Blog

Would You Trust A Voltage Indicator With Your Life & Your Business? | Safe Electrical Isolation 2 of 2

March 8th, 2021

Safe Electrical Isolation Using A Voltage Indicator

Electrical Safety

Guest Article by Paul Wilson from Martindale Electric

UKs Leading Manufacturer of Safe Isolation & Voltage Detection

Promoting Electrical Safety

Importance of Safe Electrical Isolation

Safe isolation procedures are in place to ensure that workers on site are not exposed to danger when working on or near live electrical systems and equipment. Both the standards for the equipment and the potential penalties for non-compliance have changed in recent years. With around 1,000 serious accidents in the workplace each year and 16% of all fatalities linked to electricity, it’s clear to see how following simple safe isolation procedures and using the correct electrical test and isolation equipment can keep your team safe and avoid heavy penalties.

If you are already using voltage indicators as part of your electrical safety processes, then you are creating strong foundations for a robust and safe isolation procedure, but it does not end there.

With electricity cited as the root cause of about 1000 accidents at work each year, along with increasing financial penalties and custodial sentences extending to employees as well as Directors, as per section 37 of the Health and Safety at Work Etc Act, developing safe isolation processes to guarantee a more rigorous electrical infrastructure that safeguards people and assets has never been more vital.

The best voltage indicators (VI) for safe isolation are fully compliant with the current standards and have been engineered with safety in mind, eliminating batteries and switches that could lead to false indications. Whilst VI’s are designed with inherent reliability, it is still vital to verify the performance of the voltage indicator itself.

If you are relying on the voltage indicator to prove dead, how are you verifying the voltage indicator?

The importance of confirming that the test instrument is working correctly is as important as confirming that an appliance or piece of equipment being tested is dead – and that there is no possibility of it becoming live while you are working.

The criticality of this cannot be overemphasised. VIs should be proved using a known source or preferably a proving unit – both before and after testing the circuit.

GS38 compliant VI13800 and VI15000 voltage indicators from Martindale Electric have been designed to work without the need for a battery; but if you are currently relying solely on a battery-operated device to provide a positive indication and that battery is flat, then you may not be able to prove that a circuit is dead. Equally, you may not hear the buzzer alert due to background noise. A lack of positive indication does not always prove absence, which is why the cross-check with a proving device could quite literally be a lifesaver.

Safe Electrical Isolation | Ensuring Compliance Around Electrical Safety

How can you be sure of safe isolation and proving dead?

To prove dead, it is vital to test the voltage indicator against a known source – such as a proving unit – then test the circuit, then test the VI against the known source once again to prove that the tester is functioning properly. The proving unit will verify the performance of the voltage indicator.

It is recommended to use a dedicated proving unit matched to the VI in order to fully test that all LEDs on all ranges of the VI are working – safeguarding against incorrect readings due to a faulty LED, for example. A proving unit is safer than the mains and provides a live source wherever you are working – with no need to leave the working area.

Furthermore, it is important not to over-prove: a three-phase VI should be proved at 440V whereas a common 2 pole indicator with a 690V range should be proved at 690V.

By incorporating a proving device into an electrical safety process, that process becomes inherently more robust and reliable. Although a relatively simple addition to the process, when working with or near electrical systems and equipment a proving device can significantly reduce the risk of electrical injury to you and others around you.

There have, tragically, been many instances of injury and loss of life where personnel were working on circuits that were believed to be dead when they were not or had been inadvertently re-energised. As an industry, we have a responsibility to educate as broadly as possible. It is entirely possible to minimise these risks and develop safer working practices through relatively simple changes and the introduction of safe isolation procedures.

As a result, we invest in ongoing development work to make it easier than ever to keep yourself safe. Our proving devices are available as individual units to supplement existing devices but we have also created a package, together with voltage testers and lamps, which we hope will encourage the routine testing of indicators every time they are used. We want to help the industry create new – safer – habits when it comes to electrical safe isolation, whilst always ensuring compliance.

➡ First Blog Of Series – Proving Dead To Keep You Safe | Safe Electrical Isolation 1 of 2

Safe Isolation Procedure

This chart is published with the kind permission of the JIB and shows the safe isolation procedure that you should use when working on electrical systems and equipment.

LV MV HV Jointing, Earthing, Substation & Electrical Eqpt

The UK’s Leading Electrical Safety Equipment Distributors

Thorne & Derrick provide competitive prices and fast delivery from UK stock for the complete range of Electrical Test Equipment, Voltage Detection & Safe Electrical Isolation manufactured by Martindale Electric.

T&D are the UK’s largest stockis of CATU Electrical Safety Equipment of products for underground, overhead line and substation safety at LV, MV and HV cable networks.

Insulating Gloves | Insulating Matting | Voltage Detectors | Arc Flash Clothing | Substation Safety | Portable Earthing LV MV HV

Water Treeing in High Voltage Cables | A 230kV HPPT Termination Repair

March 2nd, 2021

This series of excellent photographs taken from site have been kindly provided by: Douglas Page | Instructor & Cable Splicer at Hydro One Training and Development Services

As Ontario’s largest transmission and distribution electricity provider, Hydro One is committed to providing homes and businesses across the Canadian province with safe, affordable and reliable electricity.

Water Treeing

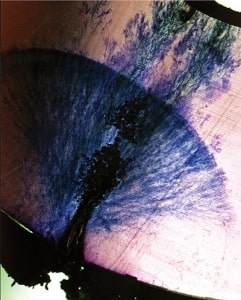

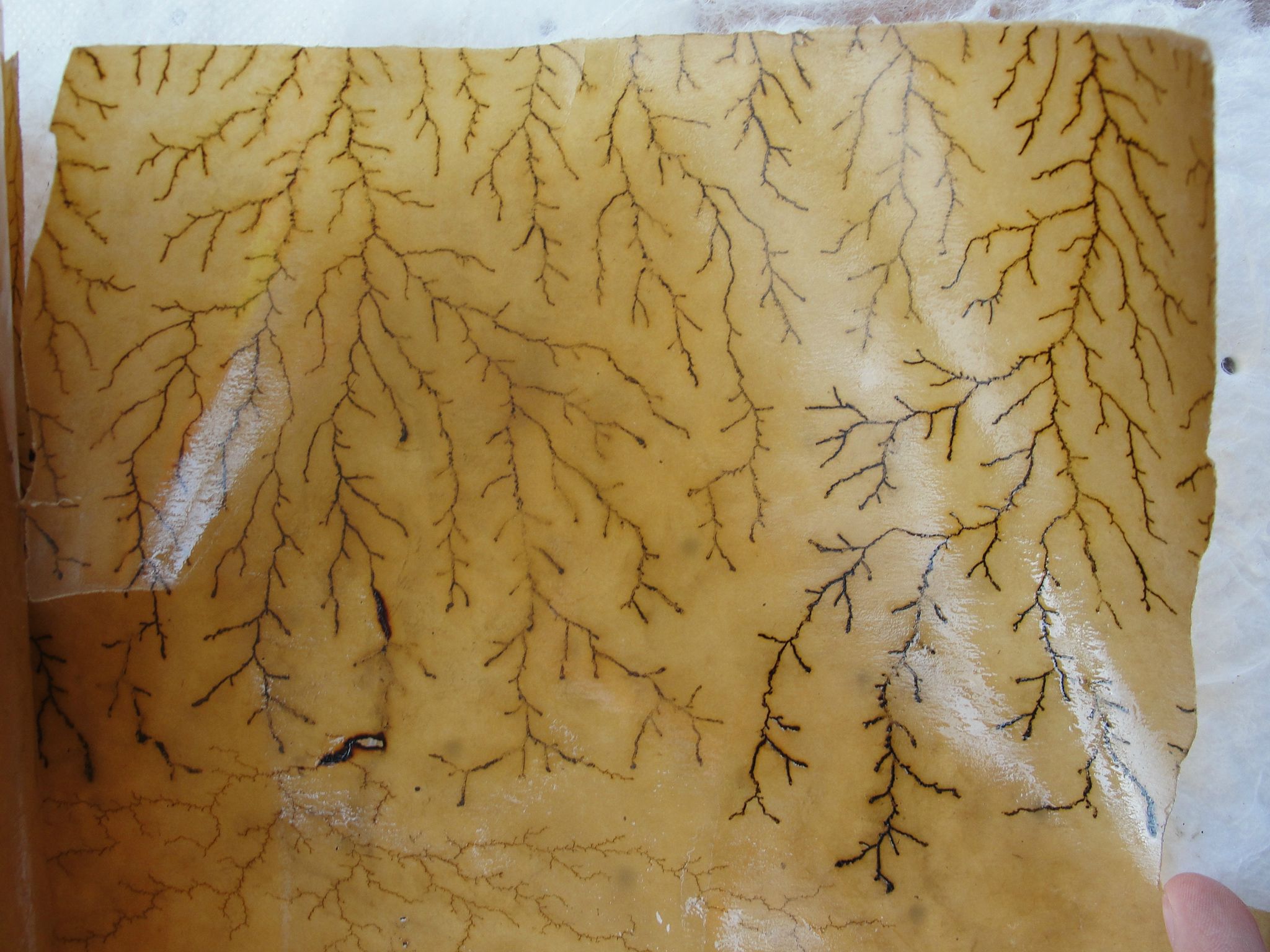

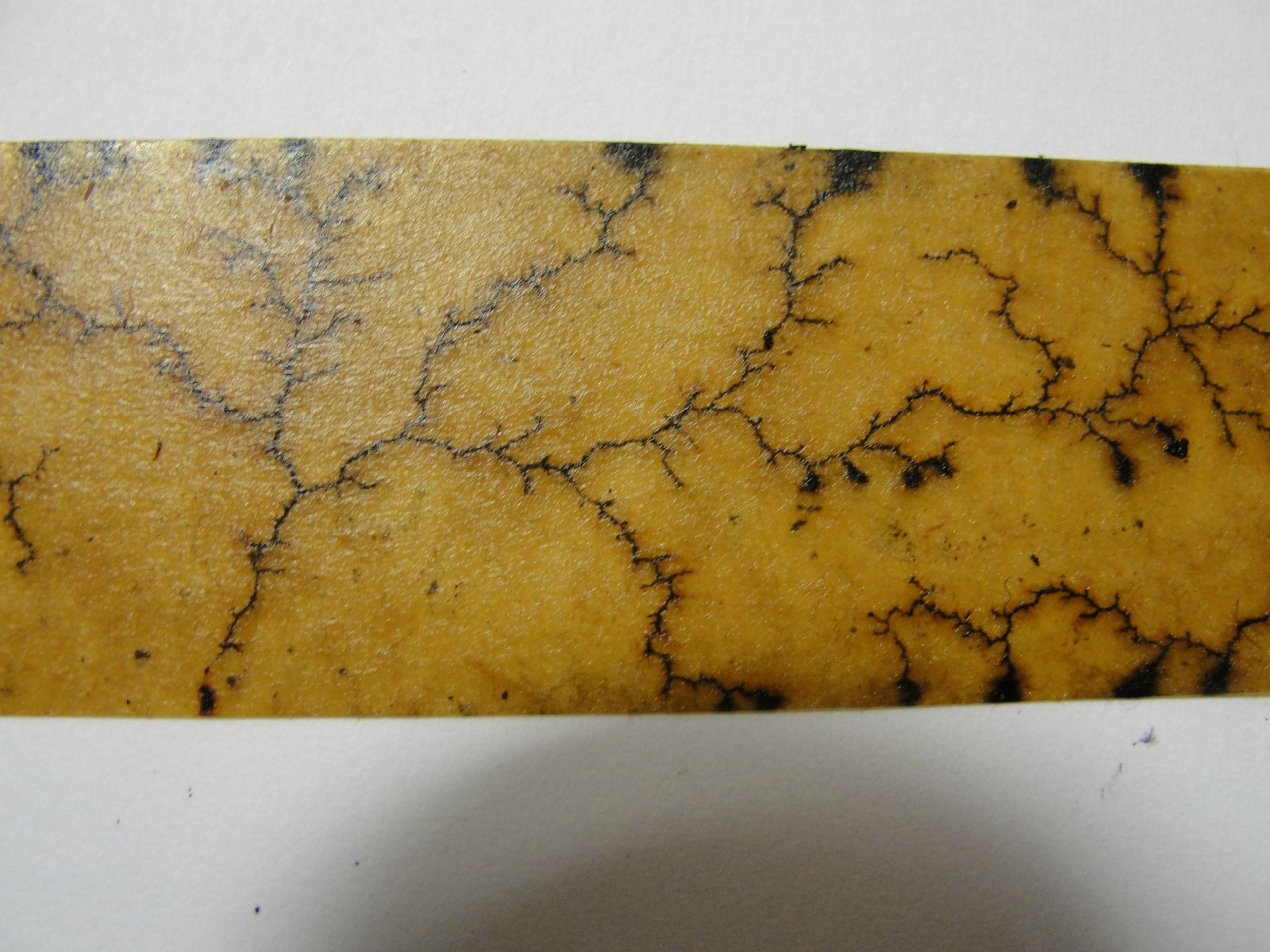

Water treeing is one of the major causes of premature failure of medium, high and extra high voltage power cables. Water-trees increase cable insulation losses and in some cases can initiate electrical trees that lead to breakdown. High voltage cables are exposed to water and moisture in general condition. Water action on cable insulation systems causes changes in their properties and creates such water-trees.

The electrical degradation process of ‘treeing’ in cable polymers occurs in the presence of electrical stress and moisture. This is acknowledged as a serious cause of non-mechanical insulation degradation and cable failures.

The water tree issue is considered by most people as solved and indeed due to improvements in the design, the manufacturing process and the insulation compound the growth of water trees in new cables has been drastically reduced.

Water tree retardant cross-linked polyethylene power cables (TR-XLPE) have extended medium voltage primary distribution cable reliability and lifetime.

Longer-life TR-XLPE cables have been successfully installed by North American utilities for over 25 years using advanced performance XLPE insulations on ‘wet’ designs for underground distribution systems.

Water-treeing and the expected remaining lifetime of aged cables on high voltage power networks provides serious challenges and requires a high-skilled response by HV cable splicers – asset managers often have to maintain and service kilometres of first generation cable requiring traditional cable jointing and repair skills that are often no longer taught in today’s modern utility jointing schools.

Accelerated aged tests conducted on new cables in laboratory conditions by CIRED have concluded, ” bow-tie trees seem to represent an image of contaminants present in the insulation and vented trees seem to be related to the impurity content of the semi-conductive layer.”

Further reading: New Test Results With 3kHz Accelerated Growth Of Water Trees In Medium Voltage Power Cables (2011).

Water-Treeing

Images Courtesy: Douglas Page

The following sequence of images convey water-treeing or arcing inside a high voltage cable termination. This a 230kV HPPT (High Pressure Pipe Type) Cable Termination or (Pothead). These images show the importance of routine oil sampling, which detected acetylene in the samples, which in turn indicates arcing or burning.

The cable splicers froze the cable below the pothead, removed the porcelain and found a high voltage cable very near failure. Then the cable splicers basically removed everything that been damaged and rebuilt the cable first, then rebuilt the stress cone. It was later found that a rubber gasket had a small imperfection that allowed contaminants (moisture debris) into the pothead, which as it accumulated had created a conductive path on and in the paper insulation, which would eventually have lead to cable failure.

The following images portray the process described above.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

132kV Prysmian Oil Filled Stop Joint & 132kV Straight Joint

March 2nd, 2021

Pictured : 132kV Prysmian Oil Filled Stop Joint & 132kV Straight Joint

Image : Simon Chapman (Cable Jointer – Balfour Beatty plc).

Prysmian HV Cable Accessories – Overview

- Straight Joints

- Stop Joints

- Outdoor Terminations (ODSE)

- SF6 – Immersed Terminations (SF6-OISE)

- Transition Joints

Prysmian Group

T&D are Distributors for the Prysmian Components range of cable joints, terminations, cleats, glands and lugs for use on LV, 11kV and 33kV cable networks.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

220kV Land To Sea Cable Joint – Welded & Crimped

March 2nd, 2021

Pictured: 1600sqmm aluminium jointed to 1000sqmm copper conductors.

Tig and mig welded and crimped by Simon Chapman (Cable Jointer – Balfour Beatty).

We would be delighted to feature more photographs in our HV Jointing Gallery from cable jointers – please submit to [email protected] with brief description of image.

Further Reading

LS 220kV Cross Bonded Joint XLPE 2500sqmm Copper

220kV 2000sqmm Copper Enamelled Stranded Cable | Sandblasting by the Jointers

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

110kV Prysmian Screen Break Cable Joint – EHV Extra High Voltage

March 2nd, 2021

By EHV Cable Jointer Andrew Brezovszky, Energex Australia.

Energex distribute electricity to more than 1.4 million residential, commercial and industrial customers across a population base of around 3.2 million in South East Queensland.

110kV Prysmian Screen Break EHV Extra High Voltage Cable Joint

Prysmian 110kV Screen Break Joint – landing the stress control joint mould onto 1600sqmm cable. An extraction tool is used to remove the pre-mould from the carrier tube.

Prysmian 110kV Screen Break Joint – an older style 110kV Prysmian screen break joint used on a super-sheathed cable (stainless steel corrugated sheath over the copper corrugated sheath).

Prysmian 110kV Screen Break Joint – completed 110kV super-sheathed XLPE cable with Prysmian screen break joints on paralleled feeders.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.