How to Protect HV Underground Cables

Published 18 Aug 2020

Republished with the Kind Permission of Sam Soady |

Eccentricity Pty Ltd Director /HV Operator / Cable Jointer

How to Protect HV Underground Cables

Underground high voltage cables have been a great innovation to the electrical distribution industry. While they make an installation look more visually pleasing than the overhead conductor systems currently being utilised, they are often exposed to scenarios which are overlooked by electrical designers and engineers.

It is common practice to protect your cables from mechanical damage via installation methods and manufacturing mechanical protection systems, however in some areas, cables have an environmental issue leading to a shortened lifespan and failure. Termites!

Even though electrical cables are not considered food for the termites it is well known they can attack underground cables damaging the integrity of the installation, which eventually leads to failures.

Some areas in Australia have a higher risk of termites such as the northern part of Queensland and the Northern Territory requiring underground cables to have an added protective layer during manufacturing.

Methods for termite protection on underground systems include hard physical barriers such as:

- Rigid HD PVC conduit systems.

- Added layer of plastic Nnlon sheath (must maintain a smooth surface).

- Metal barriers such as brass, copper or steel tapes.

- Chemical infused High Density Polyethylene with Cypermethrin.

While all systems are highly effective at providing termite protection, the most common method utilized for modern installations is option 4 – chemical infused High Density Polyethylene.

This solution provides the most cost-effective choice as additional layers are not required to be added to the normal specification/design of the cable. Some companies however have moved away from this method due to Health and Safety concerns which have arisen from the use of these chemicals.

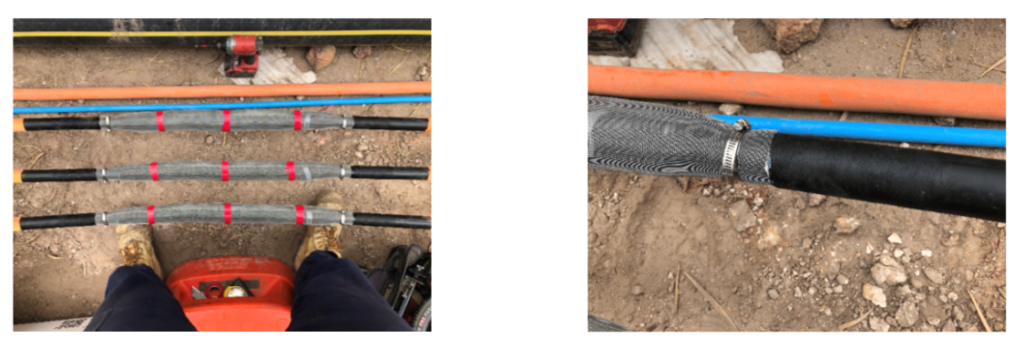

When performing joints/terminations on the cable, it is imperative to continue the termite protection all the way through the cable joint. This is generally achieved using stainless steel mesh being installed as a protective layer over the joined cable (refer image). The use of roll springs or hose clamps ensures termites cannot enter the joint body.

About Eccentricity

Eccentricity is a specialised Brisbane based company with a team of dual trade electricians and cable jointers. Our technicians are fully qualified to work on cables up to 66kV, including XLPE, PILC and EPR cables, backed by over a decade of industry experience.

With a modern and fully compliant fleet of industry vehicles, we are capable of accessing any high risk environment to perform works with a wide range of major MV HV cable jointing projects including, mining, oil, gas, renewable energy, and high voltage transmission networks.

Eccentricity has the capacity for small or large scale projects, providing reliability of power networks wherein client satisfaction is a top priority. We provide a high level of quality with all aspects of both installation and commissioning, ensuring we comply with all relevant regulations and legislative provisions.

Specialist Suppliers of High Voltage Electrical Equipment & Cable Accessories

Jointing, Earthing, Substation Electrical & Safety Equipment Distributors

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Distributors for 3M Cold Shrink & Scotchcast | Nexans Euromold | Pfisterer Connex