Side wall bearing pressure (SWBP), the radial force imposed at the bends, is by far the most common limiting factor. Excessive SWBP, usually visible in flattened armour or stretched jackets, can result in insulation damage which decreases cable life.

Common misconceptions that have only minor effects on the resulting pull calculations:

Maximum Pulling Tension – For power cables, this is usually not a limitation as the basket grip or pulling equipment usually limit pulling tensions before the conductors.

Upsizing the Conduit – Although you must maintain code required maximum fill requirements, upsizing conduits doesn’t lower tensions or SWBP by much.

Incoming Tension Assumption – Don’t sweat +/- 25 lbs on incoming tension assumptions as that will be a rounding figure in the final pull. However, using a cable feeder to push the cable in access points can help.

What does help:

Advance Planning & Field Communication – Can the field handle the reel you are specifying? Can it be placed where your pull calculation starts? Is there room to lay down cable for hand pulls or refeeds?

Straighten Out the Run – The fewer bends, the better. After two 90ᵒ bends, SWBP rises quickly.

Reduce run lengths – This reduces pulling tensions.

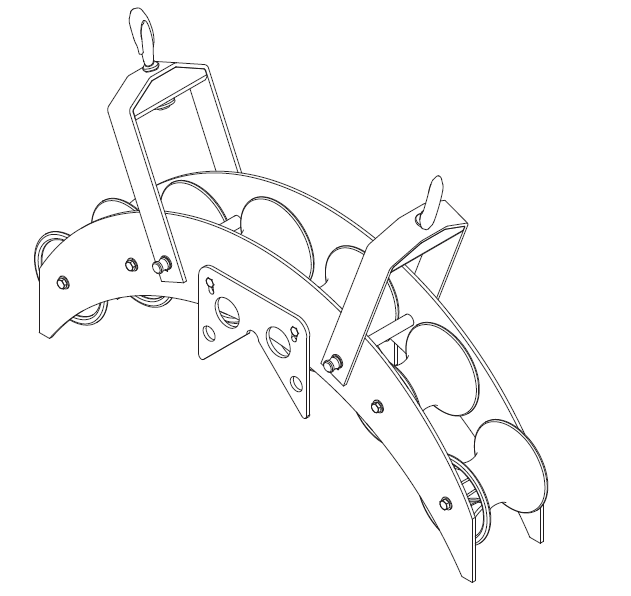

Bigger Conduit Sweeps and Sheaves – This makes a big difference to the SWBP. You should ensure that the cable minimum bend radius limitations are respected. That big 24” OD sheave is probably too small!

Tighter Coefficient of Friction (COF) Assumption – This parameter makes a huge difference in the final numbers. 0.35 is a common COF number for most common PVC jacketed industrial cables or regular building wire pulled through existing conduits. For a new installation with a good lubrication plan and experienced installation crew, 0.25 could be a more aggressive number. Southwire uses 0.15 for their no lube building wire products in PVC conduit.

Pull Boxes / Assist Tuggers – Add pull boxes to break the pull up into sections (pull out through the manhole and refeed back in). If the cables can be accessed in the middle of the run somewhere, properly set-up assist tuggers can also break up the run.

Reverse the Pulling Direction – Pull calculations are directional.

Use Equipment or Cable Products that Reduce COF – No lube cable, hydrophobic pulling ropes, Southwire SIM reels, cable tray rollers, etc., …

The final few bends might be hand pulled, reducing the need to include those sections in the cable pulling calculation. Be careful not to overbend the cable during these manual pulling steps.

Cable pull calculations can save a lot of field issues and help ensure a long, trouble-free service life of your big cable runs. A little extra effort upfront can save a lot of trouble down the road.

THORNE & DERRICK

THORNE & DERRICK