Blog

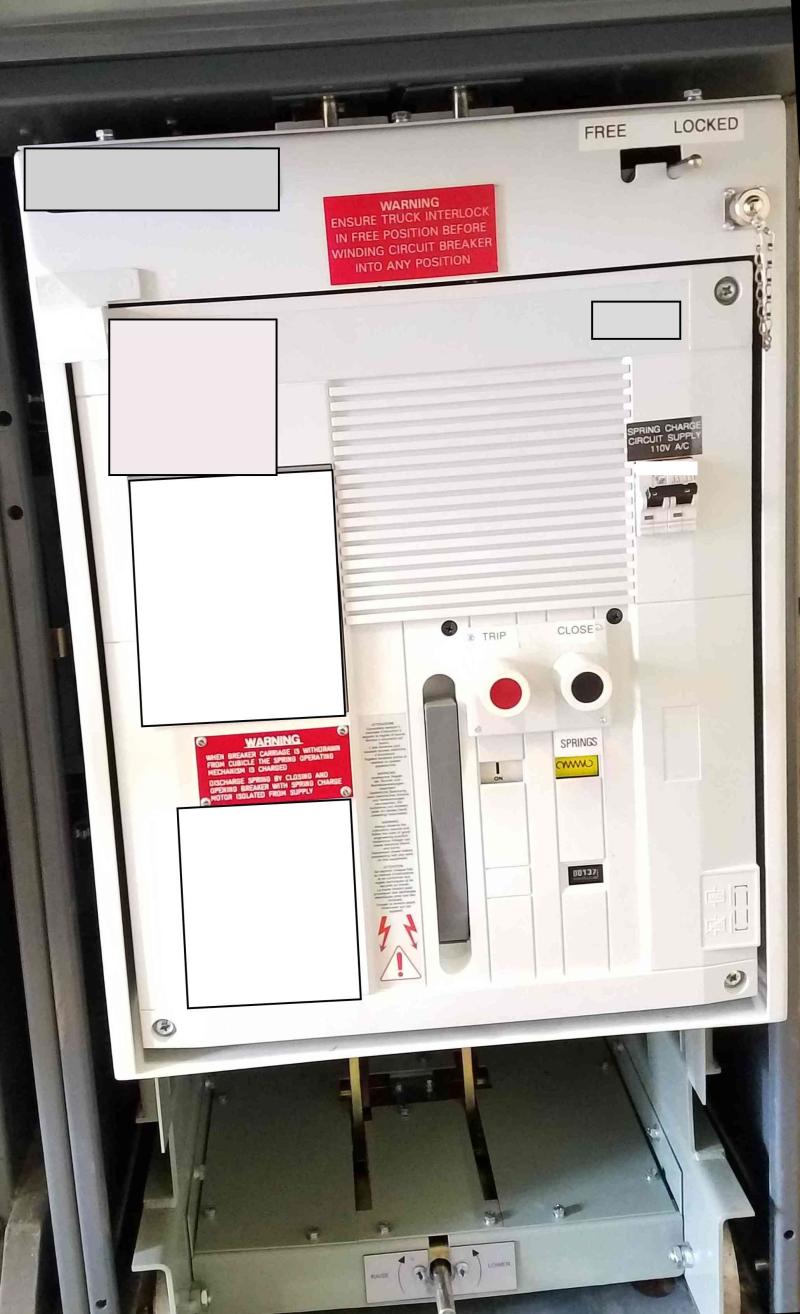

P&B VOR-S Switchgear (Vacuum Circuit Breaker Retrofit) – 2

November 4th, 2019

P&B VOR-S Switchgear (Vacuum Circuit Breaker Retrofit)

Credit: Mikolaj Kukawski | Customer Networks Manager at ESM Power Ltd

Featured Manufacturer: P&B

MV HV Switchgear

Mikolaj is an experienced Private HV Networks Manager with a demonstrated history of working in the utilities and  medium/high voltage (MV HV) sectors of industry.

medium/high voltage (MV HV) sectors of industry.

Skilled in MV HV Electrical Power Distribution Systems operation, maintenance and asset replacement. Strong operations professional with SAP experience up to 132kV for both private and DNO networks.

ESM Power design, deliver and manage LV MV HV electrical networks safely, securely and economically – this includes ICP and DNO connections at LV, 11kV, 33kV and 132kV.

➡ See complete Switchgear MV HV Album.

Switchgear MV HV | Thorne & Derrick distribute Nexans Euromold, 3M Electrical, PFISTERER Connex, Prysmian and Shrink Polymer Systems ranges of Joints, Terminations & Connectors to enable the installation and maintenance of electrical switchgear, transformers and substations.

T&D supply Cables, Accessories & Electrical Products for Low Voltage (LV 230V to 1000V), Medium Voltage (MV 3.3kV/11kV to 33kV) and High Voltage (HV 33kV to 132kV) networks.

JOINTERS BLOG

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

15,000+ Subscribers. ➡

Systems Power RVCB (Retrofit Vacuum Circuit Breaker) Switchgear – 1

November 4th, 2019

Systems Power RVCB (Retrofit Vacuum Circuit Breaker) Switchgear

Credit: Mikolaj Kukawski | Customer Networks Manager at ESM Power Ltd

Featured Manufacturer: Systems Power

MV HV Switchgear

Mikolaj is an experienced Private HV Networks Manager with a demonstrated history of working in the utilities and  medium/high voltage (MV HV) sectors of industry.

medium/high voltage (MV HV) sectors of industry.

Skilled in MV HV Electrical Power Distribution Systems operation, maintenance and asset replacement. Strong operations professional with SAP experience up to 132kV for both private and DNO networks.

ESM Power design, deliver and manage LV MV HV electrical networks safely, securely and economically – this includes ICP and DNO connections at LV, 11kV, 33kV and 132kV.

➡ See complete Switchgear MV HV Album.

Switchgear MV HV | Thorne & Derrick distribute Nexans Euromold, 3M Electrical, PFISTERER Connex, Prysmian and Shrink Polymer Systems ranges of Joints, Terminations & Connectors to enable the installation and maintenance of electrical switchgear, transformers and substations.

T&D supply Cables, Accessories & Electrical Products for Low Voltage (LV 230V to 1000V), Medium Voltage (MV 3.3kV/11kV to 33kV) and High Voltage (HV 33kV to 132kV) networks.

JOINTERS BLOG

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

15,000+ Subscribers. ➡

MV Cable Joints | Nexans NEW PRODUCT Launch

November 4th, 2019

JTS Triple Wall Heat Shrink Joints

Reliability & Safety at Reduced Cost

-

uploaded by Chris Dodds | Sales Marketing Manager at Thorne & Derrick International

A modern generation of MV Heat Shrink Joint has been developed by Nexans for the UK utility and contracting industry – the primary application is for the jointing of 11kV BS7870 Triplex type medium voltage cables.

Independent Connection Providers (ICPs) and Power Contractors now have a credible option to ensure they obtain the most competitive 11kV jointing product prices without compromising quality.

11kv

The JTS cable jointing system now provides the most cost-competitive option to power contractors: the cable joints manufactured by Nexans, “The Global Expert in Cables & Cable Systems” are tested in accordance to CENELEC HD629.1.

The internationally recognised quality standard ensures power system reliability and outage reductions when installed in accordance with the manufacturers instructions by Competent cable jointers.

The cable joints include high quality heat shrink tubes and components – the JTS range suits polymeric cables (XLPE & EPR), single core (up to 1600sqmm) with copper wire screens and voltage 11kV (Umax 24kV).

-

- Outer Heat Shrink Tube

- Triple Heat Shrink Tube (Stress Control | Insulation | Conductive)

- Sealing & Stress Relief Mastic

- Shearbolt Mechanical Connectors

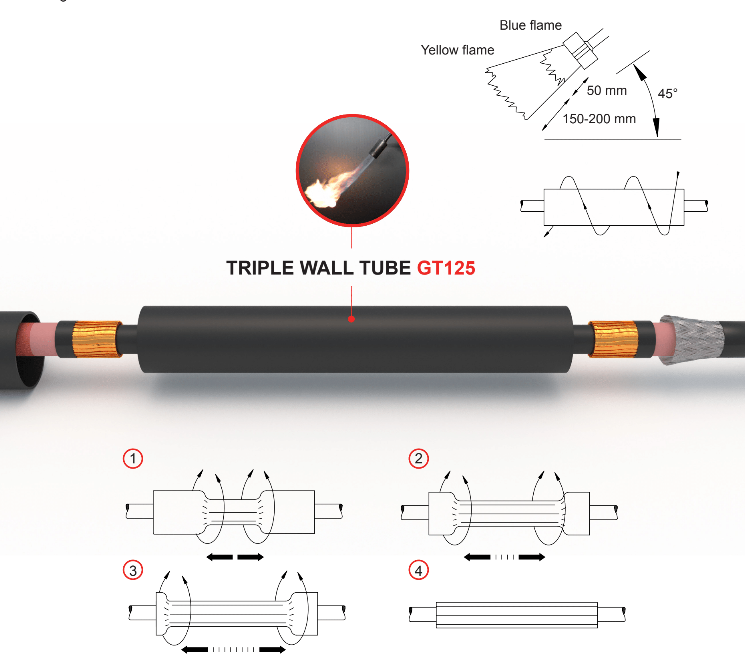

Triple Wall Heat Shrink

Single Tube with Triple Function

Traditionally, heat shrink joints required several separate stages for the installation of the complete cable joint with multiple layers of heat shrink tubes needed to provide stress control, insulation and conductive functions – the labour intensive jointing procedure introduced increased risks of jointer error including tube misalignment and flamework deficiencies (scorching of tubes by overheating).

The Triple Wall design of the JTS Joint reduces installation times with corresponding labour savings.

The triple extruded heat shrink tube with integrated stress control provides compact installation with reduced components and excellent water sealing for direct burial into underground cable trench.

Mechanical connectors are included for fast jointing of conductors without resort to hydraulic crimping tools and associated die sets.

Stocked and distributed in the UK, the cable joints are now available from Thorne & Derrick with complete technical support, fast quote service and next-day delivery.

Jointer Competency Training can be booked via Thorne & Derrick and obtained from the Nexans Training Centre | Normanton | West Yorkshire WF6 1TR

The kits include clear step-by-step Jointing Instructions – Competency Certification can be issued, contact us.

Triplex Joints & Terminations

Nexans manufactured Cable Accessories are in extensive service throughout the UK DNO power grid – the Euromold brand of separable connectors are approved and are approved by several DNO/IDNO operators dependent on the product, voltage and network.

Nexans joints and terminations are increasingly preferred and adopted by NERS Accredited Independent Connection Providers (ICPs) working on 11kV private networks.

Thorne & Derrick have an International Distribution Agreement with Nexans Power Accessories UK and are their main stockists and suppliers for their range of Heat Shrink Joints & Terminations up to 33kV.

Nexans MONOi heat shrink cable terminations are a one-piece co-extruded anti-track (red) and stress control tube for connection and terminating 11kV BS7870-4-10 Triplex Cables 95-300sqmm into medium voltage electrical equipment.

Specification & Installation Instructions For Jointers

➡ TERMINATIONS TRIPLEX Download Specification

➡ TERMINATIONS TRIPLEX Jointing Instruction

➡ JOINTS TRIPLEX Download Specification

➡ JOINTS TRIPLEX Jointing Instruction

Disclaimer: This document – Jointing Instruction – is a sample instruction to be used for reference only and is for a specific cable, the relevant instruction will change as per the cable specification it is to be used on.

Thorne & Derrick

Nexans Main UK Stockist & Distributor

Contact us for Competitive Prices & Fast Delivery from Stocks for Heat Shrink, Cold Shrink & EPDM Rubber Connectors, Joints & Terminations up to 66kV.

Go to our Price List and contact us with your enquiries.

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Accessories, Jointing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV.

Stocking & Supplying | Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Jointing Tools | Cable Pulling Eqpt | Earthing & Lightning Protection | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Euromold MV HV | Cable Terminations, Connectors, Elbows & Joints

HV High Voltage Cables | Standardization and Optimization of High Voltage Cables Design

October 30th, 2019 Thanks you Ahmed Metwally Electrical Transmission Specialist for allowing us to republish this article

Thanks you Ahmed Metwally Electrical Transmission Specialist for allowing us to republish this article

Published Study for HV Cables Optimization through CIGRE-GCC 2019

Abstract

High Voltage Cables

The electric power transmission system of National Grid Saudi Arabia (a subsidiary of Saudi Electricity Company-SEC) includes a network of underground cables ranging from MV (13.8kV) to EHV (380kV) cable. The backbone of this power distribution network has a voltage rating of 110kV to 380kV with conductor cross-sectional area varying from 400sqmm to 2500sqmm.

The high voltage underground cable network has three different voltage ratings; 110kV, 115kV and 132kV. Prior to 2003, the electricity network was being operated and maintained by four individual utility companies having their own specifications and franchise areas;

- 132kV in the Central and Southern regions

- 115kV in the Eastern region

- 110kV in the Western region

National Grid initiated a study to standardize and optimize the designs for high voltage cables suitable for all high voltage ratings. The study started unifying the cables sizes and designs, verifying performance of existing network and analysing demand forecast.

Suitable designs and sizes were worked out and appropriate ways were looked into to optimize the design by implementing the relevant international standards and taking into consideration feedback from the maintenance and projects about existing cables.

Introduction to HV Cables

Utilities around the world are going for optimization of utilized equipment (reduce capital and operational cost). Therefore, Standards & Specifications Department of National Grid Saudi Arabia formed a team of experts to study the possibility of standardizing/unifying cable design to three sizes; 1200sqmm, 2000sqmm and 2500sqmm.

In addition, it will achieve financial savings as a result of this design optimizing.

Process flow for this study is shown below:

Study Process Flow

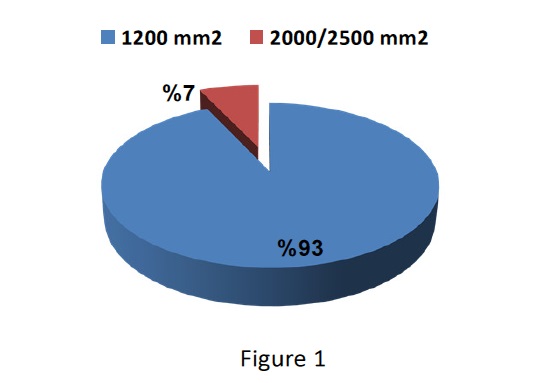

National Grid specifications have variety of high voltage cable conductor sizes which were based on IEC 60228 and the different operating areas requirements. However, based on ampacity required for each substation, National Grid is selecting 1200sqmm conductor size more often to cover load demands. And the other sizes 2000sqmm and 2500sqmm are the second most popular choices after 1200sqmm which can be applied for all substation requirements as shown in [Figure 1].

Reduction in Cable Layers

1. Reduction of Cable Insulation

The international standard IEC 60840 “Power cables with extruded insulation and their accessories for rated voltages above 30kV (Um = 36kV) up to 150kV (Um = 170kV) –Test methods and Requirements” does not specify the required nominal thickness of insulation for high voltage cables. But this is not the case with IEC 60502 which specify required nominal thickness of insulation for medium and low voltage cables.

However, the limitations of the insulation thickness for high voltage cables depends on nominal conductor electric stress which shall not exceed 8,0 kV/mm and the limitations of the insulation screen thickness depends on nominal insulation electric stress which shall not exceed 4,0kV/mm.

The required insulation thickness as pre National Grid specifications was 20.32 mm for 110/115kV cables and 21.6 mm for 132kV cables. These values satisfy the requirement of IEC 60840, but with high safety margins as shown in table 1 for 132kV cables.

Table 1

| 1200 sqmm, 132 kV cable |

2000 sqmm, 132 kV cable |

2500 sqmm, 132 kV cable |

||

| Insulation Thickness [mm] | 21.6 | |||

| The nominal Conductor electric stress [kV/mm] | 4.92 | 4.67 | 4.59 | < 8 |

| The nominal Insulation electric stress [kV/mm] | 2.62 | 2.69 | 2.77 | < 4 |

Table 2 shows parameters for 1200sqmm, 2000sqmm and 2500sqmm for 132kV cable and all the results are within the required range based on IEC 60840.

| 1200 sqmm, 132 kV cable |

2000 sqmm, 132 kV cable |

2500 sqmm, 132 kV cable |

||

| Insulation Thickness [mm] | 18.0 | |||

| The nominal Conductor electric stress [kV/mm] | 5.65 | 5.48 | 5.31 | < 8 |

| The nominal Insulation electric stress [kV/mm] | 3.26 | 3.34 | 3.43 | < 4 |

2. Reduction of Semi Conductive Layers

The same principle of the cable insulation that the IEC 60840 does not specify the required nominal thickness for cable semi-conducting layers, the team made the changes in this layer based on the manufacturers experiences when it comes to operating the triple extrusion machine and trying to maintain the eccentricity of the cable.

National Grid involved thirteen (13) cable manufacturers around the world to study and check the minimum required thicknesses for semi-conduction layer which can fulfil the requirement of eccentricity based on IEC 60840 and as a result, the conductor shield and insulation shield reduced to 1.5 mm.

3. Reduction of Metallic Screen Layer

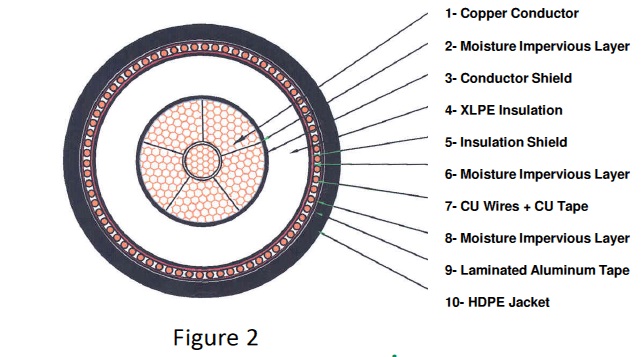

Different metallic screens are available based on National Grid specifications. Most common choice is copper wire with tape screen [Figure 2]. Its selection mainly depends on the project requirement such as radial water tightness features, electrical and mechanical properties.

However, all metallic screen types have a fundamental function to withstand the required short circuit current.

Therefore, a critical part of designing the metallic screen is to know how much an area of metallic screen can withstand the required short circuit, IEC 60949 ” Calculation of thermally permissible short-circuit current taking into account non-adiabatic heating effect” was used to calculate the required area of metallic screen of the high voltage cable that can withstand the required short circuit.

There are two ways to do short circuit calculation; using adiabatic temperature formula and using non-adiabatic factor. In this study non-adiabatic factor chosen, by using thermal constant of the media applied over either sides of the screen. Moisture impervious layers were applied to both sides.

This helped reducing area of copper wire screen from 280sqmm “as per a adiabatic calculations” to be 261sqmm “as per non-adiabatic calculation” and still fulfilled National Grid specifications to withstand 40kA for 1 second and provided good financial savings in the cost of the high voltage cable.

These reductions in the insulation thickness and metallic screen area have also increased slightly current capacity of the optimized cable comparing with the conventional cables being used in the network.

The below Table 3 shows an example of the current rating values changes.

| 1200sqmm, 132kV cable | ||

| The load Current [A] | 914 | |

| The permissible Cable current [A] – Insulation thickness of 21.6 mm – Metallic screen area of 280 sqmm |

954* | |

| The permissible Cable current [A] – Insulation thickness of 18 mm – Metallic screen area of 261 sqmm” |

961* | + 7 |

*Installation conditions: the standard trench of a single circuit in flat formation in a backfill duct bank at 1.45 m depth with 300 mm axial phase spacing, 40 ºC soil temperature, 2.0 ºC.m/W soil thermal resistivity (dry value), 1.2 ºC.m/W thermal backfill resistivity (dry value) and cross bonded system.”

Cable Manufacturers Production Capabilities

After the completion of the design of all layers of the cable, National Grid contacted several qualified cable manufacturers (local & international) and discussed the possibility of manufacturing cables with the suggested design and its effectiveness.

The responses received were consistent with the design provided by National Grid and its specifications were updated in 2018. Subsequently, manufacturers started production of the optimized cable size 1200sqmm which was type tested successfully.

Design of the System Test Loop

After getting the success capability from the cable manufacturer and the decision to approve the optimized design, it was type tested as per IEC 60840 in addition to a short circuit test in the presence of National Grid representatives to check the quality of the new design for the electrical and non-electrical tests, the main test loop included the following components; 50 m of cable test, two outdoor porcelain terminations, one straight joint and one cross-bonding joint based on the test loop in Figure 3.

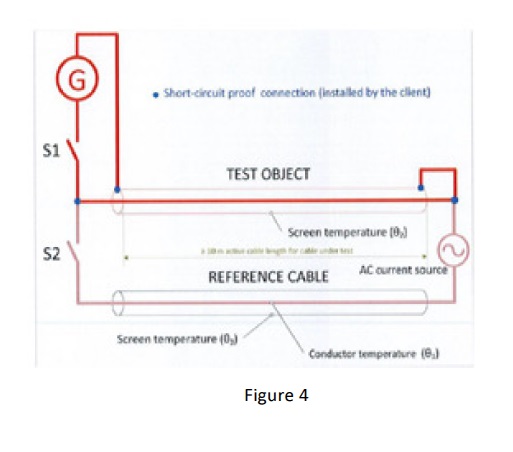

And the additional test to ensure metallic screen/sheath withstanding required short circuit was the short circuit test for which National Grid and DNV-GL “KEMA” made a procedure & the test loop The test loop is shown in Figure 4.

Financial Cost Savings

Local manufacturers were contacted for the calculation of financial savings as a result of the cable reduction and cost index [%] for HV is shown in table 4.

Benefits from this exercise in terms of financial savings in the capital budget in the next seven years were estimated to be about 25 million US dollars.

| 110kV, 115kV and 132kV Cables | ||||

| Description | 1200sqmm, Normal Design | 1200 sqmm, Optimized Design | 2000/2500 sqmm, Normal Design | 2000/2500sqmm, Optimized Design |

| Cost Index %/Km | 100 | 93 | 100 | 95 |

The Results

- Financial savings by reducing thickness of insulation & metal cover area “metallic shield” without affecting quality and efficiency of cables

- Standardization to three sizes only; 1200/2000/2500sqmm. As a result of this optimization, cable accessories will automatically be unified/standardized for specified models of cable joints and cable terminations

- Reduction in the weight of cables up to 8.6% and overall cable diameter up to 9.6%. This will facilitate the installation of cable laying thus reducing the cost of civil works

By Ahmed Metwally

Currently Electrical Transmission Specialist at Saudi Electricity Company

Job Purpose

* Approve the pre-qualification of manufacturers for electric equipment such as Cables, Cable Accessories, Link Box, SVL and Cable Cleats & Clamps.

* Authoring and updating the company specifications based on the international standards.

* Attend various type tests to verify the produced equipment is in line with requirements.

* Provide technical studies that help to use new methods in electrical transmission projects based on national and international researches.

Job Roles & Responsibilities

* Very strong experience at Extra High Voltage and High Voltage Cables and Accessories (500kV, 400kV, 380kV, 230/220kV, 132kV, 115/110kV & 69/66kV) transmission field, design, engineering, quality control and testing for substation projects.

* Attend various technical, design and progress meetings with Cables and Accessories manufacturers, SEC internal departments, and other utilities to resolve raised technical problems and to ensure smooth running of prequalification/ projects.

Achievements

* Author of the new optimized specification for high voltage cables (132/115/110kV) based on the international standard for testing and current rating calculation and induced voltage.

* Present a presentation at JICABLE2019 for the paper “Standardization and Optimization of High Voltage Cables Design.”

* Provide a technical poster at Cigre 2019 for the paper “Standardization and Optimization of High Voltage Cables Design.”

* Member of EPRI Institute – USA for EHV/HV underground cables and accessories design and installation.

Thorne & Derrick

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

Switchgear MV HV | 50 Models of Medium & High Voltage Switchgear

October 29th, 2019Switchgear MV HV

Images: Mikolaj Kukawski | Customer Networks Manager at ESM Power Ltd

- Systems Power RVCB (Retrofit Vacuum Circuit Breaker) Switchgear

- P&B VOR-S Switchgear (Vacuum Circuit Breaker Retrofit)

- Siemens SION Vacuum Circuit Breakers | MV HV Switchgear

- Schneider CBGS-0 Gas Insulated (GIS) Primary Switchboard

- ABB ZX0.2 MV Gas Insulated Switchgear | IEC/ANSI Up to 33kV

- Siemens NX-PLUS Gas Insulated Medium Voltage Switchgear

- Alstom LCGT (SF6 RMU) Ring Main Unit (Long & Crawford)

- SWS Tiger Ring Mains Unit | MV Medium Voltage

- Brush Switchgear | MV HV Electrical Equipment Up to 33kV

- Brush NSM Ring Main Unit Switchgear

- Siemens 8DA10 Medium Voltage Gas Insulated Switchgear

- Siemens NXAIR Air Insulated Medium Voltage Switchgear

- Brush Eclipse FKI/HSS Switchgear

- Schneider WS-A Medium Voltage Switchgear Gas Insulated

- ABB SafePlus Type CCV Gas Insulated Ring Main Unit RMU

- ABB SafePlus Type CCF Gas Insulated Ring Main Unit RMU

- SEL TPR6 Type CK Ring Main Unit RMU

- ABB SafePlus Type V Fixed SF6 Circuit Breaker Switchgear

- Siemens 8DJH Gas Insulated Medium Voltage Switchgear

- Lucy Sabre VRN Ring Unit Switchgear (SF6 Insulated MV HV)

- UP Systems | LV & HV Switchgear Up to 33/36kV High Voltages

- Schneider Genie Evo Insulated MV HV Switchgear

- Schneider RM6 Medium Voltage Ring Main Units

- Schneider WS-A Medium Voltage Switchgear Gas Insulated Switchgear

- Schneider D VAD3 Vacuum Circuit Breakers | MV HV Switchgear

- Siemens NX-PLUS Gas Insulated Medium Voltage Switchgear (MV)

- Reyrolle Switchgear | 11kV Switchgear Circuit Breakers MV

- Schneider Flusarc MV Compact Switchboard Ring Main Unit (RMU)

- Ormazabel CGM Gas Insulated Modular & Compact Ring Main Units

- Merlin Gerin Vercors VM6 MV Distribution Switchgear

- Yorkshire Switchgear YSF6 SF6 Circuit Breaker | HV Switchgear

- Yorkshire Switchgear Ringmaster SF6 Ring Main Unit | HV Switchgear

- ABB CBS (Circuit Breaker Sentinel) | Medium & High Voltage Switchgear

- Long & Crawford Circuit Breakers MV HV | WPD MK II OCBUNIT

- Igranic Compact 33 Isolator (ABB CK4)

- ABB SafePlus Medium Voltage Compact SF6 Insulated MV Switchgear

- Alstom VISAX Air Insulated Switchgear with Rotary Breaker

- Merlin Gerin Genie SF6 Gas Insulated switchgear | Pre-Evo

- ABB Unigear IEC Air Insulated Switchgear MV HV

- Schneider Areva PIX Air Insulated Switchgear MV HV

- Hawkvac 15 | Medium Voltage MV Indoor Vacuum Switchgear

- GEC HMX36 Vacuum Circuit Breaker | High Voltage Switchgear

- Reyrolle L800T Moving Male Oil Circuit Breaker Contact

- ABB Uniflex Double Busbar VD4 VCB IEC Indoor Vacuum Circuit Breaker

- GEC HMX36 Vacuum Circuit Breakers | MV HV Switchgear

- Brush Vacuum Circuit Breakers | VMV512 Single Busbar

- ABB NAL 14 (ABSD) Indoor Air Switch Disconnector MV HV

- MV HV Switchgear | Ringmaster Range | Schneider Electric

- GEC BVP 17 Oil Circuit Breaker | MV HV Switchgear

- Brush Hawker Siddley VMV12 Vacuum Circuit Breaker Double Busbar

MV HV Switchgear | Thorne & Derrick distribute Nexans Euromold, 3M Electrical, PFISTERER Connex, Prysmian and Shrink Polymer Systems ranges of Joints, Terminations & Connectors to enable the installation and maintenance of electrical switchgear, transformers and substations.

T&D supply Cables, Accessories & Electrical Products for Low Voltage (LV 230V to 1000V), Medium Voltage (MV 3.3kV/11kV to 33kV) and High Voltage (HV 33kV to 132kV) networks.

JOINTERS BLOG

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

15,000+ Subscribers. ➡