How To Remove Bitumen From Subsea Cables & Umbilicals Using Socomore Wipes

Published 20 Apr 2021

Cable Cleaning Wipes

Cable Cleaning | Socomore PF-BR Bitumen Remover Wipes

Bitumen is field-proved to be a highly effective corrosion protection for steel armour wires in array cables, subsea power cables, umbilicals and power umbilicals.

Socomore (formerly PT Technologies) bitumen removal wipes are used for cleaning cables (power, subsea and submarine), umbilicals and electrical equipment including cable rollers and ROV’s – the electrical cleaning solvent wipes are used by cable jointing and technician teams for cleaning and wiping down cables and equipment in the power generation, transmission, distribution and renewable sectors.

PF-BR cleaning wipes from Socomore are extra large, heavily saturated wipes specifically designed for the bitumen removal process during electrical and cabling operations. Used for cable cleaning prior to cable jointing, termination and maintenance of cables, switchgear and network equipment operating at LV MV and HV up to 440kV.

Socomore PF-BR bitumen remover wipes easily remove oils, soils, tar and bitumen. The extra large cleaning wipe reduces the requirement for many smaller wipes, reducing time and wastage during cable preparation which results in cost savings.

The easy hold and grip on the extra large bitumen remover wipe also allows the operator to clean the whole diameter of the cable with one wipe, without touching the cable – suitable for use on static and live cables; low, medium and high voltage applications (up to 440kV).

The bucket wipe system eliminates the transport, storage and logistic issues commonly associated with flammable liquid solvents. Other benefits of the product include reduced solvent consumption and VOC emissions, improving your companies Health & Safety and environmental impact.

Cleanly Remove Bituminous Compound From Submarine Power Cables.

Socomore PF-BR Electrical & Cleaning Wipes – Key Applications

- Removal of bitumen protection

- Cable cleaning before cable jointing or cable splicing

- Cleaning and degreasing switchgear and network equipment

- Cable end preparation and construction of cable joints

- Cleaning and degreasing cable and moulded connectors

- Cleaning and maintaining large generators, insulators, transformers and motors

- Cleaning and degreasing of plastic and metallic tools

- Electrical equipment and components cleaning

- Degreasing assembly connectors on underground cables

- Cleaning connector interfaces

- General multi-purpose maintenance degreaser

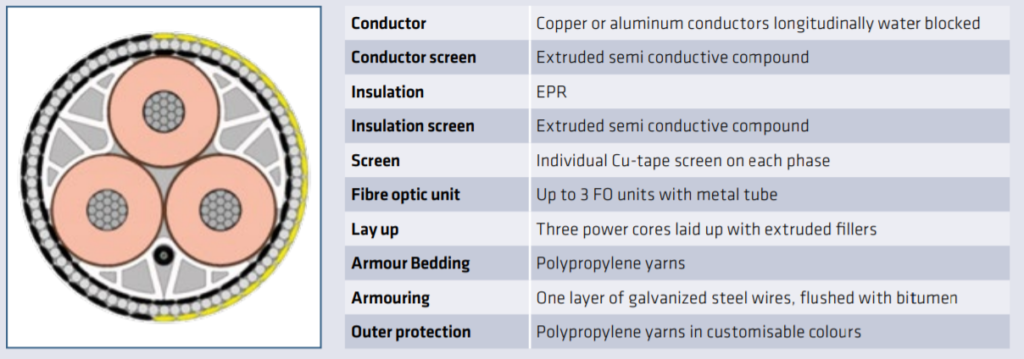

66kV Cable | Typical Offshore Wind Cable Construction | Image Prysmian

Bitumen Removal

from Subsea Cables & Umbilicals

Directions for Use

Bitumen Removal | Heat cable to soften bitumen. Holding an end of impregnated wipe lengthways in each hand, vigorously move the wipe up and down the cable until all bitumen is removed. Dispose of all jointers wipes in an appropriate bin.

General Usage | Apply a thin film of PF-BR using liquid or a pre-saturated wipe. Allow a few minutes for surface action to dislodge contaminants. Wipe off with the same pre-saturated wipe or with a clean, dry low lint cloth (recommended). Dispose of all jointers wipes in an appropriate bin.

Cable Cleaning (Jointing Operations) | Follow cable manufacturers guidelines for cable jacket stripping to semi-conductive shield peeling. Clean the cable with PF-BR – conduction and insulation – to remove residue and degrease. Always clean in the same direction from cable outward (conductor) to cable inward (semi-conductive shield) to avoid re-depositing residues already removed. Wipe off with a clean, dry low lint cloth (recommended). It is not necessary to wait for full evaporation before further working on the system. Solvent residues will not affect the subsequent full cure of epoxy resins in cable jointing systems (heat shrink or cold shrink). Dispose of all jointers wipes in an appropriate bin.

Cable Pulling & Cleaning Products

Thorne & Derrick International are the UK’s leading stockist and supplier of Cable Pulling & Cable Laying Equipment for the installation of underground land and subsea power cables and overhead lines up to 400kV – the products support cable pulling teams to install LV MV HV cables into trench, cable duct, risers and all forms of cable containment.

➡ Further Resources | Cleaning Cables In The Power Industry | PF SOLVENT

Thorne & Derrick are Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

See how T&D support, supply and service the Renewable Energy industry.

MV HV 11kV 33kV 66kV | Cable Joints, Terminations & Connections | Distributors & Stockists for 3M Cold Shrink | Nexans Euromold | Pfisterer CONNEX