66kV Cable Joints – A Failure Investigation & Conclusions

Published 07 Mar 2018

Euromold | 66kV Joints Connectors Terminations Surge Arresters

Thorne & Derrick are leading specialist distributors of MV HV Joints, Terminations & Connectors for use on 11kV/33kV/66kV cable networks – sadly cable failures are increasingly common on onshore and offshore medium/high voltage cable networks.

A toxic cocktail of unskilled labour which is untrained in both basic cable preparation and tool use is usually the cause – this lethal combination unleashes devastation on clients assets nevermind the incalculable cost of downtime associated with power outages.

This investigation and report explains the causes into why the below 66kV cable joints failed by dissecting the cable joints one by one and recording findings to what could have caused the cable failings.

Severe cable joint failure with cable faulted to destruction – caused by a combination of cable preparation failures and factors.

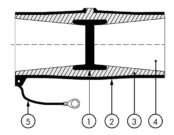

Comparing dimensions from the screen cut length to the corrugated aluminium cut shows the 66kV cable failure occured at the end of the semicon screen cut.

Failure occurred at the end of the semicon screen cut on the high voltage power cable.

Specialist cable jointing tools to effectively prepare and remove semicon screens on 11kV/33kV and 66kV power cables should always be used by jointers – cable jointers should be trained and competent to install manufacturers products.

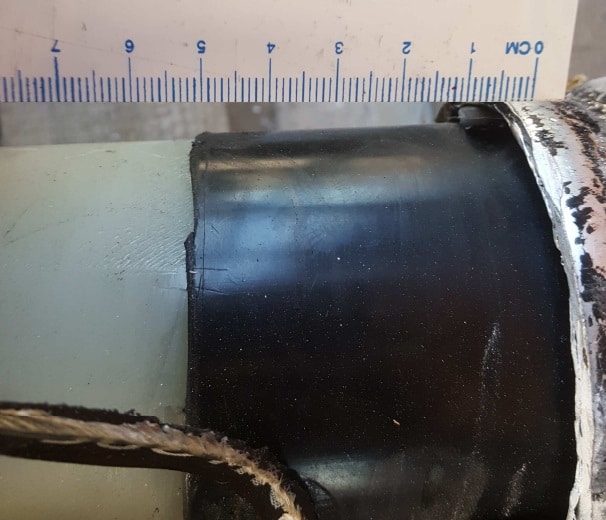

Poor heat shrinking technique by the cable jointer with non-uniform wall thickness on this heat shrink insulation tube

Conclusion

The cable joint failure was caused by the poor removal of the semi-conductive and the very bad XLPE insulation preparation. Deep and dirty cuts and burrs can seen in the insulation causing the XLPE insulation to be over stressed and this was what ultimately caused the insulation failure.

All HV cable joints and accessories should only be installed by trained professionals with all the correct accreditation. Any other terminations that have been installed by the above ‘jointer’ should be checked and replaced immediately.

Cold Shrink

3M pioneered the development of Cold Shrink technology for use as a material for the jointing, termination and connection of medium/high voltage cables. Since then cold shrink has been adopted by global utilities as a user-friendly and reliable MV-HV cable accessory range with high performance, stable life cycle and minimal joint or termination failure rates.

Should you require any support with the specification or supply of MV HV joints, terminations or connectors for use on 11kV/33kV/66kV energy networks please do not hesitate to contact us.

Cold Shrink Reliability Low Failure Rates

0.067% Cold Shrink Cable Joints/Splices

0.022% Cold Shrink Cable Terminations

*Data based upon U.S. failure data of U.S. manufactured 3M Cold Shrink Medium & High Voltage Cable Accessories between 2009 and 2012.

Thorne & Derrick

THORNE & DERRICK are national distributors LV, MV & HV Cable Installation, Jointing, Substation Earthing & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Invitation

Thorne & Derrick invite you to join LinkedIn’s largest LV-HV Electrical Discussion Group : Low & High Voltage Power, Cabling, Jointing & Electricals. Discussion subjects include cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV. Network, engage and promote your profile, company or products with over 10,000 influencers.