Earthing

HV Cable Current Ratings For A Challenging Installation

May 23rd, 2022

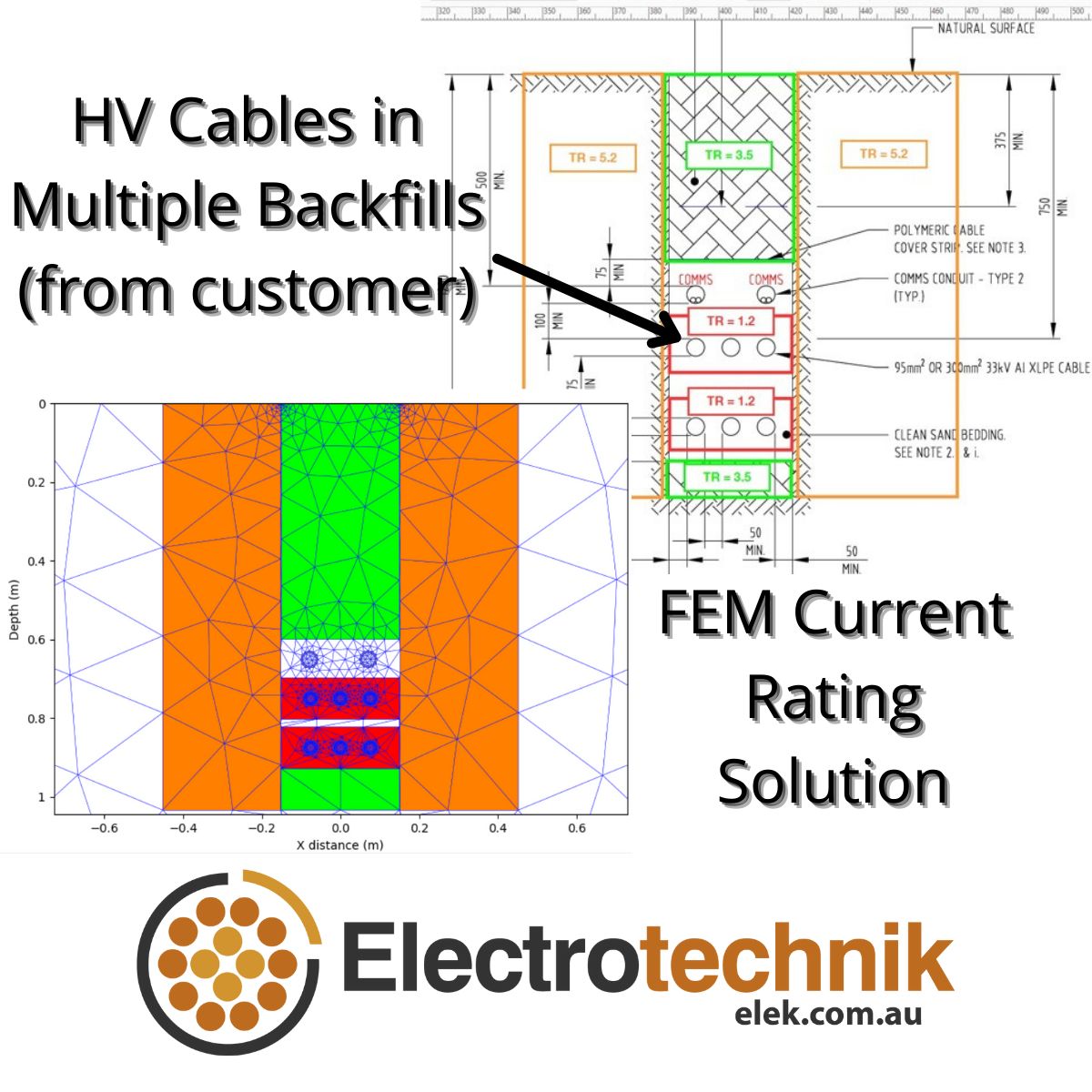

HV Cables in Multiple Backfills

HV Cable Current Ratings

FEM Current Rating Solution

The customer required HV cable current ratings for an installation involving multiple (6) zones of backfilled soil with Thermal Resistivity (TR) varying between 1.2 – 5.2 K.m/W plus the resistivity of the native soil needed to be considered.

The IEC Standard methods do not cover such a complex installation. The most IEC 60287 can deal with is a single backfill. The native soil thermal resistivity was 1.5 K.m/W which is lower than the backfill areas – the IEC Standard equations are invalid for this condition alone.

The Finite Element Method (FEM) was needed to accurately solving the heat flux distributions for this installation.

How does the FEM model work?

In FEM the space is subdivided into smaller parts known as finite elements using a technique called meshing. These elements take the shape of a tetrahedron or a triangle.

The domain of interest is space discretized and this discretization is implemented by constructing a mesh of the object. The formulation of finite element method results in a system of algebraic equations.

These equations that model the finite elements are then assembled into a larger system of equations that models the entire problem. The solution to the problem is reached by minimizing the mean squared error error function.

For the analysis of HV cables, it is assumed to be in a 2D space. The heat generated by the cable conductors is considered along with the ambient temperature. The FEM model creates the temperature array and a large set of equations are solved.

Another important consideration of the HV cable system which is modelled using FEM is the ground surface and ambient air temperature interface which involves heat convection – this aspect is neglected using the IEC method.

How much difference does FEM make?

The calculated current ratings of HV cables using FEM cannot even be compared with the (approximate) IEC Standard method because the standard method is not valid for this installation.

The current rating for the 11kV single core, 300sqmm copper conductor cables surrounded with 6 zones of soil with different resistivity as well as the native soil resistivity, soil ambient temperature of 25 deg.C. and soil/air interface was as follows:

FEM method = 283 A.

IEC method (uniform soil resistivity 5.2 K.m/W) = 201 A (-29 % underestimate).

IEC method (uniform soil resistivity 1.5 K.m/W) = 366 A (+29 % overestimate)

In conclusion, only using FEM will give an accurate calculation of HV cable current ratings for this complicated installation.

Jayson Patrick – Technical Director, Electrotechnik

![]()

Jayson is the Technical Director at Electrotechnik, a company which develops leading electrical power system design and analysis software and has extensive experience working on large-scale power systems projects in high voltage design, testing/commissioning, and power system analysis roles along with two decades of experience in professional software development.

Jayson has a master’s degree in electrical power engineering and is a professional software developer. He leads a multi-disciplinary team of developers, cloud architects, UI designers, electrical power engineers and PhD researchers. Jayson’s role at Electrotechnik involves developing new software and complex algorithms for electrical power systems design, where he is using a combination of technologies, multiple programming languages and Agile development practices.

Jayson has a passion for UI and UX design and believes in building powerful software which is accurate while being intuitive and easy to use.

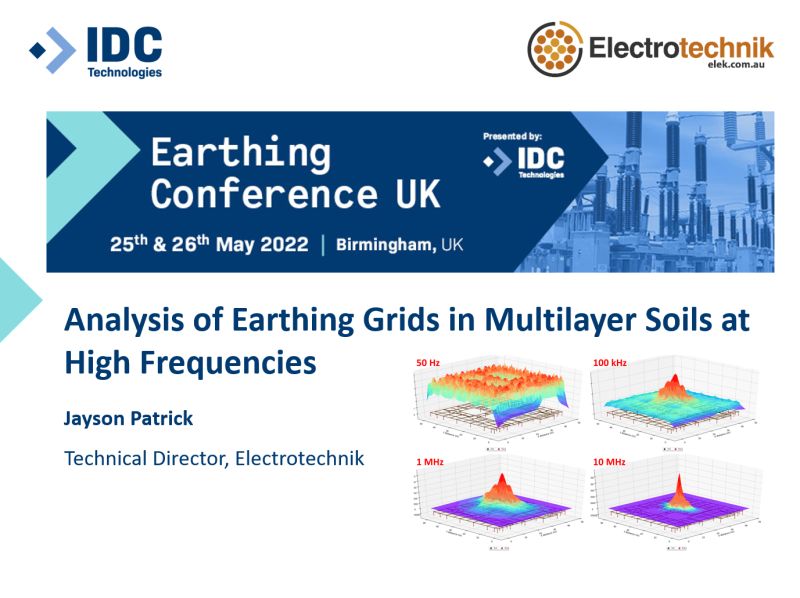

Jayson will be delivering a talk at Earthing Conference UK in Birmingham this month.

1:30pm – Day One

Analysis of Earthing Grids in Multilayer Soils at High Frequencies

Jayson Patrick – Technical Director, Electrotechnik

Modelling earthing system behaviour during both power frequency fault conditions and at high frequencies, especially related to lightning phenomena, is of interest to earthing system designers. The behaviour of earthing systems at varying frequencies is quite different and this paper will present details of the algorithm developed and results in the form of a parametric analysis for multiple grids in different soil conditions for high frequencies.

THORNE & DERRICK

T&D are Specialist Distributors to UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and HV Jointing Contractors of an extensive range of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt – this includes 11kV/33kV/66kV cable joints, terminations and connectors for both DNO and private network applications.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Surge Protection Devices | A Guide & Product Overview of Surge Protection Devices (SPD’s) with PADS Approval for Network Rail

June 30th, 2021

Surge Protection | with Network Rail PADS Approved Products

Surge Protection Introduction

Surges or Transients are short duration increases in voltage, measured between two or more conductors. These potentially harmful voltages can be induced into a building from various sources, from the direct and or secondary effects of lighting, to switching actions and equipment faults.

These events can generate thousands of volts across equipment leading to direct failure, undetected degradation and insulation faults leasing to premature failure.

An effective Surge Protective Device (SPD) should have a low let-through voltage, as this is the value of voltage that the protected equipment will be subjected to.

The lower the voltage the better the protection. the greater the voltage the higher the risk of distribution, degradation, damage to the equipment and the electrical network. As technology moves on, components within electronic equipment continue to become smaller and therefore more sensitive to these types of influences.

Surge Protection Device Definitions

Impulsive Discharge Current (for Type 1; Test Class I):

The maximum current of specified energy that a Type 1; Test Class 1 device must service during the type test.

Maximum Discharge Current; Imax:

The maximum current that a Type 2; Test Class II protective device will withstand.

Nominal Discharge Current (for Type 2; Test Class II):

In a measure of the longevity of a Surge Protective Device. It is determined by injecting multiple discharges into the SPD during its type test procedures. It is often specifies to be half of the maximum discharge current (Imax)

Voltage Protection Level / Let Through Voltage:

Is the maximum voltage across the Surge Protective Device terminals as a result of a specific discharge current. It is the maximum voltage that the equipment will see if it were positioned directly at the terminals.

Maximum Continuous Operating Voltage:

Is the maximum voltage that can be, safely, continuously applied to the terminals of the Surge Protective Device.

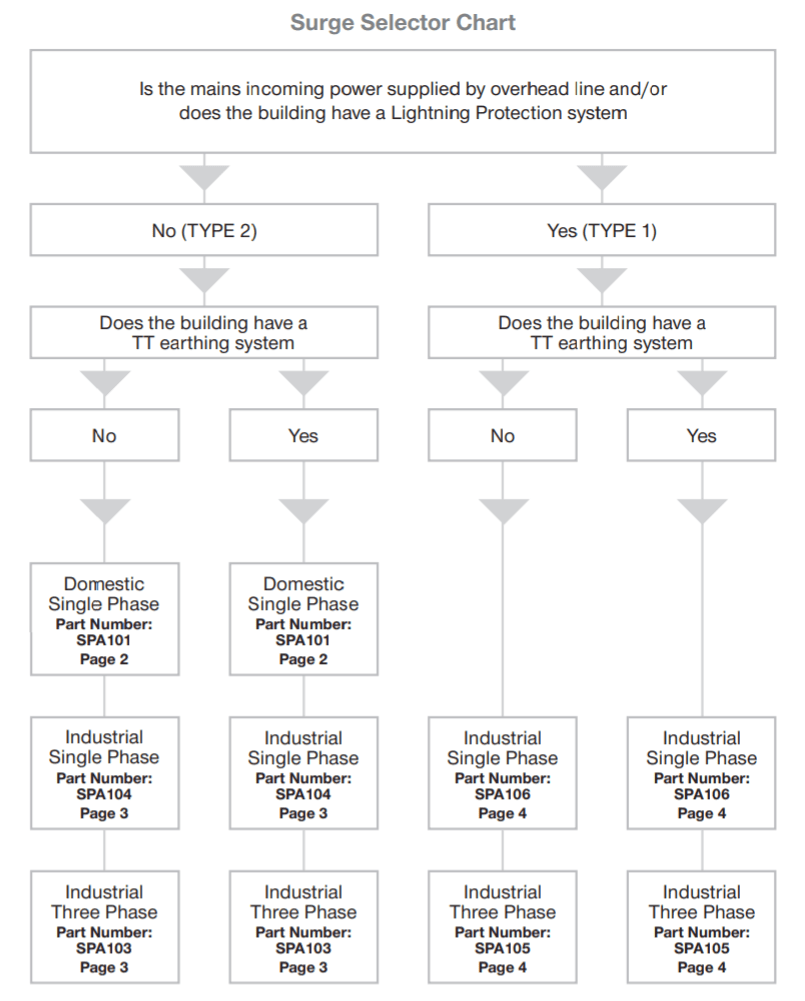

Surge Protective Device Types explained

Type 1 Surge Protection Devices (SPD’s)

A Type 1 SPD will deal with direct and proximity lightning strikes and have the highest energy discharge capacity. They are designed to survive in high stress environments, especially those at the incoming power supply. It is a requirement that they are installed where an External Lightning Protection System (Faraday cage) is fitted or the mains is fed from an Overhead Power Cable. The Type 1 should be accompanied by downstream Type 2 Surge Protective Devices.

Type 2 Surge Protection Devices (SPD’s)

A Type 2 SPD will deal with indirect Lightning strikes and the effects of surges locally generated from the numerous switching events within an installation. They are designed for the use in distribution boards located downstream of type 1 Surge Protective Devices or in the incoming power supply panel / consumer unit where an External Lightning Protection System is not fitted and the mains is fed by an underground cable.

Type 3 Surge Protection Devices (SPD’s)

A Type 3 SPD is designed to provide the lowest protection level to meet the voltage withstand of the equipment supplied from the final distribution panel. The SPD may also be of a design such that it can be placed or connected directly to the critical equipment.

PADS Approved Products

AN Wallis currently have a range of products with PADS approval for use in the rail industry, including products from the RTM series (Rail Track-Side Module), the SSI series (Solid State Interlocking) and the CRTM series:

- DSP1A/SSI/120

- DSP1A/SSI/140

- RTM150/650

- RTM12/110

- RTM12/140

- CRTM150/650

Thorne & Derrick distribute full range of AN Wallis Earthing Products | Bars | Rods | Tapes | Conductors | Clamps

RAIL CABLE ACCESSORIES, ELECTRIFICATION

& INSTALLATION EQUIPMENT

Thorne & Derrick stock and distribute an extensive range of 400V-33kV Rail Cable Accessories & Power Distribution Systems including feeder pillars to contractors undertaking Low Voltage Power Distribution, HV Electrification & Substations, DC Traction & Networks, OLE and Track Feeder Cable Renewals – complete range of Network Rail PADS approved track terminations, cable joints, cable repair and connection products up to 25kV, including 3M Cold Shrink, Pfisterer CONNEX and Nexans Euromold products.

Cable Joints, Terminations & Connections | Distributors & Stockists for 3M Cold Shrink | Nexans Euromold | Pfisterer CONNEX

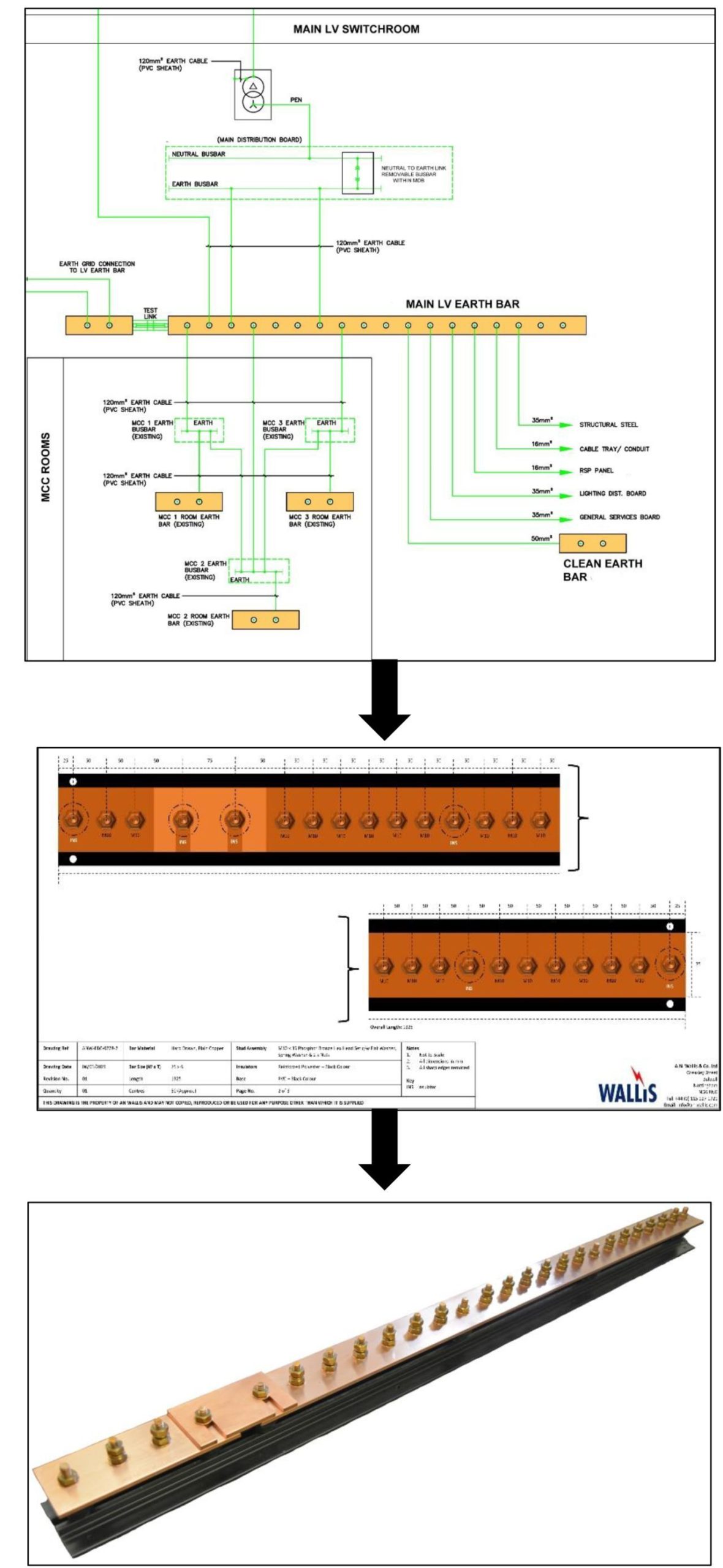

Earth Bars | High Specification Copper Earth Bars for Lightning Protection Systems

June 15th, 2021

Manufactured by AN Wallis | Distributed by Thorne & Derrick

Earth Bars

-

uploaded by Chris Dodds | Thorne & Derrick Sales + Marketing Manager

Copper Earth Bars for Lightning Protection Systems

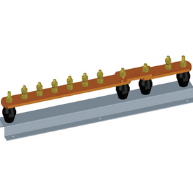

Earth bars are an integral part of an Electrical oBuilding Services or Substation technical specification for earthing and bonding; they provide a convenient common earth point for the infrastructure. It is critical copper earth bars provide long lasting, high quality earthing capable of enduring any potential dangerous fault currents.

Main earthing bars provide a recognised earth connection/ reference point and allow the local substation earth resistance to be measured using a clamp meter.

Thorne & Derrick and AN Wallis are aware of the crucial role of an Earth Bar which is why they manufacture high quality, affordable earth bars that are designed and tested to all relevant standards – manufactured from hard drawn copper bar to BS EN 13601 and tested to BS EN 62561-1 Class H.

- Earthing bars can be tinned and bases powder coated to improve corrosion resistance

- Bars are pre-drilled with cable connection holes with optional threads for installation ease

- Manufactured from highest conductivity and quality copper to British Standards

- Full range of standard, single and twin link types for LV, MV & HV switchroom/substations

- Customised to suit the earthing requirements of your project on short lead times

Customer Service

From Earthing Schematic to Earth Bar Drawing to Custom Manufactured Product.

Thorne & Derrick, UK Distributor for AN Wallis, can produce Earth Bar drawings directly from your Earthing schematic, this gives our customers a clear visual representation of the product that we can offer. This drawing can be approved (or amended) by the customer prior to us beginning the manufacturing process. This unique service ensures that the product quoted is the correct product and specification required by the customer avoiding any confusion or potential delays prior to manufacturing.

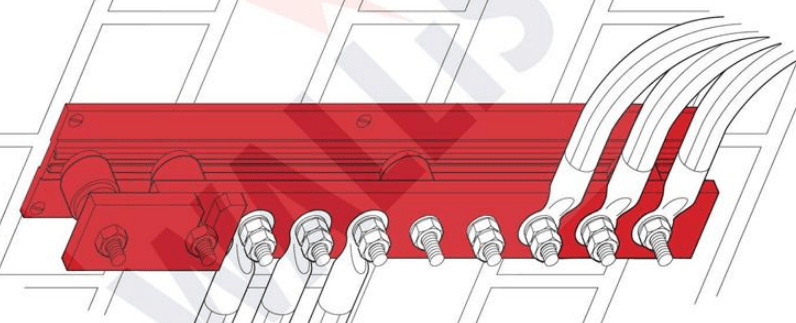

Thorne & Derrick distribute an extensive range of standard and customised special earth bars – here are the basic specification and selection factors:

- Type – Standard | Single | Twin | Multiple Links

- Termination Configuration – i.e. 1 Way + Link + 6 Way + Link + 3 Way

- Copper Bar Sizes – 50mm x 6mm Standard | or Custom Specification

- Copper Bar Finish – Bare (Standard) or Tinned Copper

- Cable Lug Termination Size – M6 | M8 | M10 Standard | M12 | Other

- Termination Material – Phosphor Bronze (Standard) | Brass | Stainless Steel

- Termination Spacings – 50mm Standard | Custom Specification

- Length Restrictions – Yes | No | Specify

- Base Material – PVC Standard | AVG Galvanised Steel | None

You can contact us with your enquiry.

Customised Earth Bars

➡ Some recent examples of custom manufactured products to client specifications.

| 6 Way + Link + 1 Way Tinned Copper Earth Bar, Stainless Steel Bolts, Mounted on Insulators & Black PVC Base. |  |

| 6 Way + Link + 1 Way Plain Copper Earth Bar, Brass Bolts, Mounted on Insulators & AVG Galv. Steel Base. |  |

| 6 Way + Link Plain Copper Earth Bar, Phosphor Bronze Bolts, Mounted on Insulators & Black PVC Base. |  |

| 16 Way + Link + 2 Way Plain Copper Earth Bar, Brass Bolts, Mounted on Insulators & AVG Galv. Steel Base. |  |

| Telecommunications Earth Bar. |  |

| 24 Way Special Earth Bar (2 Rows of 12 No. for Double Holed Lugs), 100x6mm Plain Copper Bar, M10 Brass Bolts, Mounted on Insulators & AVG Galv. Steel Base. |  |

| 10 Hole Earth Bar, 50x6mm Plain Copper Bar, No Bolts, Mounted on Insulators & AVG Galv. Steel Base Feet. |  |

| 5 Way + Link + 3 Way Earth Bar, 50x6mm Plain Copper Bar, M10 Phosphor Bronze Bolts, Mounted on Insulators & Black PVC Base. |  |

| 1 Way + Link + 1 Way Tinned Earth Bar, 50x6mm Tinned Copper Bar, M10 Brass Bolts, Mounted on Insulators & AVG Galv. Steel Base. |  |

1. 20 Way Staggered Earth Bar, 50x6mm Plain Copper Bar, M6 Phosphor Bronze Bolts, Mounted on Insulators & Black PVC Base. 2. 16 Way Staggered Earth Bar, 50x6mm Plain Copper Bar, M6 Phosphor Bronze Bolts, Mounted on Insulators & Black PVC Base. 3. 10 Way Earth Bar, 50x6mm Plain Copper Bar, M6 Phosphor Bronze Bolts, Mounted on Insulators & Black PVC Base.

10 Way + Link + 1 Way Earth Bar, 25x3mm Plain Copper Bar, M10 Phosphor Bronze Bolts, Mounted on Insulators & Black PVC Base

Copper Earth Bar Features

50mm Centres

- Standard 50mm hole centres will accommodate most earthing cable sizes

- Earth bar can be manufactured with different size hole centres

BS EN 62561-1 Class H

- Tested to BS EN 62561-1: Lightning Protection System Components (LPSC) – Part 1: Requirements for connection components

- Class H – Heavy Duty

Rounded Copper Edges

- Safer

- Easier to handle

- No sharp edges

PVC Base

- Entirely corrosion proof

- Lightweight earth bars

- High impact

- Can offer galvnised base as an alternative

PB Connection Points

- Phosphor bronze bolts, nuts, flat and spring washer

- Not Brass

- PB has better conductivity and better corrosion properties for corrosive atmospheres

BS 7430

- Designed and manufactured in accordance with BS7430 : Code of practice for protective earthing of electrical installations

AN Wallis

“I have worked with Thorne & Derrick throughout my 20 year career in the Earthing & Lightning Protection industry – we have worked closely together on multiple major UK and international projects.

“We are now working together again, using the historical AN Wallis brand and our high quality earthing products coupled with the incredible Thorne & Derrick customer service, sales and marketing abilities and their exceptional digital content to bring the focus to AN Wallis so that it is the only name thought of when requiring Earthing materials / Lightning Protection products”

- Jason Leatherland, AN Wallis Business Development Manager – Wholesale & Distribution

Earthing Bars | Standard, Single & Twin Links | Manufactured from Copper by AN Wallis

FURTHER READING

- Earth Tape – The Manufacture of Copper Earthing Tapes

- High Voltage Earthing & Grounding System Design Protecting Lives

- Copper Earthing Tape & Rods Protecting 33kV Substation & Transformer Bund

- Substation Earthing

Thorne & Derrick

Thorne & Derrick distribute the most extensive range of Low & High Voltage Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors.

We service UK and international clients working on underground and subsea cables, overhead lines, substations and electrical construction at LV, 11kV/33kV up to EHV transmission and distribution voltages.

Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

Distributors for: 3M Electrical, ABB, Alroc, Band-It, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, ProGARM, Prysmian, and Roxtec.

- Scope –single-source supply of extensive range of products

- Stock – a multi-million pound stock holding provides complete global supply solutions

- Staff – technical support from a trained, proactive and friendly team

- Delivery – UK stock turnaround with express logistics to all international destinations

Specialist Electrical Equipment Distributors for High Voltage Power Systems

Copper Brazing of Earth Tapes for 33kV Transformer & Substation Earthing Protection

May 4th, 2021

Thorne & Derrick International, based in the UK, are specialist distributors and stockists of Copper Earthing Products – technical support services include LV MV HV earthing system designs for electrical power systems and substations.

Contact us for the competitive supply of earthing products from extensive UK stocks for national and overseas delivery.

We support the following sectors:

- Electricity Transmission & Distribution Network Operators

- Electricity Generation, Power Stations & Overhead Line Towers

- Medium Voltage Substations 11kV 33kV

- High Voltage Substations 66kV 132kV

- Rail Traction Substations 25kV

- Renewable Power (Solar & Wind Energy Earthing Systems)

- Oil, Gas & Petrochemical Production Systems

- Telecommunications

- Data Centres Earthing & Lightning Protection

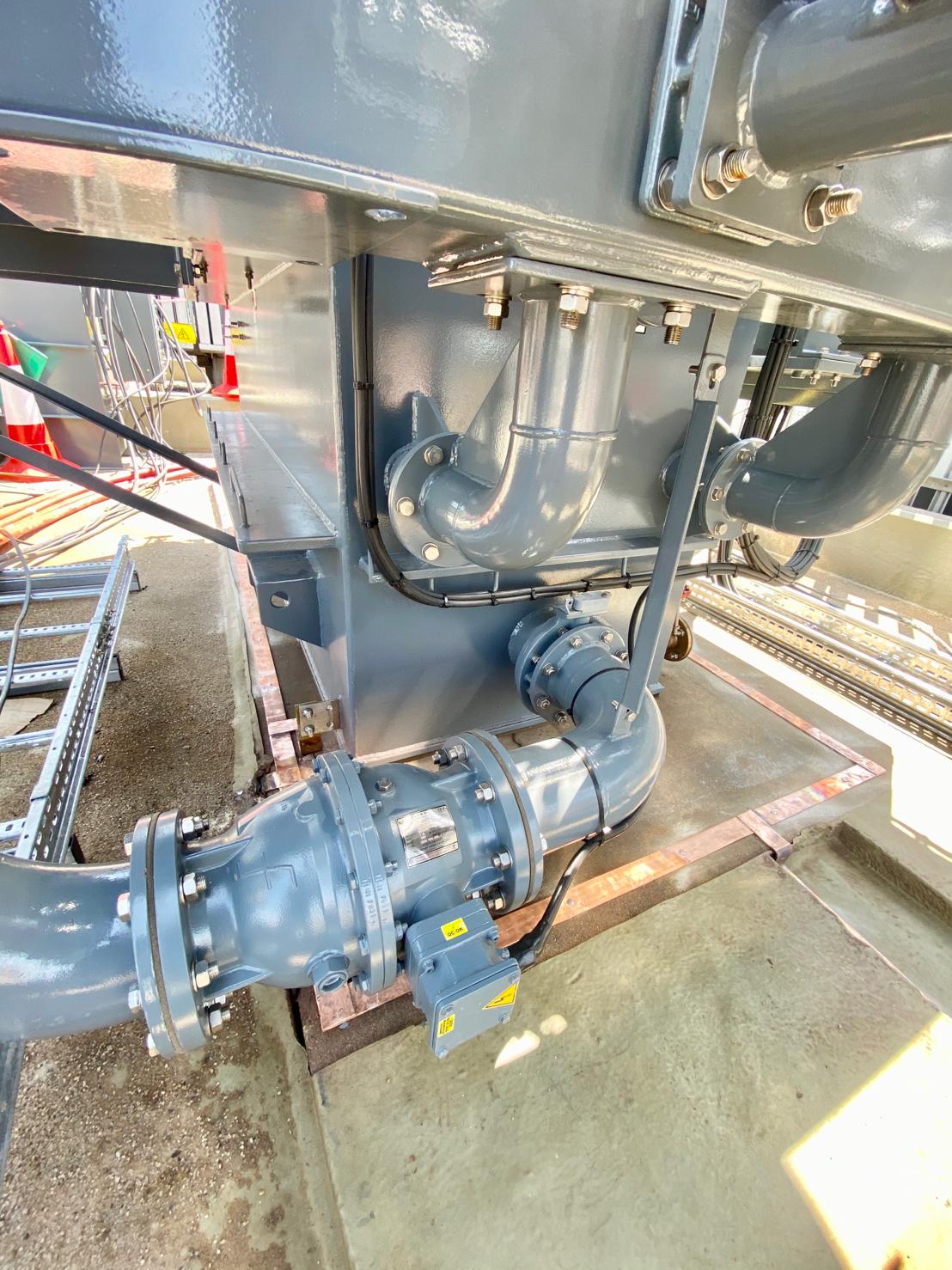

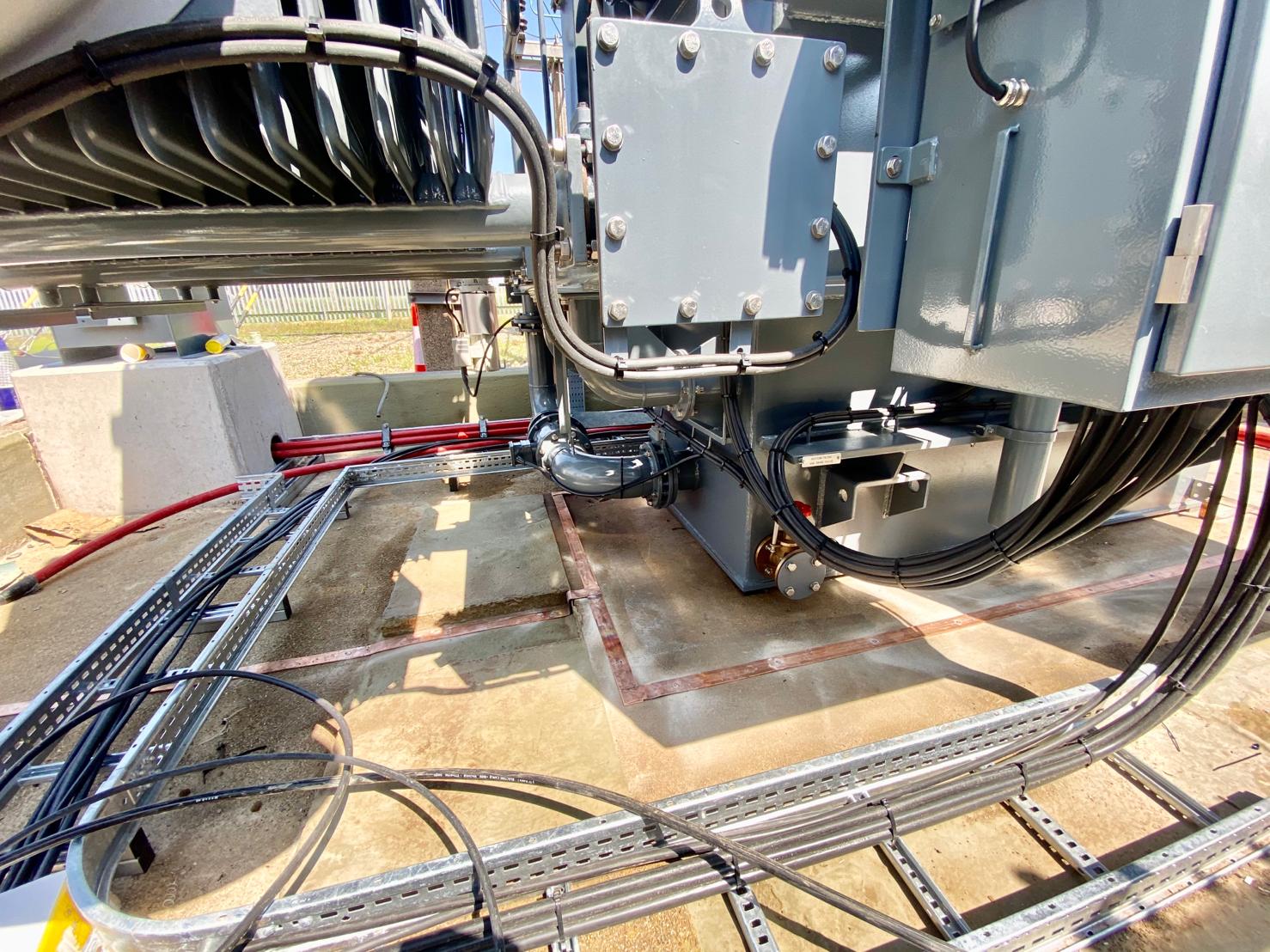

Images courtesy of: Harvey Ross – Mechanical Fitter at IDEC Technical Services

Pictured: Copper Brazing of Earth Tapes for 33kV Transformer & Substation Earthing Protection as well as installation of surge arrestors with high frequency earths in Bristol, UK. The earth bars and clamps were installed at a later date.

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Earthing & Electrical Equipment – we service UK and global businesses involved in cable installations, substation, overhead line and the installation of medium/high voltage cable joints and terminations at LV, 11kV, 33kV and HV.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

50 x 6mm Copper Earth Tapes for Transformer & Neutral Earthing Resistor (NER)

May 4th, 2021Thorne & Derrick International, based in the UK, are Specialist Distributors and Stockists of Copper Earthing Products – technical support services include LV MV HV earthing systems designs for electrical power systems and substations.

Contact us for the competitive supply of earthing products from extensive UK stocks for national and overseas delivery.

We support the following sectors:

- Electricity Transmission & Distribution Network Operators

- Electricity Generation, Power Stations & Overhead Line Towers

- Medium Voltage Substations 11kV 33kV

- High Voltage Substations 66kV 132kV

- Rail Traction Substations 25kV

- Renewable Power (Solar & Wind Energy Earthing Systems)

- Oil, Gas & Petrochemical Production Systems

- Telecommunications

- Data Centres Earthing & Lightning Protection

Images courtesy of: Harvey Ross – Mechanical Fitter at IDEC Technical Services

Pictured: 50 x 6mm Copper Earth Tapes for Transformer & Neutral Earthing Resistor (NER)

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Earthing & Electrical Equipment – we service UK and global businesses involved in cable installations, substation, overhead line and the installation of medium/high voltage cable joints and terminations at LV, 11kV, 33kV and HV.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.