Blog

Arc Flash | Don’t Let the Summer Sun Compromise Your Electrical PPE

June 30th, 2021Comments By & Republished with Kind Permission of Mark Lant, Technical Expert at ProGARM

Electrical PPE

Arc Flash Clothing

In industries working around high and low voltage electricity, the importance of Electrical PPE is widely recognised, and the latest electrical safety requirements are understood by managers and operatives alike. However, the dangers posed by an arc flash are not so well known in comparison. With temperatures of up to 35,000ºF, which is more than four times hotter than the surface of the sun, an arc flash has the potential to burn an operative’s skin within fractions of a second, meaning PPE really is the last line of defence for workers.

But the summer heat can pose a risk to workers, who may be unknowingly compromising the protection provided by their PPE in their efforts to keep cool.

The Risks of Heavy, Bulky Electrical PPE

For obvious reasons, all arc flash clothing must be full length and long sleeve, to ensure no part of an operative is left unprotected. However, this can become extremely warm for those working during the warmer summer months.

Additionally, arc flash protective clothing has historically been thought of as uncomfortable. This is primarily because the clothing was typically made from fabrics that provided great protection, but were often heavy, stiff, and rough against bare skin.

A garment can offer the ultimate protection, but if an operative does not feel comfortable wearing it, that protection diminishes when they choose not to wear the garment correctly.

Heavy, bulky and rigid Electrical PPE is frequently worn incorrectly – it’s all too easy to roll sleeves up or undo a jacket when a garment is uncomfortably hot in the warmer months, but all this seriously compromises the safety of an individual against an arc flash.

Ensuring Breathable Electrical PPE

Thankfully, uncomfortable PPE can now be a thing of the past, thanks to the use of inherent fabrics. Inherent fabric refers to material which has fire retardant properties as part of its natural make-up. In other words, they needn’t undergo a chemical process to become flame-retardant, as the polymers which make up the clothing are inherently so.

Not only do inherent fabrics offer lifelong protection, garments made with inherent fibres allow movement, breathability and moisture management. The fabric readily absorbs sweat and then dries quickly, not only providing cooling in hot, humid conditions, but doesn’t leave sweat running down the skin.

The Importance of Layering Arc Flash Clothing

While in summer, the thought of extra layers may not be appealing, the material worn beneath an arc flash protective jacket is just as crucial to protecting from the event as outer clothing.

Although the outer garments are key components for providing protection, they are not enough to match the risk posed to an operative’s safety. Therefore it’s vital that any layers worn beneath arc flash clothing, including underwear, should also be arc-resistant.

This is because, while the flames caused by an arc flash may not actually come into contact with skin through the protective outer layers, the extreme heat from the event can melt the materials used to manufacture everyday undergarments, including nylon, cotton, and polypropylene. This will inflict burns on an operative and potentially cause non-arc flash protective undergarments to melt into the skin underneath their PPE.

The key to ensuring effective arc flash protection during hot working conditions is to ensure that workers are equipped with garments that will allow them to stay cool and comfortable during their physical tasks, therefore enabling them to wear their Electrical PPE in the correct manner without overheating.

💡 Did you know? – While high voltage equipment does increase the likelihood and intensity of arc flash explosions, they can occur in any live electrical environment – even low voltage.

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

The Hidden Risks of Breaking Ground | Protecting Against Arc Flash

June 30th, 2021

Arc Flash Risks

The Hidden Risks of Breaking Ground

Those who work in electrically-charged environments are often aware of the dangers they face. Rightly so; it’s highly regulated because a wrong move could have devastating consequences. But what about when that’s not the case?

Industries from telecoms to utilities, sustainable technology to rail maintenance can find themselves in unpredictable territory when breaking ground. In this more uncontrolled environment, the risk of an arc flash or other electrical incident is a real possibility.

A CRITICAL LACK OF INFORMATION

Companies involved in breaking ground rely on underground utility maps to show whether there is a risk of disturbing live services. It’s worrying though, that there is no single, government-owned collection of maps showing the UK’s service network. Instead, some companies hold some records, creating at best a very high-level picture.

At worst, it’s dangerous; as well as the unknown risks, utility and service cable strikes cost the economy around £1.2bn a year.

The HSE has produced a comprehensive guide Avoiding Danger from Underground Services.

This talks about how to identify and manage the dangers, as well as identifying services and safe excavation. The guidance is clear about the responsibilities if you plan work that may disturb underground services, and suggests that site operators and owners should be prepared to help you locate and identify any services that could be a risk.

Stokbord Drum Cable Protection for Underground Utility Cables

THE MOST DANGEROUS RISK IS AN UNKNOWN ONE

One of the biggest problems with the unpredictable task of breaking ground is that if there’s no perceived risk then it’s likely the wrong PPE is being used. When there’s even a possibility of an arc flash occurring, it’s crucial that specialist arc flash kit is worn.

People regularly working in known live electrical environment have an advantage. They benefit from full and comprehensive assessments to ensure they’re wearing kit that will protect them should an incident occur. As an employer, the costs are significant if you don’t follow the rules with fines of over £2m not unheard of.

THE RIGHT ARC FLASH PPE CHOICE IS THE ONLY CHOICE

Research shows there is a lack of awareness about the products available to protect people from arc flashes and other electrical incidents. Conversations about thermal energy and calories per square centimetre of fabric may seem complex and overwhelming.

As a result, they can be a trigger for your businesses reverting to tried and tested PPE that suits a more generalist need.

In the event of an arc flash, that decision could be the difference between survival, significant life-changing injuries and even death. Purpose-designed arc-flash clothing, as designed by ProGARM, undergoes every possible industry test, meets every relevant certification, and matches every necessary standard. More than that, it is designed with comfort, durability and wearability in mind.

If disaster strikes when breaking ground, ignorance will be no excuse.

Further Reading

Arc Workwear Saves Lives | Watch Mitchell’s Story

Live Line Electricity Voltage Alarm | CATU ALED3

Arc Flash Risks In The Rail Industry

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

Onshore Wind Farms: Nexans Awarded Underground Power Cable Contract for Viking Wind Farm

June 30th, 2021

Nexans cables for Onshore Wind Farms

- One of the UK’s largest onshore wind farms will rely on Nexans’s cables to provide vital connections at distribution voltage level to help Scotland meet its net-zero targets.

- 800km of underground cable will create the inter-array connection for 103 wind turbines and export the power generated.

Paris, June 15, 2021 – Nexans has been awarded a multi-million euro contract by SSE Renewables to supply 800km of underground cables that will make the vital power connections for the Viking Wind Farm. The wind farm on Shetland in the North Atlantic, 170km from the coast of Scotland, is scheduled to go online in 2024. With a peak output of 443MW, it will provide enough renewable energy for almost half a million homes and play a crucial role in helping Scotland achieve its net-zero targets.

The Viking Wind Farm will comprise 103 wind turbines set around the central mainland of Shetland. The 33 kilovolt (kV) underground cables supplied by Nexans will link the wind turbine arrays together and then export the power to the main substation for feeding into the interconnector that will transfer it to the UK grid.

Derek Hastings, Head of Onshore Projects at SSE Renewables said: “The performance and reliability of the underground power cables are critical to the success of the Viking Wind Farm. There were two main reasons for awarding the contract to Nexans. First, the cables met our stringent technical requirements. Second, and very important for us, was Nexans’ ability to provide a fixed price over the 18-month contract period. This overcame the current volatility in metal and plastics pricing.”

The 650km of underground cables to be supplied by Nexans are a single core design with cross-linked polyethylene (XLPE) insulation. The conductors for the inter-array cables will be aluminium. Copper will be used to carry the higher current for the export cables. Nexans is also supplying 150km of bare copper earth cable.

Max Williams, Utility Sales Director for Nexans UK, said: “We are delighted to be involved in the Viking Wind Farm project. It is a perfect fit with Nexans’ ambition to electrify the future. The contract builds on our long-established working relationship with SSE. It also confirms Nexans’s capability to support major UK clients with large-volume, land-based power cable projects at distribution voltages.”

The cables for the Viking Wind Farm will be manufactured at the Nexans Hellas plant in Lamia, Greece and will be supplied via Nexans UK. First deliveries are scheduled for September 2021.

Onshore Wind Farms

Further reading

Nexans Windlink® Cables To Electrify The Future Of Onshore Wind Turbines

Nexans OJC Offshore Medium Voltage Junction Cabinets For Wind Power Projects

Nexans Power Cable Accessories For Wind Energy Projects – MV & HV Cables

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

Superconducting Cable Systems – The Future?

June 30th, 2021-

Reproduced with kind permission of Mane - Worldwide Recruitment Specialists.

Cable Systems

Superconducting cables could be the answer to distribution challenges in offshore wind.

Achieving submarine power transmission with low loss and high capacity is vital for the future of renewable energy. But recent breakthroughs have relied on high-voltage direct current, making them useless anywhere low voltage is mandatory. Superconductors can transmit electricity efficiency with much lower voltage and power requirements.

Now SuperNode has teamed up with Irish research institute MaREI on a superconductor project that could enable up to 10x faster offshore renewable development worldwide.

The idea is to provide a single superconductor connection for offshore renewable energy sources. It would deliver electricity back to shore efficiently via medium voltage direct current, using a subsea superconductor to move power from energy-dense areas offshore to high-demand areas onshore.

SuperNode CEO John Fitzgerald says the technology could be a game-changer for the industry and help Europe achieve its carbon-cutting targets.

While superconducting cables have been operating onshore in places like Germany and Korea for years, current onshore cable systems are not fit for offshore use or for the amounts of power needed to support a renewable grid. This is why SuperNode is developing its new Subsea Superconducting Cable System.

Leading certification body DNV GL has now awarded the system its coveted Statement of Feasibility, making it the first subsea superconductor system to receive such an award in the world. The next step for SuperNode will be to deliver a scale prototype this year.

further reading

Cable Testing – Is Resonance Testing The Way Forward For Offshore Wind?

Why Large Offshore Wind Farms Should Double Their Intra-Array Voltage

Thorne & Derrick are Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Flexible Cable Seals for Gas Insulated Substations

June 30th, 2021

Flexible Cable Seals

“Roxtec experts responded quickly, and we saved a lot of time”

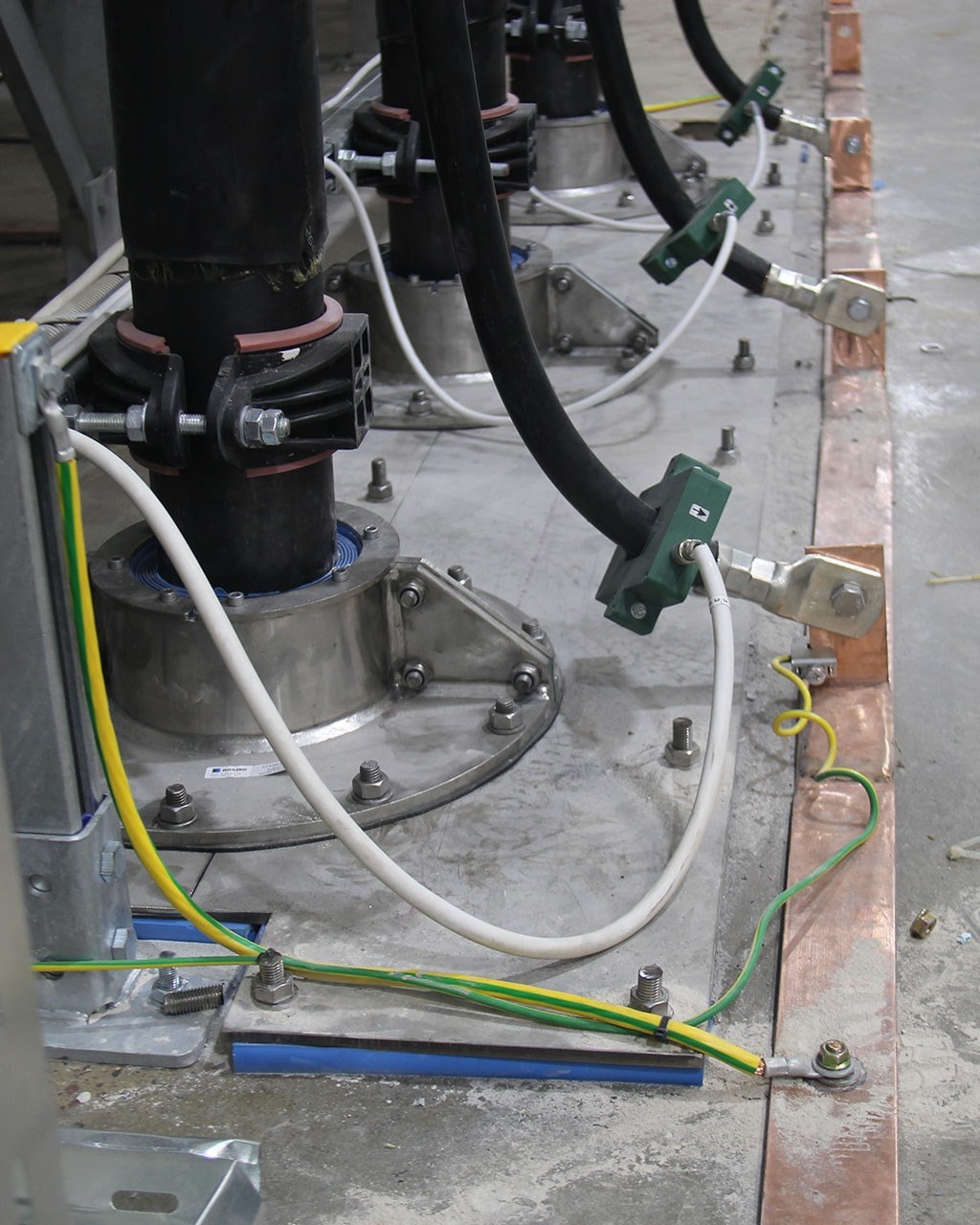

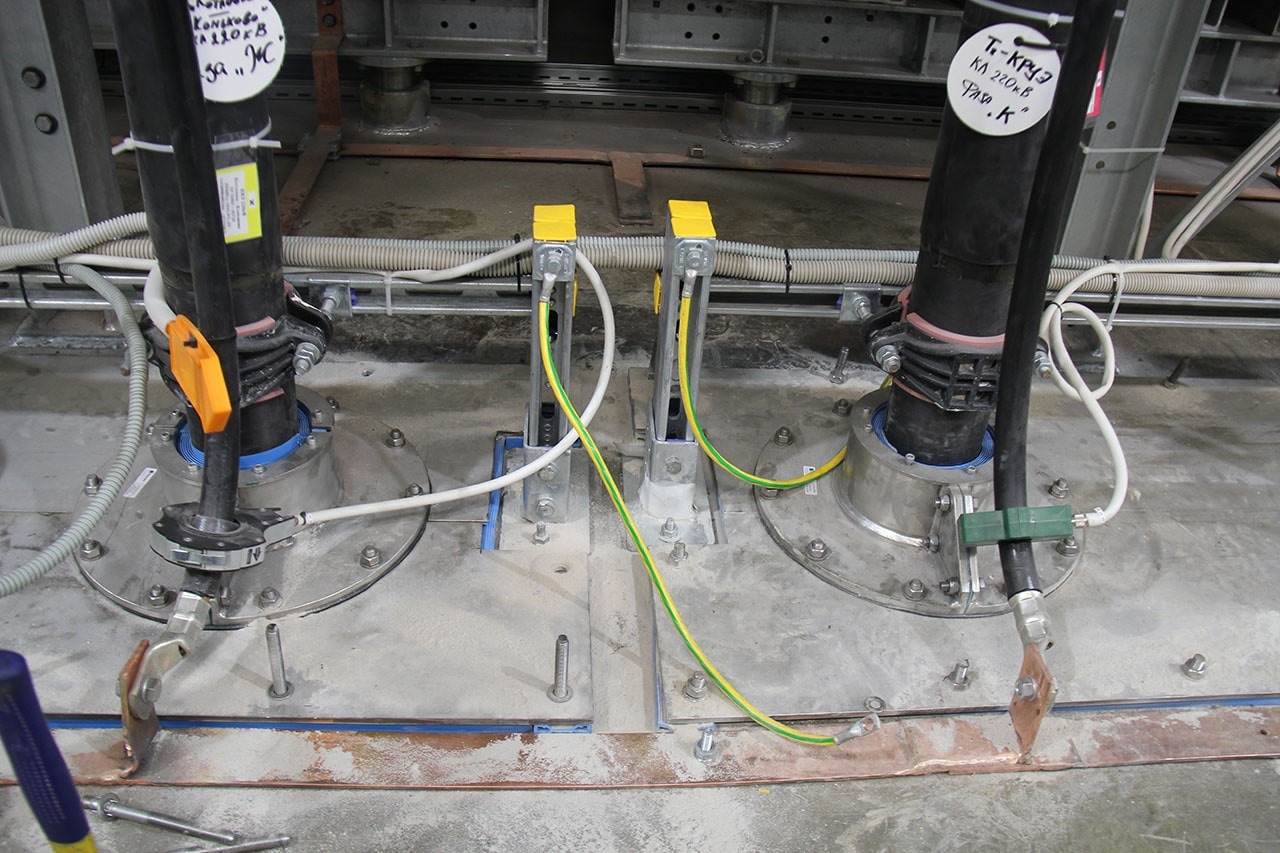

The Kotlovka 220/20 kV substation in Moscow, Russia needed fire-rated, gas-tight, and removable seals for the cables coming up through the floor to the GIS room.

Roxtec created a solution covering all these requirements.

As the sealing solution is quite demanding, Roxtec provided extra technical support to the staff of the installation company.

Roxtec representatives held installation training and performed onsite control in order to make sure that everyone involved in the project was fully satisfied.

Project facts

- Project Description – Construction of the Kotlovka 220/20 kV substation in Moscow, Russia

- Involved Companies – OEK (United Energy Company) and Enrgokompleks – owners InjEnergoProekt – designer InjPromEnergo – contractor

- Applications – Sealing solutions for cable entries from cable cellar to GIS room

- Sealing Requirements – Gas-tight and fire rated for 45 minutes

➡ To read more about the case click here

Cable Sealing Using Roxtec

Roxtec cable seals are used in cable vaults, duct banks, electrical substations, trenches and M&E building services protecting low, medium and high voltage power systems against numerous external risk factors:

- Fire – A60, H120 Class bulkhead sealing for offshore classification against jet-fire or spray and prevention of suffocating smoke spread

- Gas – ensure complete tightness against air and gas pressure or migration through cable ducts with DSEAR compliance

- Water – prevent flood and water penetration into substations and buildings – avoid humidity and partial discharge conditions

- Cables – withstand cable bending load in heavy power and high voltage cable seal applications

- Pressure – protect against catastrophic sudden or constant pressure

- Electrical – protect cables and electrical infrastructure against EMI, EMP and lightning strike effects

- Particles – control levels of of dirt, dust, chemical and fumigants from entering buildings, cable ducts and substations

- Blast – protect against vibration, shock-waves and the risk of explosion in industrial and hazardous area locations

Cable Transits – Sealing Cables & Pipes

Cable Transits

Roxtec cable transits are used to prevent water, gas, fire, dust and rodents from entering cable duct openings and potentially causing damage to cables and other electrical infrastructure.

Cable transit systems can be designed for sealing medium/high voltage substations including 11kV/33kV and “triplex” type cables in single, multiple or trefoil configuration.

Roxtec modular cable transit seals are based upon a rubber design with seals that are constructed of a number of removable layers to secure a watertight, gas tight and fire proof seal around the cable or pipe – the range includes rectangular transits and round transits to fit a variety of pipes and cable sizes.

Cable transit products ensure safety, reliability and efficiency by providing an effective, dependable seal around cables and pipes through an opening, penetration or duct.

LV MV HV Jointing, Earthing, Substation & Electrical Eqpt

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV