Blog

Three Phase Protection – Oil Fuse Cutout Replacement

January 7th, 2021Three Phase Protection

Oil Fuse Cutout Replacement By G&W Electric

The following Case Study by G&W Electric and presented by Thorne & Derrick describes the process of a major downtown city necessitated an upgrade of the electrical service by the utility company.

Thorne & Derrick are Specialist Distributors of Substation, Electrical Safety, Cable Jointing & Accessories to UK and international utilities and contractors providing electrical power at distribution and transmission voltage levels.

Challenge

Continuous expansion of a major downtown city necessitated an upgrade of the electrical service by the utility company. The utility was faced with replacing the old substation equipment with new switchgear and associated apparatus.

This apparatus was located in a separate substation building fed by 50 year old, 138kV self-contained oil filled cable. To abide by their latest safety regulations and to simplify cable connection to the new equipment, the utility decided to eliminate all oil filled devices in the building including the cable.

This necessitated changeout of the old oil filled cable to a cable utilizing an extruded dielectric insulation. Furthermore, the apparatus building was located directly adjacent to a major downtown intersection. Because of this, the utility was concerned about the amount of space and downtime required for construction work to splice the cable.

Solution

The utility investigated cable accessory suppliers with reliable track records who offered a product for their application. G&W Electric was selected because their transition joint featured prefabricated components and perforated paper roll stress relief which minimized the installation time and required expertise of the installers.

Another feature was G&W Electric’s exclusive separable connection method which permitted deadending of each cable end. This offered the unique advantage of reusing the same joint for possible future changeout of the remaining oil filled cable. The compact construction of the joint also permitted separate joint enclosures to be installed for each leg of the three phase, oil filled cable.

This permitted the enclosures to be placed either stacked above each other on a rack or parallel to each other thereby minimizing the space required. The rugged construction of the joint design allowed the utility crew to direct bury the units in a shallow opening. This helped minimize the time and cost in constructing an accessible vault.

G&W Electric engineers worked with the utility to provide a custom solution for their specific requirements. The project installation was completed in record time with little disruption of the surrounding city streets resulting in considerable cost savings.

G&W ELECTRIC

Overview of G&W Cable Accessories

In 1905 G&W introduced the first disconnectable cable terminating device.

Over 100 years later, G&W continues to create technical innovations that have improved performance and reliability. With over 100 years experience, G&W is the name you can trust for quality cable accessories. With sales representation worldwide, G&W has a proven track record for success.

G&W cable accessories are designed to accommodate cables from all manufacturers and can be created to accommodate any customer cable system. The optional mechanical shrink feature offers an easier and faster installation while reducing possible damage during installation. G&W also offers installation supervision and installation training, which can be customized to suit the audience.

G&W offers a variety of transmission cable accessories for extruded dielectric cable systems. Cable terminations are available for outdoor applications to 230kV and include porcelain or composite insulator options and premolded designs. Gas insulated substation designs are available to 230kV.

Transition cable splices and cable joints are available to 138kV and include premolded designs. All cable terminations and cable joints incorporate built-in stress control and dielectric fluid. Dry type designs are also available for maximum ease of installation.

Commercial Scalable Fault Isolation By G&W Electric

January 7th, 2021Commercial Scalable Fault Isolation

G&W Electric

The following Case Study by G&W Electric and presented by Thorne & Derrick describes how a southern utility was interested in improving service reliability by installing an underground fault detection, isolation, and restoration scheme for a circuit feeding several important residential/ commercial customers.

Thorne & Derrick are Specialist Distributors of Substation, Electrical Safety, Cable Jointing & Accessories to UK and international utilities and contractors providing electrical power at distribution and transmission voltage levels.

Challenge

A southern utility was interested in improving service reliability by installing an underground fault detection, isolation, and restoration scheme for a circuit feeding several important residential/ commercial customers. They needed a solution that could be scalable from an individual switch to a full circuit of switches capable of performing an open loop restoration. A base loop would be installed first and new switches added as the funds became available.

Solution

G&W Electric worked with the utility to help design a system that was flexible enough to meet their current and future needs. The design concept was based around multi-way automated switches connected to each other in an open loop. Communication would be through fiber optic cable for the protection circuit and SCADA.

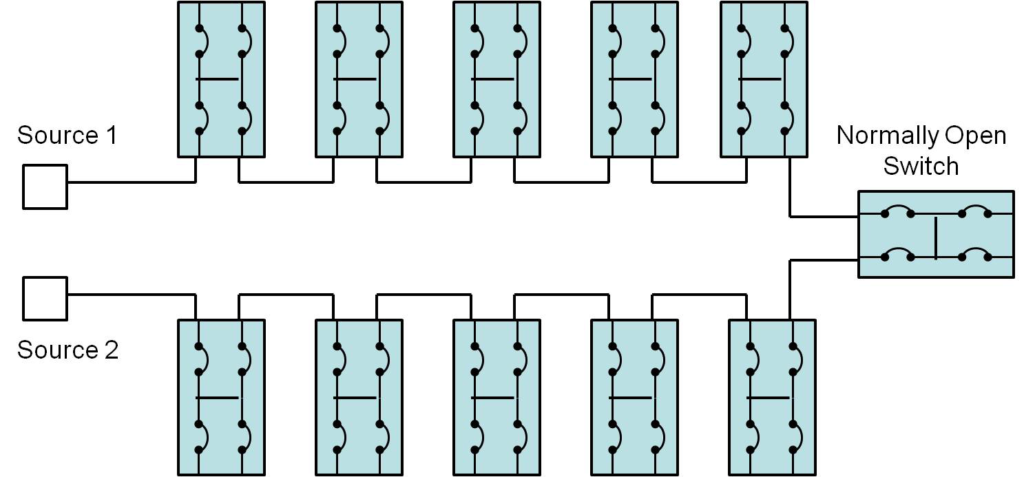

Four-way Trident®-SR solid dielectric switches were chosen for the load switching and fault interrupting. The Trident-SR was an ideal switching product for this solution due to the ease of automating it with any relay, innovative cycle speed operation, and multi-way mounting configurations. A front/back switch design was chosen due to its narrower footprint which would fit traditional air gear pads (see Images 1 and 2).

Image 1 Padmount switch with side control enclosure

Image 2 Front or back access padmount

The two source ways of the Trident-SR switches were controlled and protected by SEL-451 relays. The two load ways were controlled and protected by SEL-751A feeder protection relays. G&W Electric designed and built the two relay panels in a common enclosure on the side of the switch. Both panels had 120 V outlets which allowed operators to plug in laptops when working on or near the switches (see Image 3).

Image 3 SEL-751As and 451 were mounted in a common enclosure on the side of each switch.

The relay logic was designed to be extremely flexible so the same program could be used in multiple scenarios. This was accomplished using the extensive logic capability and multiple setting groups in the SEL-451 relay. The utility could choose whether to use the switch as a standard automatic transfer switch, as a through point automated loop switch where both

line ways are normally closed, or an open point automated loop switch where one line way is normally open.

When in the automated loop settings, each switch only communicated with the switches on either side of it. That meant there was no physical limit to the number of switches in the restoration circuit. This innovative control design allowed the utility to build their automation loops one switch at a time and add future switches as their budget permitted. It also provided a common switch design with single stock code which simplified future replacement requirements and training for their maintenance and installation crews.

The communication method for the protection circuit and SCADA system was single-mode fiber optic cable and SEL 2829 transceivers. This communication network was used to allow critical information to be passed between switches to automatically isolate faults and restore power in a minimal amount of time without having to dispatch crews.

This “smart switching” scheme is one of the most advanced technologies on the market and has been implemented by utilities worldwide who wish to provide the best service reliability to their customers.

When a fault is sensed, the relay trips the closest fault interrupter and disables the tripping of the other line way fault interrupter to maintain power to the loads. Next, a Mirrored Bits® signal is sent from the interrupting switch toward the open point. If the next switch in the line is closed, the signal will tell it to open to isolate the faulted line.

The signal is passed down the network from switch to switch until it encounters the open point. When the signal is received by the open point switch, it closes to restore power. This allows for an unlimited number of switches to be in the protective circuit and still maintain fast and effective isolation and restoration.

Conclusion

The scheme was tested and its operation witnessed by the customer at G&W Electric’s facility in Illinois. The initial phase has been installed and is up and running. It has inspired other utilities in the region to use a very similar scheme for their automated loops.

Figure 1 System Diagram

G&W ELECTRIC

Overview of G&W Cable Accessories

In 1905 G&W introduced the first disconnectable cable terminating device.

Over 100 years later, G&W continues to create technical innovations that have improved performance and reliability. With over 100 years experience, G&W is the name you can trust for quality cable accessories. With sales representation worldwide, G&W has a proven track record for success.

G&W cable accessories are designed to accommodate cables from all manufacturers and can be created to accommodate any customer cable system. The optional mechanical shrink feature offers an easier and faster installation while reducing possible damage during installation. G&W also offers installation supervision and installation training, which can be customized to suit the audience.

G&W offers a variety of transmission cable accessories for extruded dielectric cable systems. Cable terminations are available for outdoor applications to 230kV and include porcelain or composite insulator options and premolded designs. Gas insulated substation designs are available to 230kV.

Transition cable splices and cable joints are available to 138kV and include premolded designs. All cable terminations and cable joints incorporate built-in stress control and dielectric fluid. Dry type designs are also available for maximum ease of installation.

Wind Farm Fault Protection Saves Upgrading Equipment Costs

January 7th, 2021Wind Farm Fault Protection

G&W Electric

The following Case Study by G&W Electric and presented by Thorne & Derrick describes how their wind farm fault protection saves upgrading equipment costs.

Thorne & Derrick are Specialist Distributors of Substation, Electrical Safety, Cable Jointing & Accessories to UK and international utilities and contractors providing electrical power at distribution and transmission voltage levels.

Challenge

A new wind farm was being constructed in the Central Midwest.

The design was for 240 wind turbines with the goal of 400 MW of total capacity. The project was scheduled to be done in two phases with roughly half of the capacity in each phase. When fully operational, the wind farm would provide renewable energy to almost 120,000 homes. The wind farm was designed, the work was planned, and the equipment was ordered for the first 121 turbines of the project.

Coincidentally, during that time, the utility fault current levels at the wind farm substation increased unexpectedly after the above was completed. This meant that all of the equipment on order would now be under- rated.

The developer had two choices. The first was to change the current orders for new equipment, incur the costs associated with the higher rated gear, and delay the project by several months. The second option was to determine a way to reduce the fault current to an acceptable level without delaying the project.

38kV current limiting protectors mounted at the utility grid substation protects the utility from potential wind farm faults and the wind farm from potential utility faults.

Solution

The wind farm developer chose to put a G&W Electric CLiP® on the distribution voltage side of the substation transformer. The substation designer was familiar with the concept of a triggered current-limiting fuse. The 4000A continuous current requirement of the 38kV system however, was extremely high. At the time, G&W Electric had not produced a unit of that size at that voltage level. Working with the developer however, G&W Electric was able to build a CLiP that could meet the customer’s voltage, continuous current and interrupting duty requirements.

Wind Farm Fault Protection

Conclusion

The CLiP was incorporated into the design, manufactured, and installed without delaying the project or incurring the cost of upgrading all of the equipment. The customer was able use the existing equipment to protect the first 121 turbines on the project. A secondary benefit was that the utility transmission grid was also protected from any potential faults occurring in the wind farm. The developer is considering using lower rated gear on future installations with a CLiP to save money and protect equipment from changing fault currents.

G&W ELECTRIC

Overview of G&W Cable Accessories

In 1905 G&W introduced the first disconnectable cable terminating device.

Over 100 years later, G&W continues to create technical innovations that have improved performance and reliability. With over 100 years experience, G&W is the name you can trust for quality cable accessories. With sales representation worldwide, G&W has a proven track record for success.

G&W cable accessories are designed to accommodate cables from all manufacturers and can be created to accommodate any customer cable system. The optional mechanical shrink feature offers an easier and faster installation while reducing possible damage during installation. G&W also offers installation supervision and installation training, which can be customized to suit the audience.

G&W offers a variety of transmission cable accessories for extruded dielectric cable systems. Cable terminations are available for outdoor applications to 230kV and include porcelain or composite insulator options and premolded designs. Gas insulated substation designs are available to 230kV.

Transition cable splices and cable joints are available to 138kV and include premolded designs. All cable terminations and cable joints incorporate built-in stress control and dielectric fluid. Dry type designs are also available for maximum ease of installation.

Thorne & Derrick are Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

See how T&D support, supply and service the Renewable Energy industry.

MV HV Cables 11kV 33kV 66kV | Cable Joints, Terminations & Connections

How Do Cable Socks React To Salt Water?

January 7th, 2021

Cable Socks & Grips By Slingco | Offshore Cable Support & Strain Relief

Cable Socks For Saltwater

Slingco understands that choosing the right cable sock can be a challenge. There are key factors to consider when specifying cable socks, such as:

- How long the cable sock will be submerged. This could be 1 day, 1 month or longer

- The kind of environment, eg harsh conditions or rough terrain

- The effect saltwater has on a cable sock

- Whether a cable sock can still be used after exposure to saltwater

- How to choose the best cable sock for the application

Typically, where longer term saltwater exposure is involved, the choice is Aramid – specialist non-metallic socks.

Press Release | Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

Saltwater Test Results

Slingco have tested their cable socks by an independent leading, inspection, verification, testing and certification company. Here’s a sample from the test results of the effects of saltwater on steel socks.

Galvanised cable sock ZCS0307 after 40 days saltwater exposure

Galvanised cable sock ZCS0307

Extensive red rust corrosion covered the majority of the component. Red rust was observed from the first interval check, with white rust deposits on 2 sections.

Stainless steel cable sock ZCS1895 after 40 days exposure to saltwater

Stainless steel cable sock ZCS1895

Red rust corrosion was apparent on 60% of the sample. White rust deposits were observed on 5 sections, with the onset of degradation occurring after 1 week.

ARAMID SALTWATER TEST RESULTS

Aramid cable socks ZCS2816 after 40 days exposure to saltwater

Aramid cable sock ZCS2816

As you can see, there was no degradation or rusting throughout the test exposure, making these the most reliable cable socks for saltwater application.

Slingco have also undertaken extensive destruction tests on socks exposed to saltwater. To request a copy of the saltwater test report or the saltwater destruction report, please contact Thorne & Derrick.

➡ Thorne & Derrick distribute the complete range of Cable Pulling Products to support safe installation of LV, MV & HV cables into underground ducts, conduits and trenches by cable pulling, laying and jointing contractors.

Cable Socks | Pulling Underground Cables & Stringing Overhead Conductors LV MV HV

CABLE SOCKS & PULLING PRODUCTS LV MV HV

Complete range of LV, MV and HV cable pulling products for installation and enabling cable jointing in trench or ducts including LV, 11kV/33kV medium voltage (MV), 66kV/132kV high voltage (HV) and EHV transmission and distribution cables up to 400kV.

➡ See Also Cable Laying, Installation & Support Products | MV HV Windfarm

Cable Rollers | Duct Rods | Cable Socks | Cable Lubricant | Duct Seals | Cable Duct

Ellis Patents Cable Clamps Make The Sorta Connection

January 6th, 2021Ellis Patents

Cable Clamps

Two-in-One Cable Guide Clamps

Innovative two-in-one cable guide clamps, designed and developed in Yorkshire by Ellis Patents, are being used to guide and secure 4.5km of power cables being installed as part of an enormous infrastructure project in Vestland, Norway.

The Sotra Connection is a new national road being built by the Norwegian Public Roads Administration between Bergen and Øygarden municipality. The N555 project includes the construction of a new road bridge, the demolition of nine high voltage power masts and the re-routing of the related power cables through a series of tunnels and underneath the current Sotra Bridge – an element of the project known as the Stømkabel Sotrasambandet.

Ellis Patents Cable Guide Clamps, which were originally developed to solve a live project installation problem for Siemens, are being used to guide the power cables into place, before securing them and providing protection in the case of a short-circuit.

Kelly Brown, Ellis Patents Head of Sales, said: “This is perhaps the biggest infrastructure project in a generation in Norway; and when complete will provide a modern and fast connection from the Sotra islands to the country’s second biggest city and beyond.”

“The fact that our Cable Guide Clamps were specified is a matter of pride for all at Ellis, and goes to show that our new innovations are every bit as trusted as the likes of our Emperor and Vulcan+ cable cleats, which helped to establish us as the world leader in our field.”

The Stømkabel Sotrasambandet specification was secured through Ellis Patents’ Norwegian distributor, Procab.

Ellis Patents Cable Guide Clamp

Ellis Patents’ innovative Cable Guide Clamp works in two stages.

Firstly, electrical power cables are guided by it into their final location; with trumpeted entry and exit points ensuring the cable is not damaged when fed through particularly sharp angled turns. Once the cable is laid correctly, the top half of the guide is removed, a fixing piece installed directly onto the cable and the top half re-secured, thus turning it into a fully-functioning HV cable clamp.

Thorne & Derrick are Specialist Distributors of the world market-leading range of Ellis Patents cable cleats for the protection, support and short-circuit retention of LV MV HV power, transmission and distribution electricity cables.

Leading Manufacturer of Cable Cleats & Cable Clamps

Further Reading

- IEC 61914 – Cable Cleats & Short Circuit Protection Calculations

- Fire Resistance & Cable Cleats – Surviving Fire, Flame & Extreme Heat

- Triplex Cleats – Selection Guide for Cleating 11kV BS7870 Part 4.10 Cables

- Stainless Steel Cable Cleats – Preventing Galvanic Corrosion Of Cable Fixings

- Ellis Patents Cable Cleats & Cable Basket Tray for Securing High Fault Level Cables

- Stainless Steel Cable Cleats v Ties – The Myths Debunked By Ellis Patents

Thorne & Derrick

T&D are Specialist Distributors to UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and HV Jointing Contractors of an extensive range of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt – this includes 11kV/33kV/66kV joints, terminations and connectors for both DNO and private network applications.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV