MULETAPE v Rope : Pulling Cables Into Cable Ducts To Avoid Duct Cutting

Published 27 Feb 2019

Manufacturers of MULETAPE

-

uploaded by Chris Dodds - Thorne & Derrick Sales/Marketing Manager MULETAPE | Made in USA | Distributed in the UK & Europe by Thorne & Derrick

Burn Through

The Case for MULETAPE vs. Rope

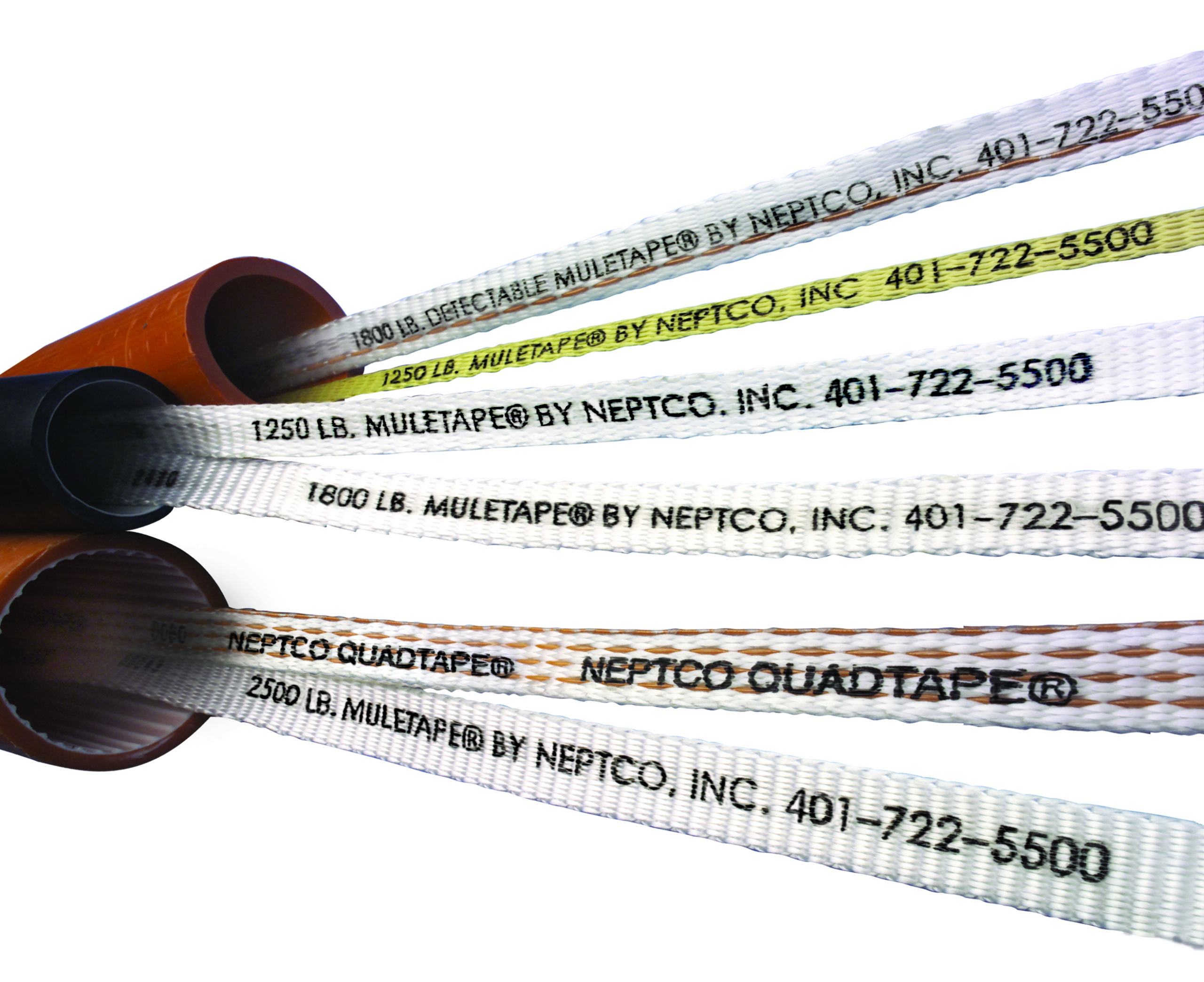

NEPTCO is a global leader in the manufacturing of materials used for the Detection & Pulling of Cables for a wide variety of commercial and industrial applications.

In this Blog, NEPTCO answer questions regarding their advanced specification MULETAPE which includes a comparison to using traditional cable pulling ropes.

NEPTCO’s range of measuring and pulling tapes substantially reduce cable installation labour, materials and stock holding costs by providing a threading line, a measuring tape and a winch line all in one product – this reduces damage to underground plants, improves efficiency and enhances worker safety.

NEPTCO’s range of measuring and pulling tapes substantially reduce cable installation labour, materials and stock holding costs by providing a threading line, a measuring tape and a winch line all in one product – this reduces damage to underground plants, improves efficiency and enhances worker safety.

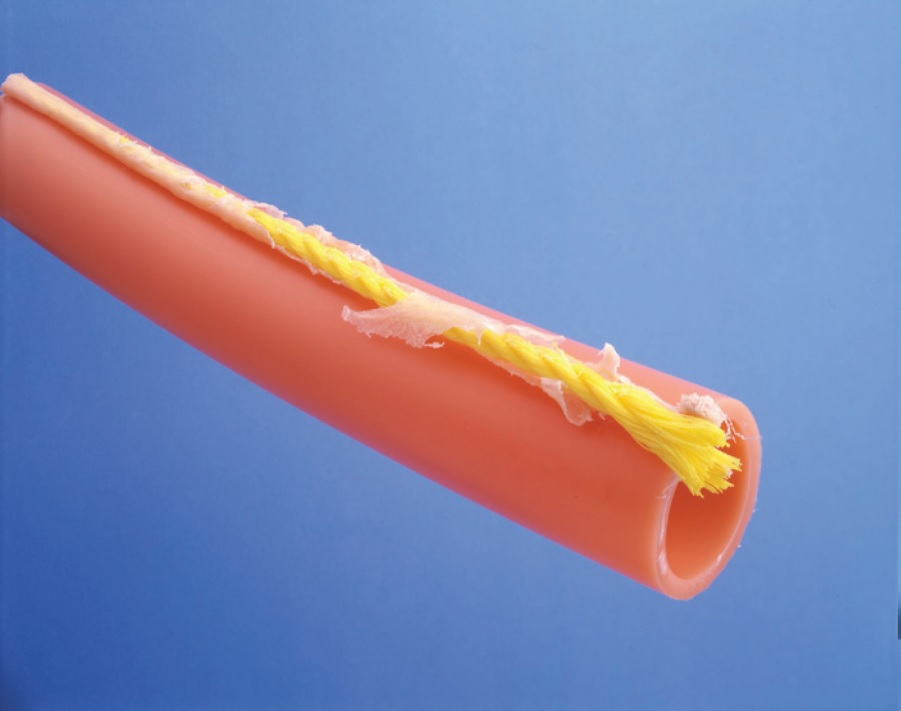

Q: What is “burn through?”

A: When polypropylene rope is pulled through PVC or polyethylene duct, the friction generated by the rope rubbing against the conduit wall creates enough heat to actually “burn through” the cable ducting or conduit – this can occur with or without cable lubricant

“Burn Through” caused by the friction from cable pulling rope.

Q: Why should this matter to me?

A: Aside from damaging the conduit or cable duct and creating opportunities, the jagged edges of the burned conduit pose a real threat to the cable installed by the contractor.

Cable surging through the damaged conduit or duct at an average rate of 100 ft. per minute will catch on the damaged areas of conduit, shredding the outer jacket. Fibre Optic cables are particularly vulnerable since the situation which can lead to excess tension and can cause micro-bending. As a result, the cable may fail prematurely, or simply not function at all.

A damaged cable as a result of using cable pulling rope.

Q: How does NEPTCO know these things happen? After all, you can’t see what’s happening underground!

A: NEPTCO has gone to great lengths to test this theory by duplicating installation conditions in the lab and in the field. Their research engineers designed the Duct Cut Tester to evaluate the performance of various conduit materials and winch lines under typical installation conditions.

The results tabulated on the reverse side of this sheet are conclusive: pre-lubricated MULETAPE out-performs polypropylene rope in every installation scenario.

Q: Why does MULETAPE work so much better than cable pulling rope?

A: MULETAPE is pre-lubricated, which helps reduce friction and the heat it generates, but MULETAPE’s wide and flat profile is also important. A round rope will concentrate all heat and energy on the small area where the rope comes in contact with the innerduct. MULETAPE is flat, and therefore spreads this heat and energy across a wider area, reducing the chance of burn through.

|

|

| MULETAPE by NEPTCO | Cable Pulling

|

|

NEPTCO Duct Cut Tester

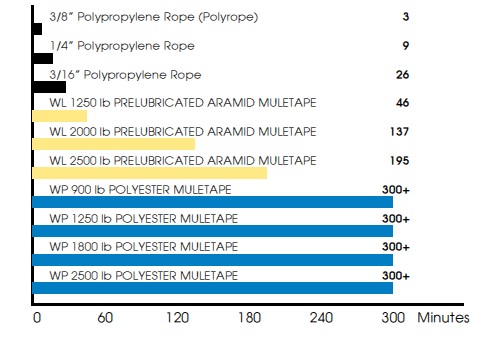

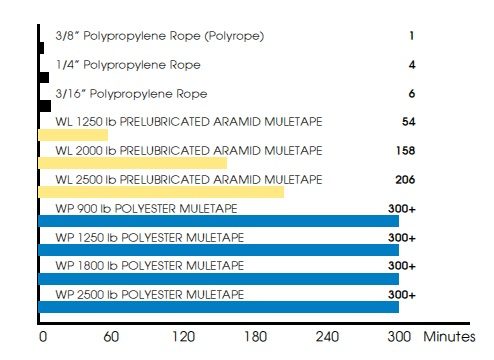

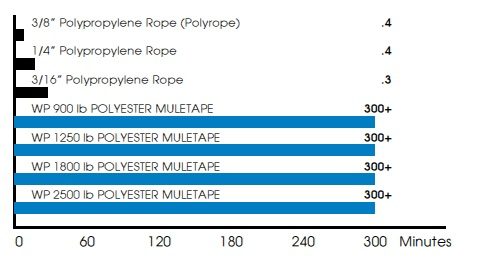

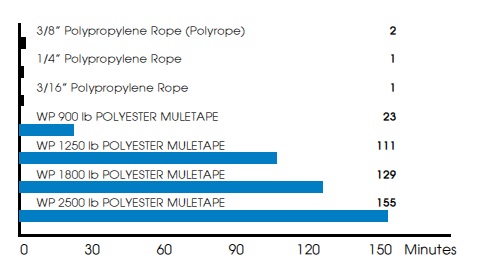

The charts below indicate the time elapsed before conduit experiences damage due to burn through:

Duct Cutting in Corrugated 1.5” ID HDPE Subduct |

Duct Cutting in Smooth Walled 1.5” ID HDPE Subduct |

Duct Cutting in Corrugated 1.5” ID PVC Subduct |

Duct Cutting in 2” Schedule 40 PVC 90° Subduct |

Q: Okay, I understand that burn through is a problem, but I’m still not convinced this is really happening in the field. Do you have any evidence that cable can actually be damaged in a real installation?

A: Absolutely. If you have ever experienced a rope breaking during a pull, it is caused by the cable getting snagged on a duct that has been burned through. The rope is usually narrower than the cable and pulling sock and is able to make its way back into the duct, however, because the cable and pulling sock are wider they may not be able to make their way back into the duct. When this happens, the tension rises, the pull becomes more difficult and the rope may break. This not only causes a health and safety hazard, the possibility that the cable is damaged is extremely high. In 1999, NEPTCO recreated a typical installation scenario in an above-ground test. The results were just as expected – the rope burned through the conduit in seconds, while the MULETAPE caused no damage.

To request a video of this experiment in CD or VHS format, please contact [email protected]

MULETAPE Features & Benefits

- Eliminates the potential for cable duct cutting

- Lower elongation reduces snap-back and enhances

- Worker safety reduces tension at the start of a cable pull

- Sequential footage or metric markings

- Reduces material, inventory and freight costs

- Cable pulling strength – 200 lbs. to 6000 lbs

- Patent pending

MULETAPE Ordering Information

| Item | MULETAPE Part Number | Strength (kg) | Typical Bowline Strength (kg) | Typical Muleknot Strength (kg) | Pail Quantity (km) | Approx Pail Weight (kg) | Pails Per Pallet |

| 41271 | WP400P | 182 | 86 | 136 | 1.4 | 6 | 27 |

| 41325 | WP1800P | 818 | 377 | 636 | 0.4 | 6.4 | 27 |

Request Your FREE MULETAPE Sample

Our products substantially reduce cable installation labour, materials, and inventory costs by providing a threading line, a measuring tape, and a winch line all in one product. Reduces damage to underground plants, improves efficiency, and enhances worker safety.

You can’t miss this opportunity if you are a Utility Company or a Contractor. Weather you are looking for pulling tapes, or a tracer wire, before you invest a large amount, we are giving you the option to see our products look and feel.

MULEGLIDE Cable Blowing & Cable Pulling Lubrication

NEPTCO‘s long-lasting silicone cable blowing/pulling lubricant called MULEGLIDE is an ideal LV, MV & HV cable lubricant, available as low-viscosity Underground Cable Blowing Lubricant or MV HV Underground Cable Pulling Lubricant, which allows for swift and safe underground cable installation.

Further Reading

- MULETAPE CALCULATOR | How To Select The Right Cable Pulling Tape For The Job

- Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

Cable Pulling & Laying Equipment

Suppliers & Distributors

Thorne & Derrick distribute the most extensive range of Low & High Voltage Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors – this includes the most extensive range of Cable Pulling & Cable Laying Equipment to enable the installation of low, medium and high voltage power cables into underground trench or duct.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV/33kV and up to EHV transmission and distribution voltages.

Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

Distributors for: 3M Electrical, ABB, Alroc, Band-It, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, ProGARM, Prysmian, and Roxtec.

- Scope –single-source supply of extensive range of products

- Stock – a multi-million pound stock holding provides complete global supply solutions

- Staff – technical support from a trained, proactive and friendly team

- Delivery – UK stock turnaround with express logistics to all international destinations