Blog

GRP Feeder Pillars – A Short Guide To Site Installation

October 9th, 2019

GRP Feeder Pillars – A Short Guide To For Site Installation

-

uploaded by Chris Dodds | Thorne & Derrick Sales Marketing Manager

GRP Feeder Pillars

The following article has been written to provide guidance to civil engineering and groundworks contractors for the installation of GRP feeder pillars used to provide low voltage electrical power distribution.

Step 1. Concrete base must be clean and free from any earth, stones or any other debris which will prevent the feeder pillar or kiosk sitting flat on its base – it is recommend that a stepped base be cast for feeder pillasr where the inner level is 50mm above the base flange, so as to prevent water ingress into the kiosk.

Step 2. Orientation of the feeder pillar is to be agreed before the pillar is positioned on to its base. It is good practice to have the pillar sitting in the middle of the base with an equal amount of slab around the pillar. The feeder pillar can be manoeuvred using a jemmy bar from inside or outside the unit; care is to be taken so as not to damage the gel surface.

Step 3. Check for an equidistant gap between the door and door frame and that the doors operate freely. The doors can be adjusted by placing shims between the base and the feeder pillar directly in line with the door hinges; these shims should be of non corrosive metal, plastic or even GRP.

Check for an equidistant gap between the door and door frame and that the doors operate freely

Packing shim

Step 4. Ensure that walls of the pillar are straight and are not “bowing”.

Step 5. Drill 12mm holes in the GRP base flange of the pillar at approximately one metre intervals using a battery drill (some feeder pillars may have already been pre drilled).

Step 6. Various anchor bolts can be used to pin the feeder pillars down depending on site specification – it is recommended to use an M 10 x 75mm sleeve anchor expansion bolt as standard. Size and depth of the hole should be in accordance with the fixing being used.

Step 7. Drill should be used at right angle to the concrete base; however, the holes can be drilled at an angle where a plywood board may prevent the drill from operating at 90 degrees.

Drill should be used at right angle to the concrete base

Step 8. Re-check door levels after bolting down the pillar.

Step 9. Apply a bead of silicon to fill the gap between the feeder pillar and concrete base. This cannot be relied upon to provide a water tight seal; it is used for cosmetic purpose and will also prevent any concrete screed from running down the face of the concrete base.

Apply a bead of silicon to fill the gap between the kiosk and concrete

Step 10. Remove the lifting eyes and seal holes with the plastic bungs provided.

Feeder Pillars – Galvanised Steel | Stainless Steel | Cast Iron | GRP

Thorne & Derrick

T&D are Specialist Distributors to UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and HV Jointing Contractors of an extensive range of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt – this includes 11kV/33kV/66kV joints, terminations and connectors for both DNO and private network applications.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

PILC Cable Joints & LV Switchgear Connections

October 9th, 2019

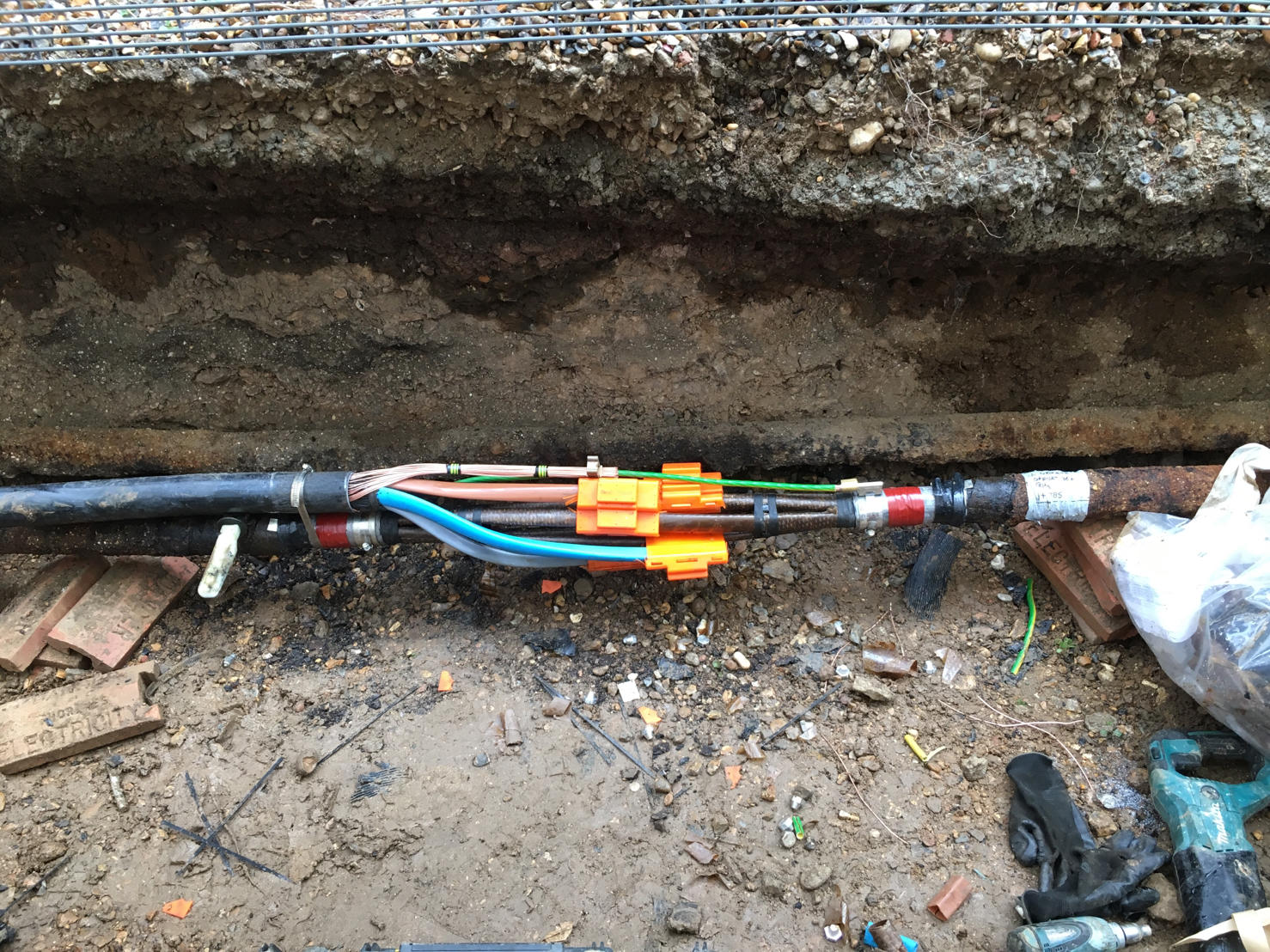

- Application: PILC Cable Joints & LV Switchgear Connections

- Cable Type: PILC Cable Joints

- Cable Jointer: Lee Richards Self Employed Cable Jointer at LR Power Services. SSE Authorised, PILC, Consac, PICAS. 33kV Pfisterer, LV-11kV. 11kV Lovink

PILC Cable Joints

Cable Jointing Contractors

Here is Lee Richards (LR Power Services) undertaking a switchgear change during a shut down involving the following LV Joints: 1 x 4c 300sqmm PILC Breech Joint, 2 x 4c 300sqmm PILC Straight Joints and 1 x 4c 185sqmm PILC Straight Joint.

Lee is a respected and acknowledged Competent Jointer – his skill set includes completion of the SSE LV HV Jointer Training program and also current 33kV Prysmian Straight Joint and 33kV Nexans Euromold T Connectors tickets.

JOINTERS BLOG

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

15,000+ Subscribers. ➡

Nexans Cable Leads Keep High Voltage Energy Transmission Flowing – 110kV, 132kV & 220kV

October 9th, 2019

-

uploaded by Chris Dodds | Thorne & Derrick Sales Marketing Manager

Nexans Cable Leads

High Voltage Energy Transmission Flowing – 110kV, 132kV & 220kV

The construction of new power plants and the growing demand for renewable energy sources has increased the need to expand and/or convert networks into transformer substations or onto overhead line towers.

Flexible high voltage cable leads are used by electrical utilities and contractors for emergency preparedness and use on substations and OHL (Overhead Lines).

As a key player in the energy industry, Nexans is pleased to offer a safe and flexible component for such projects : pre-terminated temporary site cables.

Terminated Cable Leads

These high voltage cable leads are supplied pre-terminated and can be used to temporarily connect MV HV equipment in a high voltage network, e.g. as a bypass during construction or cable repair and servicing work, or during emergencies such as natural disasters or severe weather.

When faults occur in overhead or underground lines, temporary site cables make it possible to restore energy transmission rapidly. While modification work is underway in a transformer station, temporary connections can be rapidly installed between transformers and switchgear systems or overhead lines.

Temporary site cables are available from stock or can be manufactured to meet your specific requirements.

Flexible silicone rubber outdoor cable terminations facilitate use in any position and due to their low weight, the Nexans cable terminations can be operated without additional support.

Temporary leads have the same design as high voltage cables but with reduced insulation thickness, this facilitates a small bending radius making them easy to handle and install.

Nexans manufactures temporary cables in a variety of lengths across three voltage ranges: 110kV, 132kV and 220kV.

Pre-terminated temporary site cables

Pre-Installed Flexible Silicone Rubber Terminations for Simplified Installations

Due to the conditions under which temporary site cables are installed, the cable accessories must be to easy to use and have a wide range of possible applications.

Nexans’ pre-installed flexible silicone rubber terminations facilitate use in any position.

Due to their low weight, the cable terminations can operate without any additional support structures. The monobloc design ensures the terminations are suitable for voltages from 72.5kV to 220kV offering maximum flexibility and operational reliability.

Advantages of Nexans Temporary Site Cables & Terminations

- Optimized cable lead design for very small bending radii

- Reduced insulation thickness reduces weight and improve handling on site

- The Nexans pre-installed silicone rubber terminations are maintenance-free and routine tested for partial discharge up to a test voltage of 2.5 x U0. Following every use, a new partial discharge measurement can be performed on the cables in order to rule out possible damage.

- Single or 3-chamber drums make transportation and handling much easier

Nexans HV Cable Leads 132kV

Nexans High Voltage Cable Leads

Thorne & Derrick

Nexans Main UK Stockist & Distributor

Contact us for Competitive Prices & Fast Delivery from Stocks for Heat Shrink, Cold Shrink & EPDM Rubber Connectors, Joints & Terminations up to 66kV.

Go to our Price List and contact us with your enquiries.

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Accessories, Jointing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV.

Stocking & Supplying | Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Jointing Tools | Cable Pulling Eqpt | Earthing & Lightning Protection | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Euromold MV HV | Cable Terminations, Connectors, Elbows & Joints

Ellis Patents Cable Guide Clamp – Video

October 9th, 2019-

uploaded by Chris Dodds | Thorne & Derrick Sales Marketing Manager

Ellis Patents

Cable Guide Clamp

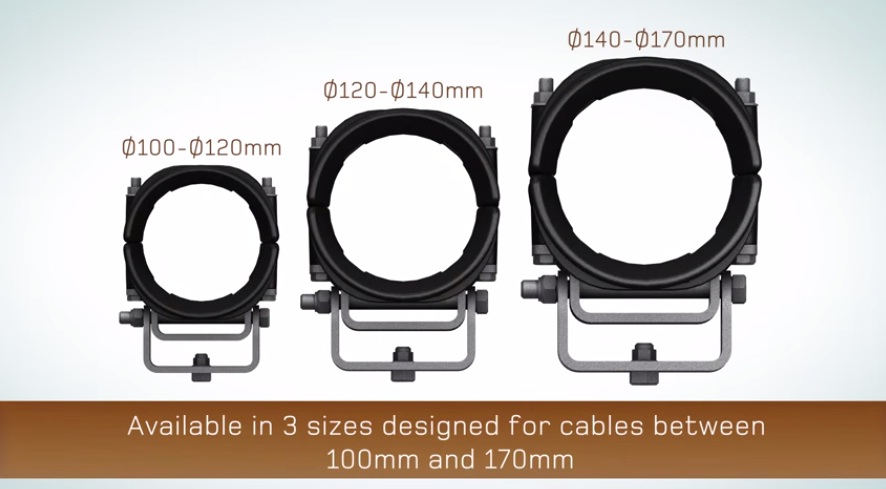

Ellis Patents Guide The Way With Guide Clamp Cable Cleats

Ellis Patents, the world leading UK designer and manufacturer of cable cleats have developed the Cable Guide Clamp – a combination of a cable guide and a cable clamp for high voltage (HV) cables.

The Ellis Cable Guide Clamp is designed to be installed in place of rollers along the HV cable route where the cable length is pushed and pulled through to its final destination.

Ellis Patent Guide Clamp was developed to provide a product that could be used during cable installation and then be used to clamp and restrain the HV power cable.

Two Stage Cable Installation & Clamping

The Ellis Cable Guide Clamp works in two simple stages. Firstly during cable pulling, the guide clamps gimballed mounting and slipper nylon construction enables simple installation and cable guiding.

Once the cable has been sufficiently pulled through and placed, the top half of the guide clamp is removed and a LSF polymeric fixing piece installed directly onto the cable.

Then, the top half of the guide clamp is replaced turning it into a fully functioning HV cable clamp. The narrow Ellis Patents design minimises the cable to cable distance resulting in greater flexibility, easier movement and therefore simpler installation.

Cable Guide Clamp Selection Table

| Cable Guide Clamp Part Number | ∅ Range (mm) |

| CGC100-112-G | 100 – 112 |

| CGC110-122-G | 110 – 122 |

| CGC120-135-G | 120 – 135 |

| CGC130-145-G | 130 – 145 |

| CGC140-160-G | 140 – 160 |

| CGC150-170-G | 150 – 170 |

Ellis Patents HV Cable Guide & Clamp – Product Dimensions

The Ellis Cable Guide Clamp was originally designed for use on an offshore project by Siemens and has now been developed for use with HV cables in many other potential applications.

Thorne & Derrick

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

Arc Gloves | New Arc Flash Dexterity Gloves from Protection Specialists ProGARM

October 9th, 2019

-

uploaded by Chris Dodds | Thorne & Derrick Sales Marketing Manager

ProGARM delivers ultimate arc flash clothing and protection, including arc gloves, conforming with the relevant industry and EN standards ensuring protection from arc flash incidents for workers carrying out installation or maintenance of LV Low Voltage, MV Medium Voltage or HV High Voltage power systems.

Arc Flash Protection

Arc Flash Hand Protection

ProGARM is the leading UK manufacturer of high-quality, Flame Resistant, Arc Flash clothing, gloves, garments and workwear – they work successfully with their UK Distributor Thorne & Derrick to save lives and reduce arc flash accident effects.

ProGARM is the only UK manufacturer concentrating on and specialising 100% in Arc Flash and Flame Resistant garments for utility workers and businesses.

Arc Gloves

The dangers of Arc Flash incidents and the importance of protection from these hazards has never been as significant as it is today. This prominence will continue to increase over the next few years.

With multiple cable strikes every day in the UK and numerous major Arc Flash incidents, businesses are looking at how best to protect their team with the right Flame Resistant garments and accessories, including arc rated gloves. The correct clothing can significantly reduce injury and save lives.

ProGARM and Thorne & Derrick are committed to continual research and improvement to innovate and develop their range of arc flash clothing as quickly as possible to bring you the best Arc Flash protection for your team – this includes hand protection against flash incidents using arc rated gloves.

Product Launch: 2700 dexterity arc gloves

ProGARM are committed to continual research and improvement to innovate as quickly as possible to bring you the new products and Arc Flash clothing and protection you require.

Arc Gloves

The latest innovation is the 2700 Arc Flash dexterity glove, designed and developed to provide a comfortable and practical glove solution for those undertaking complex work with their hands when handling underground cables and overhead lines depending of the level of arc flash protection required.

The latest development within the accessories range, these arc rated gloves combines exceptional Arc Flash protection with practical features, including abrasion resistance, elasticity and improved hand conformity with excellent wet and dry grip.

And as you would expect from ProGARM, the 2700 Arc Flash rated gloves have been designed with the user at mind. Featuring A4/Cut 5/Level D resistance alongside its inherent Arc Flash protection, they can take the place of the standard grip and grab gloves used within a variety of industry sectors. This will not only keep the practicality that operatives are used to but also combat the risks of wearing highly flammable gloves when at risk of an Arc Flash incident.

DON’T COMPROMISE ON SAFETY, PROTECTION AND COMFORT

With a calorific rating of 8.6 cal/cm², our 2700 Gloves are excellent Arc Flash resistant gloves. Having been tested to Arc category 2 using the Open Arc Test Method and conforming to NFPA 70e, mechanical risks, EN 388:2016 and thermal risks, EN 407:2004 you don’t have to compromise the hand safety and protection of the wearer.

Alongside its practical design and features, the 2700 arc glove is sure to be a complementing and necessary accessory to add to you and your team’s Arc Flash PPE solution.

WHAT IS AN ARC FLASH?

An electric arc occurs whenever a circuit breaker, switch or isolator (Device) is opened and when there is current flowing in the circuit. However, most devices under normal operating conditions are designed to control the arc when opening or closing.

An arc flash may occur when the arc is uncontrolled and there is sufficient energy released to cause harm or damage.

Arc flashes occur both at high voltage and low voltage. There is little discrimination: low voltage arc flashes injuries are just as damaging at high voltage injuries.

Put simply: An arc flash is the light and heat produced from an electrical arc supplied with sufficient energy to cause significant damage, fire or injury.

An arc flash can cause minor injuries, third-degree burns and potential death as well as other injuries including blindness, hearing loss, nerve damage and cardiac arrest. Fatal burns can occur when the victim is several feet from the arc. Serious burns are common at a distance of 10 feet – arc flash can generate heat 4 times greater than the surface of the sun.

The dangers of an Arc Flash

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

Thorne & Derrick

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV