Jointers Blogs

Jointing & Connecting Submarine Cables

May 20th, 2021

Images Courtesy of: Steven Onley – Submarine Cable Project Manager at 33Below Pty Ltd and Matthew Shields – Technical Director & Marine Engineer at Vocus Communications.

Steven Onley has 30 years of experience in submarine cable marine installation, covering all facets from contract bidding to system handover, including all offshore operations such as survey, shore ends, jointing, main lay, plough burial, PLIB and repairs as well as office-based project management. Services provided:

- Desktop Studies

- Route Surveys

- Route & Cable Engineering

- PLGR/RC

- Cable Transfers

- Shore End Landings (Direct & Pre-laid)

- Main Lay & Burial

- Post Lay Inspection & Burial (ROV)

- Cable Repairs

- Land Cable

- Procedures & Reporting

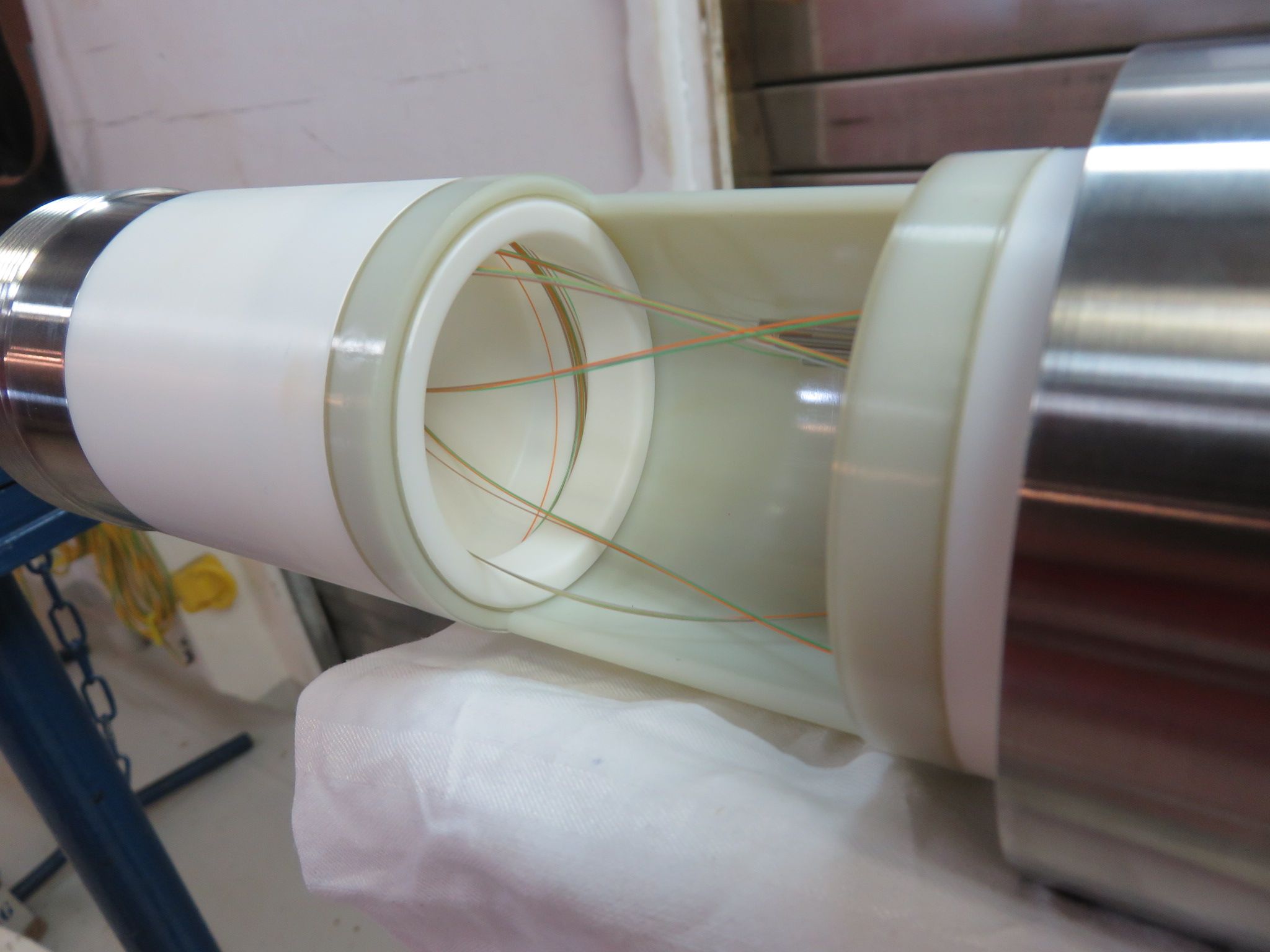

Pictured: Jointing & Connecting Submarine Cables

Steven explains ‘How do you connect submarine cable? It is not quite as simple as just making a fibre splice. Cables may only have 6-12 fibres in them, but a cable joint may take a team of 4 cable jointers as long as 18 hours to complete.

As well as making a low loss splice (<0.1dB), we need to reinstate the mechanical strength of the cable (>8 tonnes min breaking load, depending on the cable type), and also the high voltage electrical insulation (up to 12kV DC). This takes some very specialised skills.

An added complication is that each supplier like ASN or SubCom has their own proprietary method of jointing their cable. It would be impractical for repair ships to be equipped with a complete set of every supplier’s equipment, so the suppliers created the Universal Joint Consortium. A UJ (Universal Joint) kit can connect almost any type of cable to any other type of cable, regardless of supplier. Thanks to Mathew Shields for some of these photos, showing an ASN (Alcatel Submarine Networks) cable joint’

Further Reading

- Jointing 44kV High Voltage Submarine Cables Using 3M Cold Shrink Splices

- How To Remove Bitumen From Subsea Cables & Umbilicals Using Socomore Wipes

- Splicing, Wiping & Laying Submarine Cable In San Francisco Bay (1936)

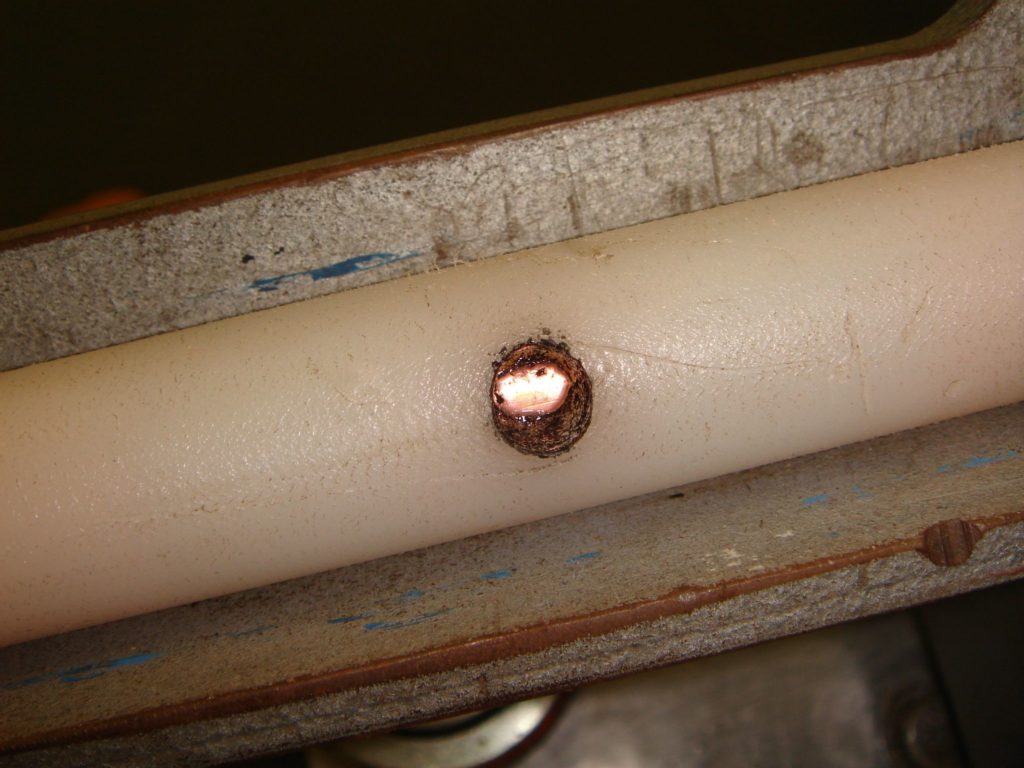

This is what can happens when there is a small scratch or contamination in the cable insulation. Submarine cables are usually powered with several thousand volts DC, which can cause a blow-out of the plastic insulation.

This example is only small (<10mm across – white cable is 21mm diameter) but it was quite spectacular when it arced as it ran along the deck while powered. You can see the burn marks around the edges as the plastic melted.

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Accessories, Jointing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV.

Stocking & Supplying | Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Jointing Tools | Cable Pulling Eqpt | Earthing & Lightning Protection | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Euromold MV HV | Cable Terminations, Connectors, Elbows & Joints

G&W Electric 220kV Cable Joints Installed To SGCC For 2016 G20 Summit

May 18th, 2021Geoffrey Cao (VP Global Operations – Energy Business) has kindly contributed the following Guest Blog emphasising the requirement for reliable high voltage electricity distribution and supporting cable accessories.

The Article explains the successful installation of G&W Electric cable joints and terminations to the State Grid Corporation of China, the largest electric utility company in the world and a state-owned transmission and distribution company.

In November 2015, G&W Shanghai received the mega 220kV cable joint order from the State Grid (SGCC) local company of Hangzhou City – the order comprised 88 units of cable joints and 6 units outdoor cable terminations for the 220kV extra high voltage network.

The project is to bury 2 circuits of 220kV overhead line to underground, as part of the infrastructure budget to renovate Hangzhou City to prepare for the G20 Summit that is scheduled in September 2016.

The G&W Electric products supplied are oil insulated outdoor terminations with composite insulator and pre-expanded cold shrink one-piece insulated cable joint.

G&W Electric 220kV Cable Joints Installed To SGCC For 2016 G20 Summit

Pictured: 220kV G&W Electric Cold Shrink One-Piece Cable Joints

Pictured: West Lake in Hangzhou

After some international events like the 2008 Olympic Games, it is well known to the world, how structured the Chinese government arranges such events, thus the significance of this project is not only customer’s acknowledgement of the high quality and reliability of product being supplied, but also the ability of on time completion of project thus subsequent construction will immediately follow the cable project completion.

The delivery of such a large volume of cable joints for 2500sqmm cable, the largest 220kV cable size, were done within 1.5 months, thanks to G&W advanced moulding technology with such a high output, efficiency and yield rate.

As standalone EHV accessory company, G&W earned high reputation to work with many cable companies for the EHV cable system in past, and this time, the accessories will be coupled with several different Chinese local cable companies.

G&W is also providing the on-site installation of all accessories supplied, which is also featured with tight time schedule due to the forthcoming Chinese new year, thus constructors will have a long holiday.

“This mega project is another good example for G&W to demonstrate ability to supply bulk quantity of extra high voltage product and our versatility to work with different cable companies for important cable system work” commented by Mr. Jim Solari – G&W Electric.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Cooper Connectors | Terminating MV Power Cable Onto GBE Transformer

May 18th, 2021Image: Danny Williamson – LV/HV Cable Jointer.

Pictured: 11kV Cooper Connectors Terminating MV Power Cables Onto GBE Transformer.

Cooper Power Series

Cooper Power Series are a part of the Eaton product range. Founded in 1947 under the name of Rural Transformer and Equipment Company, RTE developed many advances that significantly changed industry practices in underground distribution. It became part of Cooper Power Systems in 1988.

When RTE received a patent on the 15 kV loadbreak elbow design in 1966, its potential growth was probably unrealized at the time. It is estimated that there are well over 10,000,000 such elbows in service today. As a leading innovator in the industry, RTE continued to introduce new products for underground distribution systems. RTE was the first to develop non-gassing current limiting fuses. In 1994, Cooper Power Systems acquired Combined Technologies Inc. to expand their product offerings in current-limiting fuses.

Kearney engineers developed connectors, hardware and tools that made overhead line construction and maintenance easier, safer and more dependable. Family held and formed by James R. Kearney in 1926, it became a part of Cooper Power Systems in 1997.

Since then, Cooper Power Systems also came to incorporate Electromanufacturas, S.A. de C.V. (EMSA) in 1999, Cannon Technologies in 2006 and Cybectec in 2007.

Further Reading

- Cooper Power | Bushing Interfaces & Separable Connectors Guide

- ANSI Connectors | Screened Separable Connectors from Cooper Power Systems

- Cooper Connectors Terminating 33kV Cable Onto Interface E Bushings

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Jointing Masterclass – Waveform Mains & Hybrid Service Cable Joint

May 18th, 2021Image courtesy of: Antonia Stevenson

Pictured: Jointing Masterclass Using 185mm² Waveform for Mains and a Hybrid Cable for the Service Cable. Antonia attending her very first cable jointing masterclass in a jointing bay at Power Engineering Training Facility in Corby, Northamptonshire. Training provided by Richard Seaton.

Meanwhile, in a typical joint hole somewhere in the UK.

Yellow wellies on! Jointers tent up! Lunch in a puddle!

Perfect conditions for hippo’s and cable jointers…

Insulating Boots & Safety Shoes (LV MV HV 1000v 11kV 20kV)

Further Reading

- Masterclass : 110kV Cable Preparation & Termination Using Prysmian Outdoor Sealing Ends

- Cable Training School | 400kV Cable Jointing & Cad Welding 2500sqmm Copper Cables

- LV Jointer Training – LV1 Course Introduction to LV Cable Jointing (Wavecon) – Single & 3 Phase Services

- Electrical Safety – Arc Flash Accidents & Electrocution In LV-HV Installations

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Brand-Rex Fibre Installation, Termination & Testing by Networx3

May 18th, 2021Image courtesy of: Caroline Earnshaw-Florczyk Commercial Director at Networx3 Limited. Networx3 are the leading installer of blown fibre in the UK.

Pictured: Fibre Cable Installation, Termination & Testing by Networx3.

Fibre manufactured by Brand Rex, Joint Boxes by Mainframe at London Underground Barking.

Main Contractor Balfour Beatty.

Brand-Rex is a leading developer of cabling solutions for network infrastructure and industrial applications. Mainframe Communications are your one-stop solution for fibre-optics, fibre-optic products and associated services – including TÜV and LUL approved products :

- Equipment frames, racks, cubicles, cabinets and housings

- Splice trays, pivots, cassettes, frames and tap boxes

- Cable management trays, assemblies and storage

- Pig-tails, patch cords, loose-tube and multi-way cables

Video: Networx3 was commissioned to repair an Emtelle 14/10 blown fibre duct for Cybermoor. Networx3 have blown over 500 metres of fibre optic cable for Cybermoor; a community owned co-operative providing a Wi-Fi broadband network for Alston Moor and surrounding areas.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.