Cable Strikes

Cable Strikes | Ingrebourne Valley – 415V Cable Strike

May 18th, 2021

Cable Strikes

Utility Strike Avoidance Group

USAG have published a range of documents to assist industry understanding of the root cause and contributory factors behind specific incidents. The aim is to improve industry standards and reduce the number of cable strikes.

Cable damage is often caused by excavating machines – hand held tools such as pneumatic drills, crowbars, pins, picks and forks also expose workers to potential sources of danger when digging around underground cables.

Cable Hangers | Cable Ducting | Cable Protection | Electrical Safety Equipment

Incident Overview

What Happened?

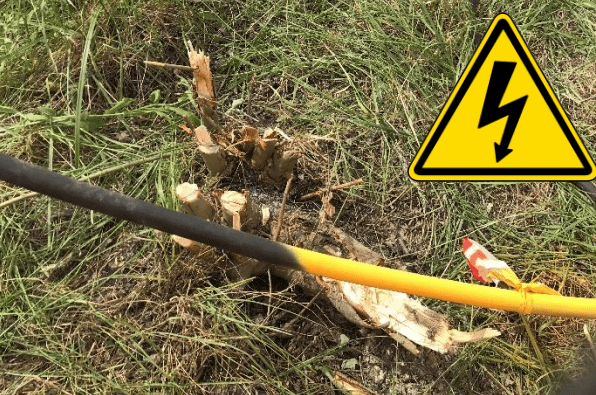

On the 2nd July, at approximately 15:35, a service strike occurred when an excavator tracked over an above ground 415V armoured cable. This cable was located in the vegetation clearance area of the satellite compound in Ingrebourne Valley. The excavator (with a grab attachment) was completing vegetation clearance works for site compound set up.

The service strike caused immediate loss of power to the neighbouring site welfare cabins of Brown and Mason. Following the strike the excavator operator stayed in the cab and called for assistance. Brown and Mason representative and their electrician were called to the scene and confirmed power had been lost and the area made safe. The excavator driver was then able to track back to safety and stand down.

The power was supplied by a generator situated in the work area of Package B. Perfect Circle and Socotec Site Management believed the area was free from services. They had received a guidance certification from the site owners which was misunderstood and heavily relied on. The certificate also failed to mention the power generator.

Immediate Causes

Failure to follow PAS 128 correctly, before any works commenced. They did not look at their surroundings and investigate any furniture which could have utility supplies, in this case the generator and cabins.

Had this been undertaken the direction of the over ground cable could have been identified, prompting further careful investigation prior to the works being undertaken.

Ingrebourne Valley 415V Cable Strike

Prior to vegetation clearance work in the vicinity of the generator, no communication took place with site neighbours Brown and Mason to address cable management/direction.

CAT and Genny scanning from the live generator cables did not take place, which would aid the clarification of the cable’s direction.

Lessons Learnt

Too much reliance was placed on service plans and client certification of services. These documents must be treated as guidance only. All services must be identified and traced on all packages.

Appropriate site planning would have identified the generator and cables as a hazard for the works. Works should not have commenced in the area of the generator until cable direction and status (live / terminated) was clarified.

There was a failure to adapt and change methodology for site restrictions caused by the dense vegetation. Where site restrictions affect prescribed and agreed methodology of works, works must stop, be reassessed, re-briefed and signed by those completing the tasks.

Perfect Circle Site Management failed to enforce PAS128 / CAT & Genny usage on site by subcontractors. All services need to be traced out, if vegetation prevents the use of CAT & Genny, stop works and reassess the methodology of works. Reduce vegetation following a safe system of work to aid access and identify services.

PAS 128

PAS defines a hierarchy of detection methods to be used to detect underground utilities:

- Survey type D shall use desktop search techniques to identify existing utility data within the survey area.

- Survey type C shall comprise a site reconnaissance to identify physical features that support the existence of utilities within the survey area.

- Survey type B shall use geophysical techniques to detect and identify utilities within the survey area.

- Survey type A shall comprise exposing the target utility(ies) within the survey area to confirm and record the location and other attribute data following safe digging practises.

Protecting Cables Against Strikes & Restoring Power Post-Strike

Thorne & Derrick have been distributors for 3M Electrical since 1985 and can provide a range of reliable and easy to install Cable Repair Products – this includes Scotch Tapes, Scotchcast Joints and Cold Shrink Tubes to provide effective re-instatement of cable sheath jackets on all types of LV MV HV cables in onshore and offshore locations with safe or hazardous area workplace classifications.

Cable Repair Products

Our range of cable protection covers manufactured by Centriforce provide underground utility protection of LV MV HV cables including Tapetile (11kV) and Stokbord (33kV 66kV 132kV) – contact us to discuss Cable Damage Prevention Products including Dectamesh, the underground detectable warning tape for alerting excavators of the presence of buried cables and to prevent potentially lethal accidents during excavation.

Cable Strikes | 132kV Cable Strike at Sellafield

May 18th, 2021

Cable Strikes

Utility Strike Avoidance Group

USAG have published a range of documents to assist industry understanding of the root cause and contributory factors behind specific incidents. The aim is to improve industry standards and reduce the number of cable strikes.

Cable damage is often caused by excavating machines – hand held tools such as pneumatic drills, crowbars, pins, picks and forks also expose workers to potential sources of danger when digging around underground cables.

Cable Hangers | Cable Ducting | Cable Protection | Electrical Safety Equipment

Incident Overview

CDM construction site at Fellside

Summary

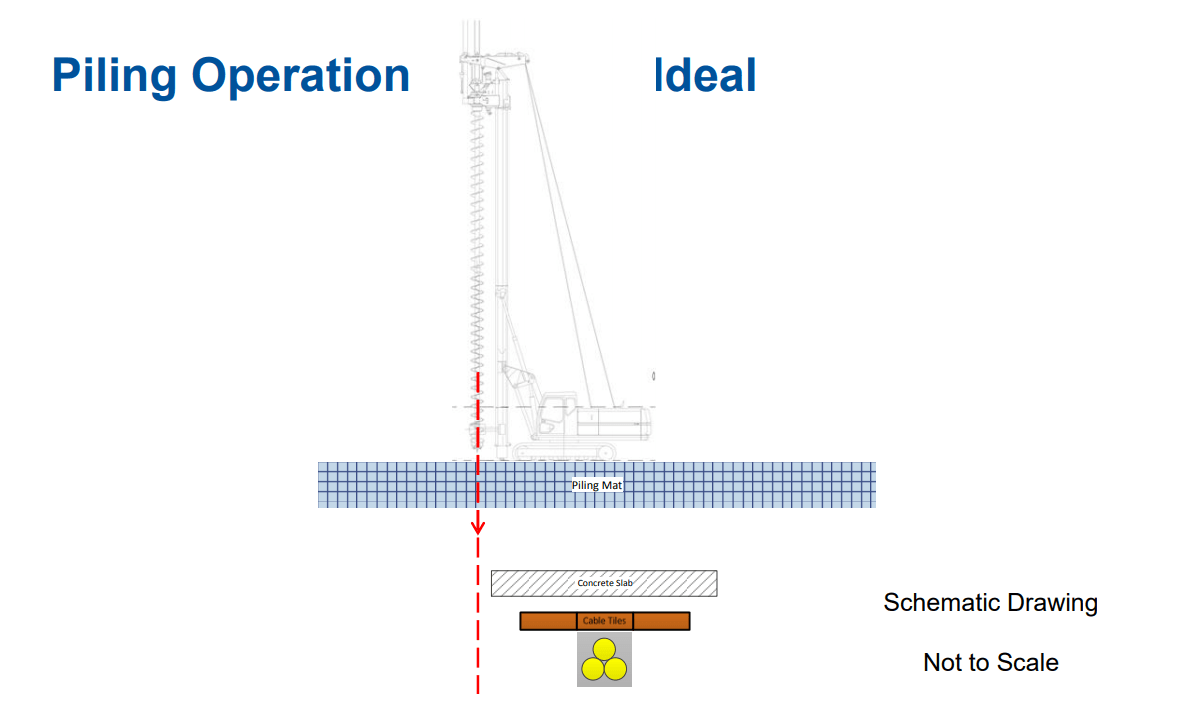

The incident happened at the Fellside CDM area; part of a project to build new fuel storage tanks for the New Steam Generation Plant, NSGP. The piling work was ongoing around a live underground 132kV cable, during which an auger struck the cable.

Pile 46 formed through 2 phases of cable

Consequences

- Banksman was put at risk of injury by electrocution

- CHP lost power supply to Gas Turbines 1 and 2 resulting in loss of significant steam raising capability and reducing the steam resilience to site

- Large voltage dip on Sellafield site leading to plant trips and disruption on the site

- The Project was delayed several weeks with additional costs

- Reputational damage to all parties

Direct Cause

Auger penetrated the 132kV cables (HTF1201)

– This cable provides power to the CHP GTs 1 and 2

– Also exports excess power generated by the CHP plant to the National Grid

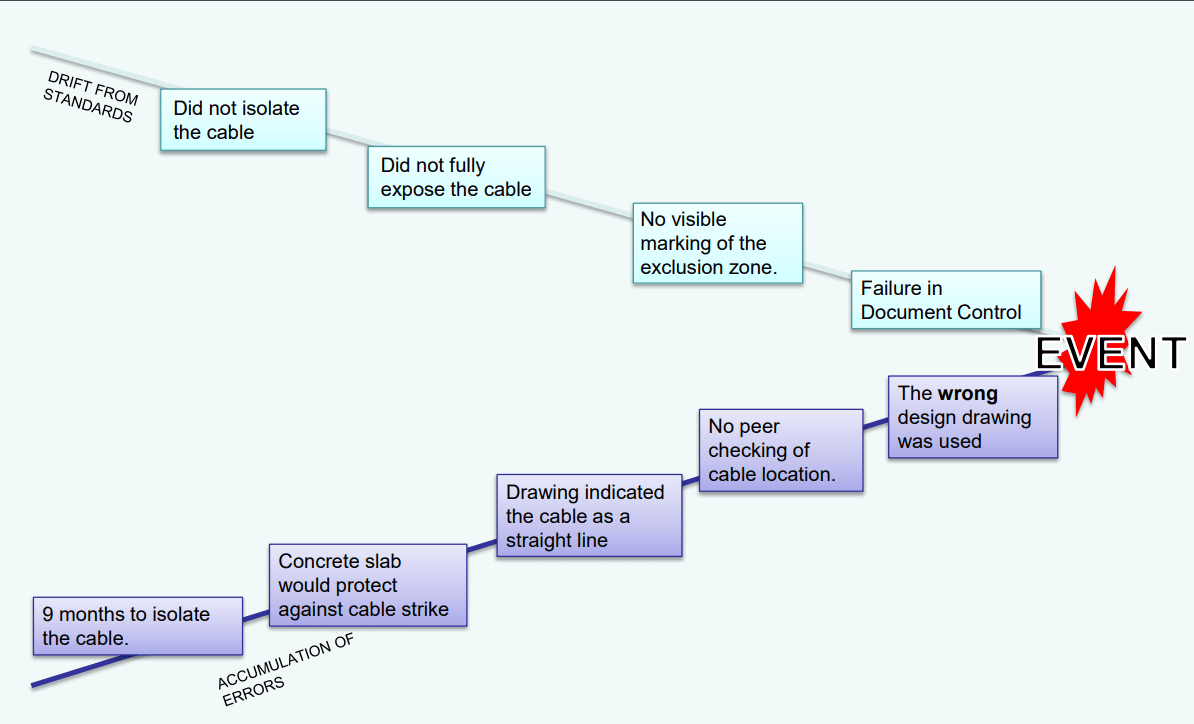

Root Causes/Contributory Factors

Failure to accurately identify the route of the cable and manage its location.

| Isolation would take 9 months | Confirmation Bias |

| Failure to isolate the cable | Risk Perception |

| Cable not fully exposed as a result of failure to isolate | Risk Perception |

| Cable was in a straight line | Confirmation Bias |

| Misconception of the purpose of the concrete slab | Risk Perception & Confirmation Bias |

View along centre line of excavated slab

Slab position markings in relation to cable

Root Causes/Contributory Factors

Failure to apply adequate document control procedures resulting in the use of a superseded design drawing.

| Document control system limited access to the drawings Not available to the Engineer on the ground |

Error Tap |

| Individuals failed to challenge the different versions of the drawings | Human Performance |

| Lack of escalation when challenged | Human Performance |

Use of Superseded Drawing (C06, not C07)

The centreline of the concrete slab was not laid over the centreline of the tiles or the cable. The pile was sunk as per version C06 of the drawing, rather than the current C07

Learning from this Event

- A lack of independent challenge to assumptions played an important part in influencing the course of events.

- It can be easy to lose sight of how our decisions can inadvertently influence safety.

- How could your work influence safety?

- What techniques and methods would help reduce this influence on safety?

Key Recommendations

The SL process for Excavations amended to a mandatory standard, that services must be isolated and positively identified (i.e. exposed) prior to excavations. If unachievable, then a formal justified mitigation to approved by a principal SAP and signed off by the Chief Engineer.

The ISA collaboration should implement improvements to their assurance and document control arrangements to ensure that the most recent and accurate information is are readily available to end users.

Arrangements equivalent to SL’s own mechanisms for providing independent challenge, oversight and learning should be developed within delivery partnerships. The Intelligent Client organisation to be educated in Human Performance, Human Factors, Nuclear Safety.

SL, PX and the ISA group should undertake collaborative working improvement activities in order to improve sharing of experiences and to foster healthy internal challenge.

Protecting Cables Against Strikes & Restoring Power Post-Strike

Thorne & Derrick have been distributors for 3M Electrical since 1985 and can provide a range of reliable and easy to install Cable Repair Products – this includes Scotch Tapes, Scotchcast Joints and Cold Shrink Tubes to provide effective re-instatement of cable sheath jackets on all types of LV MV HV cables in onshore and offshore locations with safe or hazardous area workplace classifications.

Cable Repair Products

Our range of cable protection covers manufactured by Centriforce provide underground utility protection of LV MV HV cables including Tapetile (11kV) and Stokbord (33kV 66kV 132kV) – contact us to discuss Cable Damage Prevention Products including Dectamesh, the underground detectable warning tape for alerting excavators of the presence of buried cables and to prevent potentially lethal accidents during excavation.

Cable Strikes | 10kV Medium Voltage (MV) Cable Struck By An Excavator

May 18th, 2021

Cable Strikes

Utility Strike Avoidance Group

USAG have published a range of documents to assist industry understanding of the root cause and contributory factors behind specific incidents. The aim is to improve industry standards and reduce the number of cable strikes.

Cable damage is often caused by excavating machines – hand held tools such as pneumatic drills, crowbars, pins, picks and forks also expose workers to potential sources of danger when digging around underground cables.

Cable Hangers | Cable Ducting | Cable Protection | Electrical Safety Equipment

Incident Overview

Incident Type: 10kV Electrical Strike

Project/Location: McDonalds Restaurant, Mullingar, Co. Westmeath

Client: Gas Networks Ireland

Incident Date: 24-03-2019

Summary

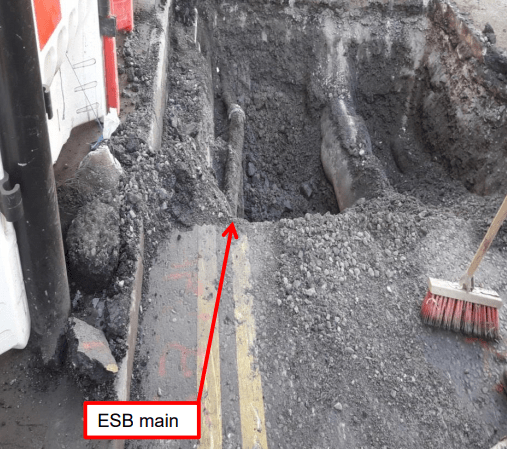

During planned weekend work a 10kV medium voltage (MV) cable was struck by an excavator. A subcontractor/DLO blended team were tasked with extending the existing gas main at a depth of approximately 1.7m.

Temporary works designs were authorised and planned for the job. Service plans were provided in the job pack and indicated the presence of a 10kV/20kV MV cable. Cable was traced, located and marked. Despite knowing the presence of existing services, the team allowed the excavator to work within 500mm of the various utilities.

The cable was struck by a combination of the bucket of the excavator and material shift towards the ESB cable at a depth of approximately 400mm.

| Action Taken |

|

| Lessons Learnt |

|

| Follow Up Action Required |

|

| Action Holders | Emmet O’Brien, Roisin Kelly & Neil Doherty – BBCLG, ALL SBU Heads of Contract & Operational Management, ALL SBU Heads of Contract & Operational Management |

Protecting Cables Against Strikes & Restoring Power Post-Strike

Thorne & Derrick have been distributors for 3M Electrical since 1985 and can provide a range of reliable and easy to install Cable Repair Products – this includes Scotch Tapes, Scotchcast Joints and Cold Shrink Tubes to provide effective re-instatement of cable sheath jackets on all types of LV MV HV cables in onshore and offshore locations with safe or hazardous area workplace classifications.

Cable Repair Products

Our range of cable protection covers manufactured by Centriforce provide underground utility protection of LV MV HV cables including Tapetile (11kV) and Stokbord (33kV 66kV 132kV) – contact us to discuss Cable Damage Prevention Products including Dectamesh, the underground detectable warning tape for alerting excavators of the presence of buried cables and to prevent potentially lethal accidents during excavation.

Cable Strikes | 11kV Strike With Auger

May 18th, 2021

Cable Strikes

Utility Strike Avoidance Group

USAG have published a range of documents to assist industry understanding of the root cause and contributory factors behind specific incidents. The aim is to improve industry standards and reduce the number of cable strikes.

Cable damage is often caused by excavating machines – hand held tools such as pneumatic drills, crowbars, pins, picks and forks also expose workers to potential sources of danger when digging around underground cables.

Cable Hangers | Cable Ducting | Cable Protection | Electrical Safety Equipment

Incident Overview

As part of installation of a wooden knee rail fence on one of our sites, a contractor was digging holes for the fence posts and caused damage to an 11kV buried high voltage cable with an auger. Fortunately, this did not result in any individual suffering harm, however, the loss of power had serious impact to the resilience on one of our sites.

The work was undertaken by a non-framework contractor who had not been issued with the essential standards, was not using the right tools and had deviated from the agreed method statement without seeking further approval from the TWOSA issuer.

11kV Strike with Auger

Action Required

Those authorised to issue a TWOSA must ensure the principles in Essential Standard 1 Excavations and Essential Standard 27 Utility Management are followed when works involve breaking ground.

In addition, they should ensure the following:

- Contractor Selection: All contractors working for or on behalf of Thames Water should be an approved framework supplier and have an in-date Achilles assessment. This should be verified prior to issue of TWOSA.

- Exchange of information: The COP must provide information on the risks and hazards on site as part of the exchange of information prior to TWOSA issue. This includes the HSI14 for the site along with any drawings, plans or other information essential to carrying out the works safely.

- Risk Assessment: With any task there are opportunities to stop and reassess the risk, in this case the opportunity to verify all services had been properly scanned and identified before issuing a permit to dig was missed. For high risk jobs it is essential that stop points are included to validate conditions – this principle is set out in Essential Standard 10 – Risk assessment

- Monitoring: Contractor activity on site should be reviewed regularly to ensure the works are being carried out to the agreed method statements and remain within the scope of the TWOSA issued. A SHE6 inspection should be recorded on Safeguard and actions raised to address any issues identified.

Everyone:

- Check all contractors working on site have a valid Thames Water Safety Passport

- Don’t be afraid to challenge if you see something that doesn’t feel quite right.

Protecting Cables Against Strikes & Restoring Power Post-Strike

Thorne & Derrick have been distributors for 3M Electrical since 1985 and can provide a range of reliable and easy to install Cable Repair Products – this includes Scotch Tapes, Scotchcast Joints and Cold Shrink Tubes to provide effective re-instatement of cable sheath jackets on all types of LV MV HV cables in onshore and offshore locations with safe or hazardous area workplace classifications.

Cable Repair Products

Our range of cable protection covers manufactured by Centriforce provide underground utility protection of LV MV HV cables including Tapetile (11kV) and Stokbord (33kV 66kV 132kV) – contact us to discuss Cable Damage Prevention Products including Dectamesh, the underground detectable warning tape for alerting excavators of the presence of buried cables and to prevent potentially lethal accidents during excavation.

Cable Strikes | 11kV Depot Cable Strike

May 18th, 2021

Cable Strikes

Utility Strike Avoidance Group

USAG have published a range of documents to assist industry understanding of the root cause and contributory factors behind specific incidents. The aim is to improve industry standards and reduce the number of cable strikes.

Cable damage is often caused by excavating machines – hand held tools such as pneumatic drills, crowbars, pins, picks and forks also expose workers to potential sources of danger when digging around underground cables.

Cable Hangers | Cable Ducting | Cable Protection | Electrical Safety Equipment

Incident Overview

11kV Depot Cable Strike

Issued to: All Network Rail line managers, safety professionals and RISQS registered contractors.

Ref: NRB 18/18

Date of issue: 05/12/2018

Location: Holgate Depot York

On the 15/11/18 at 11:30 hours an electrical contractor received burn injuries due to an electrical high voltage arc flash over while working in the depot. The Injured Person (IP) suffered burns to their left forearm and right hand which required hospitalisation and ongoing medical treatment.

The incident occurred when the IP was cutting into redundant cables using a power tool to remove them. The electrical cables being cut were considered “dead” as an agreed isolation was in place; however this was not the case and during the works the 11kV cable strike occurred.

Discussion Points

While the incident is under investigation we should all consider the dangers when working on or near high voltage cables:

- Has your task been thoroughly planned?

- Have the survey and records accurately captured all electrical conductors?

- Have the safety arrangements been reviewed by a competent person?

- Has all necessary safety information including permits and isolations been included in the Work Package Plan and Task Briefing Sheet?

- Are the briefing arrangements in place to ensure workers have and understand how to keep themselves and others safe?

- How do you make sure that you and your colleagues comply with the Life Saving Rule of “always test before touch”?

Protecting Cables Against Strikes & Restoring Power Post-Strike

Thorne & Derrick have been distributors for 3M Electrical since 1985 and can provide a range of reliable and easy to install Cable Repair Products – this includes Scotch Tapes, Scotchcast Joints and Cold Shrink Tubes to provide effective re-instatement of cable sheath jackets on all types of LV MV HV cables in onshore and offshore locations with safe or hazardous area workplace classifications.

Cable Repair Products

Our range of cable protection covers manufactured by Centriforce provide underground utility protection of LV MV HV cables including Tapetile (11kV) and Stokbord (33kV 66kV 132kV) – contact us to discuss Cable Damage Prevention Products including Dectamesh, the underground detectable warning tape for alerting excavators of the presence of buried cables and to prevent potentially lethal accidents during excavation.