Blog

33kV Euromold (Nexans) Connectors Terminating XLPE Cables Into Siemens Switchgear

March 3rd, 2020Images Courtesy of: Jeremy Hunt – HV & LV Engineering at Inter-Lect (UK) Ltd.

Pictured: 33kV Euromold (Nexans) Connectors Terminating XLPE Cables Into Siemens Switchgear – the 33kV XLPE power cable was prepared using Boddingtons Cable Jointing Tools ; this includes peeling bonded semi-conductive screen, insulation removal and chamfering and cable sheath stripping tools.

Impressive workmanship given the extremely challenging working conditions.

Thorne & Derrick International are Main Distributors for the complete range of Nexans Euromold Connectors, Joints and Terminations for medium voltage cables utilising EPDM rubber, cold-shrink, push-on and heat shrink technologies.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

33kV 4000amp Fully Insulated Duresca Busbar System

March 3rd, 2020Image: Barrie Gray – Offshore Installation Tech at Fabriom Hoboken Belgium for Siemens.

Pictured: 33kV 4000amp Fully Insulated Duresca Busbar System.

The cables that come from the turbine array strings are routed into the 33kV panelboard.

The medium voltage busbars are connected to the bus section of the board and take the load 33kV to the transformer. The transformer increases the operating voltage to 132kV and sends it to shore along the export cable.

Fully insulated busbars provide connections between medium and high voltage equipment such as generators, switchgear or transformers.

The Duresca busbar system offers a compact and safer solution compared to cable or conventional busduct solutions.

Duresca Busbar System – Benefits

- Same type of busbar for Indoor/indoor, outdoor/indoor or outdoor/outdoor application

- Solid, separate and fully isolated phase bus; no parallel cables

- Earth screen in copper, embedded in the insulation designed for fault current of 8 kA /1s

- Custom engineered for each individual installation

- Compact design with reduced bending radius

- Short assembly and erection time compared to cable, no need for special fixtures or tools

- Resistant to humidity and moister ingress, no risk of corrosion

- No need to pressurize or to add heaters; reduction of installation and maintenance costs

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Meet Andrew Brezovszky | EHV Cable Jointer

March 2nd, 2020uploaded by Chris Dodds – Sales Marketing Manager at Thore & Derrick

Contact Andy

A Jointers Hall of Fame – Curated tweets by ThorneanDerrick

110kV

➡ Masterclass : 110kV Cable Termination Using Prysmian Outdoor Sealing Ends

Thorne & Derrick’s POWER Blog is regularly updated with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

➡ View T&D’s brochure – contact our Sales Team with your requirements.

We focus on Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

We provide guidance and technical support for the installation of LV, MV & HV Cable Joints, Terminations, Substation & Electrical Equipment from our Key Suppliers including:

| 3M | CMP | Ellis Patents |

| Nexans Euromold | Elastimold | Pfisterer |

| Prysmian | Alroc | CSD |

| Roxtec | CATU Electrical | Cembre |

| Lucy Zodion | ABB | Emtelle |

With Photo Blog contributions from our social network of utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

JOINT ♦ TERMINATE ♦ CONNECT ♦ GLAND ♦ CLEAT ♦ CRIMP ♦ DUCT ♦ SEAL ♦ REPAIR ♦ CABLE ♦ SPLICE ♦ INSULATE

Masterclass : 110kV Cable Preparation & Termination Using Prysmian Outdoor Sealing Ends

March 2nd, 2020 uploaded by Chris Dodds – Sales Marketing Manager at Thore & Derrick

uploaded by Chris Dodds – Sales Marketing Manager at Thore & Derrick

We are highly privileged and grateful to Andrew Brezovszky (EHV Cable Jointer at Matrix Power Solution Pty Ltd) for contributing again to our PhotoBlog.

Andrew is an international class HV Cable Jointer with over 20 years of experience in an extensive range of HV Joints and Cable Terminations across various countries in Europe, New Zealand and Australia.

The following sequence of site photographs and commentary provided by Andrew details the stages of cable installation, preparation and termination using EHV Outdoor Sealing Ends – work was completed on a normal 8 hour/day basis over 5 days with an additional day to install sheath bonding cables and linkbox.

Cable Specification : 110kv XLPE Taihan Cable with 1600sqmm Milliken copper conductor and corrugated copper sheath.

Outdoor Sealing End (Termination) Manufacturer : Prysmian.

Prysmian |Cable Joints | Terminations | Cleats | Connectors

Getting Started

Temporary cable caps are wiped-on to protect the 110kV cable from moisture.

Getting Cleated

Standing and cleating cables is next.

Scaffolding Erected

The scaffold is built which will house our jointing team for a week. We have a generator to power the site and a mobile aircon to control temperature and humidity.

Here’s a shot from the inside before we start cable jointing.

Straightening Cables

Removing the copper sheath is next and installing the cable heating and straightening blankets. The duration is always as recommended by the high voltage cable manufacturer but it also depends upon cable outside diameters.

Cable straightening is a very important stage of the cable installation prior to preparation and cable termination.

Preparing the aluminium glands so they can be plumbed on. We also ‘preload ‘ them, to shorten the time the cable is under heat stress. This is very important, as the longer plumbing time can cause irreversible damage to the semiconducting layer as well as the cable insulation.

Stripping Off

We strip our EHV cables with Alroc tools and cut the chamfers with glass. Old school, labour intensive, etc., I know. The corrugated sheath is scored circumferentially then pulled off. The semiconductor layer and insulation is peeled off with Alroc stripping tools.

Sand & Polish Cables

This is followed by lots of sanding and polishing. Both manual techniques and machine tooling including orbital sanders and linichers are used to achieve this finish.

It is very important to prepare the conductor properly.

Cable Crimping Preparation

Crimping guide block – the cable crimping sequence is important.

Crimping complete using ram/Milliken style crimping head with basic Ryken hydraulic pump.

Stress control installed. Removing the semi-conducting screen and installing the premoulded cable joint sleeve or sealing end sleeve is a critical stage of jointing 110kV cables.

Taping Time

Jointing tapes are next.

Insulator is lowered onto the cable.

Plumb

Plumbing completed.

Armour tape used to reinforce the wipe and cable sheath.

The insulator is then filled with special silicone oil to a specific level and the top arrangements are installed.

Completed installation of 110kV Prysmian Outdoor Sealing Ends to Taihan Cable.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

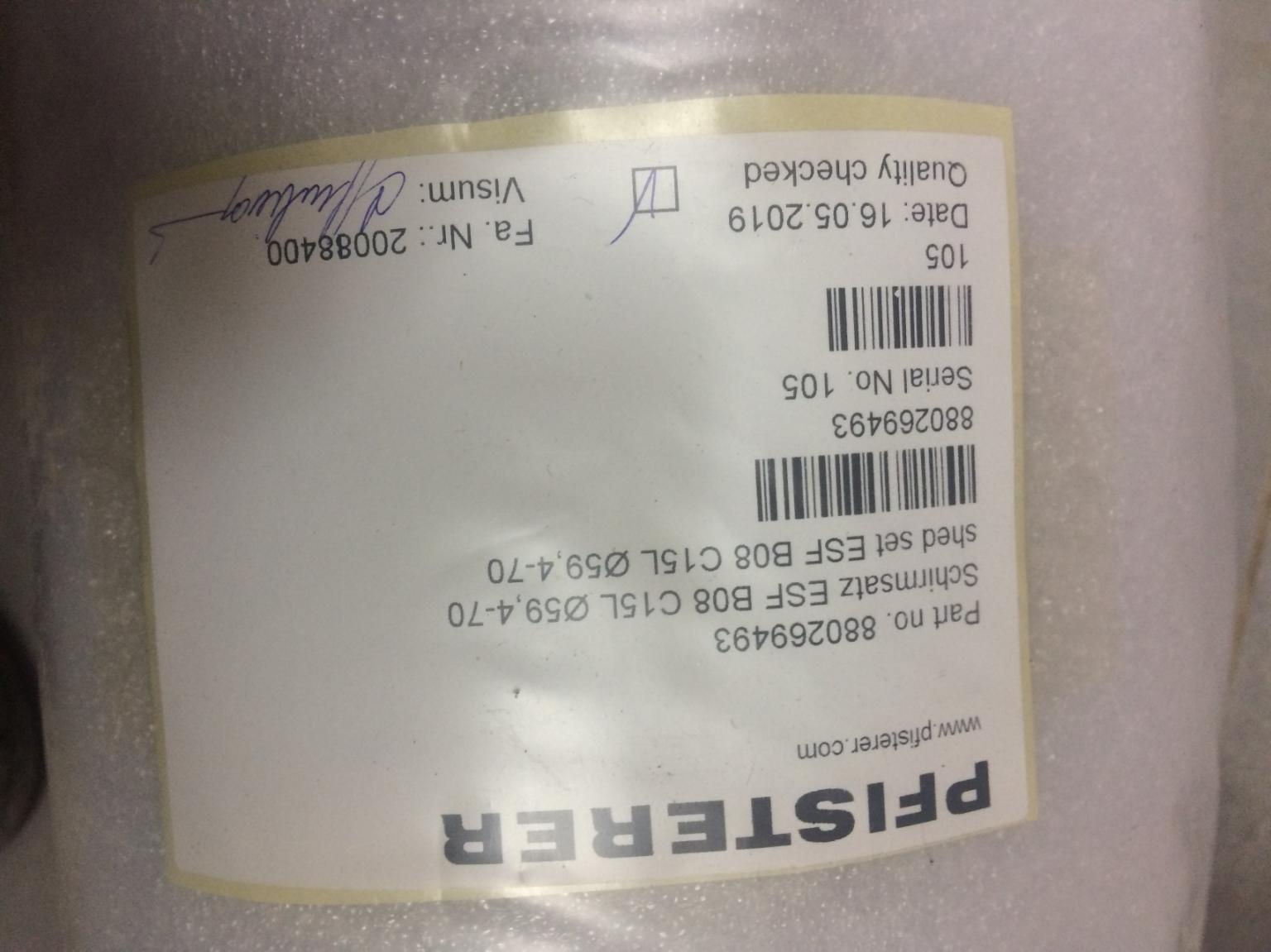

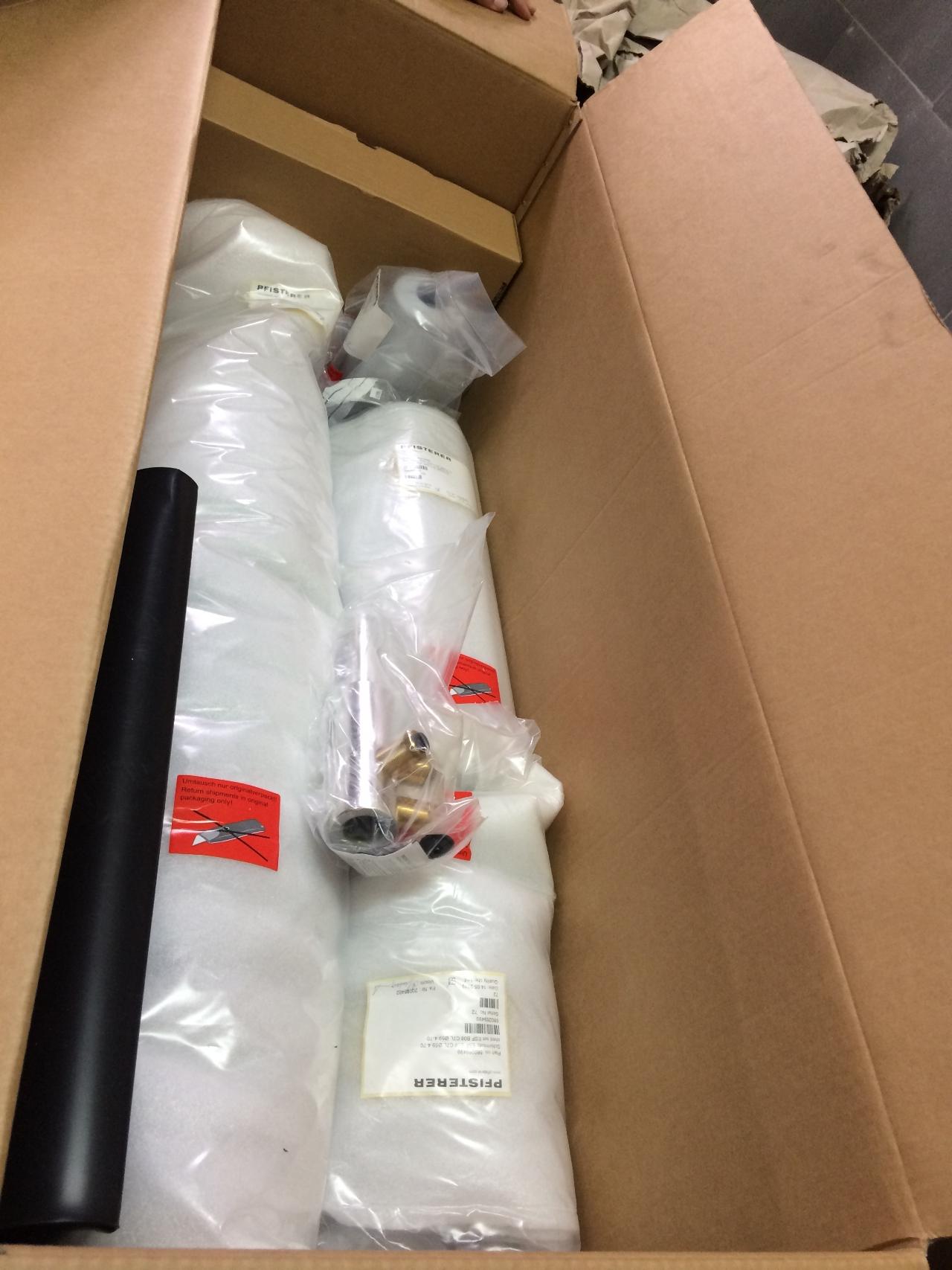

Dry, Slip-on Type Outdoor Cable Termination | Pfisterer ESF 14kV

March 2nd, 2020Images Courtesy of: Morteza Sobhani – Expert of Installation and After Sales Services – HV Sales Engineer at Shahin Mafsal Co.

Pictured: Installation of 12 pieces ESF145KV C45L in Miandoab Petrochemical, Iran.

Pfisterer Dry Type Termination ESF

Using PFISTERER dry-type cable accessories means substations or petrochemical plants, for example, can benefit from maintenance free operation. This range of MV HV Cable Aaccessories are explosion proof, therefore ensuring the safety of operating staff.

Features & Benefits with PFISTERER

- No scaffolding costs due to the safe and simple on the ground assembly of the cable terminations

- Efficient installation which allows for shorter downtimes on medium/high voltage power cables and systems

- Offers a high degree of cable termination reliability (explosion-proof)

- Uses no liquid or gaseous insulation materials

- High cost-cutting potential compared to more conventional cable terminations

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.