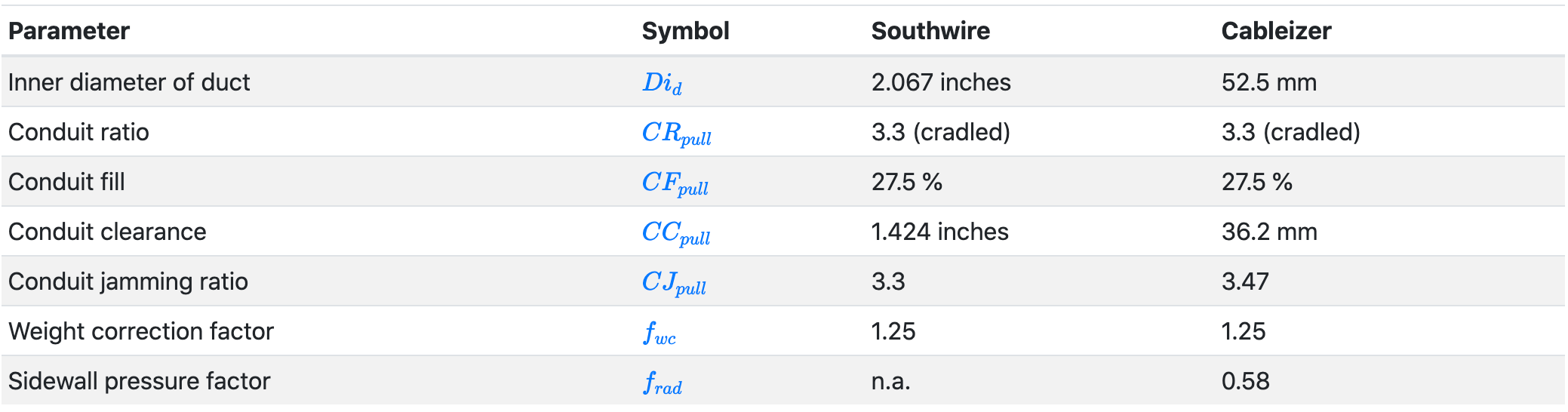

In the Conduit tab of the cable pulling module the conduit (EMT trade size 2 inch) is defined. The parameters include the inner diameter of duct Di_d, the conduit ratio CR, the conduit fill CF in percent, the conduit clearance CC in percent and the conduit jamming ratio CJ.

Cableizer does then verify if the installation is feasible and calculates the weight correction factor f_wc and the sidewall pressure factor f_rad as shown in the following table:

Route editor

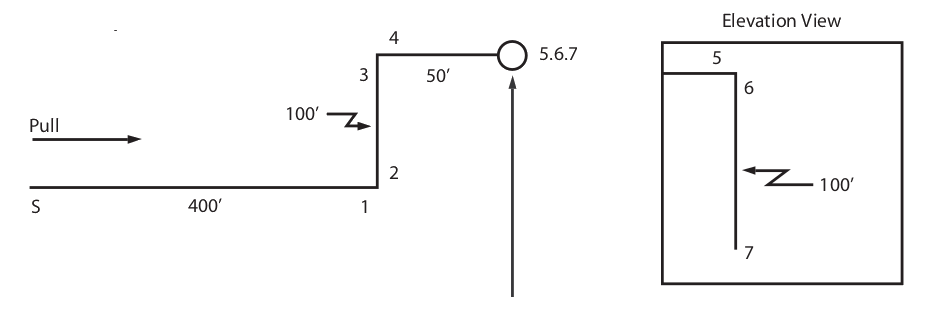

In the Routing tab of the cable pulling module the example route is composed of sections and bends. Bends have an angle ϕ_arc of 90° and a radius r_arc of 914.4 mm (36-inch sweep elbows with an inside radius of 2.91 feet). The friction coefficient μ_dyn is 0.4 all along the route. The following images show the Southwire conduit layout and the Cableizer cable route (in 3D):

Results

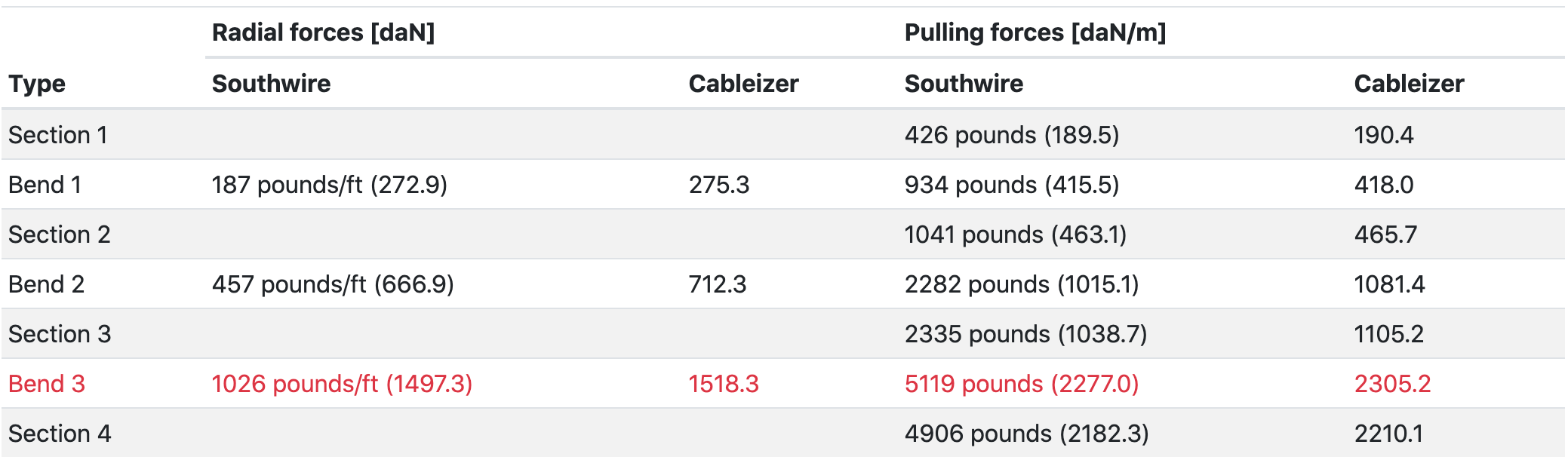

The results show a good agreement with the Southwire installation guide figures, both regarding the pulling force F_pull and the sidewall bearing pressure F_rad. In bend 3, both forces exceed the respective limits:

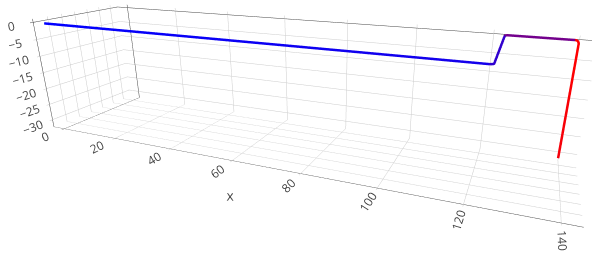

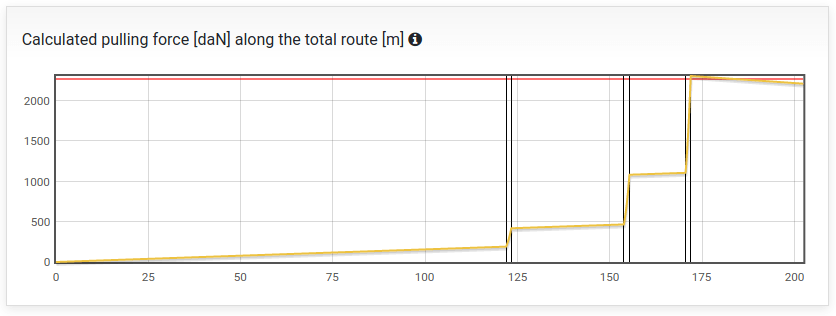

Part of the small differences in the above table can be explained by the fact that Southwire is using approximate equations for both horizontal bends and the vertical concave downwards bend (bend 3). The following figure shows the pulling forces along the cable route for the forward pulling direction. The red line shows the applicable force limits.

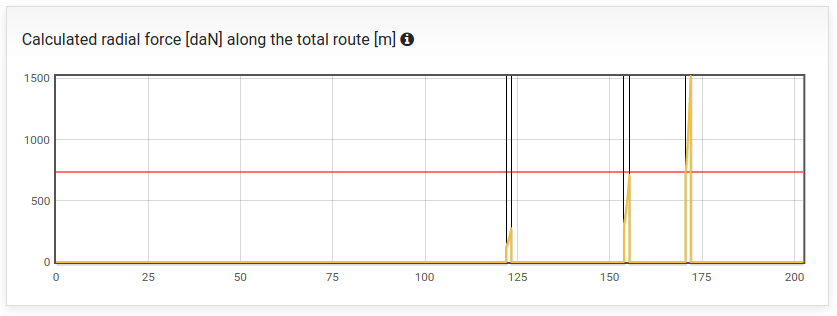

A figure showing the radial forces along the cable route is likewise generated.

Backwards pulling direction

In Cableizer, you can also simulate a pull in backward direction. In this case the maximum pulling force is reduced to 1443.7 daN and does not exceed the force limit anymore. The radial force is also considerably reduced to a maximum value of 825.5 daN/m, which is only slightly above the limit.

The forces are reduced despite the fact that the cable has to be pulled up the vertical shaft at the start of the cable route! But having the bends close to the start of the route instead of close to the end of the route significantly reduces the overall pulling forces.

The original article can be found on LinkedIn here

Cableizer – The Online Cable Optimizer

Model power cables and calculate current rating, magnetic fields, electrical parameters, short-circuit currents, pulling forces… Experience the full potential of our browser-based simulation platform cableizer.com! Our 14-day free trial includes full access to all the simulation features of Cableizer.

View the other blogs in the Cable Pulling Blog Series below:

Cable Pulling & Laying Equipment

Suppliers & Distributors

Thorne & Derrick distribute the most extensive range of Low & High Voltage Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors – this includes the most extensive range of Cable Pulling & Cable Laying Equipment to enable the installation of low, medium and high voltage power cables into underground trench or duct.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV/33kV and up to EHV transmission and distribution voltages.

Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

Distributors for: 3M Electrical, ABB, Alroc, Band-It, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, ProGARM, Prysmian, and Roxtec.

- Scope –single-source supply of extensive range of products

- Stock – a multi-million pound stock holding provides complete global supply solutions

- Staff – technical support from a trained, proactive and friendly team

- Delivery – UK stock turnaround with express logistics to all international destinations

Thorne & Derrick International, based in the UK, are delighted to announce they have entered into an Approved Stockist Agreement with SEB International, the market-leading Cable Laying Equipment manufacturer.