Blog

Long Blue Earth Clamps | Rail Portable Earthing By PBwel | Network Rail Approved

January 11th, 2021

Rail Long Blue Interlocked Earth Clamps

Portable Earthing

For The UK Rail Industry

Interlocked Long Blue Earth Clamps | Network Rail Approved By PBwel

The PBwel range of LV MVH HV electrical safety equipment for use on the rail track and the OHL network has been specifically designed with the UK Rail Industry and has proven track record of many decades service. As well as supplying a standard range of approved equipment, PBwel also can design new and customised solutions for any Rail Portable Earthing requirement.

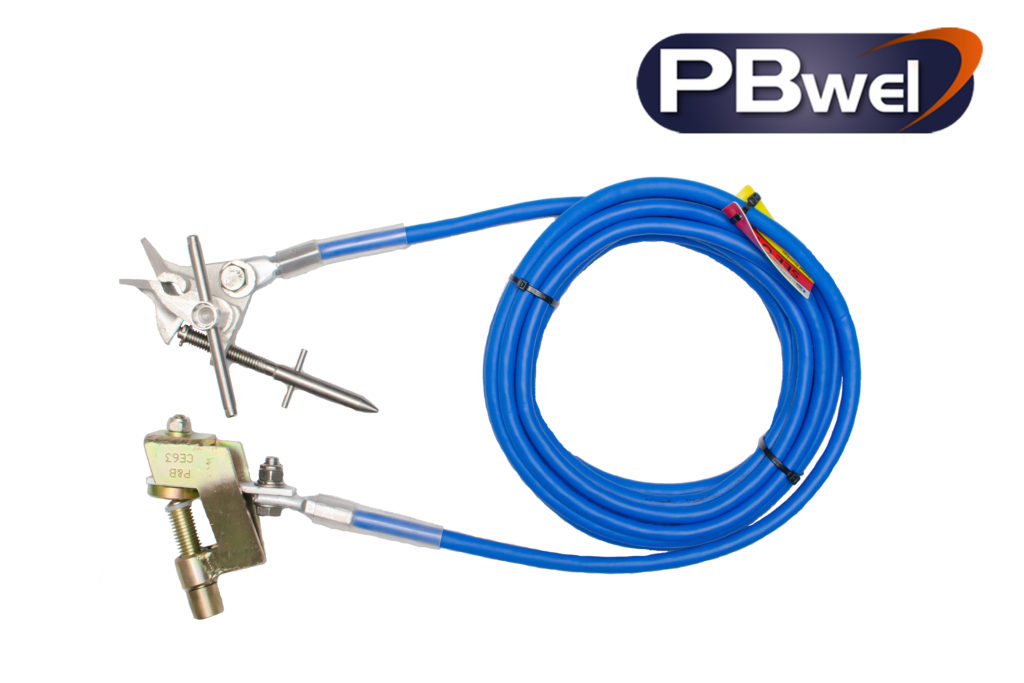

This interlocked Long Blue Earth Clamps are for providing temporary earth bonds between overhead catenary or contact conductors and earthed rail sections or recognised earthing points. The Long Blues have been specially enhanced to address the potentially fatal procedure of removing the equipment in the incorrect order of use.

To ensure that the Line End clamp is removed before the Earth End clamp, it incorporates a special key which must be used to remove the Earth End clamp. The tamper-proof lock arrangement is an integral part of both earthing clamps, and PBwel can provide up to 20 combinations, this is to deter ‘master keys’ being used to fool the system.

This interlocked Long Blues are for providing temporary earth bonds between overhead catenary or contact conductors and earthed rail sections or recognised earthing points.

The CE63 (J117-NSE) Earth End clamp is a steel fabricated clamp for application to all rail types, steel framework and earthing points. The clamp is fitted with disc springs to ensure a secure location. All components are plated to provide adequate protection on site.

Interconnecting leads are made of 50sqmm multi-stranded aluminium with aluminium palm type compression terminations and blue Arctic-grade PVC insulation. The S9BI Line End clamp is made from aluminium alloy and stainless-steel fasteners.

Insulated Operating Poles are glassed fibre insulating poles with open weave handgrips bonded to the lower pole section. Available in standard 4ft (1.22 metre) sections with machined joints to provide rigid assembly by double-sided snap action, spring-loaded locking device. The S9D type light-alloy operating socket should be fitted; the socket is then used to rotate the Line End clamp’s operating screw, to secure to the line.

Rail Portable Earthing Customer Benefits

- Lightweight Portable Earthing

- Fully Approved By Network Rail

- Solid Construction

Interlocked Long Blue Earth Clamp: specially enhanced to address the potentially fatal procedure of removing the equipment in the incorrect order of use

Long Earths

Long Blues are generally 8 metre in length. However, any earth lead length can be provided if specified for non-Network Rail work. Although an S9B to J117-D configuration is standard, Long Blues can also be supplied with CE62 Clamps (not Network Rail approved).

Interlock Earths

Interlocked Earths provide the same connections as a regular Long Blue; however, the earthing clamps utilise a lock-and-key system where the Earth End is removed using the Line End. This ensures that Engineers do not accidentally disrupt the path to earth prematurely as the Earth End can only be removed by using the Line End clamp.

Line end clamps are available in an S9B style or CE5 style (designated S9Bi and CE5i respectively).

PB WEIR – DISTRIBUTORS, STOCKISTS & SUPPLIERS

PB Weir Substation Earthing and Transmission Line Earthing Equipment include line end clamps, earth end clamps, portable earthing leads and operating poles for high voltage substations, overhead power line and transmission line applications – voltages include 11kV, 33kV, 66kV, 132kV up to 400kV.

Thorne & Derrick provide competitive prices and fast delivery from stock for the complete range of PB Weir substation earthing and transmission line earthing equipment.

In 2018 In 2018 PB Weir joined the Novarc group and re-branded as PBwel and now, through the ESP group of companies, we are able to supply, support and maintain a comprehensive range of Electrical Safety Equipment which includes: Earthing, Insulated Tools, Arc Flash Protection, Personal Voltage Detection Helmets, Insulating Gloves, Voltage Detection, Operating Poles & Lock-Out Tag-out.

ALADIN | Improved electrical safety levels for workers operating near live equipment

➡ Read More Here: ALADIN Individual Voltage Alarm With Headlamp For MV Overhead Lines 10-69kV

Product Spotlight | see Live Line Indicators designed for use upon overhead a.c. rail electrification systems operating at 25kV nominal voltage to indicate the presence of extra high voltages to aid safe working practices.

Further Reading

- E-Shark Safety Helmet By PBwel

- MTAG DR 69 kV Multi Voltage Detector Dual Range

- Network Rail Case Study New Overhead Line Equipment

- Substation Suspended Earthing Spigots By PBwel

- Drain Earths | PBwel 50sqmm Arctic Orange Field Drain Earth

- PBwel Transmission Line Earthing Leads 132kV, 275kV, 400kV

- PBwel Earthing Leads For Temporary Earthing Of Transmission Line Conductors 132kV, 275kV, 400kV

LV, MV & HV JOINTING, EARTHING, SUBSTATION & ELECTRICAL EQPT

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

PBwel Earthing Leads For Temporary Earthing Of Transmission Line Conductors 132kV, 275kV, 400kV

January 11th, 2021

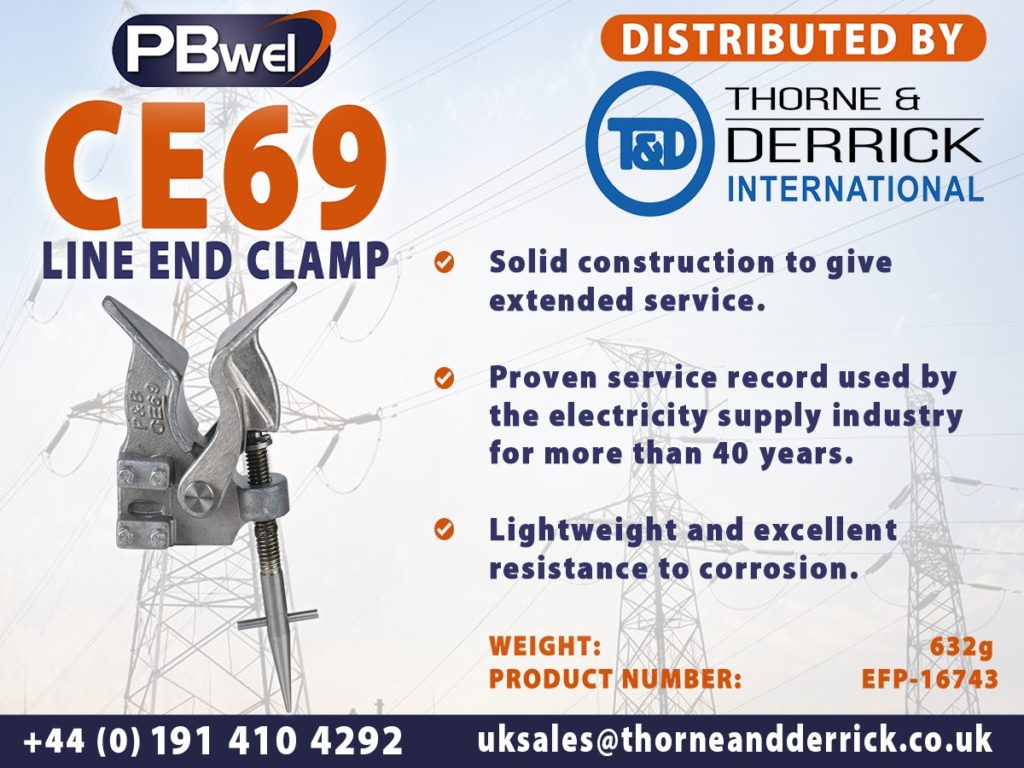

PBwel CE69 Line End Clamp

PBwel CE69 Line End Clamp

PBwel Earthing Leads

The PBwel range of Earthing Leads and equipment for the Electricity Transmission & Distribution sector are renowned within the industry and are suitable for temporary earthing of transmission line conductors within the range 132kV, 275kV and 400kV.

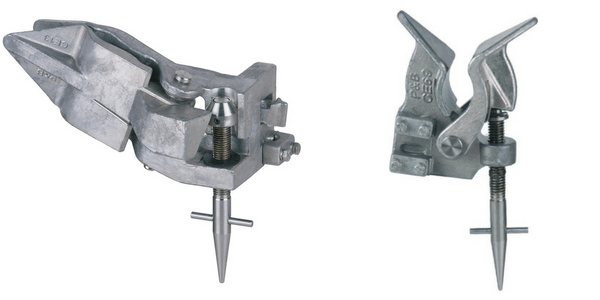

The PBwel CE69 Line End Clamp is suitable for application to conductors ranging from 13mm to 46mm.

The CE69 earth clamp is to be applied in either an upward or downward direction utilising an OL1 operating socket attached to an insulated operating pole. The spring-loaded jaws enable the clamp to be slipped easily over the line conductor and retain the clamp in position whilst the operating screw is being tightened or loosened.

A full range of Transmission Line Earthing Equipment are available for use with transmission line end earthing clamps

PBwel CE69 Line End Clamp

Technical Specification

- Clamping Diameter: 13- 46mm

- Short Circuit Rating: 20kA/ 1s

- Cont. Current Rating: 300A

- Weight: 0.632kg

- Part Number: EFP-16743

PB WEIR – DISTRIBUTORS, STOCKISTS & SUPPLIERS

PB Weir Substation Earthing and Transmission Line Earthing Equipment include line end clamps, earth end clamps, portable earthing leads and operating poles for high voltage substations, overhead power line and transmission line applications – voltages include 11kV, 33kV, 66kV, 132kV up to 400kV.

Thorne & Derrick provide competitive prices and fast delivery from stock for the complete range of PB Weir substation earthing and transmission line earthing equipment.

In 2018 In 2018 PB Weir joined the Novarc group and re-branded as PBwel and now, through the ESP group of companies, we are able to supply, support and maintain a comprehensive range of Electrical Safety Equipment which includes: Earthing, Insulated Tools, Arc Flash Protection, Personal Voltage Detection Helmets, Insulating Gloves, Voltage Detection, Operating Poles & Lock-Out Tag-out.

ALADIN | Improved electrical safety levels for workers operating near live equipment

➡ Read More Here: ALADIN Individual Voltage Alarm With Headlamp For MV Overhead Lines 10-69kV

Product Spotlight | see Live Line Indicators designed for use upon overhead a.c. rail electrification systems operating at 25kV nominal voltage to indicate the presence of extra high voltages to aid safe working practices.

Further Reading

- E-Shark Safety Helmet By PBwel

- MTAG DR 69 kV Multi Voltage Detector Dual Range

- Network Rail Case Study New Overhead Line Equipment

- Substation Suspended Earthing Spigots By PBwel

- Drain Earths | PBwel 50sqmm Arctic Orange Field Drain Earth

- PBwel Transmission Line Earthing Leads 132kV, 275kV, 400kV

- Long Blues | Rail Portable Earthing By PBwel | Network Rail Approved

LV, MV & HV JOINTING, EARTHING, SUBSTATION & ELECTRICAL EQPT

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Submersible Switch Applications By G&W Electric

January 7th, 2021Submersible Switch Applications

G&W Electric

The following Case Study by G&W Electric and presented by Thorne & Derrick describes the features of submersible switch applications in underground distribution systems.

Thorne & Derrick are Specialist Distributors of Substation, Electrical Safety, Cable Jointing & Accessories to UK and international utilities and contractors providing electrical power at distribution and transmission voltage levels.

G&W Electric Submersible Vault Switches are totally submersible to IP68 standards and offer the following additional features:

Construction: Compact, dead-front construction

Cable Entrance: Cable entrance flexibility, either top, bottom, side or front

Standards: Designed to international industry standards

Interrupting Capability: Load and fault interrupting capability

Configurations: Multi-way configurations

Operating Options: Options for operation outside the vault

Insulation: SF6 or solid deielctric insulation

Ratings: Ratings through 38kV, 25kA symmetric

Designs: Fully automated designs

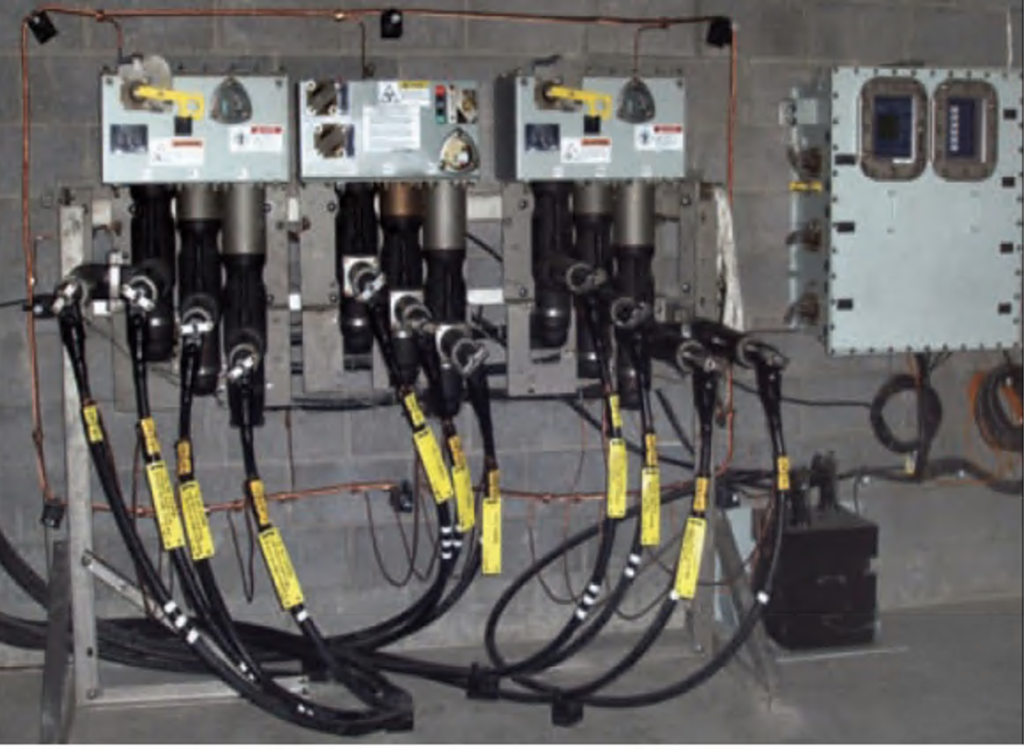

Submersible switch installed in a small, under- ground vault, subject to flooding

In underground distribution systems, electrical cable is either direct buried or fed through conduit and connected to electrical apparatus installed in either padmount enclosures or buildings above ground or in concrete vaults below ground.

Underground cables can be direct buried or installed in conduit to switch locations.

Underground vaults can be small or large, and either dry or subject to submersion. Underground systems offer many benefits compared to overhead systems including:

• A much cleaner installation site

• No more unsightly poles

• No more damage due to ice, wind or wildfire

• No more sagging lines which can sway in the wind, causing an overcurrent condition

Three-way, solid dielectric, automatic transfer switch with submersible control cabinet and potential transformers.

Top operable switch after submersion in water.

Solid dielectric switch installed in vault.

G&W ELECTRIC

Overview of G&W Cable Accessories

In 1905 G&W introduced the first disconnectable cable terminating device.

Over 100 years later, G&W continues to create technical innovations that have improved performance and reliability. With over 100 years experience, G&W is the name you can trust for quality cable accessories. With sales representation worldwide, G&W has a proven track record for success.

G&W cable accessories are designed to accommodate cables from all manufacturers and can be created to accommodate any customer cable system. The optional mechanical shrink feature offers an easier and faster installation while reducing possible damage during installation. G&W also offers installation supervision and installation training, which can be customized to suit the audience.

G&W offers a variety of transmission cable accessories for extruded dielectric cable systems. Cable terminations are available for outdoor applications to 230kV and include porcelain or composite insulator options and premolded designs. Gas insulated substation designs are available to 230kV.

Transition cable splices and cable joints are available to 138kV and include premolded designs. All cable terminations and cable joints incorporate built-in stress control and dielectric fluid. Dry type designs are also available for maximum ease of installation.

Underground Cable Transition Project

January 7th, 2021Underground Cable Transition Project

G&W Electric

The following Case Study by G&W Electric and presented by Thorne & Derrick describes the process of a major downtown city necessitated an upgrade of the electrical service by the utility company.

Thorne & Derrick are Specialist Distributors of Substation, Electrical Safety, Cable Jointing & Accessories to UK and international utilities and contractors providing electrical power at distribution and transmission voltage levels.

Challenge

Continuous expansion of a major downtown city necessitated an upgrade of the electrical service by the utility company. The utility was faced with replacing the old substation equipment with new switchgear and associated apparatus.

This apparatus was located in a separate substation building fed by 50 year old, 138kV self-contained oil filled cable. To abide by their latest safety regulations and to simplify cable connection to the new equipment, the utility decided to eliminate all oil filled devices in the building including the cable.

This necessitated changeout of the old oil filled cable to a cable utilizing an extruded dielectric insulation. Furthermore, the apparatus building was located directly adjacent to a major downtown intersection. Because of this, the utility was concerned about the amount of space and downtime required for construction work to splice the cable.

Solution

The utility investigated cable accessory suppliers with reliable track records who offered a product for their application. G&W Electric was selected because their transition joint featured prefabricated components and perforated paper roll stress relief which minimized the installation time and required expertise of the installers.

Another feature was G&W Electric’s exclusive separable connection method which permitted deadending of each cable end. This offered the unique advantage of reusing the same joint for possible future changeout of the remaining oil filled cable. The compact construction of the joint also permitted separate joint enclosures to be installed for each leg of the three phase, oil filled cable.

This permitted the enclosures to be placed either stacked above each other on a rack or parallel to each other thereby minimizing the space required. The rugged construction of the joint design allowed the utility crew to direct bury the units in a shallow opening. This helped minimize the time and cost in constructing an accessible vault.

G&W Electric engineers worked with the utility to provide a custom solution for their specific requirements. The project installation was completed in record time with little disruption of the surrounding city streets resulting in considerable cost savings.

Splicing each leg of the three phase cable permitted a low profile, shallower vault.

G&W ELECTRIC

Overview of G&W Cable Accessories

In 1905 G&W introduced the first disconnectable cable terminating device.

Over 100 years later, G&W continues to create technical innovations that have improved performance and reliability. With over 100 years experience, G&W is the name you can trust for quality cable accessories. With sales representation worldwide, G&W has a proven track record for success.

G&W cable accessories are designed to accommodate cables from all manufacturers and can be created to accommodate any customer cable system. The optional mechanical shrink feature offers an easier and faster installation while reducing possible damage during installation. G&W also offers installation supervision and installation training, which can be customized to suit the audience.

G&W offers a variety of transmission cable accessories for extruded dielectric cable systems. Cable terminations are available for outdoor applications to 230kV and include porcelain or composite insulator options and premolded designs. Gas insulated substation designs are available to 230kV.

Transition cable splices and cable joints are available to 138kV and include premolded designs. All cable terminations and cable joints incorporate built-in stress control and dielectric fluid. Dry type designs are also available for maximum ease of installation.

Three Phase Protection For Confined Space Applications

January 7th, 2021Three Phase Protection For Confined Space Applications

Confined Space Applications By G&W Electric

The following Case Study by G&W Electric and presented by Thorne & Derrick describes three phase protection for confined space applications.

Thorne & Derrick are Specialist Distributors of Substation, Electrical Safety, Cable Jointing & Accessories to UK and international utilities and contractors providing electrical power at distribution and transmission voltage levels.

Padmount recloser (left), three phase stepdown transformer (center) and single phase transformer.

Challenge

The utility serves approximately 95,000 residential and 13,000 commercial/industrial customers. The distribution system is 70% overhead and 30% underground. Nominal system voltage is 12.47kV transformed from a 34.5kV sub-transmission system.

A new substation was required to provide additional power and increased reliability to a growing tourist area of the utility’s service territory. The utility decided to tap off an existing 34.5kV line however, space for constructing a new air insulated substation was just not available. This mandated system designers to consider a different approach.

Recloser front view with SEL 351-R control

Recloser rear view cable connections

Solution

Working with their G&W Electric representative, the decision was made to go underground using padmount equipment. A standard three phase, dead-front, 2.5MVA transformer was used to step down the voltage from 34.5 to 12kV. To provide three phase protection to the new critical loads fed from the transformer, the utility also required an automatic recloser. To maintain the smallest footprint possible, G&W Electric was able to provide a padmount, three phase, solid dielectric Viper® recloser with SEL 351-R control.

The use of solid dielectric technology permitted an ideal compact solution while offering reliable protection and superior user programmable control features. A single phase, deadfront padmount transformer was also installed to provide a 120 V source for the recloser control. A new, compact, deadfront substation using state-of-the-art recloser technology provides reliable power to the new loads.

G&W ELECTRIC

Overview of G&W Cable Accessories

In 1905 G&W introduced the first disconnectable cable terminating device.

Over 100 years later, G&W continues to create technical innovations that have improved performance and reliability. With over 100 years experience, G&W is the name you can trust for quality cable accessories. With sales representation worldwide, G&W has a proven track record for success.

G&W cable accessories are designed to accommodate cables from all manufacturers and can be created to accommodate any customer cable system. The optional mechanical shrink feature offers an easier and faster installation while reducing possible damage during installation. G&W also offers installation supervision and installation training, which can be customized to suit the audience.

G&W offers a variety of transmission cable accessories for extruded dielectric cable systems. Cable terminations are available for outdoor applications to 230kV and include porcelain or composite insulator options and premolded designs. Gas insulated substation designs are available to 230kV.

Transition cable splices and cable joints are available to 138kV and include premolded designs. All cable terminations and cable joints incorporate built-in stress control and dielectric fluid. Dry type designs are also available for maximum ease of installation.