Blog

115kV Straight & Stop Joint On LPLF, PILC Cables In Cable Vault

April 20th, 2021This series of excellent photographs taken from site have been kindly provided by: Douglas Page, Instructor & Cable Splicer at Hydro One (Training and Development Services)

“It must be said, cable jointing is a team effort with multiple cable splicers, confined space entry personnel, there’s a “kitchen cook” that is outside the space, that keeps tapes and oil hot, hands us kettle after kettle of flushing oil, certain size rolls and tapes before we know we need them – there are very few splices that are completed by one person,” adds Douglas.

HV-EHV Cable Splicing Team : Douglas Page, Peter Hatziiounou, Craig Dowling, Walter Ryan and Bob McViegh in the “kitchen”.

115kV Straight & Stop Joint On LPLF, PILC Cables In Cable Vault

Pictured: Classic “roman arch” conductor, 115kV LPLF, PILC Transmission Cable (Low Pressure Liquid Filled, Paper Insulated Lead Covered).

Originally installed in the 1960’s the sequence shows back to back cable splices in a 16 foot cable vault – the cable jointing was required after the original cable splice became damaged in an explosion. The images cover the cable preparation and jointing stages required to reinstate the 115kV cable.

Conductor insert to prevent crushing the oil duct during cable crimping

Cable polishing

Hand taping by the cable splicer to restore cable to “factory insulation diameter”

After build up is complete, “carbon black” is added – this is the semi-conductive screen in modern cable manufacture

In the background is the completed insulated cable splice – the EHV cable splicers then had to make the 115kV stop joint shown in the preceding images about 18″ to 24″ distant from the straight joint on the same cable to allow the installation to be accommodated within the confines of the cable vault.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

EHV 132kV Outdoor Termination NKT Cable

April 20th, 2021Images Courtesy of: Tamer Ali – EHV Cable Jointer at Ibn Omairah Company, Saudi Arabia

Pictured: 132kV Cable Termination, NKT Cable

NKT have been a pioneer in the cable industry since the company was established in 1891. They offer a wide range of cable joints, terminations and cable accessories for LV, MV & HV projects.

NKT’s flexible and reliable solutions bring power to interconnections, hydro-electric and nuclear power plants, as well as onshore and offshore wind farms, oil and gas platforms and solar energy. We pride ourselves on delivering sustainable solutions for a lifetime and for generations to come.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

3M Cold Shrink 25kV Straight Joint & Cable Termination

April 20th, 2021Image Courtesy of: Andy O’Malley – IBEW 258, EHV Cable Jointer/Splicer

Pictured: 3M Cold Shrink 25kV Straight Joint & Cable Termination

3M Cold Shrink High Voltage Cable Termination 25kV

3M Cold Shrink High Voltage Cable Joint 25kV

Further Reading

- MANWEB – Cable Jointing Past & Present by Patrick & Andy O’ Malley

- Confined Spaces Cable Jointing Using 3M Cold Shrink Straight Joint Splice (25kV)

- EHV Cable Joint – LS Cable 240kV 3000 KCMIL XLPE Cable Circuit

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

By Anon – A Professional Australian Cable Jointer

April 20th, 2021“I am concerned that without a minimum standard, the cable jointer as we know it will cease to exist,” commented Stewart Cornelius (LV-HV Cable Jointer) recently on LinkedIn.

Stewart is a third generation jointer – he is as qualified to talk as we are obliged to listen.

Cable jointing is in his DNA and he like many other jointers take “massive pride” in their work.

I believe his heartfelt remark probably elicited the following full length article I received earlier today by private email from an internationally respected cable jointer in Australia.

Although the words just made it online today the thought has occupied professional cable jointers across the globe for years.

Professionalism & Privacy Please

The author has requested that their identity remains private.

Please respect their wishes and let’s also not speculate about who or who not it may be.

Let the person reassure you, “understand that I am committed 100% to what I have said, but I cannot be bothered with the deluge that will surely flow from people who can’t handle the facts.”

Perhaps this will galvanise some form of industry action or at least spark some further debate towards strengthening the status of Professional over Cowboy cable jointers.

Cable Tools – Alroc Cable Jointing Tools

The following is reproduced with kind permission of Anon (A Professional Australian Cable Jointer).

“I have noticed lately through LinkedIn that you have shared in dialogue regarding the ongoing fall in standards across the cable jointing spectrum. This is a subject that I have given considerable thought to in recent years. If you will permit I would like to share some of those thoughts with you outside of the LinkedIn forum.

There are a number of factors that combine and contribute to the steady rise in the number of inadequately experienced operatives throughout the voltage range.

The number of people that can tell the difference between a job done and a job well done in our trade is in decline. In the not too distant past the decisions regarding the choice of service provider laid with people who had proven, time served experience within the industry. It was often a decision made from an engineering view point. As the market has changed and become steadily more competitive these people have been displaced by those from commercial backgrounds who have little experience and make their decisions from a financial perspective only.

This opens the door for those with little experience and inadequate skill levels to exist and offer substandard services at low prices, a trend that makes it difficult for the time served experienced operative to maintain an identity. In short once the people that know the difference disappear, there will be no difference.

Training is another contributing element to the overall decline in standards. From my apprenticeship days the practical training I received was delivered by instructors who possessed, through many years in the field, a skill set of the highest order.

I can never once recall being asked to do anything that was not demonstrated skilfully by the instructor. Not the case today. These people have given way to the modern trainer, often an individual with limited experience in the industry with a poor command of knowledge and skills. The end product is often, through little fault of their own, a poorly advised poorly trained operative.

Nationally approved industry training courses, such as those available here in Australia, may sound like the answer. Sadly though they are provided by organisations that are more focussed on generating revenue than producing accomplished tradesmen.

I can assure you that even with the nationally approved courses here in Australia, the problem remains. The very organisations that are being set up to support a trade, if truth be known, are letting it down. Of course you can buy training but the key element, being experience, you cannot buy. Training on its own, regardless of how good it is, is not the answer it must be combined with experience to reverse the current trend.

Combined with your great and I’m sure much appreciated efforts to highlight what is often a little understood trade as well as the work of the guys that operate with great skill in the arena, maybe standards can be lifted. I hope so.

Food for thought……….”

Duct Seals | Cable Cleats | Cable Joints | Cable Lugs

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

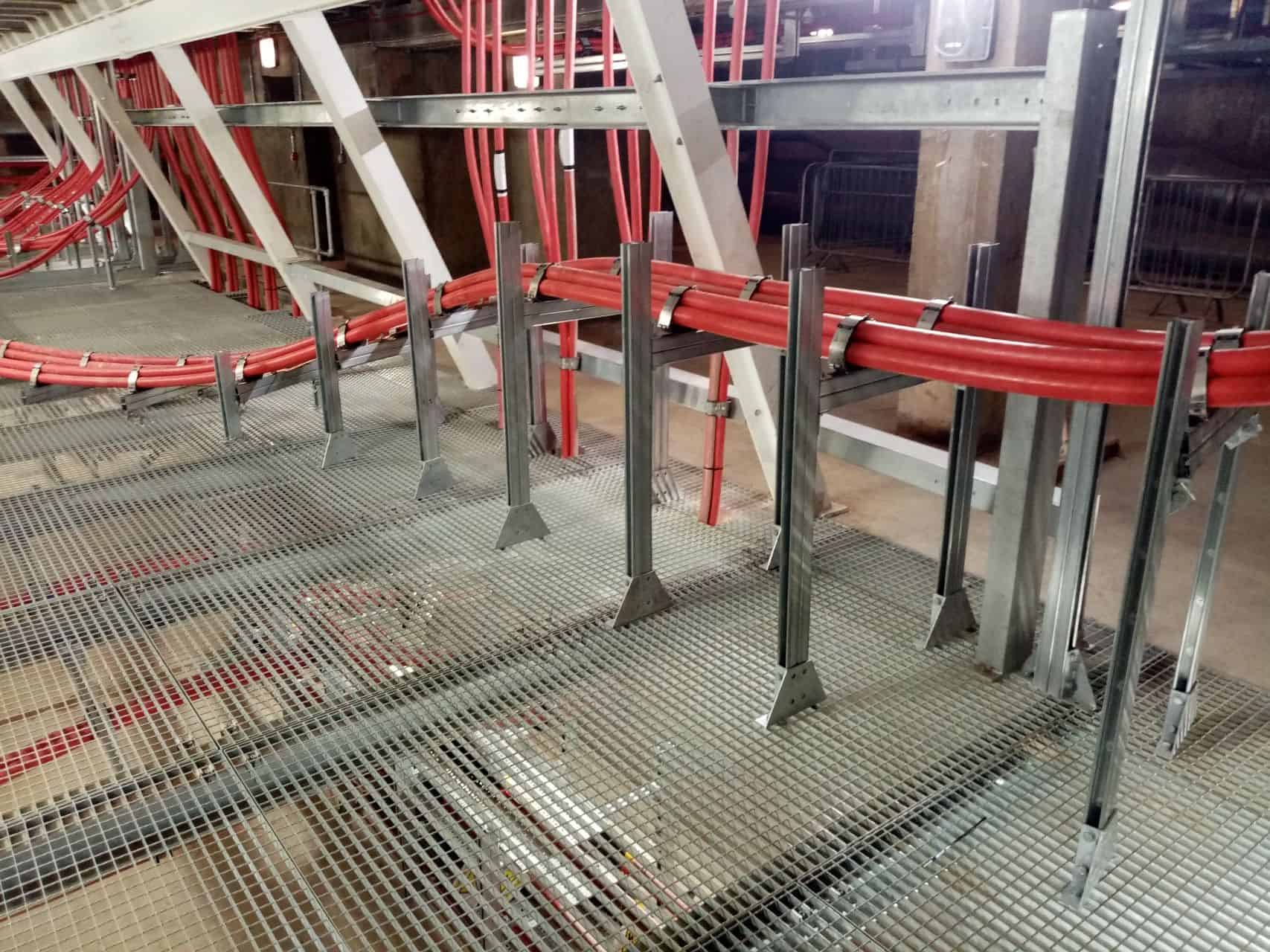

11kV Cable Installation At Carnaby Street

April 20th, 2021Images Courtesy of: Declan Scully – AP, SMSTS, HV Electrical Fitter and Electrician at UK Power Networks

Pictured: 11kV cables installed using cable cleats manufactured by Ellis Patents

WHAT ARE CABLE CLEATS?

Cable cleats are used to fix, clamp and support cables – cleats provide effective short circuit protection, support and retention to LV, MV and HV power cable systems when installed at intervals to circuits to secure electrical installations.

The cable cleats provide restraint and prevent excessive cable movement resultant from fault-current magnetic forces – cleats must be suitably rated for cable size (outside diameter) and anticipated fault current (peak fault level kA).

Correctly specified cable cleats will withstand the forces corresponding to the values of the peak prospective short-circuit current.

Power cable system designers, engineers and specifiers must consider the correct cable fixing or securing system to provide safe and adequate restraint and protection of LV, MV or HV cables – cable cleats restrain movement of cables during electrical fault conditions.

Cable cleats are available to suit all environmental conditions (onshore and offshore), industrial applications and operating voltages – specialist cable fixings for fire resistant, low smoke zero halogen (LSF LSOH) and quadrafoil (Quad) cable installations.

“Every conductor or cable shall have adequate strength, and be so installed as to withstand the electromagnetic forces that may be caused by nay current, including fault current.” IET Wiring Regulations 17th Edition BS7671:2008 (2011).

CABLE CLEAT SPECIFICATION

Selection of cable cleats should consider several key factors:

- Cable Diameter – the overall diameter of the LV-HV cable ensure the correct size of cleat is chosen. This dimension, namely the outside cable diameter around the cable sheath, is also required for calculating short circuit forces the cleat could potentially be subject to under fault conditions.

- Performance – depending on the cable installation application there may be a requirement for the cleat to include material performance and specification features, for instance fire resistance, LSF (Low Smoke Fume), LSOH LSZH (Low Smoke Zero Halogen) or corrosion resistant (stainless steel)

- Cable Type – check cable voltage and construction: LV Low Voltage, MV Medium Voltage or HV High Voltage.

Thorne & Derrick | Ellis Patents UK Distributors

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.