Blog

Medium Voltage Sensored Cable Accessories from 3M Electrical

June 24th, 2022

3M Sensored Cable Accessories for Medium Voltage Grid Automation

An effective solution for monitoring your underground distribution system

3M Sensored MedIUM VOLTAGE

Cable Accessories (SCA)

3M Sensored Cable Accessories (SCA) provide a retrofittable, compact and economical way for Distribution System Operators (DSOs) to gain visibility and data from their distribution grid with voltage and current measurements.

As the need and importance of measurement and data in the underground grid rises, 3M SCA provides a simple path to high accuracy solutions for assessing and improving fault detection, power flow and power quality. The advent of new regulations and integration of renewables into the medium voltage network, make the need for high accuracy measurements critical for assessing the health of your electrical grid and better managing the future of the network’s grid modernisation.

3M helps provide visibility into the medium voltage (MV) electrical infrastructure

3M Sensored Accessories easily retrofit inside cable compartments, air insulated switches, gas insulated switches or on transformers inside substations. When you upgrade your existing medium voltage substation with our product, you gain high accurate sensing and overall insight into multiple nodes without the need to replace.

Seeing the Whole Picture

Situational awareness is critical in the underground medium voltage distribution grid, as faults in this segment can potentially impact large numbers of customers downstream. This can be compounded by the wide-scale integration of renewables, which places additional demands on aging equipment and compromises network efficiency. Although distribution automation and control solutions have evolved to tackle these issues, acquiring key grid parameter data with high accuracy – and in real time – continues to be a major challenge, especially for underground medium voltage systems.

Now, 3M brings you advanced Sensored Cable Accessories that provide highly accurate voltage and current data, and can be deployed throughout your underground medium voltage system with low capital investment. When coupled with your existing communication infrastructure, 3M™ Sensored Cable Accessories enable real-time monitoring, giving you better visibility throughout your underground MV distribution system.

Accurate information about the state of your MV grid can help protect your customers – and your reputation – against the steep costs of outages, cable repair work and lost productivity. Better information drives better decisions: rapid fault diagnosis, fast and accurate response, and precise load control all depend on grid visibility.

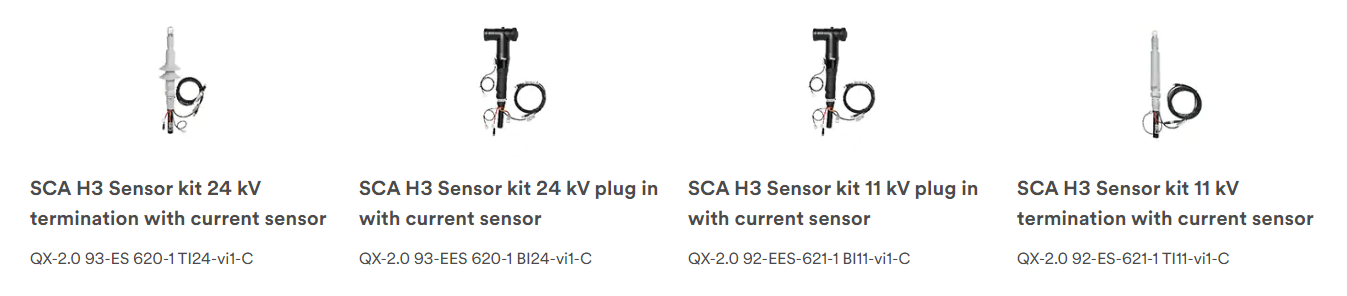

3M™ Sensored Cable Accessories

for MV Grid Automation

3M Sensored Cable Accessories consist of passive sensors that provide highly accurate analog voltage and current waveforms. Your existing power equipment can be retrofitted with these accessories, which are both easy and economical to install.

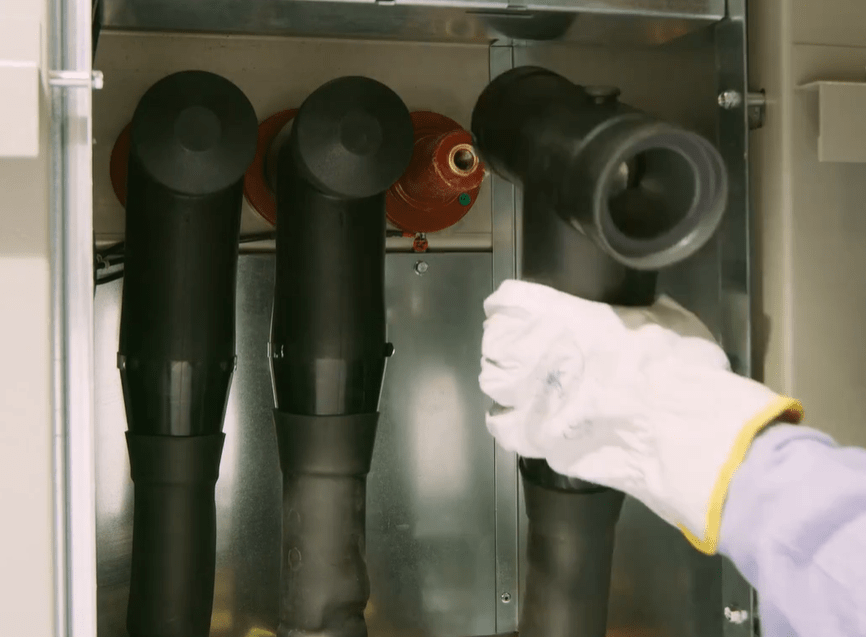

Installation of the 3M SCA

- A fast, economical solution – Ability to retrofit power equipment allows installation at your chosen locations

- Underground system data – Enables real-time monitoring of your underground system when integrated with your communication infrastructure

- Highly-accurate readouts – Provides voltage accuracy of ±0.5%* and current accuracy of ±1%*, giving you real-time data that can be used in advanced automation and control applications

- No external power source required – Enables a simpler, faster, more economical installation

- No field calibration – Factory-calibrated sensors provide reliable, accurate data, without need for calibration in the field.

- Constructed with 3M Cold Shrink technology – For a safe, reliable seal that requires no special tools, sealants, adhesives, torches or other heat sources to install

* Refer to the 3M Sensored Termination Datasheet for detailed accuracy information.

A technology breakthrough, designed to give you more

Flexibility – Upgrade your key locations

Depending on geographic location, load profile, regulatory requirements and legacy equipment, your key locations may be different from those of other utilities. 3M Sensored Cable Accessories and interfaces are engineered to give you the flexibility to monitor key parameters at critical points in your network. This retrofit solution can be installed in your existing power equipment with minimal effort, and integrated into your existing communication infrastructure.

Reliability – Consistent performance

3M Sensored Cable Accessories incorporate passive sensors, which do not require an external power source. These sensors are also factory calibrated – with no field recalibration necessary. And 3M’s advanced Cold Shrink technology provides a reliable, long-lasting compressive seal, even in challenging environments. These features help reduce installation time and chance of craft error, while also providing the data needed to manage your grid assets proactively.

Accuracy – Analog waveforms for advanced analytics

Automatic distribution and control systems require highly accurate, real-time information about key grid parameters, such as voltage and current, in order to perform to their full potential. 3M Sensored Cable Accessories provide voltage data accurate to ±0.5%*, and current data accurate to within ±1%*. The bi-directional power flow and intermittent nature of renewable resources makes this data critical to utilities’ efforts to manage efficiency, quickly locate and correct faults, and keep end customers online.

Visibility – Real-time measurements

Currently available distributed intelligence solutions are generally too expensive to meet return on investment requirements if deployed systemwide. As a result, they are concentrated at just a few nodes – giving only a partial picture of the distribution grid. Since medium voltage cable accessories are typically located close to power equipment, 3M Sensored Cable Accessories can be deployed at strategic locations on the feeder, substations and consumption points throughout the grid – allowing wide-scale deployment and coverage.

Smart grid applications for 3M Sensored Cable Accessories

- Volt/VAR Optimization (VVO), including Conservation Voltage Reduction (CVR)

- Fault detection, isolation and restoration (FDIR)

- Asset management

- Load balancing

Voltage and Current Measurement Made Easy

The 3M Sensored Cable Accessory QX-Generation 2.0 enables you to measure critical parameters (voltage, current, phase angle) in an underground medium voltage electrical network. This solution incorporates highly accurate voltage and current measurement integrated into one product which means you get precise measurements without modification of the installed equipment. Additionally, the sensors are passive components thereby not requiring an external power source for sensing.

3M Sensors and Cold Shrink technology ensures easy and fast installation for a wide range of cable cross sections.

Your Trusted Connection

3M, together with Thorne & Derrick, understand the greatest of challenges. Every minute of downtime damages your brand, and power outages can be costly. 3M technology can be trusted to adapt facilities for changing business needs, working with your team to add value to existing infrastructure, reduce operating costs and give a competitive edge.

MV HV High Voltage Cable Joints | Cable Terminations | Cable Connectors | Distributed from Stock | UK & Export Sales

WEBINAR | Nexans Power Accessories Online Training Services Session

June 21st, 2022WEBINAR

Thorne & Derrick, the UK Specialist Distributors for Nexans Power Accessories UK, would personally like to invite you to attend the ‘Online Training Session’ to help us celebrate the 4th birthday of their Normanton Training Centre. Nexans established industry-leading Training Courses provide refresher and continuous development training for existing Jointers using a combination of theoretical and practical test elements.

Sign Up Here

Friday 8th July at 10.30 am CEST

Presented by James Addy (Technical Manager) and Kristof Rottiers (Technology & Services Manager – Nexans), together they will cover the Jointer Training Courses available at their UK centre which is specifically tailored to enable the upskilling of cable jointers from LV to MV 11kV, 33kV and 66kV.

Competency Test demonstrations will be carried out and you will get the chance to discuss your Jointer Training requirements with the experts.

Thorne & Derrick stock and distribute the full range of Medium Voltage Cable Accessories manufactured by Nexans in heat shrink, cold applied slip-on and EPDM rubber technology – this includes MONO Terminations, JTS Joints and Euromold Connectors up to 33kV.

Contact our trained team of Technical Sales Engineer for competitive quotations and delivery from stock.

Showcase | Battery Energy Storage System | Cowstead Battery Storage

June 20th, 2022

Battery Energy Storage System

Eclipse Power Networks were appointed by Sembcorp Energy UK (Formally UK Power Reserve) as the Independent Distribution Network Operator (IDNO) for the 50MW Battery Energy Storage System Site (BESS) at Cowstead in Sheerness, Kent.

Cowstead Battery Storage

The battery energy storage site is connected directly to the UKPN network via their existing 132kV Overhead Line (OHL) Network. A new UKPN 132kV disconnector was required to be installed beneath the OHL Point of Connection (PoC) as part of the contestable works.

Eclipse Power adopted the 132kV cable from the new disconnector to the 132kV metered Point of Supply (PoS).

An IDNO 132kV substation, incorporating 132kV earth switches, disconnector and dead tank circuit breaker, completed the IDNO adopted network assets that feed a client adopted 132/33kV 40/50MVA ONAN/ONAF transformer and 33kV GIS substation adjacent to the IDNO compound.

The Sembcorp network assets facilitate their 50MW BESS assets, which nearly doubles their UK battery storage portfolio.

Battery Energy Storage System

Project Challenges

The project had consent challenges which Eclipse helped to resolve quickly and efficiently. Such challenges are unlikely to have been resolved as efficiently, had the client elected to use the DNO to adopt the Contestable Works.

What is an IDNO?

Independent Distribution Network Operators (IDNOs) are OFGEM licensed companies that develop, design, own, operate and maintain local electricity distribution systems within the DNO network.

IDNOs are connected to Distribution Network Operators (DNOs), either directly, or through other IDNOs. They carry power to homes and businesses around Britain. Unlike DNOs, they’re not bound to any specific geographical region and can therefore offer their services to a wider range of customers.

IDNO Vs DNO

If you are looking to use an IDNO on your next project, please get in touch with Eclipse Power Networks:

- [email protected]

- + 44 (0) 1234 486487

- Contact Form

- Linked In Company Page

About Eclipse Power Networks

Eclipse Power Networks are a licensed Independent Distribution Network Operator (IDNO) who provide clients with an effective alternative to using the local Distribution Network Operator (DNO).

Working within the UK Energy industry, we design, own, operate and maintain licensed electricity distribution networks across the UK.

Our team of specialist Electrical and Civil Engineers have extensive experience of working within the electricity supply industry at voltage levels up to and including 132kV, based out of our Head Office in Buckinghamshire.

We can offer Developers, Contractors and ICPs several significant benefits over the standard DNO connection to the National Grid.

We work across a variety of sectors including (but not limited to):

- Battery Storage

- Data Centres

- Electric Vehicle (EV) Infrastructure

- Industrial & Commercial Developments

- Residential Developments

THORNE & DERRICK

T&D are Specialist Distributors to UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and HV Jointing Contractors of an extensive range of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt – this includes 11kV/33kV/66kV cable joints, terminations and connectors for both DNO and private network applications.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Ten Most Common Errors in Arc Flash Studies | Guest Article By Power EasyPower LLC

June 20th, 2022

Ten Most Common Errors in Arc Flash Studies

- Special thanks to Emily Sotupo Marketing Co-ordinator from EasyPower LLC for the kind permission to republish – view the original article click here

Arc Flash Studies

Each year we see dozens of arc flash studies ranging from first attempts to submittals from seasoned veterans in the industry. With an eye towards improving the overall results in the field, we offer this list of “Ten Most Common Errors.” This is not a criticism of anyone or any group; it is more of an effort to bring some insight to areas that may not be that well understood, including changes in the standards, the phenomenon of arc flash, and the application of analytical tools toward that end.

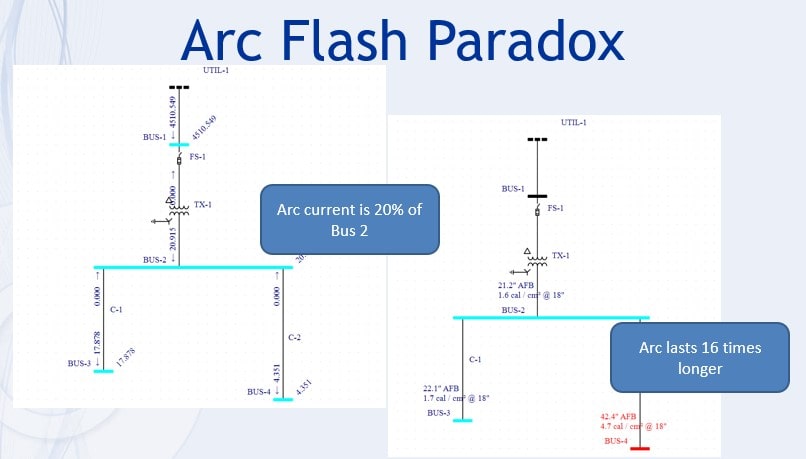

#1 – The Lack of Understanding the “Arc Flash Paradox.”

The counter-intuitive nature of the arc flash hazard tends to impede the acceptance of arc flash as a hazard by some of us with a long history in the industry. Put simply, within the same system you can have buses that have high current and high arc incident energy AND other buses that have lower current but that calculate a higher arc incident energy. Incident energy has a significant relationship to the time required to clear the arc.

Comparing Bus-4 to Bus-2 in the example below, Bus-4 has a higher incident energy in spite of having available fault current at Bus-4 that is only 20% of the fault current available at Bus-2. The length of time to clear the arc in this case has a significant bearing on the arc flash calculation.

#2 – “Infinite source” is Not the Worst Case

Nor should it be used in place of actual utility data when calculating arc flash results. Often times, the local utility company cannot or does not respond to a request for short circuit data as required for an arc flash hazard assessment. From the early days of power system design, the engineer responsible for the electrical system was tasked with the requirement to have the system be able to safely protect itself against the worst-case short circuit current that it could possibly see from the utility source. The concern was due to the short circuit rating for each piece of equipment in the system.

Each piece of equipment needed to be able to survive in the case of a short circuit fault. The results of an equipment duty analysis will determine if any system element has the potential for being over-stressed in the case of a worst-case fault at that location.

In that case, using an infinite source would be valid to determine system integrity. In the case of arc flash analysis, however, the use of a higher short circuit current value than is really expected could potentially yield a lower result for arcing incident energy since the higher current value of the infinite source would cause the protective devices to trip quicker than the same circuit exposed to actual or estimated fault current at the utility connection. This can be shown in the framework of an EasyPower study by using the Scenario Manager to compare results.

#3 – Not all buses are created equal!

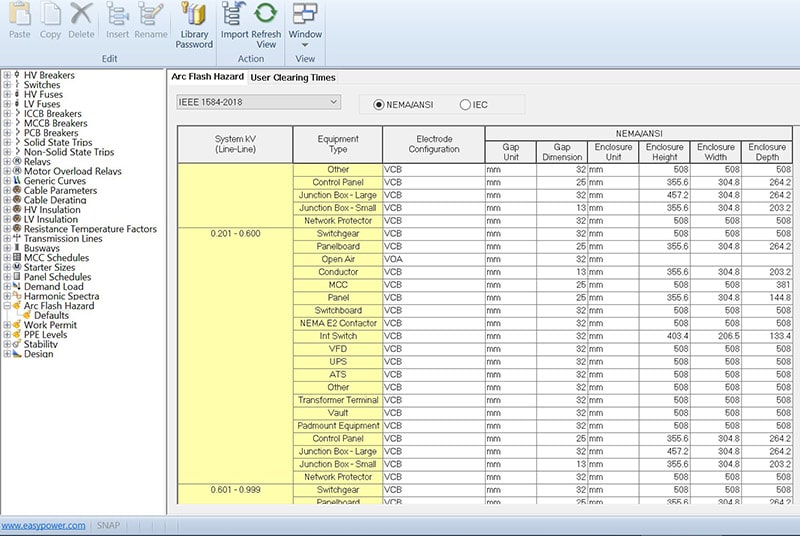

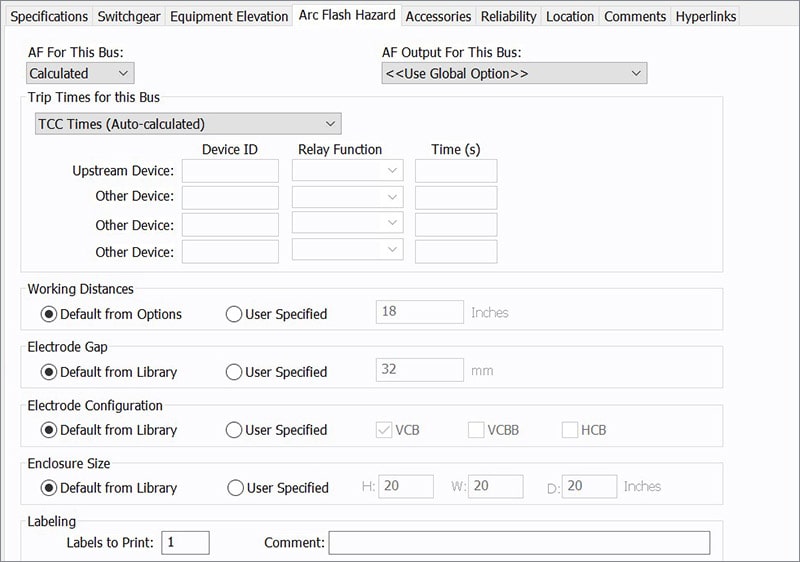

The long-awaited release of IEEE 1584-2018 promised improved alignment between model results and the test data upon which the model is built. Part of this improvement is the inclusion of a number of parameters that were not included in the original arc flash calculation method. Included in the updated standard is a table of typical values for each of these parameters along with equipment type and different voltage levels.

It is therefore a good practice to ensure that the data collection team can identify the type of switchgear or panelboard and at the same time recognize if there is a significant difference between the typical values listed in the standard and record the actual values for:

- Working distance

- Electrode gap

- Enclosure size

- Electrode configuration

In EasyPower, the default values for each of these parameters are included in the Arc Flash Hazard Default table in the Device Library. If the actual system diverges from the default values significantly, it is incumbent on the person creating the digital model of the system to update the recorded values during model creation.

Arc Flash Hazard Default Values

Typical Parameters in the Arc Flash Hazard Tab

#4 – Why Not Put 6 Inches Working Distance on the Label, Since That is What My Hand Will See?

It is expected that the results of the arc flash study will be reviewed by management with an eye towards verifying that all hot work required in the plant will be necessary and conducted with the utmost focus on employee safety.

As such, all hot work should be conducted under the auspices of properly completed Hot Work Permit. Labels do not authorize hot work. The working distance on the label is generally based upon the distance from the bus to the head or thorax of a worker while the panel cover is being removed. It is really a convenient number to permit the qualified worker to understand the relative magnitude of the hazard when the cover is removed. Additional information on the label is discouraged to prevent any misunderstanding of this restriction.

#5 – Why Calculate Equipment Duty on Plant Equipment That Has Already Been in Operation For 25 Years?

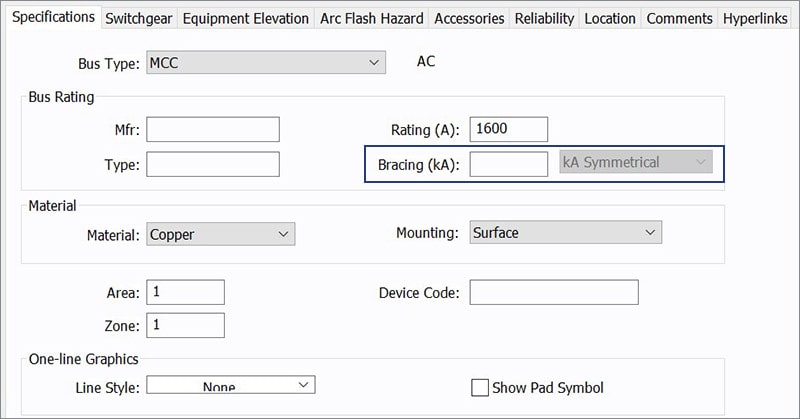

If it has been working for that long without an issue, why bother? Right? SCCR (short circuit current rating) is the maximum short-circuit current an electrical component can safely withstand without causing shock or fire hazard. In general, the SCCR for electrical switchgear or panels is based on the lowest component’s SCCR in that panel. Protective devices included in the one-line diagram must be linked to the datasheet for that element located in the Device Library.

As long as the one-line element is linked to the Device Library (meaning it is verified using the Calculate button on the Short Circuit tab of the Data dialog box), EasyPower calculates the equipment duty during a short circuit analysis.

The withstand rating of switchboards, panels, and MCC enclosures is usually listed on the nameplate of the installed element. In EasyPower, this rating should be entered in the dialog box for the element to be included in the equipment duty calculation.

Consideration should be given to system changes over the life of the installation. Changes in load size and location, increases in fuse sizes, breaker trip settings, as well as unannounced changes in utility short circuit values could render the original system design guard bands inadequate. Even if the SCCR for some elements may not have been entered during the original arc flash study, it seems prudent to include the data during study updates.

Bus Bracing Missing in the Data Dialog Box for an MCC

#6 – We Do Not Need a Coordination Study on Protective Devices During This Update. We Did It Five Years Ago

You may be correct unless:

- Some blown fuses were swapped out with a different manufacturer’s product or values because they were available during urgent times.

- Relay or LVPCB trip settings were tweaked to eliminate nuisance tripping.

- Large system loads have been added, moved, or deleted.

At a minimum, you should check the Sequence of Events. PowerProtector™ is the name of the EasyPower module used for plotting TCC curves and verifying coordination. When system fault current is displayed during a single bus fault, EasyPower illuminates an icon labeled Sequence of Events.

A simple click on that icon displays the chronological trip order of all device between the faulted single bus and the energy sources affected, providing a quick and efficient way to verify device coordination.

Arc Flash Protection & Electrical Safety Products | Distributed By Thorne & Derrick

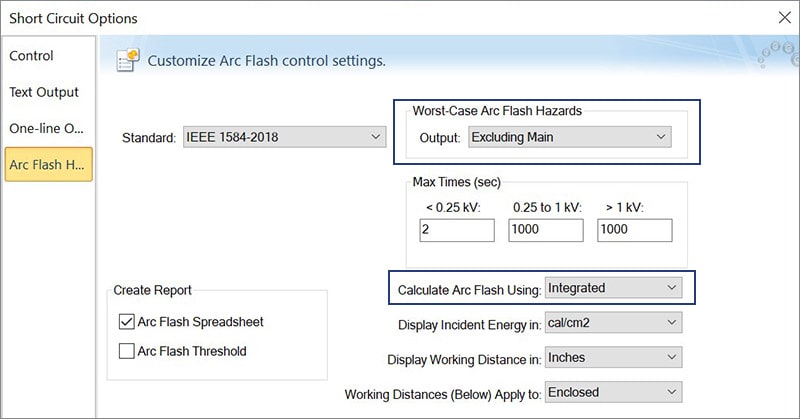

#7 – I Always Calculate Arc Incident Energy Including the Main Breaker Because I Don’t Think It Will Fail

The IEEE 1584 standards (both 2002 and 2018) recommend excluding the main breaker of a panel or switchgear when there is not an arc barrier between the incoming conductors to the main breaker and anyone working downstream on the main bus. The reason has less to do with the reliability of the breaker itself and is more based on the fact that once established, an arcing fault will produce a plasma ball, often several millimeters in diameter.

If that plasma ball contacts any electrified bus work, the arc can propagate and potentially render the protective device useless. Verifying the existence of an arc barrier between the incoming conductors and the downstream bus is the only way to recommend including the main breaker.

Worst-Case Arc Flash Hazards Indicating the Option to Exclude Main Breaker and Use the Integrated Method to Calculate Arc Flash

#8 – Half-cycle (Momentary) Current is the Worst-case Fault Current, so I Use It to Calculate Arc Incident Energy

Recognizing that the available fault current may change over time, IEEE 1584-2018 recommends that a dynamic assessment of fault current be used to accommodate changes that may be the result of reducing motor contribution, load drops, or other changes in fault current. In EasyPower, the recommendation is to use the Integrated Method.

In the EasyPower Integrated Method, during:

- The first cycle of the fault, momentary current is used for energy integration.

- The next 8 cycles, interrupting (5-cycle) current is used to calculate energy.

- For any additional time to clear the protective device, 30-cycle current is used.

9 & 10 Deal with labels, which are the source of a large number of frequent errors. These are two of the most frequent:

#9 – I Want My Labels to Show the HRC #, in Spite of the NFPA 70E Changes

NFPA 70E revision history includes the following changes:

- The 2012 version had Hazard Risk Category (HRC) tables.

- The intent was to calculate incident energy and then use the table to determine the PPE needed.

- The 2015 version changed HRC to PPE category.

- The label may have calculated Incident Energy OR PPE category, but NOT BOTH.

- Allows for a “Site Specific” option for companies to define their own categories.

- The 2018 version repeats label restrictions.

- The industry is migrating to align training for labels and PPE rating to reflect the incident energy.

While the standard is voluntary, the industry is moving to align with the NFPA 70E recommendations to label PPE with incident energy. So, the reasons (if any) to stay with using the HRC # on labels should be reconsidered. We recommend:

- Set a timetable to achieve NFPA 70E alignment.

- Decide between Site Specific or Incident Energy to determine PPE.

- Update the safety manual and training to follow NFPA 70E.

#10 – I Want to Put Maintenance Mode incident Energy on the Label

For at least the last 10 years, hardware companies have made available a feature that enables the user to temporarily set the trip time of a relay or LVPCB unit to be much quicker and provide a safer, lower arc hazard on the protected bus. This feature can be enabled by a switch on the front panel or an electric control signal routed to the back of the panel and is called Maintenance Mode.

This is a method of hazard reduction preferred over just adding more PPE for the worker at the higher energy level. It also falls into the category of hot work. Therefore, the information should not be on a label. Instead, the maintenance procedure, correct PPE, and instructions to use the Maintenance Mode feature should be approved and listed on the Hot Work Permit.

EasyPower LLC – Bio

Since our inception in 1984, we’ve been redefining how companies manage, design, and analyze their electrical power distribution. We continue to develop unprecedented technologies to make it simpler, smarter, and safer— driven by an unyielding commitment to deliver cutting-edge power system software that’s inherently easy to use.

Organizations throughout the world use our advanced— yet simple— software tools to safeguard their valuable resources of time, money, and personnel. Oil refineries, power utilities, paper and pulp manufacturers, military installations, data centers, and a host of others rely on EasyPower to keep their power systems running safely and smoothly.

From plant personnel to the most experienced electrical engineers, EasyPower users continually rave about its simplicity and power.

Our family of products includes the EasyPower® suite, ArcFlash Essentials™, and OnSite™, as well as our grounding calculation solution, XGSLab, for which we are the exclusive reseller in the United States and Canada. We also provide training for EasyPower and electrical safety in general, in addition to offering a full range of engineering services.

EasyPower Customer Service

EasyPower’s Sales Team is available to meet all of your customer service needs:

- Provide free demos

- Provide pricing information

- Customize a software package to meet your specific engineering needs

- Provide answers regarding upgrades, maintenance contracts, and key replacements

If you need Engineering Services, we are happy to process your Request for Proposal from our Consulting Team. Or, if you have Training Questions, we’ll gladly answer those as well.

Contact us by email at [email protected]

Contact us electronically by using our Contact Form, or reach us with our address or phone number here:

EasyPower LLC

15862 SW 72nd Ave, Suite 100

Portland, OR 97224

+1 (503) 655-5059

Arc Flash PPE & Electrical Safety

Main UK Stockists & Distributors of Electrical Safety Products

Thorne & Derrick provide Electrical Safety Equipment to substation engineers, cable jointers, overhead linesmen and utility workers with PPE and electrical safety equipment including insulating gloves, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out maintenance on LV-HV switchgear, substations, cables and electrical equipment.

We protect substation engineers, asset managers, SAPS, cable jointers, overhead linesmen and utility workers with PPE and safety equipment: this includes insulating gloves, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out repair and maintenance on LV-HV switchgear, transformers, substations and turbines.

All our Cable Connection & Energisation Accessories including Medium & High Voltage joints, terminations, connectors and cleats are tested to the latest international standards and supporting ranges of professional cabling tools are stocked to reduce incident, accident and downtime to plant and people.

Lucy Zodion Awarded Tender by Scottish Power Energy Networks

June 15th, 2022

-

Uploaded By - Chris Dodds (Thorne & Derrick Sales & Marketing Manager)

Press Release: Thorne & Derrick and Lucy Zodion | 17.6.22

STREET LIGHTING CUT OUTS

Thorne & Derrick, a Specialist Distributor for Lucy Zodion the market-leading manufacturer of Street Lighting & ICP Connection Solutions, are delighted to announce that Scottish Power Energy Networks (SPEN) have awarded a 2-year tender to Lucy Zodion to supply the following G81 approved products:

- Lucy 0260009009 SLF 25A Street Lighting Cut Out TYPE 1 SNE Boxed

- Lucy 0350012009 5 Way Connector Box

The Lucy Zodion range of street lighting cut-outs, controls, feeder pillars and isolators are specified and installed by ICP’s throughout the UK providing reliable and effective street lighting and electrical connections to our utility network.

Thorne & Derrick are Approved Vendors to SPEN and their Lloyds NERS accredited ICP’s, you can contact us for competitive prices and stock availability for the complete range of Lucy Zodion Street Lighting Equipment.

➡ For further information about how Lucy Zodion provide control and power distribution products for street lighting applications, please review the Lucy Titan (Cut-outs) and Lucy Trojan (Isolators) ranges of products.

Should you require any technical support or have any commercial requirements about G81 Approved 11kV/33kV Cables & Accessories please do not hesitate to contact Thorne & Derrick Sales Team.

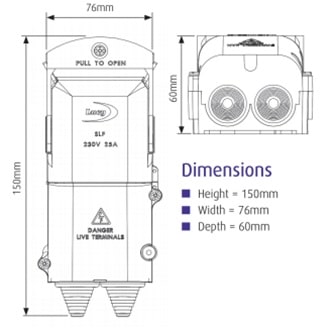

Lucy Zodion SLF fused cut out

- Separate neutral and earth (SNE) cut out

- Maximum continuous load 25A

- Simple cam lever fuse carrier removal

- Single fuse

- Double pole

- Cut-out full conformity to BS7654

- Terminals accept cables up to 25sqmm

- IP22

- 2 x 20mmØ cable entry- grommets

Lucy Zodion Cut Outs | The SLF cut out range is approved by all Distribution Network Operators (DNO’s) throughout England, Scotland and Wales – G81 approved versions are available for ICP/IDNO connections.

Lucy Zodion Cut Outs

| SPEN SAP Code* | Lucy Zodion Part Code | Description* |

| 30980590 | 0260009009 | CUT OUT 25A STREET LIGHTING TYPE 1 SNE: 25 AMP STREET LIGHTING CUT OUT, SNE CONSTRUCTION |

SLF

Lucy Zodion MLNS – 5 Way connector block

MLNS

- Maximum continuous load 100A

- Suitable for phase, neutral or earth conductors

- Serrated cable bores accept conductors up to 35mm² section

- Two M8 slotted head cable pinching screws per conductor

- Sealing wire facility

- IP22

- Removable shields for unused cable entries

- Robust thermoplastic housing

| SPEN SAP Code* | Lucy Zodion Part Code | Description* |

| 30980639 | 0350012009 | 100 A, 5 WAY SINGLE POLE CONNECTOR BLOCK. SUITABLE FOR TERMINATING PHASE, NEUTRAL OR EARTH CONDUCTORS |

*The SPEN part codes and descriptions in the tables are taken directly from the tender document.

Lucy Zodion’s SLCOs are compliant with BS7654, which covers all aspects of the cut out from the materials in which it is manufactured, to a series of tests relating to temperature, ingress protection, current and mechanical strength.

BS 7654 | 10th Edition, May 15, 2020 | Specification for single‑phase street lighting cut-out assemblies for low-voltage public electricity distribution systems – 25 A rating for highway power supplies and street furniture | purchase copy.

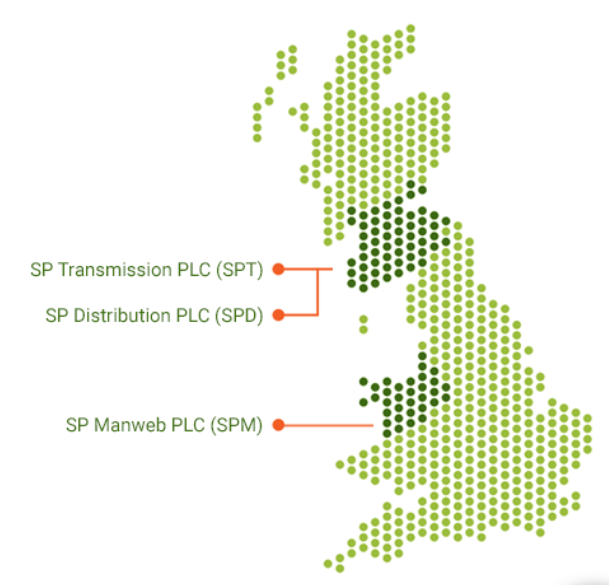

About SPEN

SP Energy Networks are a Distribution & Transmission Network Operator keeping electricity flowing to homes and businesses throughout Central and Southern Scotland, North Wales, Merseyside, Cheshire and North Shropshire – this is achieved via a network of Overhead Lines & Underground Cables which they own and maintain.

This includes over 30,000 substations, 40,000km overhead lines and 65,000km underground cables.

3 SPEN Regulated Electricity Businesses

- SP Transmission PLC (SPT)

- SP Distribution PLC (SPD)

- SP Manweb PLC (SPM)

THORNE & DERRICK

T&D are Specialist Distributors to UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and HV Jointing Contractors of an extensive range of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt – this includes 11kV/33kV/66kV cable joints, terminations and connectors for both DNO and private network applications.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV