Rewriting The R&D Rulebook With Ellis Patents

Published 10 Aug 2020

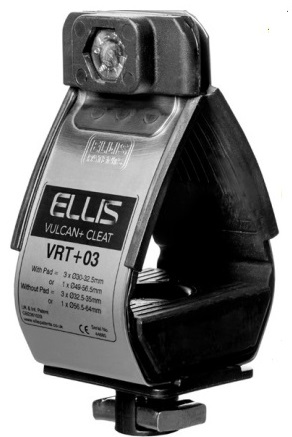

Ellis Patent Vulcan+ Cleat

-

Article Written By Stephen Walton Technical Director At Ellis Patents

Ellis Patent Vulcan+ Cleat

Thorne & Derrick Internatonal, based in the UK, are an Ellis Patents distributor for their market-leading and innovative range of cable cleats manufactured in the UK.

At first glance, the cable cleat may not seem like a product ripe for design and manufacturing innovation.

Its role in securing electrical cables in the event of a short circuit is seemingly straightforward enough to preclude it from such activity but look more closely and you’ll quickly realise you are wrong.

Stephen Walton, Technical Director of Ellis Patents, outlines how the company has evolved from being a manufacturer of traditional, standard cable cleats to solving installation and safety issues for the likes of Siemens, while also embracing new technology to rewrite the R&D rulebook.

For a long time, Ellis banged the drum about the importance of correctly specified cable cleats. The key selling point is the fact that, without correct specification, all a cable cleat would do is add to the potentially life-threatening shrapnel during a short circuit situation.

Ellis’s drumming these days is significantly quieter. The market is now well aware of the need for cleats. As a result, it has become increasingly congested, with more manufacturers than ever making them and, in some cases, producing virtual replicas of the most popular.

Ellis has responded to these changing market conditions by subtly shifting its focus. The company’s latest change has been focused on what and how it sells – a shift of approach that was born out a growing demand for project-specific solutions.

Initially, this was confined to bespoke cable cleats being designed and manufactured to exact client specifications and short-circuit tested to exact project conditions. This now has developed to a stage where Ellis is called in, presented with a problem and asked to solve it.

For example, the company helped Siemens with the installation and subsequent restraint of seven large diameter high voltage (HV) cables on HelWin 2 – a 690MW offshore HVDC platform.

Ellis’s cable guide clamp provided low-loss transmission between the North Sea offshore wind farm, Amrumbank West and Germany’s onshore grid.

Today, Ellis has an in-house R&D facility that enables it to deliver new, production-ready products in a matter of days. It recently developed a twist foot fixing mechanism that reduces installation cost and time for its Emperor and Vulcan+ cable cleats in less than a fortnight.

Utilising its own 3D CAD rapid prototyping facilities, and Stratasys Objet 24 and 30 printers, the development process began with a brainstorm during which possible solutions were suggested and sketched.

The most popular of these were then drawn up in 3D and printed overnight. Samples were cleaned, assembled and function tested the following morning. The promising designs were then refined and reprinted over the following days until a final version was agreed on and a functional prototype printed and passed on to sales and production for feedback.

To take a product from an idea to a fully functional, production ready prototype in less than a fortnight really does rewrite the R&D rulebook.

Traditionally, creating a production-ready prototype would have required the development of injection moulding tools, which involved significant investment in time and resources, and typically took six to eight weeks to manufacture.

Once received, only small changes to the tools were feasible, meaning any major alterations added another 6-8 weeks to the entire process.

However, by harnessing 3D printing technology and bringing as many elements of the design and testing process in-house, Ellis can now work within the tight timeframes of a live project and ensure it doesn’t lose any momentum by delivering bespoke solutions to installation issues in days.

The new product Ellis’s new twist foot cleats, which are supplied pre-fitted on its Emperor and Vulcan+ cleats, are suitable for all installations using cable channel and ladder with inverted rungs. There are singlefooted versions for cables in trefoil up to 58mm and double-footed versions for cables with diameters ranging from 59-128mm.

The single version locks in place with nothing more complex than a 90º turn and the tightening of the integral securing bolt, while the double-footed version is secured with tabs that are simply rotated 90º to engage the channel nut before the securing bolt is tightened.

Stephen Walton is Technical Director of Ellis Patents. A Chartered Mechanical Engineer with over two decades of  industry experience, Stephen joined Ellis in 2015 and has since played a key role in the development of a large number of new and improved products, as well as in the positioning of the North Yorkshire company as the first port of call for contractors seeking bespoke solutions to installation headaches, and project-specific cable cleat solutions. He has also been one of the driving forces behind Ellis’s early adoption of new technology, which is helping the company rewrite the R&D rulebook.

industry experience, Stephen joined Ellis in 2015 and has since played a key role in the development of a large number of new and improved products, as well as in the positioning of the North Yorkshire company as the first port of call for contractors seeking bespoke solutions to installation headaches, and project-specific cable cleat solutions. He has also been one of the driving forces behind Ellis’s early adoption of new technology, which is helping the company rewrite the R&D rulebook.

Ellis Patents Vulcan, Atlas & Emperor Cable Cleats

Ellis Patents are global leaders in the innovation and manufacture of nylon cable cleats, aluminium cable cleats and stainless steel cable cleats – Ellis satisfy the operational requirements of the construction, oil, gas, rail, utilities, wind energy and power generation industries.

Further Reading

- IEC 61914 – Cable Cleats & Short Circuit Protection Calculations

- Fire Resistance & Cable Cleats – Surviving Fire, Flame & Extreme Heat

- Triplex Cleats – Selection Guide for Cleating 11kV BS7870 Part 4.10 Cables

- Stainless Steel Cable Cleats – Preventing Galvanic Corrosion Of Cable Fixings

- Ellis Patents Cable Cleats & Cable Basket Tray for Securing High Fault Level Cables

- Stainless Steel Cable Cleats v Ties – The Myths Debunked By Ellis Patents

Thorne & Derrick

T&D are Specialist Distributors to UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and HV Jointing Contractors of an extensive range of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt – this includes 11kV/33kV/66kV joints, terminations and connectors for both DNO and private network applications.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV