Offshore Wind Farm Cables

66kV 72.5kV | Power Cables Accessories for Offshore Windfarms

December 8th, 2022

Power Cable Accessories

Nexans Power Accessories is the leading European innovator and manufacturer of Low, Medium & High Voltage Cable Accessories as well as connection technology for energy transmission and distribution networks, including both onshore and offshore renewable projects. The Nexans range of Medium Voltage Power Cable Accessories ranged is stocked and supplied in the UK by Thorne & Derrick, contact us for commercial quotations, specification support, product training or to discuss your requirements.

The standard product range of GPH® compression or mechanical connectors and cable lugs is developed and produced as well as customised solutions.

Nexans also manufactures ready-to-install pre-assembled cable lengths and factory tested cable bridges for industrial applications.

Power Cable Accessories for High Voltage Power & IAC Cables 66kV 72.5kV

Catalogue Contents | ↓ Catalogue Download ↓

Nexans

With the brand name EUROMOLD® Nexans Power Accessories is a European market leader for medium voltage cable accessories. T&D offer the entire portfolio of separable connectors for Interfaces A to F in proven EPDM technology with at least 3mm conductive jacket. In this scope, longtime know-how and technological advance was successfully transferred into high voltage applications.

Nexans provide a complete range of cold-shrinkable and slip-on accessories, e.g. pre-moulded terminations and joints for cables and epoxy bushings for transformers and switchgears, up to 170kV.

An extensive range of additional equipment and a variety of dedicated installation training and jointer tooling make Nexans a strong partner in the transmission and distribution of energy.

|

R909TB/G – EUROMOLD® Tee connector

Interface F Separable tee shape connector designed to connect designed to connect polymeric insulated cable to equipment (transformers, switchgears, ……). Also connects cable to cable when using the appropriate mating parts. -Thick conductive EPDM jacket The R909TB/G separable tee connector is type tested acc. to IEC 60840 |

| AFN72 – EUROMOLD® Slip-on Termination For indoor and outdoor use up to 72.5kV U (Um) 60-69 (72.5) kVDry type, non size sensitive terminations for use indoors, outdoors and exposed to prolonged sunshine and other weather conditions.To connect polymeric insulated cable to equipment and for the outdoor terminating onto overhead lines or bus bars-Its compact and modular design supports the suitability for different pollution levels-All termination housings are tested for AC withstand and partial discharge prior to leaving the factory The AFN72 slip-on termination is type tested acc. to IEC 60840, and meets the requirements of IEC/TS 60815-3; SPS class d and e. According to IEC 60112: CTI>600 |

|

|

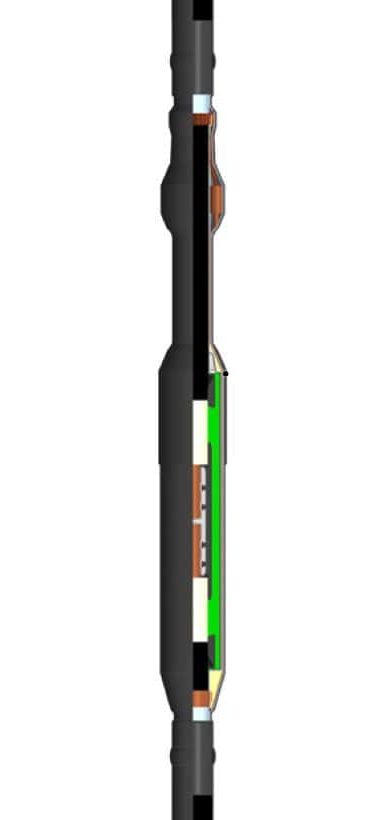

72MSJ Single Core Straight Joint

Slip-on technology up to 72.5kV Non size sensitive slip-on single core straight joint made of silicone, optimised for mechanical connectors. For jointing coper wire screened polymeric cable to be laid in air or directly buried. The product is fully screened and fully submersible. -All joint bodies are tested for AC withstand and partial discharge prior to leaving the factory The slip-on single core straight joint 72MSJ is type tested acc. to IEC 60840. |

Euromold

R909TB/G – EUROMOLD® Tee connector, Interface F

R909PB/G – EUROMOLD® Coupling connector

900SA-CD – EUROMOLD® Surge arrester, Interface F

R900BE/G – EUROMOLD® Bushing extender, Interface F

R900DR-B/G – EUROMOLD® Dead-end receptacle, Interface F

900GP-SBT – EUROMOLD® Grounding plug, Interface F

Possible arrangements Interface F

R900AR-8 / R900AR-12 – EUROMOLD® Equipment bushing, Interface F

Fixings for equipment bushings

AFN72 – EUROMOLD® Slip-on termination for indoor and outdoor use

AFNS72 – EUROMOLD® Slip-on termination with support

FEV72.5 – Outdoor termination with composite insulator

ESC – EUROMOLD® Premoulded EPDM stress cone

Ready to install, pre-assembled cables

72MSJ – Slip-on single core straight joint

72MSJ-x-SB – Sectionalizing slip-on single core straight joint for cross-bonding application

LHV1 – Multitool for cable preparation and installation

➡ See Also | Heat Shrink MONO Terminations MV HV | Heat Shrink JTS Joints MV HV

DOWNLOAD | Distributed in the UK by Thorne & Derrick International

Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

See how T&D support, supply and service the Renewable Energy industry.

Stockists & Suppliers | UK & International Projects

High Voltage Cable Accessories 66kV 72.5kV | Nexans Euromold | New Catalogue Download

December 2nd, 2022-

uploaded by Chris Dodds | Sales & Marketing Manager at Thorne & Derrick

Joints Termination Connectors Tools

Nexans Power Accessories is the leading European innovator and manufacturer of Low, Medium & High Voltage Cable Accessories as well as connection technology for energy transmission and distribution networks, including both onshore and offshore renewable projects. The Nexans range of Medium Voltage Power Cable Accessories ranged is stocked and supplied in the UK by Thorne & Derrick, contact us for commercial quotations, specification support, product training or to discuss your requirements.

Power Cable Accessories for High Voltage Power & IAC Cables 66kV 72.5kV

Catalogue Contents | ↓ Catalogue Download ↓

Euromold

R909TB/G – EUROMOLD® Tee connector, Interface F

R909PB/G – EUROMOLD® Coupling connector

900SA-CD – EUROMOLD® Surge arrester, Interface F

R900BE/G – EUROMOLD® Bushing extender, Interface F

R900DR-B/G – EUROMOLD® Dead-end receptacle, Interface F

900GP-SBT – EUROMOLD® Grounding plug, Interface F

Possible arrangements Interface F

R900AR-8 / R900AR-12 – EUROMOLD® Equipment bushing, Interface F

Fixings for equipment bushings

AFN72 – EUROMOLD® Slip-on termination for indoor and outdoor use

AFNS72 – EUROMOLD® Slip-on termination with support

FEV72.5 – Outdoor termination with composite insulator

ESC – EUROMOLD® Premoulded EPDM stress cone

Ready to install, pre-assembled cables

72MSJ – Slip-on single core straight joint

72MSJ-x-SB – Sectionalizing slip-on single core straight joint for cross-bonding application

Slip-on tools

900OJF P1-P1 – Offshore junction frame

900OJF P2-P0 – Offshore junction frame

900OJC P2(3)-P1(2)(SA) – Offshore junction cabinet

➡ See Also | Heat Shrink MONO Terminations MV HV | Heat Shrink JTS Joints MV HV

Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV Cable Accessories & Electrical Products.

Onshore Cable Pulling Starts At Seagreen Offshore Wind Farm

September 6th, 2021

Cable Pulling & Laying

Work is underway to pull cabling through 19.5 kilometres of underground ducts which will connect the GBP 3 billion Seagreen Wind Farm to the Scottish National Grid.

The cable pulling is the latest stage in the cable installation process and another milestone in the construction of the 1,075MW 114-turbine development 27 kilometres off the coast of the county, which when operational, will power up to 1.6m homes throughout the country.

Once finished, the cabling will reach from where the project makes landfall in Carnoustie to a new dedicated substation currently under construction in Tealing.

Onshore Electrical Infrastructure Project Manager, Steven Reid from SSE Renewables is responsible for the cable installation project.

”The start of the cable pulling process marks an important achievement in the delivery of the onshore electrical transmission infrastructure following significant efforts from the Project Team and the support of various stakeholders,” Reid said.

”Again, I‘d like to express our thanks to all who live along the route for their co-operation and understanding as the project has progressed up to this stage of delivery. Working with our Contractor Nexans, we now look forward to continue to deliver the installation of the 19km of cabling safely and with the least amount of disruption possible to the surrounding community.”

Electrical Arc Flash Protection for Offshore Wind Farm WorkersSeagreen is a joint venture between SSE Renewables and Total.

First power at the wind farm is expected by early 2022 with full power coming on stream in 2022/23.

Seagreen selected Montrose Port as the home for the operations and maintenance base for the 114-turbine development in October 2019.

See how T&D support, supply and service the Renewable Energy industry.

Cable Pulling & Cable Laying Equipment

Superconducting Cable Systems – The Future?

June 30th, 2021-

Reproduced with kind permission of Mane - Worldwide Recruitment Specialists.

Cable Systems

Superconducting cables could be the answer to distribution challenges in offshore wind.

Achieving submarine power transmission with low loss and high capacity is vital for the future of renewable energy. But recent breakthroughs have relied on high-voltage direct current, making them useless anywhere low voltage is mandatory. Superconductors can transmit electricity efficiency with much lower voltage and power requirements.

Now SuperNode has teamed up with Irish research institute MaREI on a superconductor project that could enable up to 10x faster offshore renewable development worldwide.

The idea is to provide a single superconductor connection for offshore renewable energy sources. It would deliver electricity back to shore efficiently via medium voltage direct current, using a subsea superconductor to move power from energy-dense areas offshore to high-demand areas onshore.

SuperNode CEO John Fitzgerald says the technology could be a game-changer for the industry and help Europe achieve its carbon-cutting targets.

While superconducting cables have been operating onshore in places like Germany and Korea for years, current onshore cable systems are not fit for offshore use or for the amounts of power needed to support a renewable grid. This is why SuperNode is developing its new Subsea Superconducting Cable System.

Leading certification body DNV GL has now awarded the system its coveted Statement of Feasibility, making it the first subsea superconductor system to receive such an award in the world. The next step for SuperNode will be to deliver a scale prototype this year.

further reading

Cable Testing – Is Resonance Testing The Way Forward For Offshore Wind?

Why Large Offshore Wind Farms Should Double Their Intra-Array Voltage

Thorne & Derrick are Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Why Large Offshore Wind Farms Should Double Their Intra-Array Voltage

May 11th, 2021

-

Reproduced with kind permission of Mane - Worldwide Recruitment Specialists.

Offshore Wind Farms

Offshore wind farms are now the biggest contributor of green energy to the National Grid. But the cost of installing and running them is problematically high – and the race is on to solve that problem as the 2050 net-zero deadline looms closer.

Could pumping up the intra-array voltage from 33kV to 66kV be the answer?

A Carbon Trust study found that increasing to either 48kV or 66kV would cut costs and increase yields over the life cycle of a wind farm. Of the two, 66kV brought the bigger benefits.

While 33kV is the most practical choice for wind farms at present, it means the power has to be stepped up to a much higher voltage like 110kV at an offshore substation for transmission in the UK. This generates massive costs in cabling and substations, which are often remote and difficult to access.

Higher voltage array technology should not only cut these costs but also boost efficiency by preserving more of the energy the wind farms generate.

The Carbon Trust predicts that switching to 66kV could reduce the cost of offshore wind power by 1.5%. To encourage this, it launched a competition to fast-track the development of 66kV cables, “The Race for 66kV”, awarding funding to three winning companies, Prysmian, Nexans and JDR.

Phil de Villiers, the Carbon Trust’s Head of Offshore Wind, said higher voltages could increase transmittable power by over 100%, and also make it possible to develop much larger arrays with more turbines per array.

Developers are already showing interest, including major players like Eon, RWE Innogy, ScottishPower Renewables, Dong, Statkraft, Vattenfall, SSE, and Statoil.

Thorne & Derrick are Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV