Electrical Safety

Insulated Tools | IEC60900 v VDE Tool Types for Live Working at Low Voltage

March 23rd, 2023

Insulated tools complying with IEC EN 60900

Types of Insulating Tools, IEC 60900 vs VDE, Tool Care Information

Insulated and insulating hand tools are used for live working and work near live parts, with voltage ratings up to 1000V AC and 1500V DC. CATU Insulated tools comply with the international standard IEC 60900.

They are identified by the mark: 1000V (Double Triangle) IEC EN 60900

The CATU Electrical range of insulated tools comply with IEC 60900 standards, and are used by cable jointers and electrical engineers for live working and jointing cables up to 1000 volts. Available from Thorne & Derrick.

INSULATED and Insulating HAND TOOLS

Insulated hand tools are classified into 3 categories :

INSULATED HAND TOOLS

Hand tools made of conductive material(s) fully or partially covered by insulating material. Fully insulated tools covered with insulating materials with the exception of conductive parts on the working surface reduce the risk of short circuiting between two parts at different potentials.

INSULATING HAND TOOLS

Hand tools made totally or essentially from insulating material(s) except for inserts made from conductive materials used for reinforcement, but with no exposed conductive point. Insulating tools can have several working heads, and are used to protect the user from electric shocks and minimize the risk of short circuiting between two parts at different potentials.

HYBRID HAND TOOLS

Hand tools made from insulating material(s) with exposed conductive parts at the working head (e-g : cutting edges) (some non exposed conductive part can be used for reinforcement).

HYBRID tools can have several working heads. They protect the user against electric shocks and reduce the risk of short circuiting between two parts at different potentials.

For this category of hand tools, this catalogue uses the term «hybrid» in conformity with the draft of edition 4 of the NF EN IEC 60900 standard.

What is the difference between VDE and IEC 60900 Standard?

Insulated Tools from CATU

VDE is a German institute that certifies tools against the European IEC 60900 Standard.

Under this standard, the statement of conformity issued by a manufacturer stating compliance with the norm is sufficient, and hence it is not mandatory to certify the tools by an independent body. The VDE certification therefore offers those who require a higher degree of confidence, a third party verification of the compliance. However, VDE is not the only third party certification available in the market, and there isn´t such a thing as a VDE norm or certificate for tools.

What VDE certifies, like any other third party independent body does, is that the tools comply with the IEC 60900 norm and that the manufacturer has the required capabilities and means to manufacture and test de tools against the requirements of the standard. As a result, it is common that manufacturers only certify a few references (i.e. few sizes in each product category) and not all the references. Once the independent body certifies a specific size, all other sizes within that product category can also be considered as safe as the ones VDE certified, considering that that they would be manufactured following the same process, tested with the same test equipment and backed by the Statement of Conformity of the manufacturer.

Insulated Tool Care

Only use tools that are marked with the official international 1000-volt rating double triangle symbol shown above, if there is any chance that the tools will make contact with a live electrical source.

Electrical Safety Equipment | Insulating Matting | Voltage Detectors | Substation Kits | Phase Comparators

Visual inspection

Perform a visual inspection on your insulated tools each time you plan to use them. If any cracks, nicks or other damage to the outer orange layer is visible, don’t use the tool.

Beware of temperature

Only use insulated tools in areas whose ambient temperatures are compatible with the manufacturer’s specifications. All of our tools are carefully manufactured to be extremely resilient, but it’s still a good idea to check beforehand. Always keep tools away from heat sources as this will cause damage.

Beware of non insulated parts

Don’t touch any parts of the tool that are not insulated as these parts could come into contact with an energised source and you will be at risk of electrical shock.

Keep away from sharp objects

Ensure you keep your insulated tools away from any sharp objects, such as utility knives, to prevent damage to the outer material. A tool case or bag is a good solution.

Clean your tools

It’s important to take care of your insulated tools by cleaning and maintaining them regularly this will ensure many years of reliable service. All of our tools are tailor-made to be robust and long-lasting but it’s always a good idea to keep on top of the housekeeping.

Of course, ideally, the mains should be shut off before commencing any repair or inspection. However, when this is not possible, it is important to remember that insulated tools are an important link in the overall chain of safety and should be used alongside PPE, such as insulated gloves, boots and electrical safety matting.

ELECTRICAL SAFETY Distributors

Main UK Stockists & Distributors of Electrical Safety Products

Thorne & Derrick provide Electrical Safety Equipment to substation engineers, cable jointers, overhead linesmen and utility workers with PPE and electrical safety equipment including insulating gloves, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out maintenance on LV-HV switchgear, substations, cables and electrical equipment.

We protect substation engineers, asset managers, SAPS, cable jointers, overhead linesmen and utility workers with PPE and safety equipment: this includes insulating gloves, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out repair and maintenance on LV-HV switchgear, transformers, substations and turbines.

All our Cable Connection & Energisation Accessories including Medium & High Voltage joints, terminations, connectors and cleats are tested to the latest international standards and supporting ranges of professional cabling tools are stocked to reduce incident, accident and downtime to plant and people.

IEC 61482-2 | Arc Flash Clothing & Protection Standard (Version EN-IEC 61482-2: 2020)

March 22nd, 2023EN-IEC 61482-2: 2020 Protective clothing against the thermal hazards of an electric arc

EN IEC 61482-2:2020 Supersedes IEC 61482-2:2009

IEC 61482-2 Standard is an International Electrotechnical Commission standard regarding live working – protective clothing against the thermal hazards of an electric arc. This part of EN 61482 specifies requirements and test methods applicable to materials and garments for protective clothing for electrical workers against the thermal hazards of an arc flash.

Electric shock hazards and other effects like noise, light emissions, pressure rise, hot oil, the consequences of physical and mental shock or toxic influences are not covered by this standard. Protection of eyes, face, head, hands, and feet against electric arc hazard fall outside the scope of this standard.

EN IEC 61482-2 includes two methods for testing. Garments can be certified according to one of the test methods or to both test methods.

What is an electric arc?

Electric Arc and the Arc Flash created is an extremely dangerous and least understood hazard of electricity. It occurs as a result of extreme discharges of voltage or electrical current from equipment including switchgear, transformers and heavy electrical equipment. The Arc generates a high level of energy for a very short span of time (up to 1 second). The intense heat can create temperatures as high as 19,000°C and it also produces electric shock, force and large quantities of thermal radiant energy.

What is the Risk?

In any situation where your employees are working with electricity, an Arc Flash can occur and as such the maximum energy of default circuits in any electrical installation must be able to be determined. The risks of an electric Arc exposure are:

- Electrocution – potentially fatal

- Extremely high levels of Radiant Heat

- 1st, 2nd or 3rd Degree burns – 3rd Degree burns cause permanent damage

Arc Testing Methods

EN-IEC 61482-1-1:2019 supersedes IEC 61482-1:2009 – “Open Arc Test Method”

USA Arc Flash Test Method

The Open Arc Test Method (ATPV test and garment test) determines the Arc Rating Arc Thermal Protection Value (ATPV level), ELIM (incident energy limit) or Energy Break Open Threshold (EBT) of flame-resistant material (Method A) and clothing (Method B). The basic principle is that the ATPV of the garment must be higher than the Arc Flash energy level as calculated. The “Open Arc” test method is the same as the original North American method for measuring the Arc Thermal Performance Value (ATPV) as used in ASTM F1959. The Arc Rating is expressed in cal/cm² (calories per centimetre square).

EN-IEC 61482-1-2:2015 – “Box Test Method”

European Arc Flash Test Method

In the Box Test Method, materials and clothing will be tested using two methods: the material box test method and the garment box test method.

The material box test method is used to measure and determine material response to an arc exposure when tested in a flat configuration. A quantitative measurement of arc thermal performance is made by means of the energy transmitted through the material. During this test, a fabric sample is exposed to an electric arc produced by a 4kA or 7kA short circuit. In this test, the arc does not last any longer than 500ms. The amount of heat transmitted through the sample is measured during and after the test.

Based on the resulting data and a Stoll curve, the length of time it would take to cause the onset of second-degree burns is subsequently determined. Samples are also assessed for after-flaming, hole formation, melting, etc.

The garment box test method is used to test the function of the protective clothing after an arc exposure (i.e., no heat flux will be measured). This test must be conducted on a complete garment. In doing this, the objective is not to determine the energetic value, but to assess the garment after exposure to an electric arc for defects in the seams, fastenings, and other closures.

The garments are tested and evaluated in two classes in the same test:

- APC1 (Arc protection class) protects against electric arc of 4kA (arc energy 168 kJ)

- APC2 protects against electric arc of 7kA (arc energy 320 kJ)

The standard requires the following:

- A garment must have at least an ELIM value of 3,2 cal/cm2 (130 kJ/m2), or else an ATPV or EBT value of 4 cal/cm2 (167.5kJ/m2) according to IEC 61482-1-1 or APC1 when tested according to EN IEC 61482-1-2

- Garments must be sewn with inherently flame-resistant threads

- If a garment has a higher rating of arc protection on the front than on the back, the garment’s torso, sleeves, and legs must be made using the arc-rated material; the back of the garment can have a lower arc rating

- Garments must have no exposed external metal (i.e., any internal metal or melting parts are to be covered inside to avoid contact with the skin)

- The garment label must show the lowest ATPV or class if the garment is comprised of different panels of material; more detailed information about areas of the garment with varying levels of protection may be provided on the garment’s label or in the manufacturer’s instructions pertaining to use

- The protective clothing material must have some minimum tensile, tear, and burst resistance and minimum dimensional stability (e.g., for wear and tear associated with cleaning)

- The garments must cover the entirety of the wearer’s body. For example, jacket and trousers must be worn together with other personal protective equipment (PPE), including a helmet with a protective visor, protective gloves, and protective footwear (i.e., work boots) to achieve the correct level of protection. Layering is very important and will increase protection (e.g., if you wear flame-retardant underwear beneath your flame-retardant garments, you are better protected).

ARC FLASH PPE & ELECTRICAL SAFETY

Main UK Stockists & Distributors of Electrical Safety Products

Thorne & Derrick provide Electrical Safety Equipment to substation engineers, cable jointers, overhead linesmen and utility workers with PPE and electrical safety equipment including insulating gloves, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out maintenance on LV-HV switchgear, substations, cables and electrical equipment.

We protect substation engineers, asset managers, SAPS, cable jointers, overhead linesmen and utility workers with PPE and safety equipment: this includes insulating gloves, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out repair and maintenance on LV-HV switchgear, transformers, substations and turbines.

All our Cable Connection & Energisation Accessories including Medium & High Voltage joints, terminations, connectors and cleats are tested to the latest international standards and supporting ranges of professional cabling tools are stocked to reduce incident, accident and downtime to plant and people.

Safe Working on Electrical Installations by DEHN | Earthing & Short-Circuiting Devices

March 21st, 2023

Earthing & Short-Circuiting Devices Electrical Safety

Safe Working on Electrical Installations

Earthing and Short-Circuiting Devices

Save you life during work on electrical installations

When working on electrical installations, it is crutial that the five safety rules are observed.

Earthing and short-circuiting at the work location is the key element of these rules. It ensures a de-energised state for the duration of the work in case of interference voltages, atmospheric overvoltages or accidental re-connection.

Thorne & Derrick provide an extensive range of electrical safety equipment including insulating gloves, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out maintenance on LV-HV switchgear, substations, cables and electrical equipment.

Electrical Safety Products for LV MV HV Cables, Conductors, Substations & Earthing

Five Safety Rules

In Accordance with EN 50110-1 (DIN VDE 0105-100)

- Disconnect completely

- Secure against re-connection

- Verify that the installation is dead

- Carry out portable earthing and short-circuiting

- Provide protection against adjacent live parts

The installation must be disconnected completely and secured against re-connection first. After testing and verifying with a voltage detector that the installation is dead, the earthing and short-circuiting device is connected to the earthing system. Then, it is connected to the parts to be earthed using an earthing stick. The earthing and short-circuiting device should be visible from the work location.

Electrical safety Equipment From DEHN

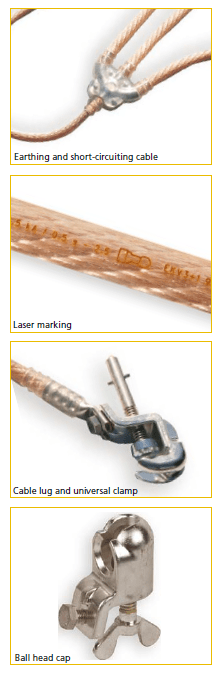

Short-circuiting cable

Short-circuiting cable

The transparent node unit and cables ensure easy visual inspection and allow the user to immediately detect signs of damage and corrosion. The cables and the connection element are fixed, thus preventing this connection from becoming loose even in case of the dynamic load of short-circuit currents. The cables are particularly robust and available with a cable crosssection up to 150 mm².

Laser marking

The new laser marking on the short-circuiting cable ensures permanent marking with the most important product information – directly on the product.

Universal clamp

We have clamps for every application: For fixed ball points with a diameter of 20 mm and 25 mm and flat clamps for copper bars. The PVC-sheathed cable lug ensures protection against twisting and damage.

Ball head cap

Ball head caps are available as rigid and adjustable ball head caps. A ball head cap that can be rotated by 4 x 90° allows the earthing and short circuiting device to be used in the most favourable position. The connection between the fixed ball point and the ball head cap ensures an extremely high degree of short-circuit strength.

Earthing and short-circuiting devices are produced in a standard-compliant and proven manner and are extensively tested in our test laboratories.

In-house production of all components ensures maximum quality and safety in terms of function and handling. With earthing and short-circuiting devices from DEHN you are always on the safe side.

Earthing and short-circuiting configurator

Easy online configuration of earthing and short-circuiting devices

Safe working on electrical installations is only ensured if the earthing and short-circuiting device is configured correctly. Thus, the selection of the earthing and short-circuiting device is always the first step. The new earthing and short-circuiting configurator makes selection easy:

- The intuitive menu navigation allows quick selection of the right earthing and short-circuiting device for your application.

- Precise and perfectly harmonised selection of the connection elements and earthing and short-circuiting cables.

- The variant number allows to clearly identify the finished product and order it at a later date.

- You may also use the Part No. of your previous orders for configuration.

- The selected product can be added to the shopping cart, sent via e-mail or printed.

- The technical data on the product are directly linked – online and thus always up to date.

➡ New earthing and short-circuiting configurator

Earthing and short-circuiting device in 8 steps

- Selection mode

First select

a. Product view or

b. System view

Select the product view if you already know which cable cross-section and clamps are to be used. In the system view the parameters of the switchgear installation are entered, for example the maximum short-circuit current and the type of earthing. Whether product or system view – both solutions lead to a technically sound earthing and short-circuiting device. - Basic structure

Define the basic structure of the earthing and short-circuiting device. - Phase cable end cross-section

Select the phase cable end cross-section of the short-circuiting cables. - Earth cable end cross-section

Decide whether the earth cable ends should have the same cable cross-section or a reduced cable cross-section. - Phase cable end equipment

Select the shaft type and connection element to be used on the phase cable end. - Earth cable end equipment

Select the operation and connection element for earth cable ends. - Earthing stick

Optional earthing sticks are available as accessory in different lengths and versions. - PDF of your selection

You can print the result of your selection, add it to the shopping cart or send it via e-mail. You may certainly return to your selection to make changes.

DEHN

DEHN are committed to the protection of workers and material assets. The energy and the spirit of innovation of more than 1,400 employees are reflected in their developments and innovative products in the field of lightning protection, surge protection and safety equipment.

The continuous growth of the DEHN group reflects their strong commitment to lightning protection, surge protection and safety equipment. The company’s global network of 11 subsidiaries and numerous sales partners passes on know-how and distributes high-quality products that are produced at their headquarters.

DEHN ensure that your buildings and installations are protected during operation, maintenance and repair. Their focus is particularly on wind energy, photovoltaic, process industry, traffic and communication solutions. You can be assured: DEHN protects.

ELECTRICAL SAFETY PROVIDERS

We protect substation engineers, asset managers, SAPS, cable jointers, overhead linesmen and utility workers with PPE and safety equipment: this includes insulating gloves, arc flash clothing, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out repair and maintenance on LV-HV switchgear, transformers, substations and turbines.

All of our Cable Connection & Energisation Accessories including Medium & High Voltage joints, terminations, connectors and cleats are tested to the latest international standards and supporting ranges of professional installation tools are stocked to reduce incident, accident and downtime to plant and people.

Thorne & Derrick Appointed UK Stockists & Distributor for the Hand Safety Tool Company

February 14th, 2023

Press Release | Uploaded by Chris Dodds 14.2.2023

Thorne & Derrick are delighted to announce we have been appointed the UK Distributor for the Hand Safety Tool Company range of No Touch Hands Free Tools.

This range of market-leading tools reduce serious hand injuries in the workplace when manoeuvring suspended loads during push-pull operations. To support the introduction of the product range we can provide on-site or online Demonstrations to end-users. There are a diverse range of all-purpose designs that keep hands off and away from potential injury areas and keep workers out of the risk zone. Over recent months our Sales and Marketing Teams have benefited from Product Training with Jim Walts (Director – The Hand Safety Tool Company) and we now have in place stock of their ShoveIt range of tools.

Reducing Risk & Worker Injury

Thorne & Derrick are available and interested to discuss potential applications to improve safe operations in the utility, rail, renewable, oil/gas, port authority, manufacturing and construction industry sectors. The tools mitigate high-risk pushing and pulling operations and associated hand or finger injury – users can guide loads, move and position objects, as well as grab slings and taglines without physically placing hands on the item.

The range of Safety Tools keep your hands off loads enabling “hands-free” lifting – this mitigates the risk of load handling and improves Health & Safety in the workplace.

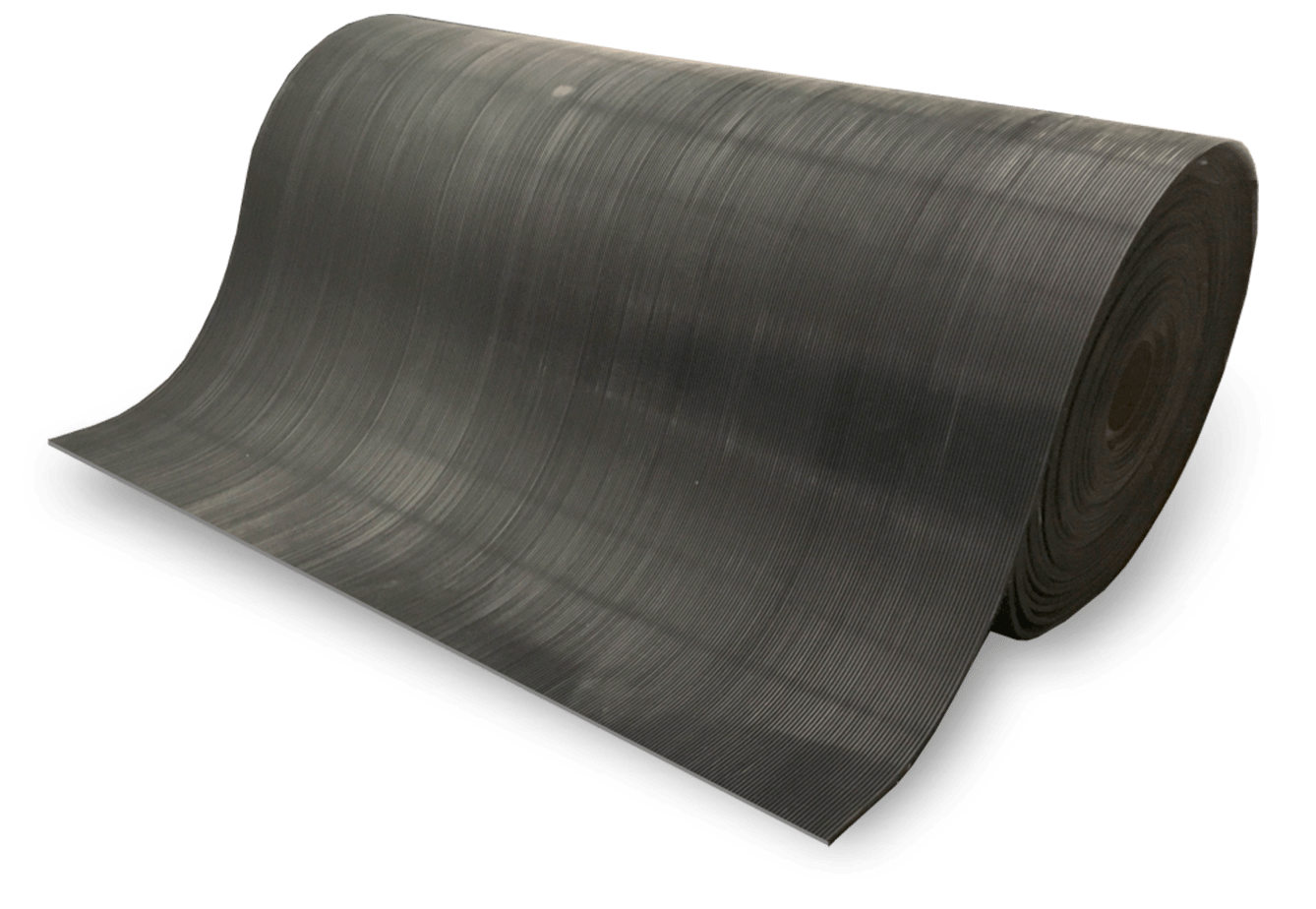

Insulating Matting | Bespoke Cut to Size Switchboard Mats

February 14th, 2023Matting

Thorne & Derrick are able to arrange manufacture of insulating and switchboard matting from our wide range of premium, low odour, rubber matting to your exact sizes and design and in accordance to IEC61111. Our REACH/PAH/CE approved compliant rubber compounds provide no off gassing which can cause nasty smells within internal environments. Rubber which has a pungent odour usually has been heavily recycled and been manufactured with the use of prohibited chemicals which are banned by REACH/EU. REACH regulations are tightening, and many online reviews of current non regulated matting products found on the market have regular end user complaints of a ‘toxic odour’ and ‘smell’ that does not disappear’. The advice given by the supplier is to ‘clean with soap and water’ or ‘leave outside for a prolonged period’.

The truth is really these products are most probably non-compliant and should not be placed into the European market. Contact us for odour free matting options.

Stockists & Suppliers of the CATU Electrical Safety range of Insulating Matting | LV MV HV

| Class Of Insulating Matting According To IEC61111 | Proof Test | AC Maximum Working Voltage | Withstand Test Of Insulating Matting |

| Class 0 Matting | 5kV | 1000V – LV Low Voltage | 10kV |

| Class 1 Matting | 10kV | 7500V – MV Medium Voltage | 20kV |

| Class 2 Matting | 20kV | 17000V – MV Medium Voltage | 30kV |

| Class 3 Matting | 30kV | 26500V – MV Medium Voltage | 40kV |

| Class 4 Matting | 40kV | 36000V – HV High Voltage | 50kV |

LV MV HV Electrical Safety