Blog

Comparison of Geometric Stress Control vs Dielectric Stress Control in 3M Cold Shrink Terminations

January 31st, 2025

Geometric Stress Control vs Dielectric Stress Control

Here is an in-depth analysis on the comparison of Geometric Stress Control vs Dielectric Stress Control, used in LV MV HV 3M Cold Shrink Cable Terminations. High Dielectric Stress Control (also known as Refractive Stress Control) is used in all 3M Electrical Cold Shrink Cable Terminations, whereas Geometric Stress Control is commonly used due to ease of manufacturing processes, but faces a number of disadvantages.

What is Electrical Stress Control?

Electrical Stress Control is known as a potential voltage difference across a distance, typically being reported as kV/mm (or v/mil). In the scenario of a larger voltage difference of a distance results in a higher electrical stress to be controlled.

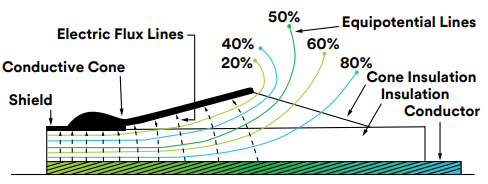

The insulation shield on cable terminations provides uniform electrical stress in the cable insulation. In the event of insulation shield removal from the cable termination, the electrical stress will concentrate at the end of the insulation shield (as shown in the image example). The equipotential lines being close together at the end of the insulation shield, results in very high electrical stress.

Cable termination failure will occur with no Electrical Stress Control.

3M Cold Shrink Cable Termination With No Electrical Stress Control

Geometric Stress Control

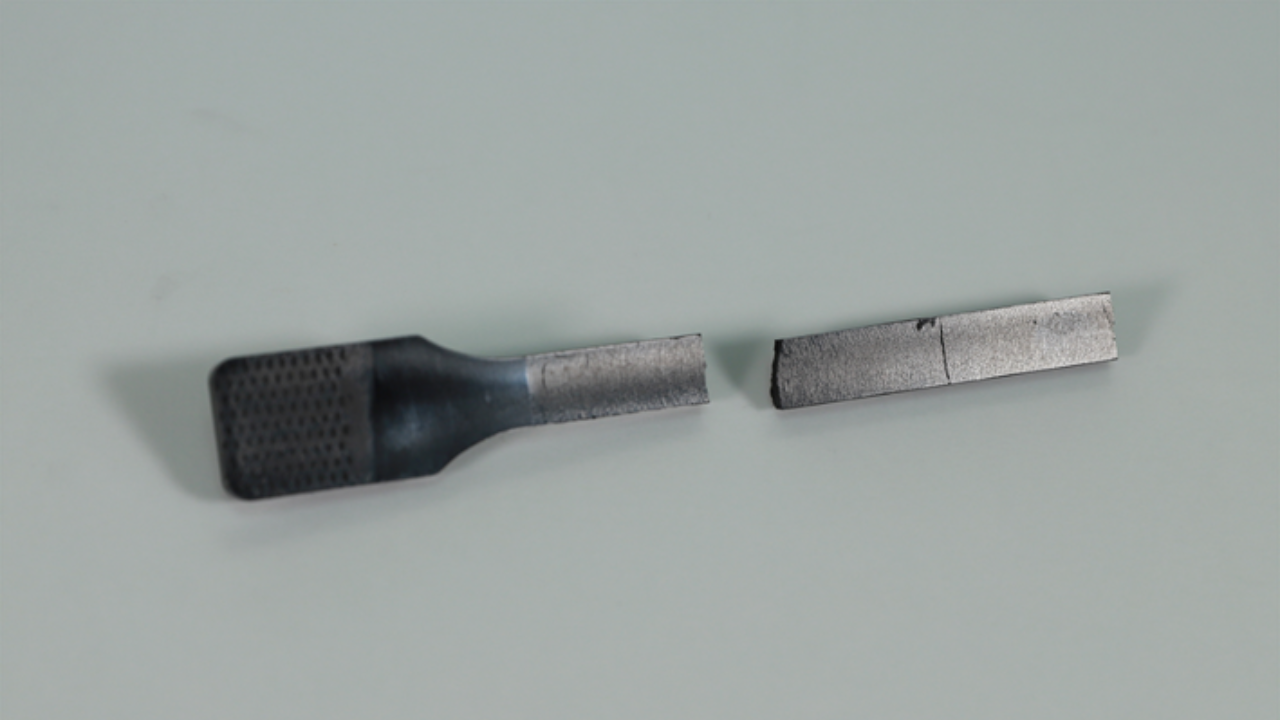

The process of Geometric Stress Control, is the use of extra insulation to overcome high electrical stress. As seen in the example image, the insulation is gradually increase in a ramp formation, with the insulation shield being extended to the top of the ramp. Similar to cable terminations with no stress control, the equipotential lines are still very close together at the end of the extended insulation.

High electrical stress determines that the cable terminations using this level of Electrical Stress Control will have higher surface stress, which requires a longer termination to meet standards and can also cause more tracking in highly contaminated areas. Longer cable termination lengths lead to geometric cable terminations have a long creepage distance, which may not translate to better performance because of the high surface stress on geometric terminations.

3M Cold Shrink Cable Termination With Geometric Stress Control

Dielectric Stress Control

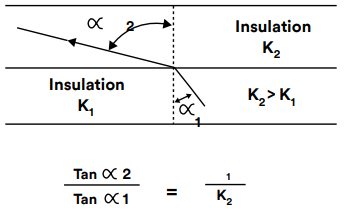

The other method of Electrical Stress Control is through the use of high Dielectric Stress Control (or Refractive Stress Control), used for 3M Cold Shrink Cable Terminations LV MV HV. The material used offers a high dielectric constant, meaning the material is not an ideal electrical insulator in comparison to materials with lower dielectric constants.

The following table provides further insight on dielectric constants of varied insulating materials, ultimately determining that Electrical Stress Control materials require a significantly higher dielectric constant than the table insulation due to the cause of equipotential lines bending or refracting:

| Stress Control Material | Typical Dielectric Constant |

| Air | 1.0 |

| XLPE | 2.5 – 3.0 |

| EPR | 3.0 – 3.5 |

| Silicone | 3.5 |

| Stress Control Tubes | 14 – 25 |

| Stress Control Mastic | 25 – 30 |

After refracting the equipotential lines, high Dielectric Stress Control spreads out the equipotential lines, resulting in significantly less surface stress than on a Geometric Stress Control 3M Cold Shrink Cable Termination. The image below demonstrates the process of high Dielectric Stress Control spreading out the equipotential stress lines. In this case, the equipotential lines are much further apart at the end of the cable insulation shield for Dielectric Stress Control vs Geometric Stress Control.

3M Cold Shrink Cable Termination With Dielectric Stress Control

Electrical Stress Controls SUMMARY

The following table highlights the advantages/pros for both Geometric Stress Control & Dielectric Stress Control:

|

Advantages Geometric Stress Control vs Dielectric Stress Control |

|

| Geometric Stress Control | Dielectric Stress Control |

| Easier to design and manufacture, making it more cost-effective. | Lower surface stress on cable terminations, allowing for shorter and more efficient cable terminations that still perform well at higher voltage (HV) levels. |

| Widely used in cold shrink and push-on cable terminations, ensuring familiarity and availability. | Better performance in contaminated environments with reduced tracking due to lower surface stress. |

| Performs well in low voltage (LV) & medium voltage (MV) applications. | Higher position tolerance with more flexibility in design, as the dielectric tube overlaps the insulation shield. |

| Less susceptible to dielectric losses as it doesn’t rely on high dielectric materials. | Developed and reliably used for over 45 years by 3M, demonstrating proven reliability and performance. |

The following table highlights the disadvantages/cons for both Geometric Stress Control & Dielectric Stress Control:

|

Disadvantages Geometric Stress Control vs Dielectric Stress Control |

|

| Geometric Stress Control | Dielectric Stress Control |

| Not as effective for higher voltage systems (e.g., 25 kV), where it tends to fail under testing. | More complex and difficult to design and manufacture, which can increase costs. |

| More prone to higher surface stress on terminations, which can affect long-term performance. | Material has higher dielectric losses, leading to minor temperature increases (2 to 5 degrees Celsius) at the semicon step of the cable. |

| Can have issues in contaminated environments due to higher surface stress, leading to potential tracking. | Slightly higher dielectric heating, though typically not impacting performance at normal operating voltages. |

| Requires longer termination lengths compared to dielectric stress control. | The dielectric stress control design, especially with the overlapping high dielectric tube, might add more bulk or weight to the termination |

Systems up to 69kV, high Dielectric Stress Control cable terminations perform better than Geometric Stress Control terminations. Offering better results due to widespread equipotential lines, ultimately creating a lower surface stress on the Cable Joints & Terminations. The lower surface stress reduces the chances of tracking and allows a shorter termination to perform better than a longer Geometric Stress Control termination. Some of 3M’s Cold Shrink high Dielectric Stress Control terminations have been in service sine 1977, concluding a long and reliable history.

High Voltage Cable Systems & Accessories

Thorne & Derrick distribute the most extensive range of MV HV Medium & High Voltage Cable Joints, Terminations & Connectors from manufacturers including 3M, Prysmian, Nexans Euromold, Elastimold, Pfisterer CONNEX & SEANEX and Shrink Polymer Systems.

Heat shrink, cold shrink, push-on and slip-over cable accessories enable the jointing, terminating and connection of 11kV-33kV and 66kV-132kV cables to oil, air or gas insulated switchgear, transformers, motors and overhead lines distributing electricity at medium/high voltages.

Reflect Aluflex Kit for Safe Portable Earthing & Rail Line Isolations | PENTA

January 27th, 2025

Reflect Aluflex Kit PENTA

The practical and convenient market-leading Reflect Aluflex Kit, manufactured by PENTA, is an ideal solution to night-time working on and around electrical distribution and rail lines. The highly reflective lead kit is a combination of PENTA‘s Special DEP Earth with Reflect Aluflex & S9B Reflect Kit, providing enhanced visibility to allow for safe portable earthing and rail line isolations, making for seamless inspections.

Reflect Aluflex Cable

The PENTA reflect Aluflex cable, included in the Reflect Aluflex Kit is used for connecting between a Line End Clamp and an Earth End Clamp. The reflect Aluflex cable is equipped with orange marking helix for identification with additional reflective silver helical strips to aid identification throughout night-working or when used in tunnels with restricted lighting. The strands of the Aluflex cable remain visible between helical strips to aid inspection. Supplied in any length required, in a range of sizes, including 50sqmm, 70sqmm, 95sqmm, 120sqmm & 150sqmm, according to ENA TS 42-21 specifications.

♦ Energy Networks Association TS 41-21 Compliant

The ENA TS 41-21 standards covers portable earthing equipment for use on MV HV power cable systems above 1kV and up to 400kV, which has a rated value tested in accordance with this ENA TS.

HV Substation Portable Earthing Leads | PENTA

Orange Reflective Aluflex Lead | PENTA

Reflect Aluflex Kit Safe Portable Earthing & Rail Line Isolations

Special DEP Earth with Reflect Aluflex

The PENTA Reflect DEP earth is specially designed for use within the rail industry. Its reflective properties allow operators and authorised personnel to easily locate the position and check the proper fitting of the earth at night, whilst its orange appearance ensures the purpose of the lead is clearly identified.

S9B Reflect Kit

The PENTA Reflect cable is a revolutionary new product which allows for quick identification due to its orange band. The reflective band aids location and checking of earths on site at night. The clear outer sheath allows inspection of the fine aluminium stands unlike traditional orange Aluflex leads.

S9B Reflect Kit | PENTA

PENTA Portable Earthing Equipment

80 Years of Designing & Manufacturing

a Comprehensive Range of Portable Earthing Equipment

As trusted suppliers to the electricity industry for many decades, PENTA‘s wide variety of Portable Earthing Equipment, including the Reflect Aluflex Kit, is used to provide short circuit protection and to control induced voltages and associated currents within substations, on overhead transmission and distribution lines and within the electrified rail network. PENTA also manufacture protection, monitoring and indicating instruments.

Thorne & Derrick distribute the extensive range of trusted PENTA Substation Earthing Equipment & Electrical Safety Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors. We provide exceptional service, fast delivery and the best prices to UK and international clients working on underground cables, overhead lines, substations and electrical construction.

Empowering Growth: Just Williams Ltd Delivers Sales & Marketing Training at Thorne & Derrick

January 16th, 2025

(L To R) – Jessica Williams (CEO of Just Williams Ltd), Dylan White (Sales Engineer), Regan Redpath (Apprentice Sales Engineer), Chloe Johnston (Apprentice Sales Engineer), Charlie Baines (Apprentice Sales Engineer), Aiden Dawson (SEO Specialist), Laurence Taylor (Sales Engineer), Ella Bradley (Apprentice Sales Engineer), Mia Lynn (Administrative Assistant Apprentice), Millie Temple (Content Creator Apprentice).

Driving Growth: Just Williams Ltd Delivers Sales & Marketing Training at Thorne & Derrick

Yesterday, the team at Thorne & Derrick International had the pleasure of hosting JWSA Sales Academy for an intensive and engaging sales and marketing training session. Led by Jessica Williams, founder and CEO of Just Williams Ltd, the session brought fresh insights, practical tools, and strategies to strengthen Thorne & Derrick’s position as a leader in hazardous areas and industrial equipment distribution.

Empowering Solutions-Focused Sales

The training session centred around building a solutions-driven mindset—one that addresses customer pain points with tailored approaches. The session kicked off with an engaging presentation by Jessica, who encouraged the team to think beyond traditional sales & marketing tactics and focus on crafting customer-centric solutions.

Topics covered included:

- Understanding Customer Needs: How to identify pain points and position products as effective solutions.

- Refining Sales Techniques: Building meaningful, trust-based relationships that foster long-term client partnerships.

- Strategic Marketing Insights: Aligning marketing initiatives with sales goals to create cohesive, results-oriented strategies.

Interactive and Impactful – JWSA Sales Academy

The team actively participated in discussions, sharing their experiences while absorbing Jessica’s expert advice. It was a collaborative and motivating environment that combined Thorne & Derrick’s expertise with Jessica’s fresh perspective. The exercises and tailored examples resonated with everyone, making the session not just theoretical but highly practical.

The highlight of the day was the hands-on application of key principles, with the team brainstorming real-world scenarios to practice their new skills. This tangible approach ensured everyone left the session feeling confident and empowered to implement what they’d learned.

A Day to Remember – JWSA Sales Academy Training

Jessica also got hands-on with Thorne & Derrick’s ShoveIt manufactured by Hand Safety Tool, showcasing her enthusiasm for the company’s innovative products.

Thorne & Derrick’s team expressed their appreciation for the session, describing it as an invigorating experience. One team member noted, “The tools and strategies we learned today will have an immediate impact on the way we approach clients and marketing efforts. Jessica’s insight was invaluable.”

A Bright Future Ahead

As the team applies their newfound skills, customers can expect an even higher standard of service and solutions from Thorne & Derrick. Yesterday’s training is a clear step forward in their journey to deliver excellence and innovation at every turn.

Feel free to contact us today to discuss any of your upcoming projects or enquiries!

JWSA Sales Academy – Feedback from Thorne & Derrick Staff

Aiden Dawson (SEO Specialist) – “Jess’ sales academy was executed brilliantly, being straight-up, insightful and perfect for building on team unity. Jess as a person, is a breath of fresh air and offers a multitude of skill sets that allowed her to dissect the ins and outs of T&D’s sales and marketing structure in no time at all, providing the opportunity to uncover the chinks in our armour and delivering crucial insights on how we can improve, both as a team and individually. It’s clear why the Just Williams Sales Academy is an ideal solution to business growth and I’d personally recommend the academy to any business, regardless of industry or niche.”

Chloe Johnston – (Apprentice Sales Engineer) – “The Just Williams Sales Academy was valuable and insightful in providing practical, hands-on training in key sales skills. It offered a structured approach to improving communication, client engagement, and relationship-building techniques. The academy enabled us to understand the sales process, from prospecting to closing deals. It also provided valuable insights into overcoming objections and tailoring sales strategies to meet individual client needs. Jess expressed the value of Linked In and how we can interact with our customers and connections.”

Charlie Baines (Apprentice Sales Engineer) – “Jess’ sales academy was masterfully conducted, providing direct, insightful training that strengthened team cohesion. Jess brings a refreshing presence and a wide range of skills, allowing her to swiftly evaluate T&D’s sales and marketing framework, pinpoint areas for improvement, and offer essential guidance for both team and individual growth. I would recommend the sales academy to any business, as I am sure the other participants would also.”

Ella Bradley (Apprentice Sales Engineer) – “Yesterday’s training not only emphasized personal growth and self-improvement but also fostered a strong sense of camaraderie within our sales team. It was inspiring to experience the collective support and encouragement from everyone, which reinforced the collaborative culture we strive to cultivate. The session provided valuable insights into both individual and team development, leaving us feeling more motivated and united as we continue to pursue our goals together.”

Laurence Taylor (Sales Engineer) – “Jess Williams’ sales training was truly exceptional. The sessions were engaging and packed with practical strategies and tips that can be applied immediately. I highly recommend it to anyone looking to boost their sales skills and achieve better results.”

Mia Lynn (Administrative Assistant Apprentice) – “I personally thought Jess’s training was very insightful and to a high standard. The icebreaker she used was a good way to make us all feel engaged and comfortable. The way she spoke to us as the audience was professional but passionate and interesting. Overall, I’d recommend ‘Just Williams’ to any business that is looking for a service like theirs.”

Thorne & Derrick are Specialist Distributors to international Utilities, UK DNO’s, ICP’s and HV Jointing Contractors of an extensive range of LV HV Cable Jointing, Substation, Tooling & Installation Equipment from 600V to 66kV – we service wind energy, solar power, battery storage, rail, utility, datacentre and the explosive atmosphere industries.

Based in the UK, we are highly customer responsive and absolutely committed to providing a world-class service.

Since 1985, we have provided expert technical support and express delivery from extensive UK stocks to world-wide destinations.

Key Product Categories: Connectors, Joints & Terminations MV HV | Cable Preparation & Jointing Tools | Duct Seals | Cable Transits | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Clothing & Protection | Cable Pulling | Earthing & Lightning Protection | Feeder Pillars

Team Growth Meets Website Growth

January 15th, 2025Make Way For Marketing

We’d like to welcome Aiden to the Thorne & Derrick team, who will be acting as an SEO Specialist at our Chester-le-Street offices, taking on a pivotal role in our online organic growth opportunities! As well as SEO, Aiden brings a variety of marketing skills to the table, which will play a crucial part in scaling T&D’s future marketing prospects. Continuously developing our avenues into the world of marketing, we’re excited to see a reflection of his 5+ years of experience in the industry, in all things SEO, Paid Advertising, E-Mail Marketing, Social Media, and more, whilst collaborating with the rest of our esteemed marketing team.

Aiden | Welcome To The Team

Tell us about yourself…

“Where do I start? Well, first things first, I’m a Geordie through and through. Now we’ve got the important stuff out of the way… I’m a 23-year-old easy-going lad from Chester-le-Street of all places. Little did I know, my marketing career would take off right around the corner at Thorne & Derrick.

I’d say I’m a very ambitious person, eager to achieve my goals (which can sometimes be my worst enemy, if I have any form of competition). So, if you like your freedom, I wouldn’t recommend challenging me to a game of pool or Mario Kart. However, I believe I have quite a relaxed personality, which allows me to be a logical thinker in times of stress or panic.

I’ve always been a big foodie (which doesn’t help my efforts in the gym), there’s just nothing better than a cheeky Chinese takeaway in front of the telly. Like most people, a holiday abroad is a need, not a want. Whilst I’m still young, taking my opportunities to see the world is something I’d love to continue doing.”

What’s your experience in the industry?

“My marketing journey began via a developing interest in digital creativity as a whole, initially driving towards graphic design after studying the ins and outs throughout school and college, eventually resulting in a Level 3 Extended Diploma. However, my interests expanded during the job search after college, diverting towards digital marketing apprenticeships. Granting the opportunity to utilise my experience in graphic design, digital marketing proved an excellent career path to take, generating exciting new skills that will be of crucial value to businesses for the foreseeable future.

Following my application with QA Apprenticeships, I landed an ideal digital marketing position within a design, marketing, and web development agency in Newcastle Upon Tyne. Through extensive learning with QA and hands-on experience at the agency, I completed my Level 3 Extended Diploma in digital marketing and retained my position at the agency. Throughout my 4+ years at the agency, I developed many useful techniques and skills, such as social media management, paid advertising, content writing, and more.

Additionally, I created my own freelancing business, building on the experience and knowledge from my time at the agency to develop my very own collection of clients. My freelancing experience allowed me to delve deeper into the digital marketing world, as well as other digital avenues, such as SEO, e-commerce, and graphic design. As much as I enjoyed freelancing, it determined my preference and desire to work within a team, as well as generating a newfound love for SEO.

Finally, bringing us to the present!”

How was your first few weeks at Thorne & Derrick?

“My first few weeks at Thorne & Derrick have certainly fulfilled my hopes! I have been welcomed into the company with open arms and have begun building strong relationships with the rest of the team. I have been encouraged to share my knowledge, experience, and thoughts with my colleagues, which has allowed me to feel like an appreciated member of the team from day one. With that being said, working alongside a professional group of individuals, with extensive expertise in marketing and sales, has been invaluable to me. The industry and marketing execution T&D follows is mostly new territory for me, which is why the initial assistance from our brilliant marketing team has granted me the ability to settle in seamlessly.

I can’t wait to see what’s to come at T&D, and I’m looking forward to being a piece of the puzzle in the company’s continuous growth and success.”

The Perfect Cable Tie for Solar Applications | Panduit Nylon 612

December 19th, 2024

Nylon 612 Cable Ties are Perfect for Solar APPLICATIONS

Panduit manufacture an extensive range of industry approved cable ties with styles, sizes and materials including stainless steel to meet a full range of electrical, industrial, and networking applications. Nylon 612 cable ties are manufactured by Panduit are trusted to bundle, support, fasten and manage data, telecoms, control, instrumentation and power LV MV HV cables in industrial and hazardous area industries including oil/gas, petrochemical, rail, renewable, construction and mining/quarrying industries.

The typical 100 MW solar project uses over one million cable ties to manage miles of PV wire at every stage of the DC distribution system. Typical plastic ties are not expected to last the entire 25+ year operating life of a solar power plant. When they fail, you pay for a new tie in addition to the labor for installation, and those costs add up quickly. But some nylon blends do a whole lot better in this tough application than others, so proper tie selection can help maximize long-term reliability and ROI .

The tie degraded and failed after 3000 hours of UV exposure in the lab.

Why Nylon 612 is the Perfect Material for Solar Cable Ties

Material selection is paramount whenever cable ties are exposed to the outdoors. One of the most advanced formulations for such applications is that of Nylon 612, offering unrivaled durability and resistance to UV and chemical attack. Among other nylon variants such as 6.6 and 12, Nylon 612 has emerged as the ideal choice for solar cable management.

Improvement of UV Resistance in Cable Ties

One of the major challenges for cable ties to be used outdoors is from the effects of ultraviolet (UV) radiation. Materials engineers improve UV resistance through the addition of additives that block, absorb, or stabilize against UV radiation. For example, a typical outdoor-rated Nylon 6.6 features carbon black, which blocks UV radiation and greatly lengthens the material‘s life in the sun. These ties will also fail over time in direct sun exposure even with carbon black.

On the other hand, Nylon 612 offers up to 10 times more UV resistance compared to the standard black Nylon 6.6 ties. This increased resistance ensures long-term performance in solar installations and makes it an excellent material for projects requiring durable, low-maintenance cable management solutions.

Resisting Environmental and Chemical Stress

Beyond UV exposure, outdoor environments introduce other stressors that can degrade plastics. Atmospheric moisture from rain, fog, and marine environments can vary in pH levels and introduce high salt concentrations. In cases where moisture interacts with coated metals, weak concentrations of zinc chloride may also appear, posing a challenge for standard nylon materials.

Although nylon is naturally resistant to many chemicals, harsh outdoor conditions can push its limits. It is here that Nylon 612 excels. Having a chemical resistance profile similar to the premium Nylon 12, Nylon 612 resists degradation from acids, alkalis, and salts. The table below highlights its superior performance:

Nylon chemical resistance comparison

| Solution | Nylon 6.6 | Nylon 612 | Nylon 12 |

|---|---|---|---|

| 10% HCl | Poor | Excellent | Good |

| 35% NaOH | Fair | Good | Excellent |

| 50% ZnCl2 | Fair | Excellent | Excellent |

20-Year Outdoor Lifetime with Warranty

Panduit Nylon 612 cable ties represent the best in class, with up to a 20-plus year outdoor life expectancy. Such ties are supported by a 20-Year Build Solar Better Warranty for assurance to solar installers. Reliability of a “fit-and-forget“ nature reduces long-term maintenance costs and improves overall return on investment.

Alternatives to Nylon Cable Ties

While Nylon 612 is a great material for solar cable ties, some engineers prefer to specify alternatives for certain projects. Stainless steel ties, like Panduit‘s Stronghold Stainless Steel Ties, boast unparalleled durability and can often last the life of a solar project. For flexible installations, Solar Wire Hangers may also be a practical solution.

Network Infrastructure & Industrial Electrical Wiring

Should you require customer service, specification support or a competitive quotation please do not hesitate to contact us – extensive range of Cable Accessories, Protection & Management products available for LV MV HV Electrical Infrastructure projects in commercial, industrial and hazardous area sectors.

Wiring Duct | Cable Terminals | Absence of Voltage Testing | Cable Cleats | Cable Identification | Cable Ties | Abrasion Protection & Heat Shrink | LV HV Cable Accessories | Lockout Tagout | Stainless Steel Cable Ties & Identification | Panel Systems | Grounding Connectors | Contact us for Further Information