Blog

Specifying Quality Cable For Your Projects

September 3rd, 2019

-

Blog Written By BASEC | 7 of 10 Articles

Thorne & Derrick collaborate with BASEC to advocate the importance of electrical safety and educating industry stakeholders about specifying and buying accredited, tested and certified cables and cable accessories.

We would like to thank BASEC for allowing us to republish a selection of articles aimed to protect and inform the electrical sector – together we promote compliance with industry standards, specifications and ultimately confidence in end installations to provide LV MV HV Cable Quality.

Specifying quality cables for construction projects may not be top-of-mind when preparing building specifications, however, failures in cable can result in costly damage and even loss of life. Purchasing independently-verified cable is one way to ensure the cable you specify is safe to use and meets all relevant regulations.

As your customer’s first point of contact, at the specification stage, construction projects will have key requirements or a need for specific criteria to be adhered to.You’ll often be involved in assessing and awarding the main contractor who will be responsible for conducting the risk assessments and ensuring control measures have been put in place, prior to the project commencing.

Ensuring quality materials and cable accessory products are specified at the start of a project, is one of the most effective ways to manage risks and minimise any potential costs of poor quality, which may arise from using substandard materials or products.

Working closely with the main contractor, electrical installers with the appropriate credentials can be selected. Special attention from the experts can be used to your advantage to ensure that any issues with cable quality can be identified and addressed, prior to any significant impact on the project.

When on-time delivery is a critical component of a project cable products, if decided upon late in a project’s timing plan, may not be available or could have long-lead times associated to them.

Cable products are almost always made to order, however if the timing plan has not accounted for these lead times a margin of error can be built into the project without full realisation. Off the shelf products may at this point be sought based on availability, meaning that they may not potentially be the right product for the application.

In the same way that buildings are required to meet regulatory standards for a wide range of requirements, cable products must also meet specific standards for quality and safety. However, simply meeting a standard does not guarantee a cable will be suitable for its application.

To ensure that cable products specified are of the highest quality and will perform as intended, in the right application, products should be independently verified. A comprehensive set of tests should be conducted on a cable at the manufacturing source to confirm how the product will perform in long-term service.

Many high-profile projects specify cable products, prescribing that they must be tested independently to provide an objective assessment of performance and conformity.

Your role in cable specification

As a trusted advisor, customers rely upon your guidance to help meet their business or project objectives and to ensure that the products specified for use in their projects will meet all relevant standards and regulations.

Keeping up-to-date with the latest industry developments in materials and regulations can also be difficult, as these continue to evolve rapidly.

Who is BASEC?

BASEC is the preferred testing and certification partner to the worldwide cable industry. Partnering with cable manufacturers around the world BASEC is focused on improving product quality and safety. Cable manufacturers who are BASEC approved, have undertaken a rigorous auditing programme which looks in detail in how the business and its factories are operating, as well as the processes and production methods they follow.

Product samples are randomly selected from the product ranges undergoing product certification and these are sent to BASEC’s laboratory for testing. Once product approvals are awarded, these are publicly displayed on www.basec.org.uk, giving access to all members of the supply chain a live platform to check and verify documentation from their suppliers.

Alongside factory assessments manufactures management systems for quality, environment and health and safety can be assessed. A key purpose of verifying cable quality at the beginning of the supply chain is to ensure manufacturers consistently produce high-quality products.

What is the Registered Stockist scheme?

BASEC’s stockist scheme is a new certification scheme, which opens the doors of approval to the supply chain and increases the level of independent market surveillance within the cable market. Industry can now cross check cable quality at the point of sale.In years gone by, BASEC was a certification that could only be obtained by those who had their own manufacturing factories and plants. In a bid to drive higher levels of quality and safety, stockists and wholesalers alike can become approved suppliers.

Becoming a Registered Stockist means that measures are in place to test the quality of the product just before it enters the market, where BASEC can in confidence verify performance test results against those achieved at the manufacturing source.

Why should I specify independently-verified cable?

By specifying BASEC approved cable, you can have complete confidence that the product selected has been tested independently to ensure it meets the performance requirements specified. The BASEC mark is recognised around the world, which give you and your end customer complete peace of mind that the product installed will be safe and resilient in operation.

The Registered Stockist BASEC mark provides assurance throughout the supply chain of assured quality, scrutinised at various check points, from source to end user.

How can I find a registered stockist?

Registered Stockists will be listed in a stockist selector application on the BASEC website www.basec.org.uk, following the formal awards ceremony this summer. Where the pioneers of the stockist market, entering the scheme right now, will showcase their certification.

Cable Quality Seminar

BASEC run a number of FREE Cable Quality Seminar’s across the country suitable for anyone and everyone who is working to deliver projects which include cable installations.

Do not miss your opportunity to build your awareness of cable quality.

Click here to register now.

Middle East Electricity 2020, Dubai

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Electricians Guide to CPR

September 3rd, 2019

-

Blog Written By BASEC | 10 of 10 Articles

Thorne & Derrick collaborate with BASEC to advocate the importance of electrical safety and educating industry stakeholders about specifying and buying accredited, tested and certified cables and cable accessories.

We would like to thank BASEC for allowing us to republish a selection of articles aimed to protect and inform the electrical sector – together we promote compliance with industry standards, specifications and ultimately confidence in end installations to provide LV MV HV Cable Quality.

Below are some Frequently Asked Questions regarding CPR for electricians. If you have any other queries not covered here please do not hesitate to contact us.

What is CPR and what does it cover?

The Construction Products Regulation is a piece of European legislation (EU Regulation 305/2011) that includes all types of products used in the building industry e.g. doors, window frames, cement, plasterboard, plaster, toilets pans, sinks etc.). Within the EU member states, anything that is FIXED into the fabric of the building is in scope and must be CE marked for CPR. “Safety in case of fire” is one of 7 performance characteristics.

CPR for cables came in to effect on 1 July 2017 so from this date any cable that is within the scope of the regulation must be CE marked for CPR.

Does it relate to all electrical cables?

Currently it only relates to the way cables react to fire not the way they resist fire (continue to operate in a fire). Therefore this relates to those cables that are NOT designed to resist fire. This includes PVC and LSHF armoured, flat twin and earth and single core, and many others including data and optical cables.

If they’re fixed into the fabric of the building they are in scope. Appliance power flexes aren’t in scope, or those just buried in the ground and not entering a building.

What does it mean for cables?

The biggest direct impact has been on manufacturers, and the least on end users (such as electricians). In a very simple nutshell for electricians, cables are given classifications according to their performance in a fire (how they REACT). There are 7 classes of cables ranging from Aca (best) – Fca (worst) (Aca, B1ca, B2ca, Cca, Dca, Eca, Fca).

What do these classes mean?

A Class “Aca” cable would be the very best performing cable during a fire and a Class “Fca” would be the worst performing cable under CPR. IMPORTANTLY, the class represents the cables performance to the CPR requirements and not to any product standard to which it claims compliance (e.g. BS 5467).

Therefore, there could be two different BS 5467 PVC SWA cables on the market, both fully complying with BS 5467, but under CPR their reaction to fire could be different and therefore would be classified differently.

What’s the difference between the classes?

Different classes require different criteria to be applied. Therefore cables will be made and tested to achieve the requirements of a particular class. It is not just the way they’re made and tested, it involves who tested them and how the manufacturing process is controlled.

Cable cannot simply “jump up class” by tweaking the manufacturing or doing some more tests. Class Cca cable could be sold as Class Dca (as Class Cca is superior to Class Dca), but Class Dca cannot be sold as Class Cca.

Who specifies what class cable can be used for what installation?

The classes of the cables may be specified by the client, or may not be. In the UK, there are no official Regulations stating which classes have to be used for which applications. For instance, a client could ask for “BS 5467 SWA PVC cable (CPR Class Cca minimum)”.

To fulfil such a contract you would need to use Class C cable. Failure to do so would be a breach of contract – in the same way if a client asked for a BASEC approved cable and you used a non-BASEC cable. In this case it could be difficult to find a Class Cca BS 5467 cable; however, a BS 6724 cable may be found which was Class Cca and this change of specification would need to be cleared with the client.

Do higher classes of cable cost more?

The cost for cable may be greater as you go up the performance scale. A client should specify only what they really need for their installation.

For instance, conductors in a twin and earth cable made of gold would work, but they would be very expensive and are not required. In the same way, if the installation specifies a Class Dca cable but the client then asks for a Class B1ca cable – it would work but it could be expensive and might not be justifiable.

What classes will I see?

Typically you won’t see much if any class “Aca” of “B1ca” cable as these tend to be for specialist applications. In the main you will probably be asked for classes Eca and Dca, with some Cca, although certain high-end clients in high-risk industries may occasionally request class B2ca.

When will these classes matter?

The impact on electricians is mostly when quoting for jobs. If a class has been specified you need to make sure that you are quoting for the correct class of cable. When ordering and collecting your cable at the wholesalers ensure that you have selected the right class for the job.

How will I know what class of cable I have?

All cable sold under the CPR needs to be clearly labelled as to its class – this could be on the cable and a label will be applied to reel or if sold as a pre-cut shank, the label may be applied to the shank.

The wholesaler is responsible for ensuring that the cable has the appropriate marking before it is offered for sale. Please note that cable already in the supply chain on 1 July 2017 does not need to be classified or CPR labelled, but there is unlikely to be much of this now so do treat any you see with caution.

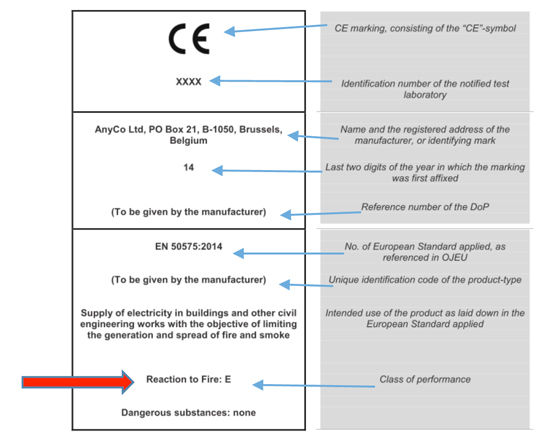

What does Reel / Shank label look like?

Below is an example taken out of the Regulation of a label you may see (although this is an example and may vary slightly), the class of performance is the key. This label would be applied to a Class Eca cable.

CPR Reel Shank Label

Will BREXIT cause this legislation to be repealed?

Under the EU Withdrawal Bill, all existing EU legislation will be copied in to UK law. This means that the Construction Products Regulation will continue to be law in the UK after Brexit in March 2019. The law could, in theory be changed at some point in the future, but there is no indication of this at the moment and so it is very much ‘business as usual’ for the foreseeable future.

Cable Quality Seminar

BASEC run a number of FREE Cable Quality Seminar’s across the country suitable for anyone and everyone who is working to deliver projects which include cable installations.

Do not miss your opportunity to build your awareness of cable quality.

Click here to register now.

Middle East Electricity 2020, Dubai

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Tratos Supplies BASEC Approved Medium Voltage Cables Into Large Electricity Distribution Network

September 3rd, 2019

Tratos & BASEC

-

Blog Written By BASEC | 9 of 10 Articles

Thorne & Derrick collaborate with BASEC to advocate the importance of electrical safety and educating industry stakeholders about specifying and buying accredited, tested and certified cables and cable accessories.

We would like to thank BASEC for allowing us to republish a selection of articles aimed to protect and inform the electrical sector – together we promote compliance with industry standards, specifications and ultimately confidence in end installations to provide LV MV HV Cable Quality.

➡ Read BASEC case studies and see why cable manufacturers choose BASEC as their preferred testing and certification partner.

BASEC Case Studies

Western Power Distribution, United Kingdom

Western Power Distribution (WPD) operates one of the largest electricity distribution networks in the United Kingdom, supplying power to more than 7.9 million customers, over a 55,000 square kilometres service area.

In addition to connecting new homes and businesses to their electricity network, WPD is responsible for the operations and maintenance of power lines and for returning excess electricity to the National Grid. As the sole electricity distribution network operator for South Wales, the Midlands and the South West of England, the installation of quality cable is critical to the success of the business.

Challenge

Underground transmission cables perform the essential function of carrying power between substations and buildings. As these cable products are buried underground, quality materials are essential to ensuring that these products operate effectively in the underground conditions, and will not require anything more than the minimal maintenance that can be delivered once in-situ.

In order to ensure the efficient and consistent supply of power to these areas WPD contracted Tratos to supply Medium Voltage (MV) cables into the network and to maintain their stock. Tratos is an innovative cable manufacturer which produces cables to the high standards required by industry.

In this case, Tratos supplied 11kV and 33kV MV cables to be used in a wide range of applications, including underground power lines, power distribution, and mobile substation equipment.

Outcome

BASEC certification is used throughout the worldwide cable industry to demonstrate that the cable products manufactured meet the highest quality and safety criteria in line with recognised standards.

Tratos has achieved BASEC approval, on key products, to evidence their levels of compliance, quality and suitability for use in a range of specific applications, for examples in their primary business offering of power supply, as well as for a number of industry standards including CPR and management systems approvals.

The cable products supplied by Tratos into WPD were rigorously tested by BASEC and approved to BS 7870-4.10, a standard specific to power distribution, applicable to a wide range of cable applications between 6.35 and 33kV. One of the key tests the standard specifies is the Shrinkage test, which is designed to determine the amount of shrinkage that may occur when insulation is exposed to high operating temperatures.

The test is extremely important for underground transmission cables. If the amount of shrinkage is excessive this could lead to conductors becoming exposed during their normal use. As the first cable manufacturer, in Europe, to achieve BASEC approval to meet this standard, Tratos reinforces their commitment to meeting high levels of quality and safety, and to all relevant regulations. In turn, ensuring that the end user of their product can be confident that the product meets the required standards and is fit for purpose.

Any successful cable manufacturer conducts in-house testing, but most importantly also undertakes independent testing to ensure that their cable products meet the standards required before releasing them into the market.

Pressures to meet commercial targets and achieve greater production efficiencies can mean that sometimes, in-house testing can be less stringent than a dedicated independent testing house. By undertaking product testing through an independent certification body, like BASEC, a manufacturer can benefit by enhancing their reputation by leveraging the BASEC brand as a value-add.

Recognised brand marks, accreditations and certifications are used in end user markets, such as rail, utilities and power, oil and gas and many others, in order to provide the end-to-end supply chain with assurance that cable products are compliant and will also perform as they say they will. Only when cable products have been rigorously tested to the highest industry recognised standards is the BASEC mark of independently approved quality and safety awarded for use.

Cable Quality Seminar

BASEC run a number of FREE Cable Quality Seminar’s across the country suitable for anyone and everyone who is working to deliver projects which include cable installations.

Do not miss your opportunity to build your awareness of cable quality.

Click here to register now.

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Top 10 Articles | Thorne and Derrick & BASEC #CABLEQUALITY

September 3rd, 2019

Pictured Left to Right: Natalie Lundie (Supply Chain: Marketing Lead at Thorne & Derrick), Harpreet Suree (Marketing Manager at BASEC) and Chris Dodds (Sales & Marketing Manager at Thorne & Derrick).

BASEC are collaborating on knowledge and content sharing with Thorne & Derrick.

With a shared passion and ambition to enhance electrical safety through the education and encouragement of industry stakeholders to specify and buy accredited, tested and certified Quality Cables & Cable Accessories.

#CableQuality is the hashtag – securing public safety through the specification and installation of BASEC approved and verified LV MV HV electrical cables by competent and qualified electricians is the objective.

Read on………

- Promoting Good Practices For Cable Products Following The Grenfell Tower Report

- End User Specification Of Approved Cable Products: Where Is The Value?

- Fire Testing Of Cables Is Important, But Not At The Expense Of Other Characteristics

- Top Dos And Don’ts – Cable Delivery, Pulling And Installation

- How To Write A Good Cable Specification

- New Testing and Certification Scheme Launched for YY, SY, CY Control Cables

- Specifying Quality Cable For Your Projects

- When Quality Matters: Early Indicators Of Error

- Tratos Supplies BASEC Approved Medium Voltage Cables Into WPD

- Electricians Guide to CPR

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Engineers Jointing A Cable In A Manhole, Manchester, 1935.

September 3rd, 2019 Image: BT.com

Image: BT.com

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Underground Cables & Overhead Lines

Courtesy of BT a nostalgic and photographic record recalling bygone days of engineers laying, jointing and installing telephone and power cables.

- Engineers Working On The Construction Of The New London Central Exchange, 1901.

- Laying Underground Cables In Maida Vale, London, 1939.

- Engineers Working On Cables Near The Severn Railway Tunnel, Gloucestershire, 1940.

- Engineers Soldering And Jointing Telephone Cable, 1945.

- Laying Underground Cables In Chiswick, London, 1949.

- Cable Cross Connexion Cabinet, Queen Victoria Street, London, 1949.

- Engineers Laying Underground Cable, 1951.

- Laying Underground Cables, Chester, 1963.

- Engineers Working On Underground Cables Below Wood Street, London, 1967.

Image Disclaimer: Note these images are not to be used for any advertising, marketing or promotional purposes by third parties, or for internal communications requirements such as newsletters or non-commercial websites, without the expressed permission of BT and the copyright holder.