Blog

Cable Pulling For Alith Project 110kV XLPE Power Cable

May 12th, 2020Image Courtesy of: Mohamed Megally (Electrical Design Engineer ASG Holding)

Pictured: High Voltage Cable Pulling For Alith Project 110kV XLPE Power Cable Manufacturer – Jeddah Cables Factory

Thorne & Derrick are leading stockists and distributors of an extensive range of Cable Pulling Products & Equipment.

Snaking During Cable Pulling 110kv KAEC project – the high voltage power cable is installed undulating and underground to retain approximately 5 metre for each circuit for future use.

Further Reading

- Masterclass : 110kV Cable Preparation & Termination Using Prysmian Outdoor Sealing Ends

- Nexans Cable Leads Keep High Voltage Energy Transmission Flowing – 110kV, 132kV & 220kV

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Old Circuit Breaker (MSM 170kV) Replaced By New Circuit Breaker (COMPASS I 170kV ABB SpA)

May 12th, 2020Image Courtesy of: Luigi Salvatore (General Director Global Technologies Services srl).

Pictured: Old Circuit Breaker (MSM 170kV) Replaced By New Circuit Breaker (COMPASS I 170kV ABB SpA) in SE Buzzi Unicem Guidonia Plant.

Further Reading

- Brush Hawker Siddley VMV12 Vacuum Circuit Breaker Double Busbar – 50

- GEC BVP 17 Oil Circuit Breaker | MV HV Switchgear – 49

- GEC HMX36 Vacuum Circuit Breakers | MV HV Switchgear – 45

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

115kV G&W Oil Filled Straight Joint

May 11th, 2020Cable Jointer : Steve Fielder – HV/EHV Cable Jointer

Location : Baltimore USA

Who is Steve?

“I have been working in the cable industry for 29 years. Originally trained at BICC Cables, went on to work in R&D and type approve cable systems ranging from 11kV up to 400kV oil, XLPE up to 500kV EPR cables and High Pressure Oil and Gas Pipe Type.”

“I became more heavily involved in the High Pressure Pipe Type cable systems in North America working on a range of different projects from 115kV up to 345kV,” Steve informs.

Who are G&W?

G&W Electric has been a global supplier of high voltage electric power equipment since 1905.

G&W Electrical products include EHV cable joints, cable terminations, overhead and underground distribution switches, Lazer® Automation solutions, reclosers, distribution and transmission cable accessories and current limiting system protection devices.

Unite jointer with joint and watch the magic unfold…..

115kV Break Down – cable joint break down, ferrule cut out, ready to be re-made.

Sweated Bonding – EHV jointing on insulated G&W remake

Master Jointer – If jointing instruction is the sheet music, then joint is the instrument and the Maestro is Steve Fielder….

Further Reading – More G&W blogs

Challenges With Aging Electrical Infrastructure By G&W Electric

110kV G&W Cable Termination – HPFF High Pressure Fluid Filled

G&W Gas Straight Joint (40kV 3 Core PILC)

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Medium Voltage Electrical Safety Tips | MV HV

May 7th, 2020

MV and LV Electrical Substation Hub: Courtesy OSHA

-

Guest Article By Sam Pherwani. P.Eng, CESCP Engineer, Instructor, Entrepreneur

Medium Voltage Electrical Safety

Five years+ of doing this, I’m still a student.

However been grateful to my customers for the exposure to windfarms, oil and gas, substations, pulp/paper meeting many fine electricians and learning from spirited discussions on how industry in US and Canada interprets Electrical Safe Work practices. Of course, NFPA 70E/NEC/CSA Z462 form the basis of Electrical Safety on this side of the pond.

These few pointers come out of experience in the Medium Voltage (per ANSI C84.1) Electrical Systems practically (2.4kV-69kV). Hope we see more of these best practices considered and frequently I might add, as the new world rolls into a better future.

- Electrical Safety Footwear – Conventional Electrical Hazard rated Safety Boots most electrical workers have are rated to ASTM F2413-11 and CSA Z195-14 offer very little electrical shock protection, 600VAC or less if in wet conditions. Most well written MV electrical safety Risk Assessment forms (JHA/JSAs) call for secondary protection such as dielectric insulating mats or dielectric insulating safety overshoes but human error, inertia sometimes causes these steps overlooked. ASTM F1117 Class 2 AC EN 50321 dielectric boots now offer 17kV/20kVAC protection, comparable to Class E hard hats, making it a better fit for MV workplace.

- Arc Rated Suits & Arc Flash Protective Clothing – Until NFPA 70E-2015 the soft “do not exceed” threshold for unsafe energized work was 40 cal/cm2 of incident energy at working distance (3-4 feet, length of hot-stick away from equipment). Since then, PPE manufacturers making arc flash suits rated to as high as 140 cal/cm2 have influenced the standards to soften stance on that verboten verbiage. Their rationale – no OSHA recorded fatalities for arc blast at these higher cal ratings. My take – first of all, probably none of the mavens have experienced a 100 cal blast first hand from within the arc flash suit or PPE. Secondly, G-forces of even a 1.5 cal/cm2 blast could rattle human vitals like jello, permanently marring a victim with weakened resistance to other adverse forces soft or direct, possibly even a shorter lifespan if not an instant injury. Personally, I’d find a way to minimize high incident energy exposure regardless of the arc flash protective clothing.

- Current Probe – So you want to work on MV Medium Volage electrical equipment (make modifications) … you de-energize the system, test for absence of voltage, and apply grounds, You troubleshoot with a voltage detector, not clearly distinguishing between nominal, stray, backfed or induced voltages. Would be nice to have a current meter clamped device hotstick mountable to gauge trace currents. Can’t find one? Until we do, here is one good at least for measuring current draw on troubleshooting. An amp-probe such as this one works well in tandem with a tick tracer. https://sensorlink.com/products/ampstik-plus. Consider adding one to your toolbox.

- Rescue Hooks – OSHA 1910.269, 70E-110 are not clear on when rescue hooks or insulating sticks are to be used for shock mitigation. The urban legend of using a 2×4 lumber on an electrocution won’t die, the victim might, especially in an MV environment. In addition to switching bare overhead substation equipment, racking of breakers, 4160V MCCs justify use of rescue shepherd hooks. The second Qualified Electrical person should secure the worker with a rescue hook and correct body position, weight pulling outward passively. Many a site has a rescue hook sitting in a warehouse collecting dust, just for the fact nobody included it in their electrical safety program conditions.

- Infrared Thermograhy – 70E/Z462 very clearly say equipment may not be in normal operation if equipment is not properly maintained. So you buy a maintenance contract (per NFPA 70B, CSA Z462, NERC) for peace of mind. You still could have a potential situation where a transformer or breaker is in imminent danger of failure owing to end of life, service fatigue, process upsets or transients. Infrared thermometers, prohibitively expensive 20 years ago are now very feasible tools, reasonable in price and are way preferable to contact troubleshooting methods. A big plus is predictive maintenance if baseline images/videos have been established. Care is required to use rated instruments in outdoor MV environments, outside restricted approach shock boundary.

- Performing Ground Resistance Studies – You inherit a substation, so you’re only worried about above ground equipment maintenance right? Whats under the ground can hurt you … Copper theft, corrosion, increase of plant or station capacity from initial Ufer/ring ground design, improper grounding and bonding could result in fault currents light up the ground in ripples (step & touch potential hazards). Yes, those yellow sleeves on guy wires have a real purpose. NEC 250 requires 25 ohms or under as ground resistance for industrial sites but utilities, power generation consultants usually count five ohms or less as rule of thumb. Its a good idea every few years to perform a ground resistance test – three/four point method, preferably during a shutdown in vicinity of mains transformer.

Further Reading

- Electrical Safety – Arc Flash Accidents & Electrocution In LV-HV Installations

- Arc Flash Calculation – Selecting Clothing & PPE To Protect Lives Against Arc Hazard

- IEC 61482-2:2018 – Get Up To Speed With The New Arc Flash Standard

- Arc Flash PPE | 7 Top Considerations

- Arc Flash The Basics

Arc Flash Clothing | Polo Shirts | Jackets | Coveralls | Trousers | Sweatshirts | Helmets

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

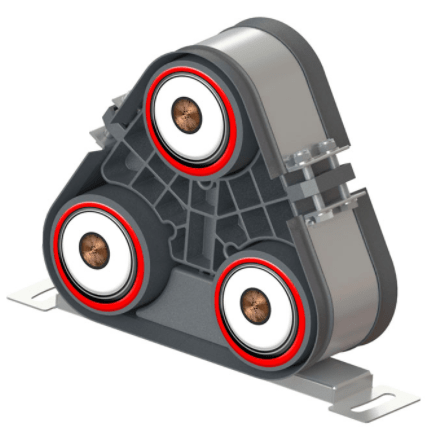

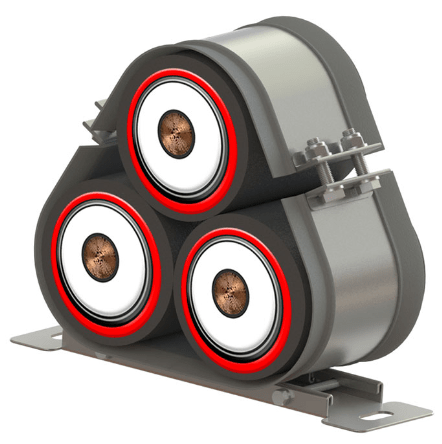

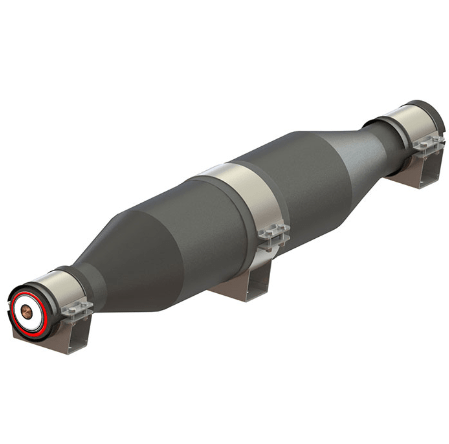

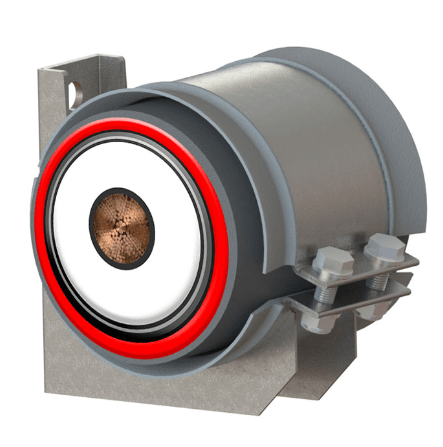

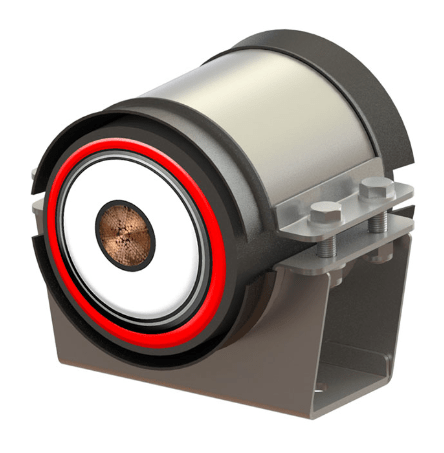

High Voltage Cable Cleats for HV Cables from CMP

April 23rd, 2020

HV Cable Cleats

As part of its comprehensive cable cleat range, CMP offers a selection of high voltage (HV) cable cleats that are designed to safely restrain high voltage cable (s). CMP is able to provide cable cleats for any level of cable voltage; for example 3.3kV, 230kV or 1,000kV.

Manufactured from the highest quality materials, CMP’s HV cable cleat range has excellent corrosion resistance, strength and durability, making them suitable for use in the harshest of environments.

Designed and manufactured in accordance with the International Standard IEC 61914: Cable cleats for electrical installations, CMP cable cleats undergo rigorous short circuit testing.

CMP designed two bespoke trefoil cable cleats for high voltage cable for the major, and highly technical Singapore Tunnel Project.

What standards does the range comply with?

All CMP high voltage cable cleats are third-party certified in accordance with the International Standard IEC 61914: Cable cleats for electrical installations, to ensure the securing and retention of cables without sustaining damage to the cable(s).

Where specific client requirements mean that the short circuit test parameters fall outside of the criteria laid out in IEC 61914; for example the customer specific size of cable to be tested is larger, or the number of cleats per test setup is smaller; then the test procedure and criteria of IEC 61914, and the customer’s test requirements, are both adhered to.

CMP has conducted numerous additional client specific tests, with certification obtained as required on a project specific basis.

What materials are used for CMP’s High Voltage Cable Cleats?

CMP’s high voltage cable cleats are manufactured from the highest quality 316L stainless steel to provide products with high creep strength and excellent corrosion resistance.

A selection of products within this range are also available in aluminium. The grades of aluminium we use are selected for their high corrosion resistance and superior tensile strength.

Cleats can be optionally powder coated – CMP offers standard Epoxy or Polyester powder coating. A polymer alloy coating which is UL94 V0 flame retardant, and Low Smoke and Fume Zero Halogen (LSF0H) is also available.

The polymer cleat liners supplied as standard are classified as Low Smoke and Fume Zero Halogen (LSF0H) and Phosphorus-Free.

Bespoke HV cable cleats for specific project requirements

CMP works with clients to design and manufacture bespoke cable cleat solutions to cater for specific project requirements. We can supply industrial products which do not require certification, designed to exact requirements.

We also offer a design service which includes all testing and third party certification of the products.

Using Finite Element Analysis (FEA) during the product design process, CMP’s dedicated cleat development team are able to model the stresses on cable cleats under short circuit situations, allowing them to make accurate predictions as to how products will perform when installed. This saves vast amounts of time in the early development and testing phases, reducing the overall lead time for our customers.

| Product Code | Description | |

|

HVSS-EC | High voltage trefoil cable cleat with expanded cable centres. (Fixed and sliding base variants available) |

|

HVSS-CC | High voltage trefoil cable cleat with closed centres. (Fixed and sliding base variants available) |

|

SHVSS-JSC | Single high voltage, stainless steel, joint support cleat |

|

SHVSS-WM | Single high voltage wall mounted cleat |

|

SHVSS | Single high voltage cable cleat |

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV