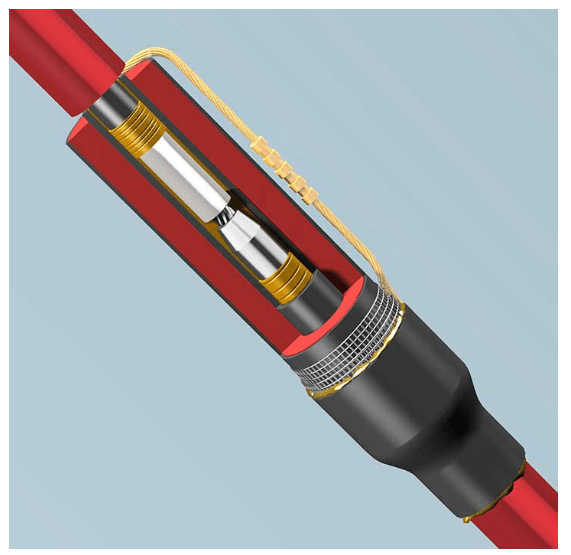

33kV Cable Joints 3 Core XLPE Heat Shrink Straight Joint Kits

Cable Joints 33kV | 3 Core | XLPE | Heat Shrink

Thorne & Derrick | Distributed from Stock | Approved Supplier | UK & Export Sales

Cable Joints

HV cable joints are suitable for jointing medium/high voltage (MV-HV) 33kV 3 core polymeric cables (XLPE EPR) to DIN VDE 0276-620, BS6622, BS7870-4.10 and other international cable standards.

33kV cable joints use heat shrink tubes and suit 33kV cables with 16sqmm to 300sqmm 3 core conductors (copper Cu and aluminium Al) – suitable for power cable jointing, repair and installation in ground, air or cable ducts.

Also available for MV-HV power systems a complete range of 33kV cable terminations can be supplied in heat shrink, cold shrink or EPDM rubber (separable connector) type for connecting 33kV cables into air, oil or gas insulated high voltage electrical equipment and switchgear.

33kV Joints

33kV heat shrink cable joints suit both armoured and unarmoured cables – this includes high voltage industrial power (XLPE BS6622 BS7835 with steel wire armour SWA and/or lead sheath) and marine offshore ship cable (EPR BS6883 with galvanised/phosphur wire braid) and copper wire or copper tape screen.

Options include transition (PILC to XLPE) and transition trifurcating (3 x single core PILC to 3 Core XLPE) cable joints at 33kV – contact us to discuss your requirements.

3 Core XLPE Cables

33kV Cable Joint

- Cable Joint Type – Heat Shrink

- Configuration – Straight Joint

- Cable Voltage – 33kV

- Number of Cores – 3 Core

- Cable Insulation – Polymeric XLPE EPR

- Conductors – 16sqmm, 25sqmm, 35sqmm, 50sqmm, 70sqmm, 95sqmm, 120sqmm, 150sqmm, 185sqmm, 240sqmm, 300sqmm

- Cable Type – XLPE EPR (Polymeric)

- Suit MV HV Power Cables

- Location – Cable Trench, Direct Burial, Cable Containment

- Connectors Option – Cembre Crimp Connectors | Pfisterer SICON Shearbolt Connectors

- Also: 33kV Joint 3 Core PILC Cables

Heat Shrink Cable Joints

Test Technical Data

The following table provides an excerpt of data from the Type Test Reports for Heat Shrink Cable Joints for 6.6kV, 11kV and 33kV voltages.

| Summary of Cable Joint Test Voltages | ||||||

| Test | Test Voltage | Rated Voltage U01U (Um) kV | ||||

| 3.8/6.6 (7.2) | 6.35/11 (12) | 8.7/15 (17.5) | 12.7/22 (24) | 19/33 (36) | ||

| Humidity & Salt Fog | 1.25U0 | 5 | 8 | 11 | 16 | 24 |

| Partial Discharge | 1.73U0 | 6.5 | 11 | 15 | 22 | 33 |

| 2U0 | 7.5 | 12.5 | 17.5 | 25 | 38 | |

| Heating Cycle Voltage & AC Voltage / 15 min and 500 hours | 2.5U0 | 9.5 | 16 | 23 | 32 | 47.5 |

| AC Voltage / 1 min | 4U0 | 15 | 25.5 | 35 | 51 | 76 |

| AC Voltage / 5 min | 4.5U0 | 17 | 28.5 | 39 | 57 | 85.5 |

| DC Voltage / 15 min | 6U0 | 23 | 38 | 52 | 76 | 114 |

| Impulse (Peak) | – | 60 | 95 | 95 | 125 | 194 |

| Test Sequence & Requirements | ||||||

| Test | Test Clause of EN 61442 | Test Sequence | Test Requirements | |||

| A1 | A2 | A3 | ||||

| 1 | DC Voltage Dry | 5 | X | X | 15 min at 6U0, no breakdown or flashover | |

| 2 | AC Voltage Dry | 4 | X | X | 5 min at 4.5U0, no breakdown or flashover | |

| 3 | Partial Discharge At Ambient Temperature | 7 | X | Max 10pC at 1.73U0 | ||

| 4 | Impulse Voltage At Elevated Temperature | 6 | X | 10 impulses of each polarity, no breakdown or flashover | ||

| 5 | Heating Cycle Voltage In Air | 9 | X | 126 cycles at 2.5U0, no breakdown or flashover for terminations and 63 cycles in air and 63 cycles in water for cable joints | ||

| 6 | Partial Discharge At Elevated & Ambient Temperature | 7 | X | Max 10pC at 1.73U0 | ||

| 7 | Thermal Short Circuit (Screen) | 10 | X | 2 short circuits at 1sc no breakdown | ||

| 8 | Thermal Short Circuit (Conductor) | 11 | X | 2 short circuits to raise conductor to 6sc of the cable, no breakdown | ||

| 9 | Dynamic Short Circuit | 12 | X | 1 short circuit at 1d, no breakdown | ||

| 10 | Impulse Voltage At Ambient Temperature | 6 | X | X | 10 impulses of each polarity, no breakdown or flashover | |

| 11 | AC Voltage Dry | 4 | X | X | 15 min at 2.5U0, no breakdown or flashover | |

| 12 | Humidity | 13 | X | 300 hours duration at 1.25U0 | ||

| 13 | Examination | – | X | X | X | For information only |

Heat Shrink Cable Joints & Terminations

Complete range of medium and high voltage cable joints and terminations for XLPE & PILC single / 3 core cables, including 11kV:

➡ HV Cable Joints | HV Cable Terminations | 11kV Joints Single Core PILC

➡ 11kV Joints 3 Core XLPE | 11kV Joints 3 Core PILC

Cable Joints XLPE | 33kV Cables

The table enables the cable joint kit selection for 17.5kV, 24kV and 33kV 3 core cables with XLPE insulation using heat shrink type kits:

| SPS 17.5kV Cable Joint – Order Code | Heat Shrink Cable Joint Kit Range – 3 Core Cables |

| SPAJ 17.5X-16-35-3 | 16-35sqmm |

| SPAJ 17.5X-50-95-3 | 50-95sqmm |

| SPAJ 17.5X-120-185-3 | 120-185sqmm |

| SPAJ 17.5X-240-300-3 | 240-300sqmm |

| SPS 24kV Cable Joint – Order Code | Heat Shrink Cable Joint Kit Range – 3 Core Cables |

| SPAJ 24X-16-35-3 | 16-35sqmm |

| SPAJ 24X-50-95-3 | 50-95sqmm |

| SPAJ 24X-120-185-3 | 120-185sqmm |

| SPAJ 24X-240-300-3 | 240-300sqmm |

| SPS 33kV Cable Joint – Order Code | Heat Shrink Cable Joint Kit Range – 3 Core Cables |

| SPAJ 36X-35-95-3 | 35-95sqmm |

| SPAJ 36X-120-185-3 | 120-185sqmm |

| SPAJ 36X-240-300-3 | 240-300sqmm |

Cable Terminations

To support the range of 33kV joints, T&D also distribute 33V cable terminations for both indoor and outdoor use on underground and overhead power networks – typically used to connect high voltage power cables into air insulated switchgear/substations the heat shrink terminations provide excellent reliability, safety and availability from stock for immediate delivery:

- Stress Control & Anti-Tracking

- Electrical Insulation MV HV Terminations

- Adhesive Lined Moisture Protection Heat Shrink Tubings

- Excellent Mechanical Protection Of MV HV Cables

- Resist UV & Thermal Degradation

- Visit Joints, Terminations & Connectors MV HV

33kV Cable Accessories & Electrical Equipment

33kV Cable Installation Equipment | Cleats | Lugs | Glands | Earth Tapes | Substation Safety – leading manufacturers including Furse, CMP, Pfisterer, Prysmian, Alroc & Nexans Euromold