Blog

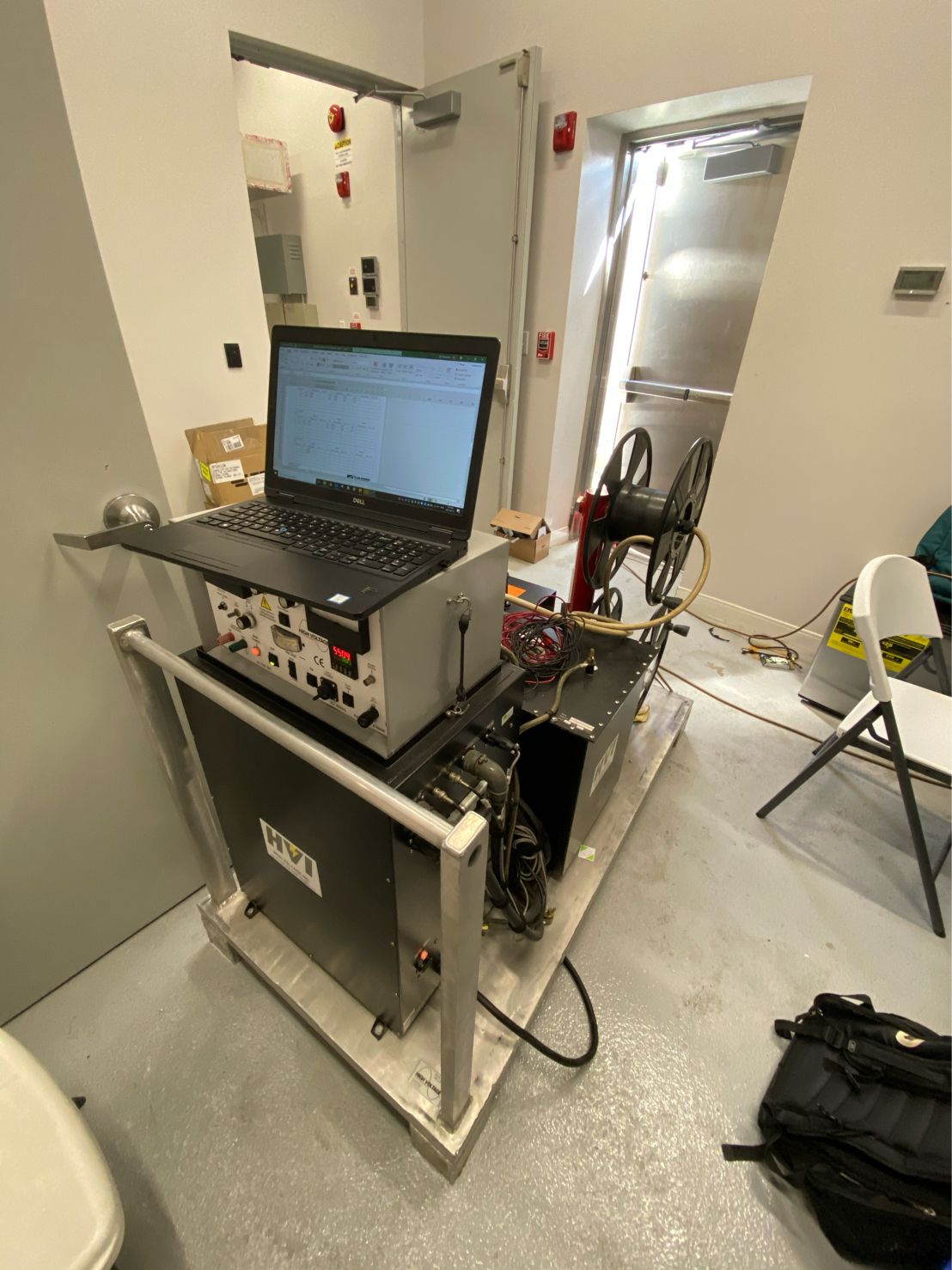

VLF Testing Of 69kV Cables With Pfisterer SF6 Cable Joint

March 30th, 2021Images Courtesy Of: Bruno Da Silva – Owner at HV Connect LLC – MV, HV, EHV Cable Splicing & Testing

Pictured: Assisting Team Power Solutions in the Cayman Islands for the VLF Testing of 69kV cables with PFISTERER Size 4 SF6 cable joint, after the cable splicing.

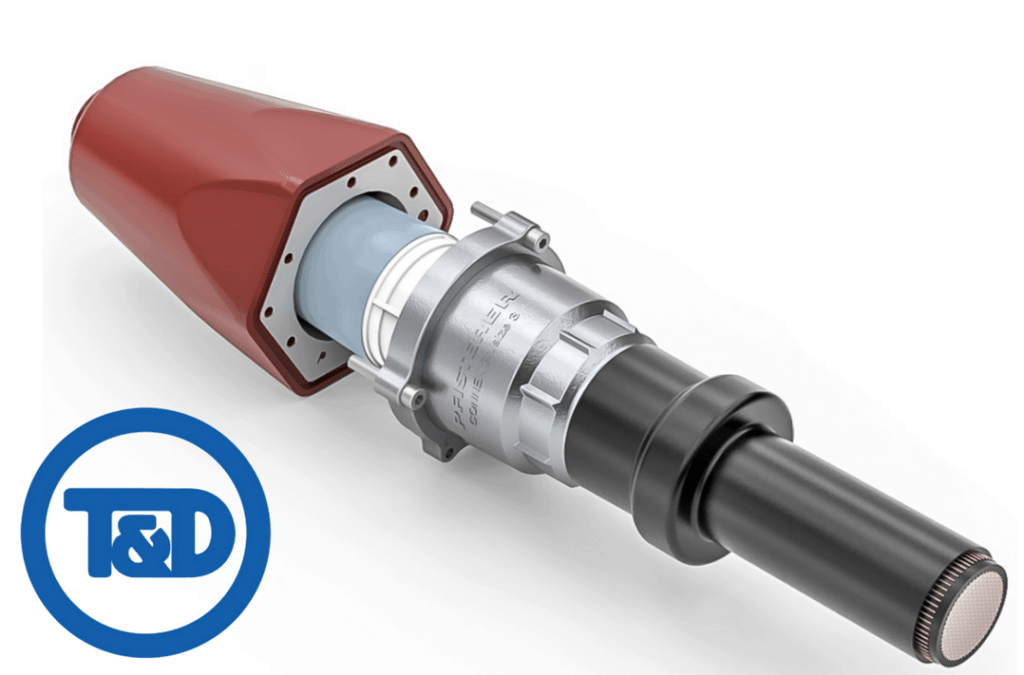

MV Connex Products | Ex Stock Thorne & Derrick

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

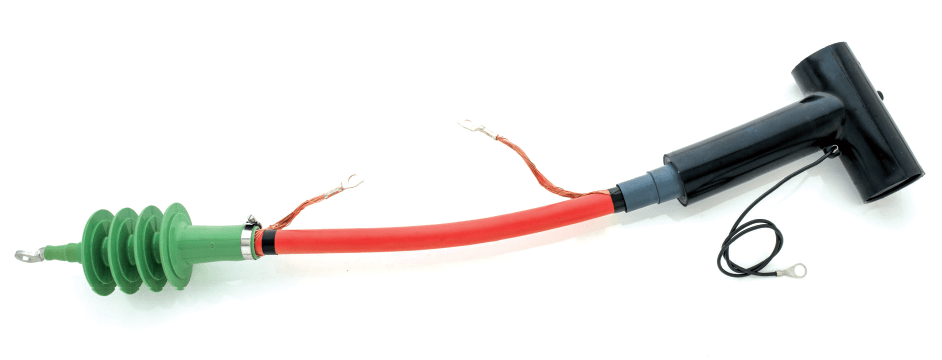

MV Cable Leads | Pre-Terminated Medium Voltage Cable Leads for 33kV Power Networks

March 30th, 2021

Cable Leads MV 33kV

MV Cable Leads

Pre-assembled custom, ready-to-install MV cable leads manufactured by Nexans are available equipped with Interface “A” to “F” separable connectors and terminations (Heat Shrink, Cold Shrink and Slip on). Cable types available are standard MV XLPE and Class 5 Flexible cables. Just contact Thorne & Derrick and specify connector/termination type, cable type and length and we provide competitive prices and short lead times for the delivery of custom MV cable leads – assembled and tested. Typical applications for cable leads include connecting between MV distribution transformers and electrical switchgear. Testing options available include Megger, HI Pot (AC withstand to 72kV) and partial discharge (PD). Contact us with your requirements.

MV Cable Lead | Here a medium voltage (MV) cable in shown terminated using Nexans AFN Slip-on Cold-applied Cable Termination with Screened Separable Connector for connection to MV switchgear, transformer or electrical equipment up to 33kV

Thorne & Derrick

Nexans Main UK Stockist & Distributor

Contact us for Competitive Prices & Fast Delivery from Stocks for Heat Shrink, Cold Shrink & EPDM Rubber Connectors, Joints & Terminations up to 66kV.

Go to our Price List and contact us with your enquiries.

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Accessories, Jointing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV.

Stocking & Supplying | Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Jointing Tools | Cable Pulling Eqpt | Earthing & Lightning Protection | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Euromold MV HV | Cable Terminations, Connectors, Elbows & Joints

MV ‘Backup’ Fuses (Current Limiting Type) Are Not Rated For ‘Overload’ Current Interruption

March 30th, 2021MV ‘Backup’ Fuses

From IEEE Std C.37.48.1

“MV backup fuses can interrupt any current between its rated minimum interrupting current and its rated maximum interrupting current. If a backup fuse is melted open at a current level less than its minimum interrupting rating, the fuse is not required to, and may not successfully, interrupt the circuit. In this case, the fuse melts open at only a few places, often a single point, along the length of the element. Burn back of the element proceeds very slowly, as the arc heat causes the sand to melt and form a resistive fulgurite. During arcing conditions, a large amount of heat is released in a limited area within the fuse. This heat can prevent the sand and the resultant fulgurite formed in the sand from developing dielectric properties needed to withstand circuit voltage. As a result, the fuse may fail to interrupt the current and be destroyed as it attempts to clear.”

Solution(s): Include a protective device in series which is rated for overload operation (increase back-up fuse size to get out of the zone), employ full range fuses.

In this case, an upstream SF6 breaker was able to be coordinated with the needs of the CL fuse – here the fuses are immediately ahead of the transformer primary.

Guest Post by Matthew Denis | Principal Engineer at Rockwood Engineering (Ontario Canada)

Services | Medium Voltage Electrical Power System Design & Analysis | Power System Analysis including: Protection Coordination, Arc Flash, Short Circuit, Harmonic & Load Flow | Power Quality Assessment/Mitigation | Power Distribution Design (Industrial, Utility, Commercial, Agricultural), Medium Voltage Power Systems Design

MV Fuses | Thorne & Derrick distribute the complete range of ABB Medium & High Voltage Fuses (MV-HV) for the protection of 11kV & 33kV switchgear, transformers, cables and substations.

Definition: MV Back-up Fuses by ABB

Current limiting back-up fuses. The current limiting fuse family is generally composed of three different fuse groups: back-up fuses, general purpose fuses and full range fuses. All of them limit the value of prospective short-circuit currents during the interruption process, thereby extending the life time of nearby installed electrical equipment. The main difference is in the minimum breaking current that characterizes the lowest fault current that the fuses are capable of interrupting. This value is generally highest for back-up fuses, slightly smaller for general purpose fuses and smallest, with the value close to the minimum melting current, for full range fuses. But reaction time is critical for the protection function. That is why back-up fuses, with an interruption time for the minimum breaking current in the range of a few seconds down to a few tense of milliseconds, are the most commonly used. The total clearing time in cases of high short-circuit currents is even shorter i.e. only a few milliseconds. That is why back-up fuses can be used as typical overload protection elements. General purpose and full range fuses capable of interrupting even the smallest values of currents can only be considered as over current devices since the interruption time is greater than one hour. Therefore, these types are used rarely and are usually recognized as a separate element of protection, without any linkage to the opening function of load break switch. ABB current limiting fuses have low minimum breaking currents, i.e. close to three times the rated current In.

WHITEPAPER: World’s First 2-Pole HV 13.8KV Non-sparking Generator For Use In Hazardous Areas

March 29th, 2021

Power Generation Equipment In Hazardous Areas

First 2-Pole HV 13.8KV Non-sparking Generator

The BRUSH Group are proud to announce this ground-breaking technological advancement with the official issue of the first in a new series of White Papers, detailing the development and new industry standards surrounding the world’s first Non-sparking 2-pole generator.

This application-led solution reduces procurement, operation and maintenance costs on generators and associated equipment installed in explosive environments.

Launched at the FPSO World Congress event by Roy Beardshaw, BRUSH’s Head of Engineering, the paper details the current industry standards and how this exciting new development can change the use of power generation equipment in hazardous areas.

Chris Abbott, CEO of BRUSH commented: “the innovation that BRUSH has made with the non-sparking high voltage generator truly leads to a step change in the operational flexibility and cost for power generation units in hazardous environments.”

The paper focusses on the limitations of the current industry approach and how this innovative solution not only brings exceptional safety levels, but also offers operators significantly lower running, maintenance and ownership costs.

The intelligent, new BRUSH 2-Pole HV Non-sparking Generator design has gained independent approval and been classed as non-sparking for Zone IIA and IIB gas applications. These are typical operating environments on the open deck of oil rigs, FPSO’s (Floating, Production, Storage and Offloading) vessels and many chemical processing plants.

World’s First Non-sparking 2-pole Generator

WHITEPAPER CONTENTS

- Application Focus: FPSOs and Oil Rigs

- Severity of Risk: Operating in Explosive Environments

- The Current Approach: Evolution, Limitations and Cost Implications

- The BRUSH Innovative Solution: 13.8kV Non-Sparking Generators

- Testing and Inspection to EN 60079-15: Verification and Validation

- Industry Benefits: Reduced Footprint, Faster Start-Up and Lower Maintenance Costs

- Reduced Plant Footprint, Lower Power & Reduced Lifetime Operational Costs

- Setting New Industry Standards for Power Generation in Hazardous Environments

To download the White Paper in full and see how industry standards in power generation within hazardous environments will never be the same click the image below.

ABOUT BRUSH

The BRUSH Group has a long and rich history serving power generation customers as an OEM of generation, control, and distribution products. While primarily known for supplying industry leading turbo-generators and power management systems, BRUSH also designs and manufactures transformers and switchgear of equally high quality.

Today, the integrated companies operate as “One BRUSH” with competency centres for 2-Pole & 4-Pole generators, power management and control systems, transformers, switchgear, and OEM services. BRUSH serves the global power generation and distribution markets with a strong foundation of technical knowledge to support grassroots projects, capacity expansions, and drop-in-replacements.

Thorne & Derrick

T&D are Specialist Distributors to UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and HV Jointing Contractors of an extensive range of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt – this includes 11kV/33kV/66kV cable joints, terminations and connectors for both DNO and private network applications.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

All international sales enquiries can be serviced and supplied by our Export Power Team.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Cembre B-FL750ND | 18V Handheld Cordless Hydraulic Tool With Bilinear Structure

March 26th, 2021

Bilinear Hole Punching Tool

Cembre B-FL750ND

The B-FL750ND 18V Handheld Cordless Hydraulic Tool from Cembre is the new generation of handheld, cordless cable cutting and cable crimping tools, characterised by the “Bilinear” structure of the tool’s mechanics.

Operator comfort and convenience are key factors in producing repeatedly consistent high integrity crimped joints. Cembre ‘ND’ bilinear tools have their mechanical centre of gravity nearest to the operator’s wrist to optimise the overall ergonomics of the tool and provide a wider support for the hand.

Thus the innovative misalignment between the pump drive mechanism and the hydraulic system both reduce the torque generated on the operator’s wrist and best distribute the stresses acting on the hand.

A greater punch speed and punching force result from a revitalised hydraulic system with double speed action. The balanced punching head pivots 180deg through a full 360deg rotation for ease of use in confined spaces.

![]() Equipped with intelligent automatic return at the end of the pressing cycle (Smart Release) and Li-Ion 18 V-2Ah rechargeable high capacity batteries.

Equipped with intelligent automatic return at the end of the pressing cycle (Smart Release) and Li-Ion 18 V-2Ah rechargeable high capacity batteries.

Fitted with a maximum pressure sensor for enhanced precision and repeatability of the maximum pressure cycle, and a pressure relief valve providing additional safety for the operator.

![]()

The Electronic Pressure Sensor (EPS) guarantees the precision of the crimping operation, checking the actual value of pressure and informing the operator about possible errors.

The OLED display provides essential real time operating data, including:

- generated crimping force thus verifying accordance with best practice

- battery charge status

- general operating information

- the number of work cycles completed and remaining before recommended maintenance.

Weight and balance have been reconfigured to yield improvements in handling and convenience. The more rigid structure of the bi-component plastic body provides greater mechanical protection while its rubber inserts boost operator safety and comfort.

Quieter operation, illumination of the working area via LED lights and a minimum of vibration enhance the tool’s practicality.

The integrated memory card enables the user to store data from up to 200,000 compression cycles for transfer to a computer via a USB cable. (SMARTOOL technology).

Cembre B-FL750ND | Bilinear Puller Type Hole Punching Tool

Cembre B-FL750ND

Operating features:

- Bilinear mechanical design

- Smart Release system to automatically retract the ram at the end of the crimping cycle

- OLED multifunctional display with touch button

- Electronic Pressure Sensor (EPS)

- SMARTOOL technology for viewing and downloading operational data

- 180° rotating head

- Start button protected against accidental operation

- Manual pressure release button

- Illumination of working area via 4 x LED lights

- Bi-component plastic body

- Ergonomic design for operator comfort

- Li-Ion 18.0 V-2Ah rechargeable high capacity battery

- Battery connection system with release button.

18V Handheld Cordless Hydraulic Tool

Technical Characteristics

| Type of Action | Hole Punching |

| Maximum Diameter Pierceable | 140mm |

| Battery Material | Li-Ion |

| Battery Voltage | 18V |

| Battery Current | 2Ah |

| Length | 136mm |

| Height | 474mm |

| Width | 81mm |

| Weight | 4.1kg |

| Available Punching Accessories | Round punch, square punch, rectangular punch, D punch. |

LV Lugs & Connectors – complete range of copper crimp connectors suitable for use with joints and terminations for low voltage cables | Cable Lugs | Cable Splice Connectors | Aluminium Lugs | Aluminium Splices | Bi-Metallic Cable Lugs

Cutting & Crimping Tools

Thorne & Derrick

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV | Cold Shrink