Elastimold Elbows | Loadbreak & Deadbreak Elbow Connectors

Elastimold Elbow Connectors

Elbows

Thorne & Derrick distribute Elastimold Elbows to provide a convenient method to connect and disconnect cables and terminate equipment on MV-HV power distribution systems including switchgear and transformers with outer cone bushings that require a separable connector style type of cable termination.

Elastimold Separable Connectors have been designed and tested per IEEE 386 Standard For Separable Connectors – this Standard details the definitions, service conditions, ratings, interchangeable construction features and tests established for Loadbreak and Deadbreak separable insulated connector systems for use on power distribution systems rated 2.5kV to 35kV and 900 A or less.

Medium voltage cable accessory products are designed and constructed for all joint, connect and termination applications including padmount, subsurface, vault, indoor, outdoor, direct sunlight, direct buried and continuously submerged in water.

Contact Thorne & Derrick for further information on a complete range of Connectors (EPDM & Silicone), Joints and Terminations (Cold Shrink & Heat Shrink) for the connection, repair and terminating of MV HV power cables into air or gas insulated type electrical equipment distributing electrical power up to 66kV.

Elastimold Elbows Loadbreak & Deadbreak Elbow Connectors

The following table shows voltage and current ratings which apply to all Separable Connectors including 200-Amp Loadbreak, 200-Amp Deadbreak and 600 Series Deadbreak products.

| Connector Class Ratings | 15kV | 25kV | 35kV |

| Operating Voltage Maximum line-to-ground |

8.3kV | 15.2kV | 21.1kV |

| BIL Impulse withstand 1.2 x 50 microsecond wave |

95kV | 125kV | 150kV |

| Withstand Voltage AC One Minute DC Fifteen Minute |

34kV 53kV |

40kV 78kV |

50kV 103kV |

| Corona Extinction level @ 3pC Sensitivity |

11kV | 19kV | 26kV |

| 200-Amp Products Continuous Current: Symmetrical Momentary Current: |

200 Amp10kA sym, 10 cycle duration* | ||

| 600 Series Products Continuous Current: Symmetrical Momentary Current: |

600 and 900 Amp25kA sym, 10 cycle duration* | ||

* Designed for 90° C maximum continuous operating temperature.

The below table shows switching and fault close ratings which only apply to 200-Amp Load-Break Connectors.

| Loadmake/Loadbreak Switching | Fault Close | |

| 15kV Class Rating | • 1ø and 3ø circuits 8.3kV line to ground, 14.4kV max. across open contacts • 10 loadmake/break operations at 200 Amps max. with 70 to 80% lagging power factor |

1 fault close operation at 8.3kV or 14.4kV; 10,000 amps RMS sym; 10 cycles (.17 sec.) 1.3 max. asym factor applies to new or used mating parts (up to maximum designated switching operations) |

| 25kV Class Rating | • 1ø and 3ø circuits 15.2kV line to ground, 26.3kV max. across open contacts • 10 loadmake/break operations at 200 Amps max. with 70 to 80% lagging power factor |

1 fault close operation at 15.2kV or 26.3kV; 10,000 amps RMS sym; 10 cycles (.17 sec.) 1.3 max. asym factor applies to new or used mating parts (up to maximum designated switching operations.) |

| 35kV Class Rating | • 1ø and 3ø circuits 21.1kV line to ground, 36.6kV max. across open contacts. • 10 loadmake/break operations at 200 Amps max. with 70 to 80% lagging power factor. |

1 fault close operation at 21.1kV or 36.6kV; 10,000 amps RMS sym; 10 cycles (.17 sec.) 1.3 max. asym factor applies to new or used mating parts (up to maximum designated switching operations) |

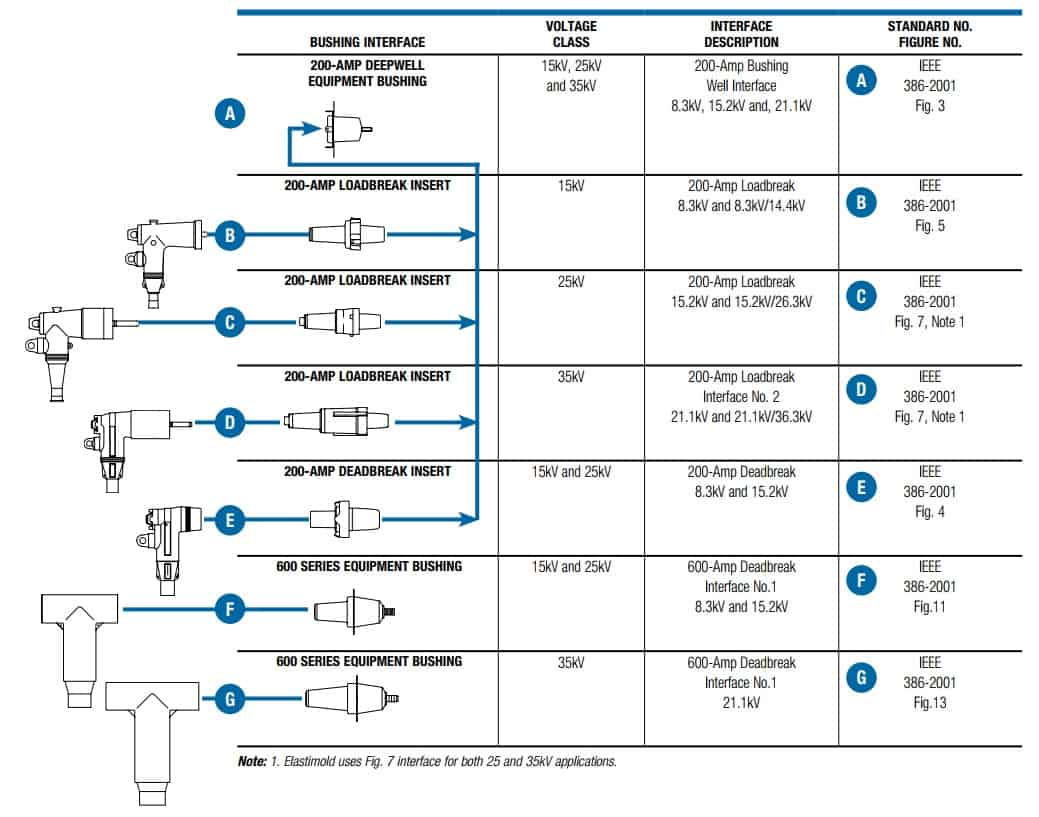

Standard Interfaces For Separable Connectors, Components & Equipment Bushings

IEEE Standard 386 defines the specific interface dimensions that 200 Amp and 600 Series elbows, inserts, junctions, equipment bushings and any mating components must conform to ensure interchangeability. The image below provides information concerning the types of interfaces supplied by Elastimold for various applications and is useful to ensure proper matching of components.

IEEE Standard 386 Conformity Table

Thorne & Derrick provide competitive prices and specification support for medium and high voltage loadbreak and deadbreak elbow connectors, manufactured by Elastimold, from extensive stocks to UK and international destinations.

Load Break v Dead Break Elbows Explained

The following explanation has been provided by a Field Engineer & Cable Splicer.

Load Break

A load break elbow when used with a hot stick can be connected or disconnected at high voltage under load, but can only be used with up to a 250kcmil cable. At 100% insulation level, a 250kcmil is good for 345A in underground duct, so you would be de-rating your system by using a 200A elbow with a 250kcmil cable, but they are still widely used due to the flexibility given to the high voltage distribution system at the equipment.

Think about it…if you had a critical application where power disruptions were extremely costly and maintenance was required on up-stream equipment in, let’s say a non-critical area, this type of elbow would be great. You could disconnect the load without disturbing the critical portions, perform the maintenance and then reconnect it. Just make sure to take safety precautions, making and breaking electrical connections under load is very dangerous. The load break elbow is typically not used in man-holes, because it does not allow expansion like the dead break elbow. The construction of the load break elbow does not allow it to be connected to other elbows, but the dead break does.

Dead Break

A dead break or “hammerhead” elbow can only be disconnected when not under load, this is because you need to actually unscrew a pin to detach it. It would be pretty tough to unscrew the pin with a hot stick and the arc from the disconnected load, if under load, would be pretty substantial. A dead break elbow allows an increased current rating (up to 600A) and can be used on basically all cable types. At 100% insulation level a 750kcmil cable is rated 610A in underground duct.

When would you use a 750kcmil? In most non-utility cases you would design or install sets of 500kcmil or smaller if you needed more than one 500kcmil could handle. Even from a 1200A breaker, two sets of 500kcmil per phase would be sufficient for distribution (about 1000A), if the load was even that high. Most of the time you set the relays down to the actual load in order to limit the copper used. A dead break when used in man-holes for splicing cables allows the flexibility of connecting more than two cables together as well as future expansion if required.

Say another building was added that needed power, you could just connect that building to the existing array of dead break elbows. This also works great when temporary power is needed for construction or even if the circus is in town and they need medium voltage (it happens!). They can pick up power from the man-hole with the dead break elbows or from a piece of equipment with dead break elbows. I’ve heard that ships are now starting to use medium voltage shore power, I wonder what kind of connections they use.

A dead break elbow still provides flexibility during maintenance it just requires a brief outage to allow the cable splice to be broken. This high voltage outage could be scheduled at an off-peak time or after ensuring that all back-up systems were already running and/or transferred to another source such as a generator. I wouldn’t trust a UPS alone in this case unless it was connected to a second source of power like a generator.

The amount of time to disconnect the splice and coordinate the outage would cut it real close. Deadbreak elbows are fairly large, so make sure to check the space restraints of the location you are installing them. If you do run into a space problem, there are various other seperable splices on the market that may be suitable, check with the manufacturers.

Joints, Terminations & Elbow Connectors For MV-HV Power Systems

➡ Should you require customer service or technical support please contact us – view the full range of Elastimold Elbows below.