Innovation : Heat-Shrinkable Joint with Triple Layer Tube By Nexans

Published 30 Mar 2021

Nexans JTS Heat Shrink Joints

JTS Triple Wall Heat Shrink Joints

By Nexans

Simple & Shorter Installation Time with Reduced Risk of Failure

-

Republished Article From Transmission & Distribution - Australasian Power Technologies By Nexans Australmold

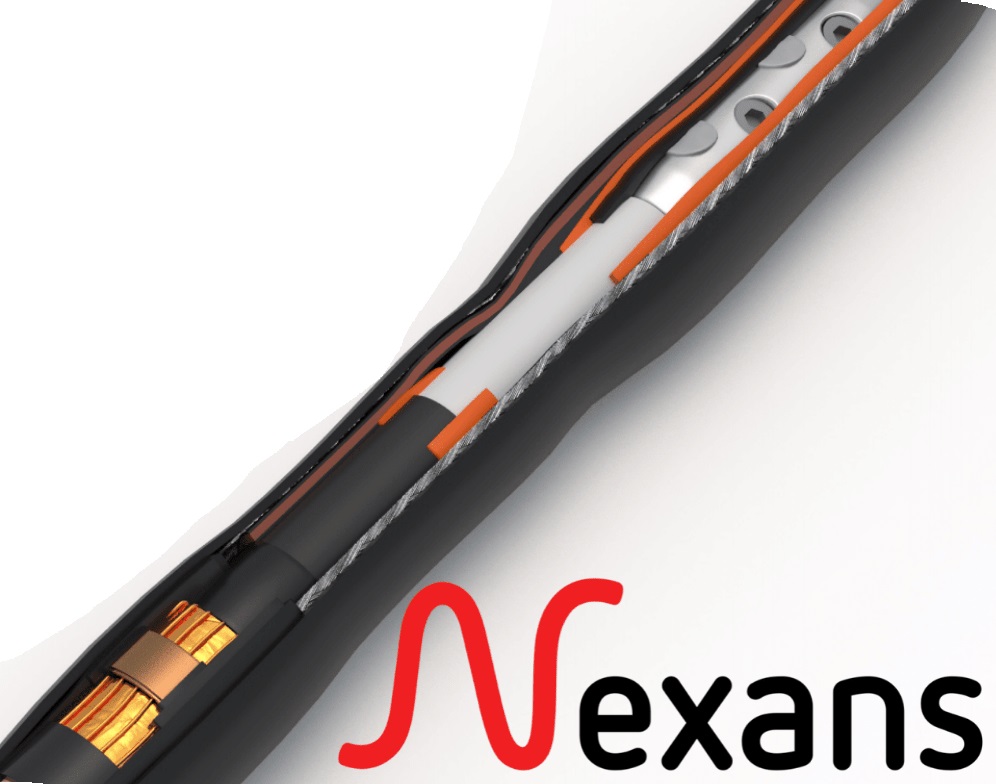

The Nexans Italy site of Offida launches the JTS, its new heat-shrinkable joint with triple layer tube. The triple layer heat shrink tube represents a technical innovation that allows MV cable jointers to heat only 1 tube instead of 3 for 12kV to 24kV applications, and 2 tubes instead of 3 for 36kV to 42kV cable jointing applications.

Nexans have reduced complexity and the time to install the cable joint, while improving the quality of the global connection by reducing its operations. The new range of Nexans JTS heat-shrinkable medium-voltage straight joints is compatible with MV single- or three-core polymeric cables with copper wire screen, copper tape screen or with aluminium tape screen.

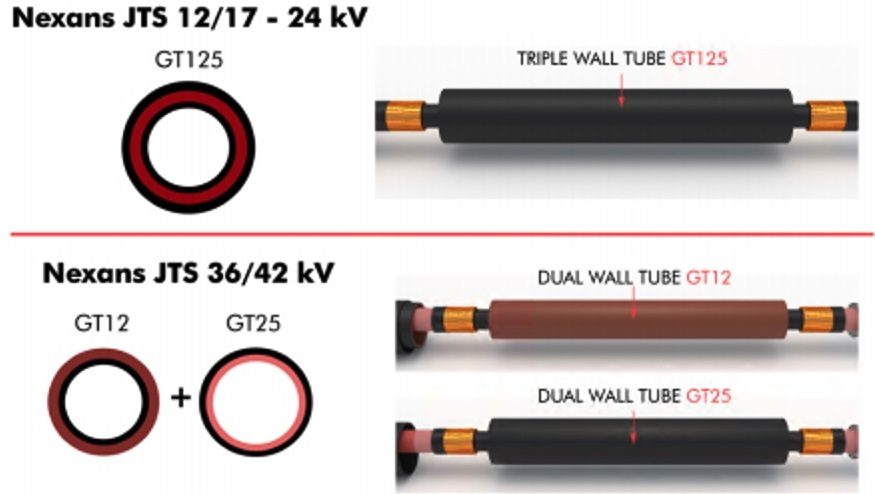

For 12kV to 24kV applications, the Nexans JTS 17/24 heat-shrinkable joint is the new high performance, compact and easy-to install joint: a single body with all electrical functions integrated!

The JTS 17/24 is using the Nexans “TRIPLE GT125”, an integrated stress control field, insulating and conductive tube, which can support voltage classes up to 24kV.

A double layer pad with conductive rubber inside and HK orange mastic outside ensure a Faraday cage and smooth the effect of the electrical field and of the voltage gradient in the connector area.

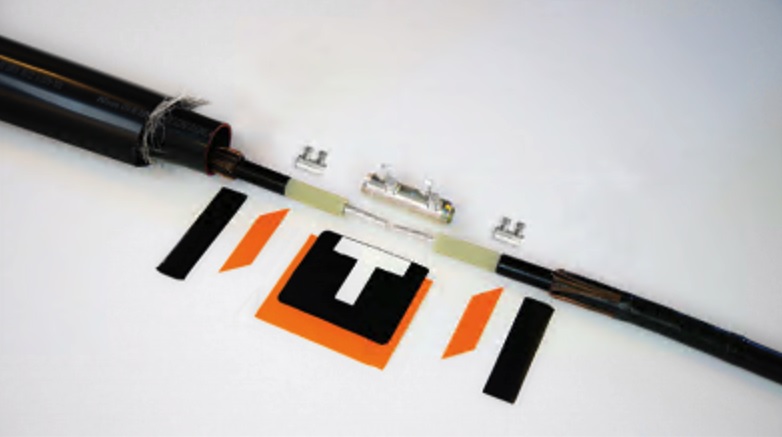

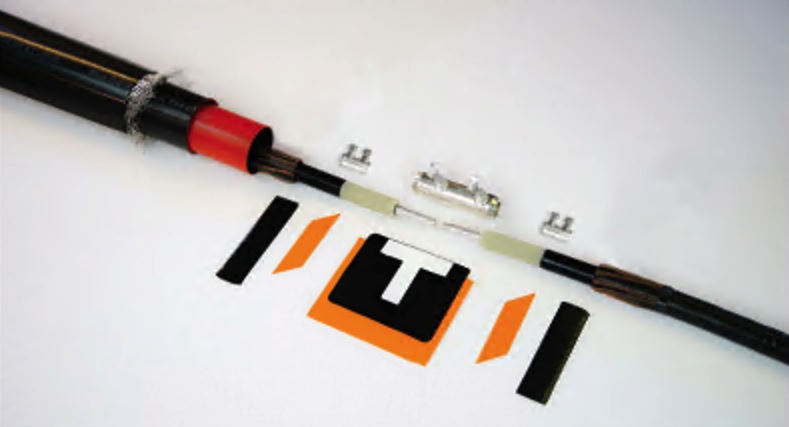

For ANZ customers, the electrical continuity of the screen is ensured by copper screened mesh and two mechanical shear-off screen links. Finally, the outer sheath is restored with heavy wall adhesive lined tubing. MC types are supplied with GPH® mechanical connectors.

For 36kV to 42kV applications, the Nexans JTS 36/42 heat-shrinkable joint is also a high performance, compact and easy-to-install cable joint: double bodies with all the electrical functions integrated!

The JTS 36/42 is using an integrated coextruded “stress control field + insulating” (DUAL GT12) nested in a coextruded “insulating + conductive” tube (DUAL GT25), which can support voltage classes up to 42kV.

All the rest is the same as the 17-24JTS.

Nexans Italy in Offida has an extensive know-how in the fields of heat-shrinkable materials, as well as mastics. The heat-shrinkable (HS) technology dates from the 1960s. In Nexans, thanks to a strong R&D activity, the heat shrink technology has been improved and tailored for 50 years, according to the evolution of the market needs.

Today, Nexans produce a complete range of heat shrink tubes to cover Low (LV) and Medium (MV) voltage cable jointing applications up-to 52kV in our Extruders/Expanders lines, with diameters starting from 20mm till 300mm and up to 4 different layers.

Mastics for electrical use: the complete range of Nexans mastics have been developed and are manufactured totally in the company. They are produced by means of a 630 litre mixer in a dedicated part of the plant. Resins for electrical use, casting and insulating have been designed by Nexans Italy for more than 35 years.

Nexans R&D team of engineers and technicians use the most advanced tools and equipment to create, verify and test all our products among the different laboratories and material research centres of the Nexans Group.

Nexans Power Accessories Italy is well equipped to perform physical and chemical analysis of insulating, anti-tracking, and stress control materials, both for tubing and mastics. We supply jointer training and failure analysis for all our customers. In the electrical laboratory we can perform type test and routine test (PD measurement at hot and ambient temperature, heating cycles in air and water, humidity and salt fog). For steel wired armour cable and termite protection please contact your local sales office.

NEXANS JTS 17/24KV

NEXANS JTS 36/42KV

Nexans JTS Heat-Shrinkable joint

Features & Benefits

- Tube nesting / positioning and parking issues eliminated => typical cable jointing errors eliminated

- Only one tube to shrink for the 3 functions (stress control – insulation – conductive) for voltage classes 12/17kV & 24kV

- Only two tubes to shrink for the 3 functions (stress control – insulation – conductive) for voltage classes 36kV & 42kV

- Reduced installation time / training time, with standard cable preparation tool work

- Simplified stress control with 2-layer plate as used with Nexans cold shrink joints => no need to conform the mastic before shrinking the tube

- Design adapted for all type and brands of mechanical / crimping connectors

Nexans JTS Heat-Shrinkable joint

highlights

- Short and slim design cable joint

- Quick and easy to install for medium voltage power cable systems

- Excellent electrical insulating properties

- Advanced screen connection and armour continuity of MV joint

- Heavy wall tubing for high mechanical strength and impact resistance

- Proof against water penetration and chemicals aggression

- Stabilised UV protection of the cable

- Halogen-free material content

- Compliant to reach regulations

- Premium technical support up to medium/high voltage classes

- Made in EU

Nexans manufactured Cable Accessories are in extensive service throughout the UK DNO power grid – the Euromold brand of separable connectors are approved and are approved by several DNO/IDNO operators dependent on the product, voltage and network.

Nexans joints and terminations are increasingly preferred and adopted by NERS Accredited Independent Connection Providers (ICPs) working on 11kV private networks.

Thorne & Derrick have an International Distribution Agreement with Nexans Power Accessories UK and are their main stockists and suppliers for their range of Heat Shrink Joints & Terminations up to 33kV.

Further Reading

-

Nexans JTS1 Heat Shrink Cable Joints (Specification & Instruction)

Size: 2.58 MB

Nexans JTS1 Heat Shrink Cable Joints (Specification & Instruction)

Size: 2.58 MB

-

JTS Joints – Technical Specifications Approvals Testing & Capability

Size: 9.98 MB

JTS Joints – Technical Specifications Approvals Testing & Capability

Size: 9.98 MB