Duct Seals

Hauff-Technik Puts Down Roots in the UK

March 2nd, 2023PR | BY Hauff-Technik | 02.03.2023

Hauff-Technik, a leading manufacturer of sealing systems for cables, pipes and building entries has put down roots in the UK.

With the new subsidary in Chesterfield in the heart of England, Hauff-Technik are strengthening their sales activities in United Kingdom.

Today, we are establishing our next national company: Hauff-Technik UNITED KINGDOM Ltd.

The establishment of a further subsidiary is intended to respond more intensively to customer needs, increase competitiveness and achieve even faster market development.

The newly founded Hauff-Technik UK Ltd. is based in Chesterfield, UK and is headed by Thomas Koelle and Jan Holly as Managing Directors.

“By being able to supply a wide range of products from stock, we have fast lead times for delivery within 24 hours on the UK mainland,” says Thomas Koelle. “With a dedicated team of two field sales representatives, we do not only offer direct local contact, but also offer in-house training as well as on-site support and advice,” adds Jan Holly.

“The foundation underlines our long-term strategic interest in the British market and also its important position within Europe. We would like to significantly expand our sales efforts in the UK in the future and are now laying the foundation for this,” comments Dr. Michael Seibold, Managing Director of the parent company Hauff-Technik, based in Hermaringen in Baden-Wuerttemberg.

Previously, the company had three subsidiaries: Hauff-Technik GRIDCOM GmbH in nearby Rosenberg, Hauff-Technik MIDDLE EAST LLC in the United Arab Emirates, and Hauff- Technik SWISS AG in Switzerland.

Hauff-Technik Puts Down Roots in the UK

Hauff Technik are leading manufacturers of sealing systems for cables, pipes and building entries. They have been protecting buildings from penetrating water, gas, fire, dirt and vermin for the past 60 years. Specialising in sealing cable entries for secondary substations, Hauff Technik’s innovations help protect and set standards in the energy supply sector.

Contact Thorne & Derrick for the most extensive range of Cable & Pipe Sealing Systems to protect electrical substations, cable ducting systems, building entries and power infrastructure at LV MV HV.

Further Hauff Technik Reading

- Hauff-Technik Officially Approved By Scottish & Southern Electricity Networks

- Cold Shrink-Fit Method vs. Heat Shrink-fit Method

Offshore Wind Power Cable Management | Top 5 Challenges

August 31st, 2022

Top 5 Challenges In Wind Power Cable Management

Offshore Wind Power Cable Management

Roxtec Top 5 Challenges

Thorne & Derrick are Approved Distributors for Roxtec, the leading manufacturer of sealing solutions for cables and pipes, to protect electricity Transmission & Distribution assets including windfarm substations against water ingress, gas migration and fire hazards.

Below Roxtec have compiled the top 5 most common issues we all struggle with on offshore substations.

1. Specifications & Certificates

We all want to ensure safety and operational reliability, and use high quality products to deliver the best result we can. Therefore, we often meet specifications and requirements demanding a multitude of certificates. However, it is not guaranteed that all types of cable sealing methods are approved.

The best thing would be to find a sealing solution that has passed all tests and certifications.

2. Uncertain Estimates

It can be difficult to know how many cables or pipes, or what size power and instrumentation cables, we need to route. We can never be sure about making the right openings, or about how to seal all those penetrations. Even the best of estimates cannot predict all late design changes.

What we need is a sealing system that is as adaptable as possible to the number and size of cables, pipes or openings. It should be so flexible that we would be able to have spare capacity.

3. Hard Cables To Handle

It is difficult, or almost impossible, to move and bend a large high-voltage or medium-voltage power cable into the desired position for routing through a deck or bulkhead. It takes a lot of time to reorganize the routing path in order to gain a couple of millimeters of bending radius.

What you need is a solution where you can position and apply a seal to fit around the cables, even if they are in an off-center position.

4. Tricky Design Work

Given the issues mentioned above, the work of design engineers often becomes a nightmare. We need to plan, calculate and design in cable and pipe penetrations at an early stage considering both rollout and maintenance. Sometimes, it means recalculating each opening.

Imagine a web-based design tool that we can use to design and redesign transits in no time.

5. Time-Consuming Installation

We know renewables can save the climate, and we know speed is crucial and time is money. Therefore, it is so frustrating to struggle with sealing solutions that are neither flexible nor easy to install. We cannot accept that project plans fail due to complicated installation work tasks. We should only engage suppliers of user-friendly products who will also train the installation team.

Roxtec provides offshore wind farms with an “all in one” solution for cable entry sealing, cable management and vibration damping. Standardise with Roxtec seals for efficient offshore windfarm cable protection design, quick roll-out and certified protection – cables are securely fixed, sealed and cable lifetime is extended.

Thorne & Derrick are Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable

LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

See how T&D support, supply and service the Renewable Energy industry.

Thorne & Derrick Welcome CSD Sealing Systems To Their Offices

February 21st, 2022

CSD Sealing Systems

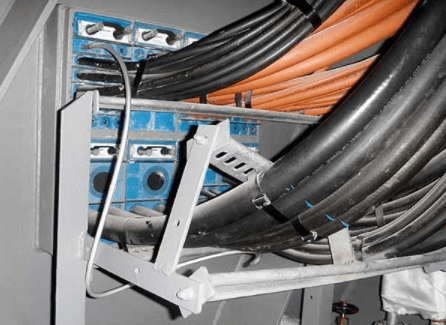

Last week, Thorne & Derrick welcomed Ian Joynson & Chris Thompson from CSD Sealing Systems to their offices for training and a live product demonstration of their market-leading NOFIRNO product – the NOFIRNO system is Type Approved for the harshest ratings for A, H and Jet Fire Class, and is also approved for watertight, gas-tight, blast and shock applications.

Thorne & Derrick are Approved Distributors for CSD Sealing Systems – we have specified and distributed their products across numerous onshore and offshore substation projects.

The half-day agenda covered developments and approvals within the UK DNO Utility sector, product conformance to ATEX Directive for hazardous areas and explosive atmosphere installations plus a round-up of our sales pipeline, current projects and future sales/marketing plans.

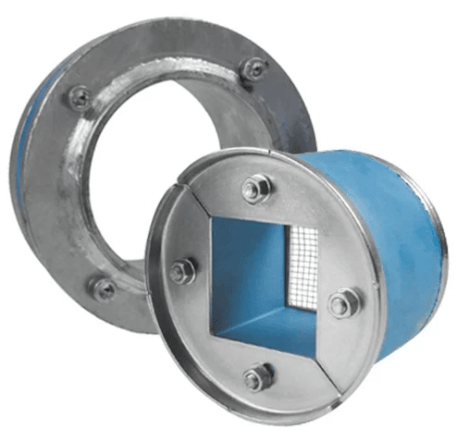

CSD are specialists in duct seals and sealing systems that protect against water ingress, gas escape and spread of fire through cable duct and service entries located in substation basements, cable vaults, switchrooms and access man-holes at low, medium and high voltage electricity distribution networks.

Our working relationship spans an impressive 16 years with both companies having a strong customer focus. Consultation and technical advice as well as installation training and support helps us to ensure the client not only receives the correct product for the application but that they can safely and successfully install it, without fail.

Live Product Demo of CSD Nofirno by Chris Thompson

The CSD product range is suitable for applications within the shipbuilding, offshore and onshore construction industries and is also widely used across the utility and nuclear industry. The systems can provide up to 4 hours of fire protection, will offer the highest levels of flood protection and gastight integrity and are proven to provide in excess of 50 years long term sealing protection.

CSD are the UK representative of Beele Engineering BV, a company with over 40 years’ experience in the development and production of penetration sealing systems. CSD work closely with many site operators helping to meet the requirements for protection against fire, flood and hazardous gas ingress to ensure assets and employers are fully protected.

Thorne & Derrick provide competitive prices and fast delivery from stock for the complete range of CSD duct seals – this includes CSD RISE, RISE RAPID, NOFIRNO, ACTIFOAM and SLIPSIL products.

Thank you for visiting our offices to educate the sales and marketing team on the development and production of the CSD duct seals and sealing systems range.

Ian Joynson UK Onshore Sales Manager Presneting The CSD Product Range To The Sales & Marketing Team

CSD Sealing System (UK) have specialised in the supply and installation of technically advanced cable transits, flexible pipe penetrations and RISE and Nofirno cable duct seals within the UK for over 25 years.

CSD are ISO9001:2015 certified and aim to provide the highest levels of service and support to our customers, assuring first class products and first class service whatever the industry.

Sealing Cables | Water Ingress, Gas Migration & Fire Spread

Thorne & Derrick

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

Cable and Pipe Transits For Naval Vessels

September 3rd, 2021

Cable Transits & Duct Seals

Increased Safety & Security

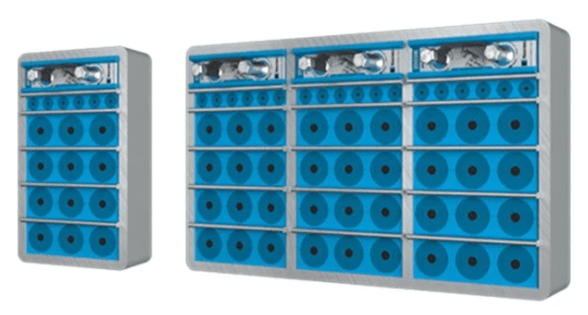

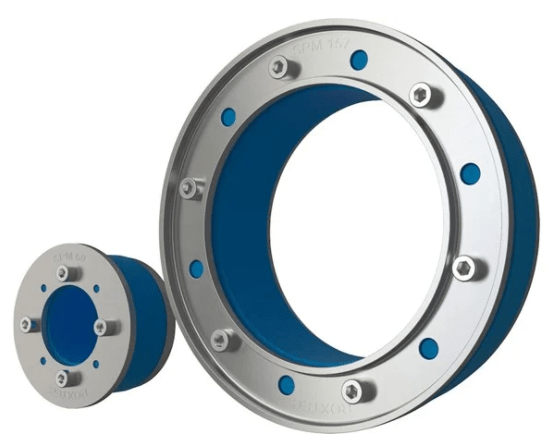

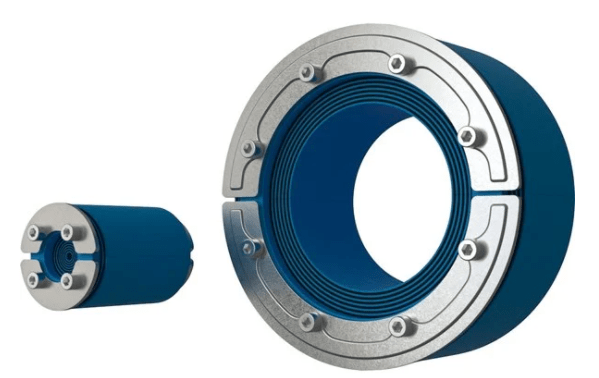

With world class cable transits protecting against multiple risks, you pave the way for maximum survivability. Cable transits and duct seals from Roxtec are your solution for safety, EMI/EMP protection and blast load resistance.

The vibration damping, the area efficiency and the light-weight nature of the pipe seals contribute to a more silent operation and more free space onboard. Roxtec solutions simplify everything – from planning to future upgrades.

Application areas

Explore the multitude of applications where you can benefit from Roxtec’s solutions.

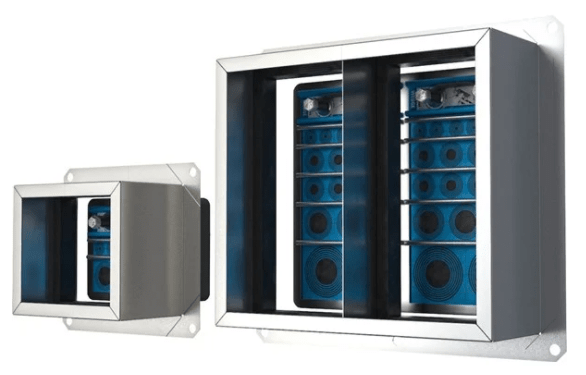

Cabinets & enclosures

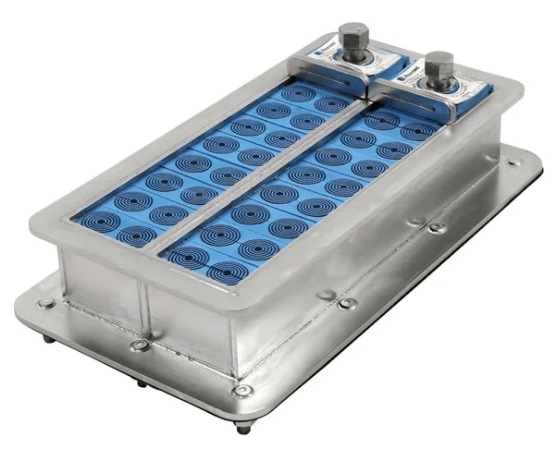

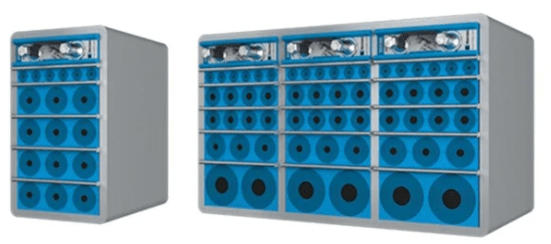

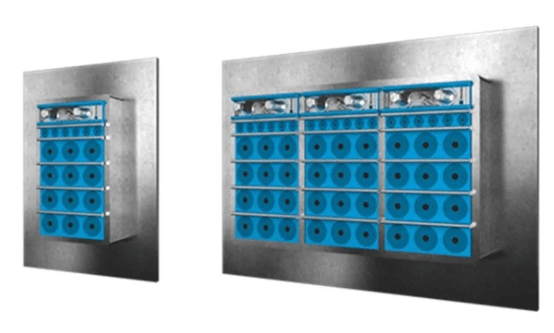

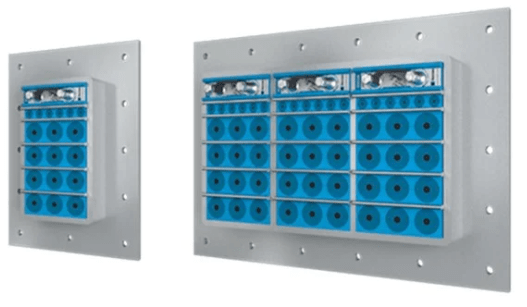

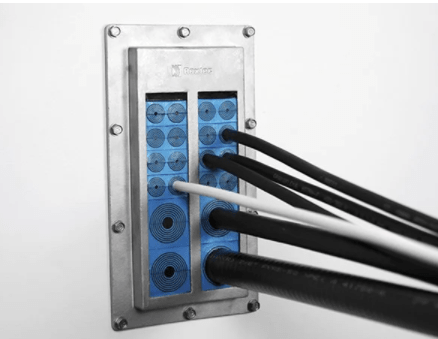

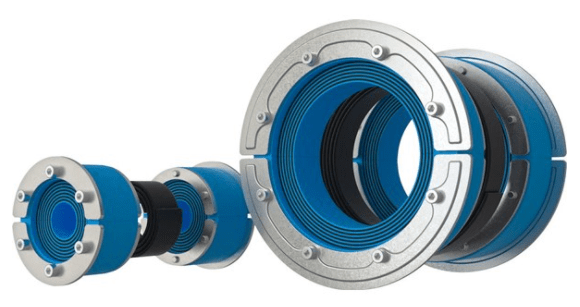

Roxtec CF 8/32 Transit

Roxtec multi-cable transits offer several additional customer benefits and can entirely replace cable glands. Use Roxtec’s compact, area efficient seals to ensure EMI/EMP protection and to be able to reduce the size of your cabinets, junction boxes and enclosures as well as to reduce engineering hours spent on cable data and cable gland configurations.

Why use Roxtec?

- Watertight

- Gas-tight

- Dust-tight

- One cut-out for dozens of pre-terminated cables which may vary in size

- Built-in spare capacity for upgrades and retrofits

- Solutions for armoured cables

- EMC solutions for electrical safety

- Ex solutions for hazardous locations

Recommended Sealing Solutions

| Description | Fire | Tightness | |

|

Roxtec S Transit Transit for welding to the structure. For welding into a precise aperture. |

A-CLASS H-CLASS |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec HD Transits High cable density transit device with frame in 316L. For harsh environments. |

N/A | IP66/IP67 UL/NEMA 4.4X, 12, 13 |

|

Roxtec HD Ex Transits High cable density transit devices for Ex environments with frame in 316L. |

N/A | IP66/IP67 UL/NEMA 4.4X, 12, 13 Ex e/ Ex tb |

|

Roxtec CF 8/32 Transit High cable density transit with aluminium frame |

N/A | IP66/IP67 UL/NEMA 4.4X, 12, 13 |

Command control room

Roxtec S Transit

Roxtec cable transits ensure electromagnetic shielding and protect equipment both inside, and around the command control room. Use Roxtec EMC solutions to secure data, communication and high-precision operation in order to improve survivability.

Why use Roxtec?

- EMI/EMP protection

- Watertight

- Firestop

- Gas-tight

- Dust-tight

- Blast load resistant

- Flexibility for cables of different sizes

- Built-in spare capacity for upgrades and retrofits

- EMC solutions for electrical safety

Recommended Cable & Pipe Sealing Solutions

| Description | Fire | Tightness | |

|

Roxtec S Transit Transit for welding to the structure. For welding into a precise aperture. |

A-CLASS H-CLASS |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec RS Seal Penetration seal for a single cable or pipe. For installation in existing sleeves or core drilled holes. |

A-CLASS H-CLASS EI 60 EI 120 UL 1479 |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec CF 8/32 Transit High cable density transit with aluminium frame. For high demand areas. |

N/A | IP66/IP67 UL/NEMA 4.4X, 12, 13 |

Communication area – Crypto & Sonar

Roxtec cable and pipe transits ensure electromagnetic shielding both inside, and around the sonar and crypto rooms. Use EMC solutions to protect equipment and create an internal barrier for sensitive information. Stop RFI, optimize communication security and ensure safety and survivability.

Roxtec RS Cable Transit Frame

Why use Roxtec?

- EMI/EMP protection

- Watertight

- Firestop

- Gas-tight

- Dust-tight

- Flexibility for cables and pipes of different sizes

- Built-in spare capacity for upgrades and retrofits

- EMC solutions for electrical safety

Recommended Cable & Pipe Sealing Solutions

| Description | Fire | Tightness | |

|

Roxtec S Transit Transit for welding to the structure. For welding into a precise aperture. |

A-CLASS H-CLASS |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec RS Seal Penetration seal for a single cable or pipe. For installation in existing sleeves or core drilled holes. |

A-CLASS H-CLASS EI 60 EI 120 UL 1479 |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec CF 8/32 Transit High cable density transit with aluminium frame. For high demand areas. |

N/A | IP66/IP67 UL/NEMA 4.4X, 12, 13 |

Engine room

Roxtec cable and pipe penetration seals are perfectly suited for large cables and pipes entering the engine room through decks and bulkheads. Use Roxtec transits to ensure the best possible protection for the heart of the ship.

Roxtec S Transit for Engine Rooms

Why use Roxtec?

- Watertight

- Gas-tight

- Firestop

- EMI/EMP protection

- One opening for dozens of cables and pipes

- Flexibility for cables and pipes of different sizes

- EMC solutions for electrical safety

| Description | Fire | Tightness | |

|

Roxtec S Transit Transit for welding to the structure. For welding into a precise aperture. |

A-CLASS H-CLASS |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec RS Seal Penetration seal for a single cable or pipe. For installation in existing sleeves or core drilled holes. |

A-CLASS H-CLASS EI 60 EI 120 UL 1479 |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

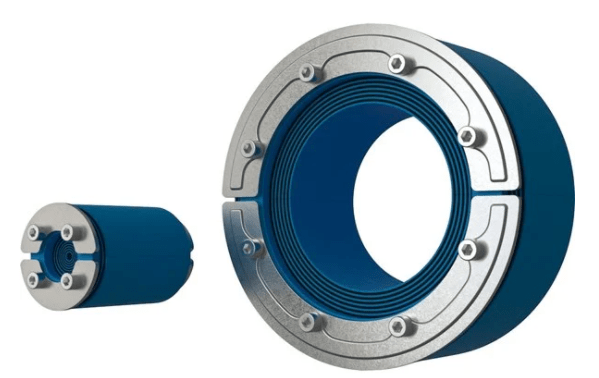

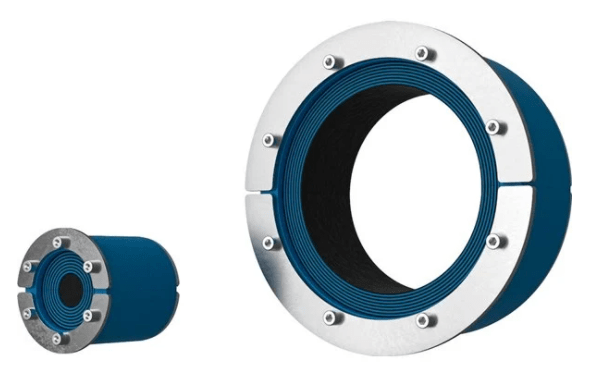

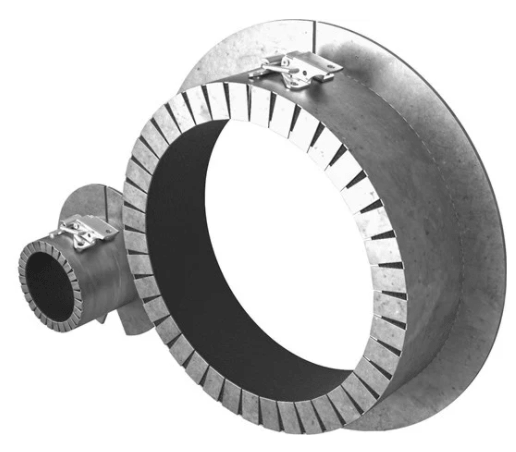

Roxtec R Transit Round transit for sealing around multiple cables and pipes in a limited area. For installation in existing sleeves. |

A-CLASS H-CLASS EI 60 EI 120 UL 1479 |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

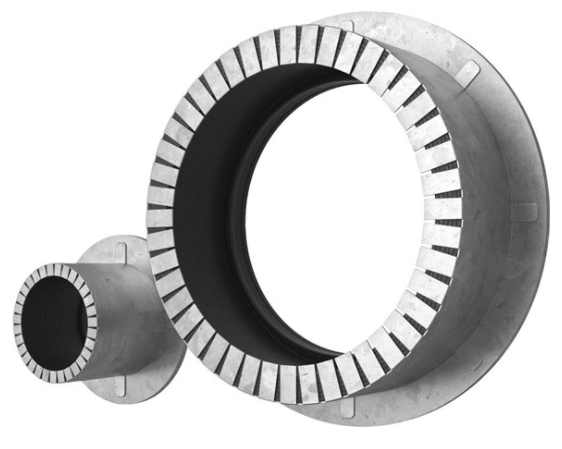

Roxtec R X Transit Transit for sealing around multiple cables and pipes in a limited are without welding or bolting. For attachment through expansion. |

A-CLASS | Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec CF 8/32 Transit High cable density transit with aluminium frame. For high demand areas. |

N/A | IP66/IP67 UL/NEMA 4.4X, 12, 13 |

|

Roxtec RS X Seal Transit for use when welding is not allowed, recommended or desired. For high pressure penetrations. |

A-CLASS | Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec SBTB Transit Transit with metal frame for an extra level of fire protection. For high fire demands. |

A-CLASS H-CLASS |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec SF Transit Cable and pipe transit with metal frame and flange for welding to the structure. For wide aperture tolerance when welding. |

A-CLASS H-CLASS UL 1479 |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec SFHM Transit with metal frame and flange for bolting to the structure. |

A-CLASS H-CLASS |

Water: 4 bar (catastrophic) |

|

Roxtec SRC r20 Transit Transit with metal frame for load-bearing structures. Corner radius 20mm. |

A-CLASS H-CLASS |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

Gas-tight areas

Roxtec seals are not only your solution for safety, they provide EMI/EMP protection and excellent blast load resistance. Additionally, the transits reduce vibration and are area efficient in order to allow more free space onboard.

Roxtec SBTB Transit for Gas-Tight Area

Why use Roxtec?

- Watertight

- Firestop

- Gas-tight

- Flexibility for cables and pipes of different sizes

- Built-in spare capacity for upgrades and retrofits

- Back-to-back solutions for increased protection

| Description | Fire | Tightness | |

|

Roxtec S Transit Transit for welding to the structure. For welding into a precise aperture. |

A-CLASS H-CLASS |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec RS Seal Penetration seal for a single cable or pipe. For installation in existing sleeves or core drilled holes. |

A-CLASS H-CLASS EI 60 EI 120 UL 1479 |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec R Transit Round transit for sealing around multiple cables and pipes in a limited area. For installation in existing sleeves. |

A-CLASS H-CLASS EI 60 EI 120 UL 1479 |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec SBTB Transit Transit with metal frame for an extra level of fire protection. For high fire demands. |

A-CLASS H-CLASS |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec SF Transit Cable and pipe transit with metal frame and flange for welding to the structure. For wide aperture tolerance when welding. |

A-CLASS H-CLASS UL 1479 |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

Hydraulic and compressed air systems

Roxtec’s round cable transits and rectangular penetration seals are ideal for single or multiple cables, pipes and tubes. Use Roxtec transits to ensure certified fire protection in A-0 to A-60 rated areas and maintain the ability to reopen the seals whenever you need.

Roxtec R Transit for Hydraulic & Compressed Air Systems

Why use Roxtec?

- Watertight

- Firestop

- Vibration damping

- Noise reduction

- One opening for dozens of cables and pipes

- Flexibility for cables and pipes of different sizes

- Ex solutions for hazardous locations

| Description | Fire | Tightness | |

|

Roxtec S Transit Transit for welding to the structure. For welding into a precise aperture. |

A-CLASS H-CLASS |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec RS Seal Penetration seal for a single cable or pipe. For installation in existing sleeves or core drilled holes. |

A-CLASS H-CLASS EI 60 EI 120 UL 1479 |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec R Transit Round transit for sealing around multiple cables and pipes in a limited area. For installation in existing sleeves. |

A-CLASS H-CLASS EI 60 EI 120 UL 1479 |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec R X Transit Transit for sealing around multiple cables and pipes in a limited area without welding or bolting. |

A-CLASS H-CLASS |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec RS OMD Seal Flexible transit with adaptable outside to fit non-standard sleeve sizes. |

A-CLASS H-CLASS UL 1479 |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec RS X Seal Transit for use when welding is not allowed, recommended or desired. For high pressure penetrations. |

A-CLASS | Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

Power Generators, Motors and Thrusters

Roxtec cable seals are perfect for large cables entering the engine room through decks and bulkheads. Use Roxtec transits to achieve well-organized pipe penetrations and cable entries both inside, and around machine areas and engine control rooms. Also, benefit from savings resulting from the reduced space requirements of cabinets and enclosures.

Roxtec ComSeal

Why use Roxtec?

- Watertight

- Firestop

- EMI protection

- Dust-tight

- One opening for dozens of cables

- Flexibility for cables and pipes of different sizes

- EMC solutions for electrical safety

| Description | Fire | Tightness | |

|

Roxtec CF 8/32 Transit High cable density transit with aluminium frame. For high demand areas. |

N/A | IP66/IP67 UL/NEMA 4.4X, 12, 13 |

|

Roxtec ComSeal IP55 rated entry seals with aluminium frame |

N/A | IP55 UL/NEMA 3, 12, 12K |

|

Roxtec C RS T Seal Round seal for single cable entries |

N/A | IP66/67 IP69K UL/NEMA 4, 4X, 12, 13 |

Water pipes

Regardless of your preferred pipe material, Roxtec has the sealing solution. Roxtec pipe seals are A-0 and A-60 approved for all metal and most plastic pipes.

Use them to ensure watertight deck and bulkhead penetrations, to avoid the risk of water spreading from any leaking pipes and to be able to reopen the transits whenever you need.

Roxtec RS Seal for Water Pipes

Why use Roxtec?

- Watertight

- Firestop

- Vibration damping

- Certified solution

- Easy and safe installation of pipes

- Can be used for fresh, chilled and waste water

| Description | Fire | Tightness | |

|

Roxtec S Transit Transit for welding to the structure. For welding into a precise aperture. |

A-CLASS H-CLASS |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec RS Seal Penetration seal for a single cable or pipe. For installation in existing sleeves or core drilled holes. |

A-CLASS H-CLASS EI 60 EI 120 UL 1479 |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec R X Transit Transit for sealing around multiple cables and pipes in a limited area without welding or bolting. |

A-CLASS H-CLASS |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec SPM Seal Seal for metal pipes for use when welding is not allowed, recommended or desired. Easy to install without welding. |

A-CLASS | Gas: 0.67 bar (catastrophic) Water: 1 bar (catastrophic) |

|

Roxtec RS OMD Seal Flexible transit with adaptable outside to fit non-standard sleeve sizes. |

A-CLASS H-CLASS UL 1479 |

Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec RS X Seal Transit for use when welding is not allowed, recommended or desired. For high pressure penetrations. |

A-CLASS | Gas: 2.67 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec RS PPS Penetration seal for large single plastic pipes. For installation in existing sleeve. |

A-CLASS | Gas: 2 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec S with SE PPS Transit for multiple plastic pipes. For welding into precise openings. |

A-CLASS | Gas: 2.5 bar (catastrophic) Water: 4 bar (catastrophic) |

|

Roxtec Sleev-it Fire Penetration Seal Fire penetration seal for single plastic pipes. For fire rated divisions. |

A-CLASS B-CLASS |

N/A |

|

Roxtec Sleev-it Waterproof Penetration Seal Penetration seal for plastic pipes for basic protection against fire, gas & water. Waterproof seal for exact/fixed pipe diameters. |

A-CLASS B-CLASS |

Water: 1 bar (catastrophic) |

Further Reading

- Flexible Cable Seals for Gas Insulated Substations

- Data Centres | Safely Sealing LV HV Cables & Electrical Equipment

- Roxtec Pipe & Cable Seals | Offshore & Onshore Windfarm Product Spotlight

- Sealing Cables & Pipes Using Roxtec | Battery Storage Applications

Cable Sealing Using Roxtec

Roxtec cable seals are used in cable vaults, duct banks, electrical substations, trenches and M&E building services protecting low, medium and high voltage power systems against numerous external risk factors:

- Fire – A60, H120 Class bulkhead sealing for offshore classification against jet-fire or spray and prevention of suffocating smoke spread

- Gas – ensure complete tightness against air and gas pressure or migration through cable ducts with DSEAR compliance

- Water – prevent flood and water penetration into substations and buildings – avoid humidity and partial discharge conditions

- Cables – withstand cable bending load in heavy power and high voltage cable seal applications

- Pressure – protect against catastrophic sudden or constant pressure

- Electrical – protect cables and electrical infrastructure against EMI, EMP and lightning strike effects

- Particles – control levels of of dirt, dust, chemical and fumigants from entering buildings, cable ducts and substations

- Blast – protect against vibration, shock-waves and the risk of explosion in industrial and hazardous area locations

Cable Transits – Sealing Cables & Pipes

Cable Transits

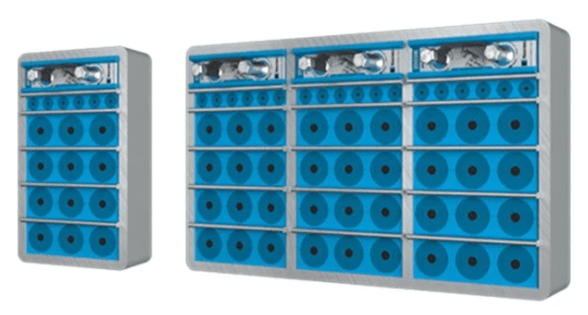

Roxtec cable transits are used to prevent water, gas, fire, dust and rodents from entering cable duct openings and potentially causing damage to cables and other electrical infrastructure.

Cable transit systems can be designed for sealing medium/high voltage substations including 11kV/33kV and “triplex” type cables in single, multiple or trefoil configuration.

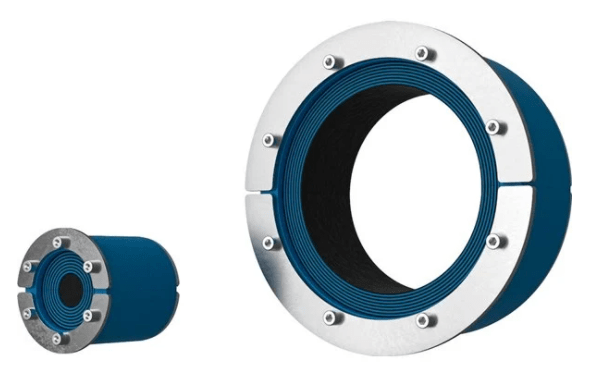

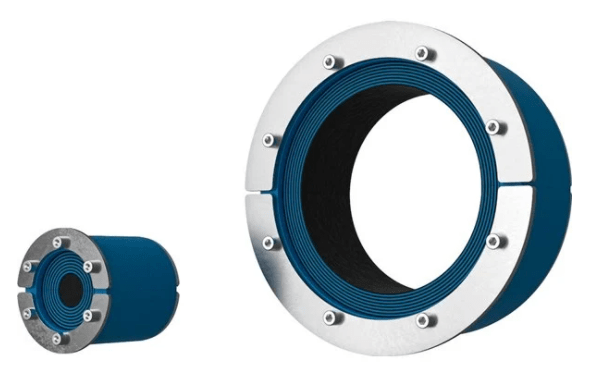

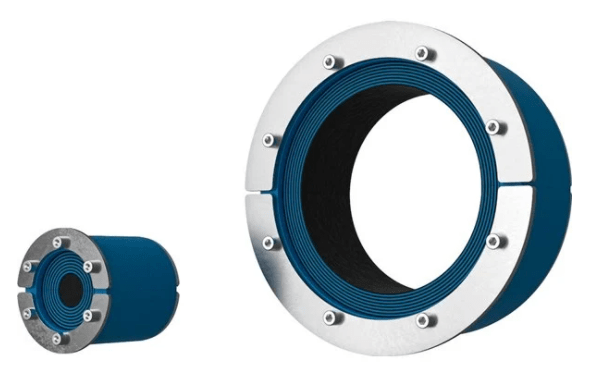

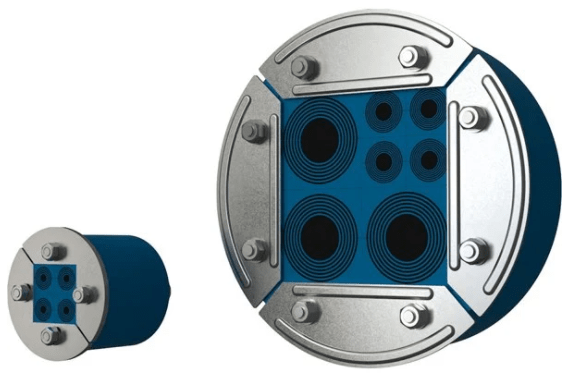

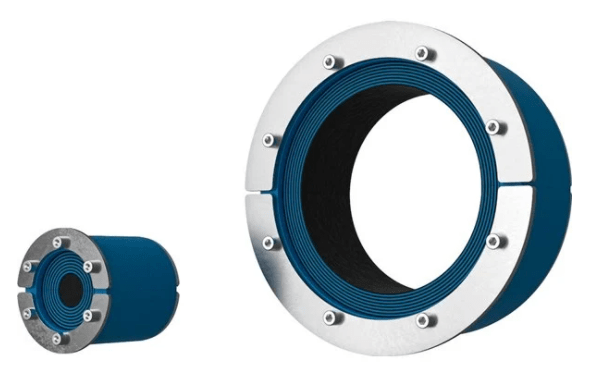

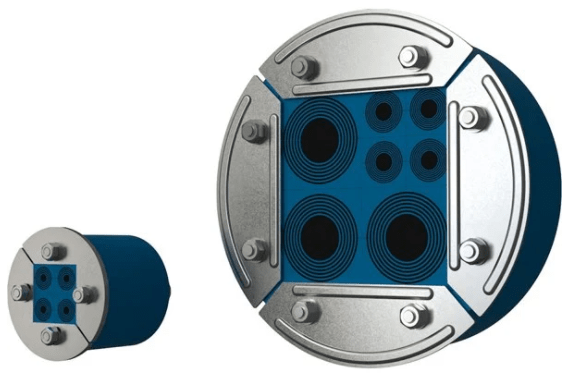

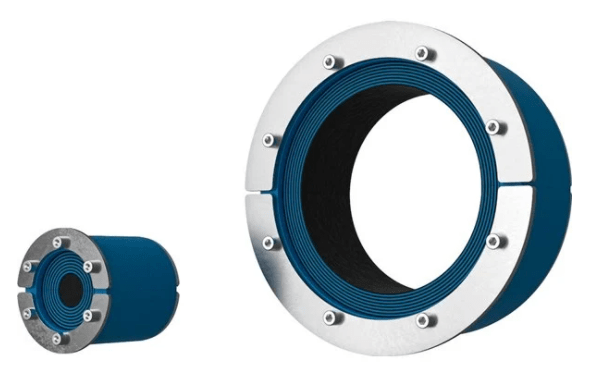

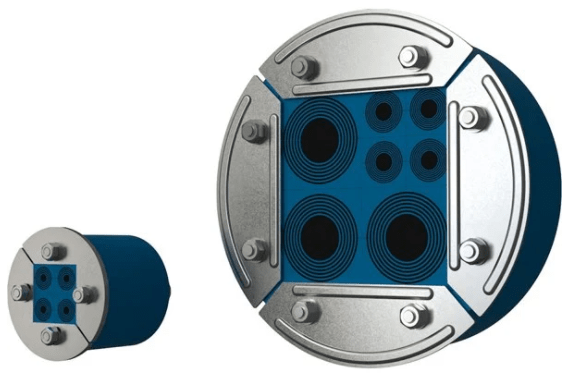

Roxtec modular cable transit seals are based upon a rubber design with seals that are constructed of a number of removable layers to secure a watertight, gas tight and fire proof seal around the cable or pipe – the range includes rectangular transits and round transits to fit a variety of pipes and cable sizes.

Cable transit products ensure safety, reliability and efficiency by providing an effective, dependable seal around cables and pipes through an opening, penetration or duct.

LV MV HV Jointing, Earthing, Substation & Electrical Eqpt

Nofirno Sealing System Successfully Tested for Use in Explosive Environments

July 13th, 2021

Nofirno

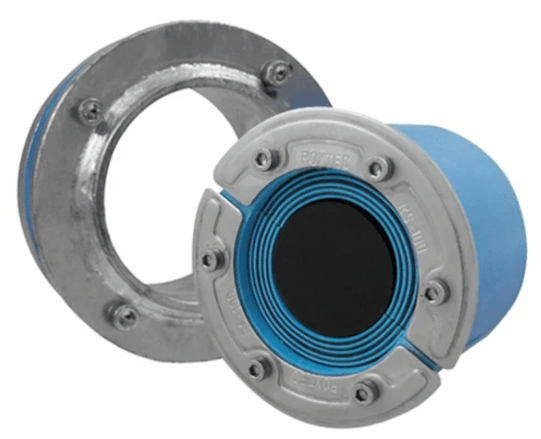

NOFIRNO systems are used to seal cable ducts in an extensive range of Process industry sectors including the fine and speciality chemicals, petrochemicals, pharmaceuticals, hydrogen and polymers manufacturing sectors. The NOFIRNO range of duct seals are used to protect against water ingress, gas migration, fire spread and rodent infestation into electrical substations and buildings through LV MV HV cable ducting systems.

ATEX directive requirements can be imposed for specific uses in hazardous area locations (Zone 1/2 Flammable Gas & Zone 21/22 Combustible Dust) where there is a potential risk of explosion. Kiwa has thus investigated the extent to which the NOFIRNO sealing system (from Beele Engineering) fulfils ATEX directive 2014/34/EU.

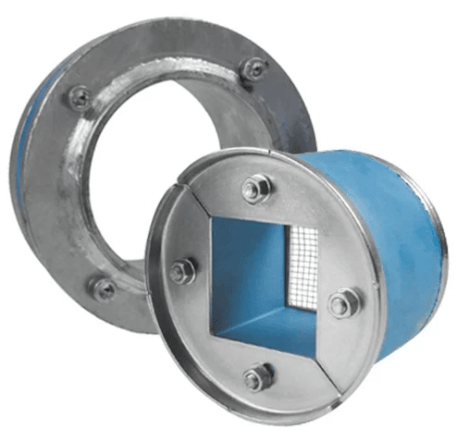

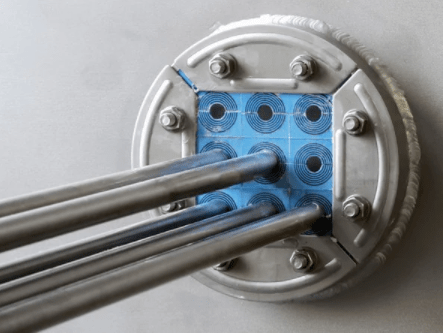

Comprised of rubber and filler sleeves and sealant, the system is used to treat transit openings for cables and pipes in walls, floors, bulkheads or decks, so that they are fire-resistant and sealed against gas, smoke and water. Kiwa’s research has shown that NOFIRNO is extremely suitable for use in environments such as those covered by the ATEX directive and described in the European standard EN 1127-1 ‘Explosive atmospheres – Explosion prevention and protection – Part 1: Basic concepts and methodology’.

Because the NOFIRNO sealant, NOFIRNO rubber sleeves and the complete NOFIRNO sealing system do not fulfil an autonomous role and are not equipment in the sense of the ATEX directive, the risk evaluation focused on use of the NOFIRNO in cable and pipe transits. All possible ignition sources related to the sealing system were also investigated.

Among the possible ignition sources which were assessed, were hot surfaces, flames and hot gases (including hot particles), mechanically-generated sparks, electrical equipment and power leakages, cathodic corrosion protection, static electricity, lightning, electromagnetic and ionising radiation, ultrasonic sound waves, adiabatic compression and shockwaves and exothermic reactions, including materials self-igniting.

Kiwa concluded that for all hazardous situations as described in EN 1127-1, there is no ignition source for NOFIRNO sealant, NOFIRNO rubber sleeves, NOFIRNO rubber filling sleeves and the complete, installed NOFIRNO system.

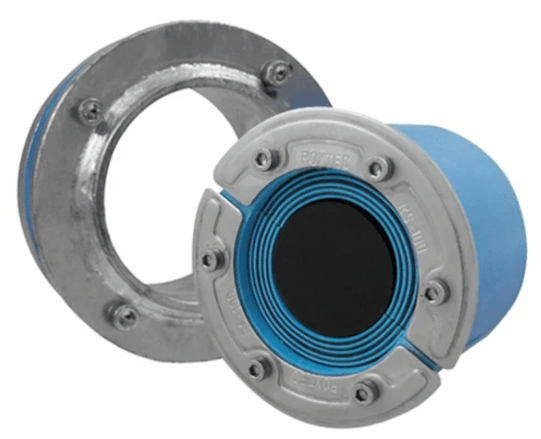

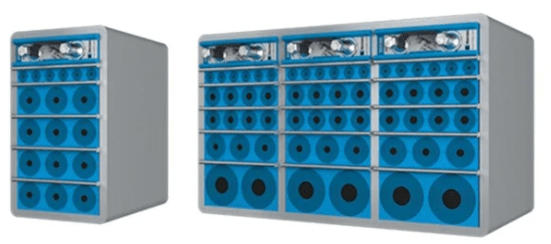

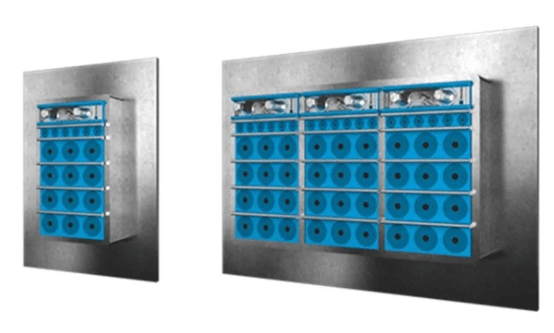

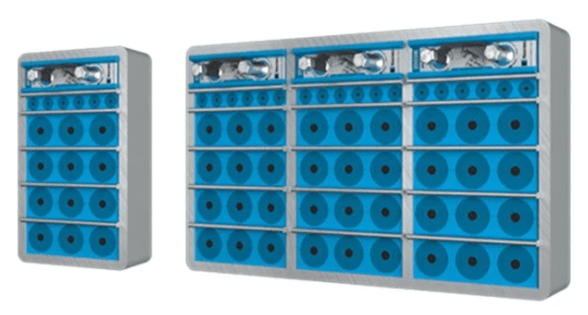

CSD NOFIRNO DUCT SEAL SYSTEM

Watertight, Gastight & Fire Protection & Sealing for Cables & Duct Entries

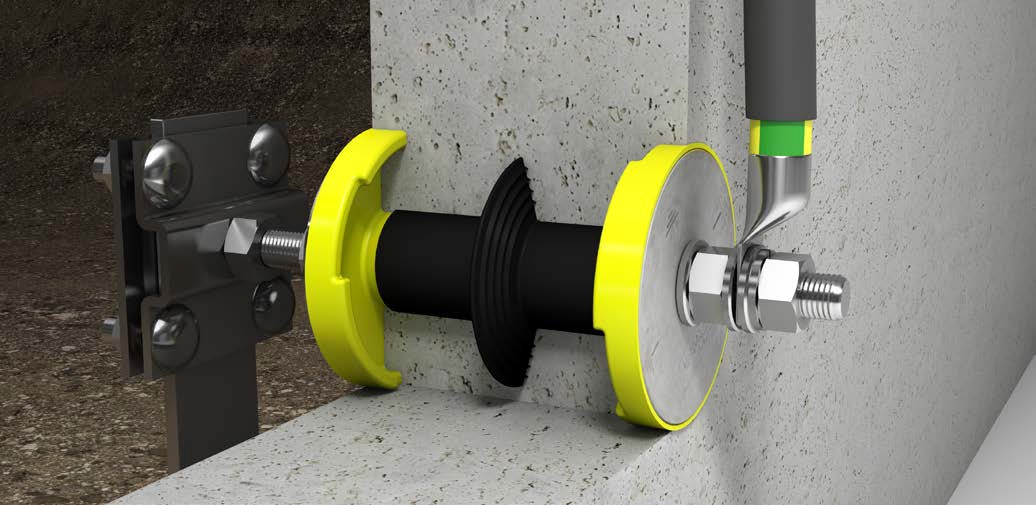

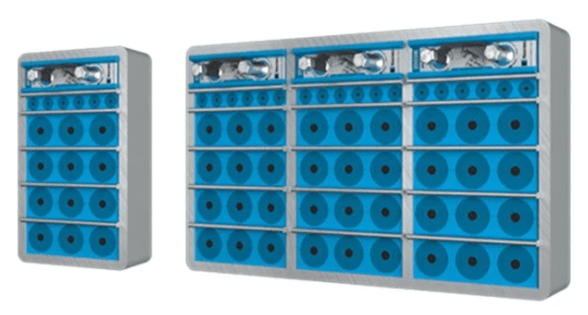

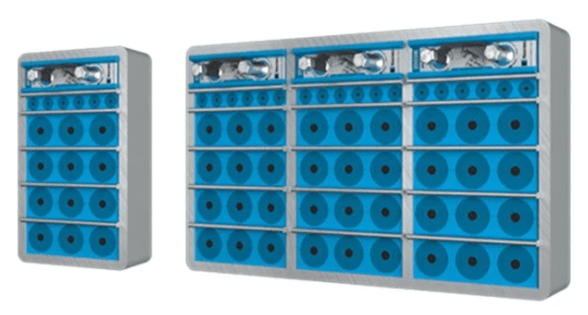

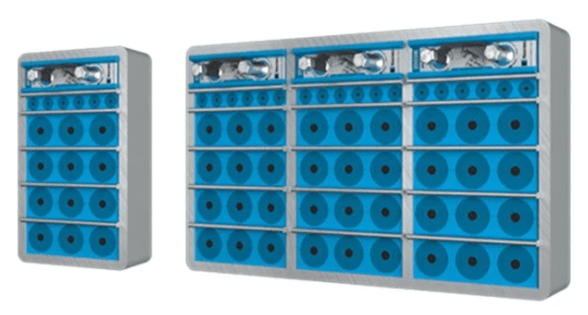

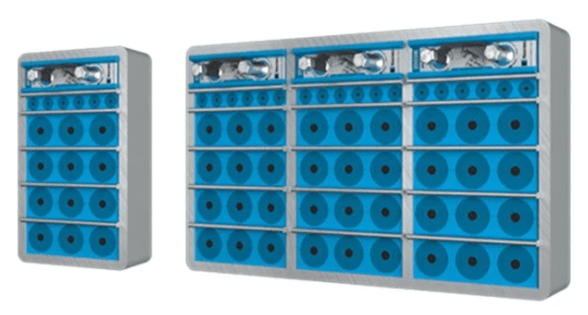

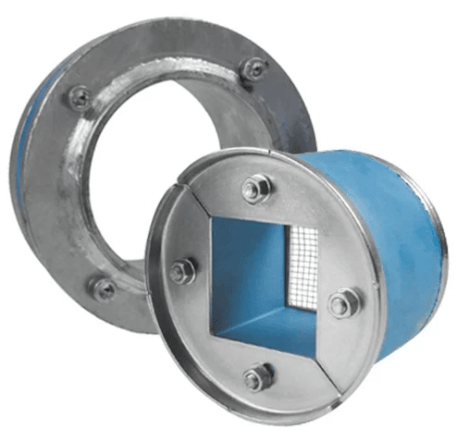

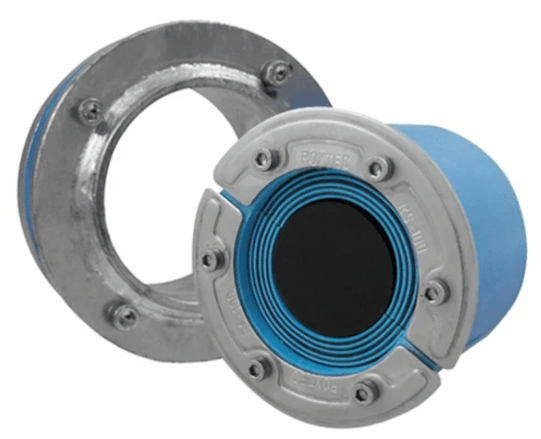

CSD NOFIRNO duct seals is a multi-cable and pipe transit sealing system designed specifically for cable duct seals and building entries providing an effective and simple solution protecting against flood water and gas ingress.

NOFIRNO duct seals consist of rubber multi sleeves which are in bonded strips of 10 sleeves and a high quality silicone based sealant which are quicker and easier to install than the CSD standard RISE duct seals.

The bonded sleeves can be easily torn off for filling smaller gaps and using cutting tool sleeves can be quickly slit to allow fitting around cables ensuring cable separation – NOFIRNO duct seals are also used to pack the free space, providing a backing for the application of the cable sealant.

Completing the seal with a 20mm layer of NOFIRNO sealant will provide a technically advanced and high performance duct seal. View the complete range of CSD Sealing Systems to protect against damage caused by water ingress, gas spread or fire/flame to cables and ducts.

Should you require any assistance with the safe and effective sealing of cables and pipe systems to ensure DSEAR | ATEX Regulatory Compliance please do not hesitate to contact Thorne & Derrick.

Duct Seals | Watertight | Gastight | Fire Resistant | Resist Rodents | Cables LV MV HV

Thorne & Derrick are Specialist Distributors to the Process Industries – we supply and support businesses working on the design, construction and maintenance of UK, European and international projects.

We can competently specify and competitively supply an extensive range of Hazardous Area Equipment (ATEX & IECEx) to provide Power, Heating & Lighting to the Explosive Atmospheres industries – this includes LV HV Cables, Accessories Jointing, Substation & Electrical Eqpt from 600V to 132kV.

Based in the UK, we are highly customer responsive and absolutely committed to providing a world-class service.

Since 1985, we have provided expert technical support and express delivery from extensive UK stocks to world-wide destinations.