Blog

Protect Signal Cables From Rodent Damage | Brush Solutions For Railways

October 19th, 2020

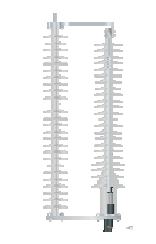

RODENTBRUSH – Brush Solutions For Rodents

Brush Solutions For Rodent Control On Railways

RODENTBRUSH

Trackside cable ducting and electrical junction boxes are warm dry places, with many points of access through which a determined rodent can squeeze and make a nest. Problems occur because rats love to chew and as they gnaw the plastic casing they can dangerously expose vital signal cables.

A break in signal control can cause whole sections of the railway to be out of use until the fault can be located and repaired. This results in expensive engineering costs and possible train delays.

➡ Further Reading Rat & Rodent Resistant Cable Duct Seals For LV MV HV Cables & Substations

Created and developed in close association with Railtrack, the RODENTBRUSH is specially designed to fill the spaces around cabling where rats and mice get in. RODENTBRUSH is flexible, flame retardant and offers the simplest solution to prevent cables from being chewed and subsequent signal failure;

- Simple to install and remove for cable maintenance

- Maintains airflow in the gap, avoiding cable overheating

- UL94-V0 flame retardant brush material

- Network Rail certificate of Acceptance PA05/0110

RODENTBRUSH has been installed successfully by rail contractors across the UK and France, avoiding expensive engineering costs and delays. Trials show that rodents don’t like the feel of the filament on their faces and whiskers.

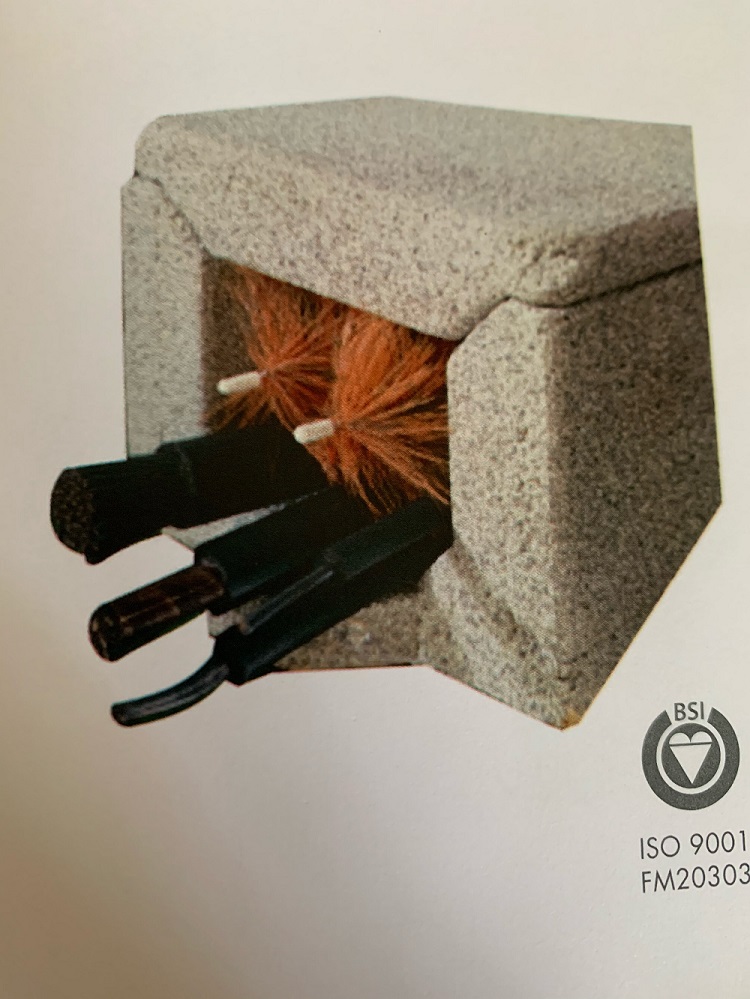

In trackside ducting, RODENTBRUSH fills the cavity and deters rodents from entering. In signal boxes and enclosures, RODENTBRUSH can be pushed into any gaps and spaces at the base of the compartment to act as a deterrent to inquisitive rats.

RODENTBRUSH in Trackside Cable Ducting

Unlike other forms of pest control, RODENTBRUSH can be easily removed for routine maintenance and then replaced foe ongoing cable protection. RODENTBRUSH can be exposed to all elements allowing air to circulate and water to drain away. The result is protected cables that allows the network trains to keep moving.

The RODENTBRUSH is a flexible twisted in wire brush with an insulate core, flame retardant fill material and protective moulded end caps.

Network Rail Certificate Of Acceptance PA05/01110

RODENTBRUSH has been tested and approved by Network Rail for use as a deterrent to rodents in cable troughs containing signalling or telecommunication cable and similar areas of infrastructure.

| Brush Diameter | Brush Length | Product Code |

| 100mm | 500mm | S85FRS0001 |

| 1000mm | S85FRS0002 | |

| 2000mm | S85FRS0003 | |

| 5000mm | S85FRS0004 |

Kleeneze-KOTI is the UK’s leading brush strip manufacturer. Our range of flexible SUPERSEAL brush strip seals and door seals is the largest in the UK, available from stock for next day delivery. If you need something different, we have over 50 years experience in custom technical brush strip solutions for all industrial and commercial applications.

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

Live Mains Breach Joint 3c185SAC XC – 4c.25PILCSTA

October 19th, 2020Jointer: Louis Harrison (LV Jointer at PWR-X)

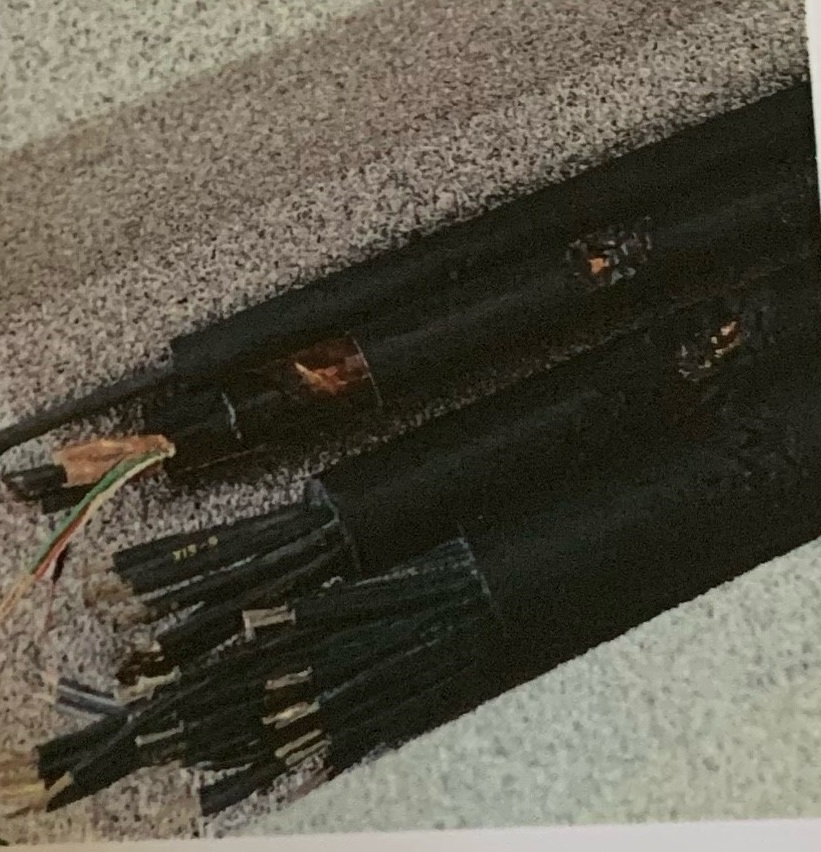

Pictured Below: Live Mains Breach Joint 3c185SAC XC – 4c.25PILCSTA

The Cable Jointing Team at PWR-X completed a low voltage mains breach joint 3c185SAC XC – 4c.25PILCSTA. This joint was the DNO connection for their ICP client. PWR-X are now authorised to carry out point of connection cable joints in the Electricity North West area.

Location: Failsworth, Manchester

DNO: ENW

Cable Jointing Specialists

About PWR-X

PWR-X Limited is based in the North West of England but cover jobs nationwide.

Currently offering cable jointing services from LV – 132kV. Specialising in HV/EHV their staff have developed a high skill set and experience of working for different DNO’s and private networks. All staff are directly employed and authorised by the DNO’s whose systems they work on.

As a company PWR-X pride itself on always meeting their client’s demands. The focus is always the client’s satisfaction, whilst delivering the work in a safe manner and remaining a cost effective option. With an extensive knowledge of different DNO’s networks project management and pre-site visits on LV/HV/EHV projects is also available.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Whitepaper | EMP/EMI Protection In Control Rooms/Centres In Critical Infrastructure

October 19th, 2020

Abstract

This Whitepaper is written to visualise and implement means to protect electronic equipment in critical infrastructure against Electro Magnetic Pulse & Electro Magnetic Interference (EMP/EMI).

The paper by Roxtec, the world-leaders in the manufacture of cable transits initially describes potential EMP/EMI threats; both man-made and natural.

The main threats; natural EMP (like solar storms and lightning) and man-made EMP (like HEMP, NEMP, RFW etc) are presented and discussed as needed background information for planning of adequate protection solutions.

Introduction

- Definitions, Threats & Implications

- Terminating Cables In Substations

- Critical Infrastructure

- Authority Protection Requirements & Specs

- EMP/EMI Shielding Construction & Solutions

- Verification, Tests & Measurements

- Construction, Knowledge & Competence

- Documentation

- Reference Documents

Hazardous Areas & Explosive Atmospheres (Gas & Dust) | Ex e and Ex tb Explosion Protection Certified by ATEX & IECEx | Zone 1/21 & Zone 2/22

Roxtec modular cable transit seals are based upon a rubber design with seals that are constructed of a number of removable layers to secure a watertight, gas tight and fire proof seal around the cable or pipe – the range includes rectangular transits and round transits to fit a variety of pipes and cable sizes.

Process Industry

Typical Applications

Buildings & E-houses

Wall entries

Floor entries

Underground entries

Control rooms

Analyzer shelters

Substations

Remote instrument buildings (RIB)

Field auxiliary rooms (FAR)

Local equipment rooms (LER)

Terminal Boxes, Cabinets & Enclosures

Remote I/O cabinets

Hazardous locations (Ex e)

Ordinary locations

Electric heat tracing systems

Automation and control cabinets

DCS panels

Motor control cabinets

Safety instrumented systems (SIS)

Fire and gas detection control cabinets

Machine monitoring systems

Lighting panels

Thorne & Derrick are distributors for Roxtec, the leading manufacturer of sealing solutions for cables and pipes, – protecting cables and pipes in the process industry sector against water, gas and fire.

Further Reading

Sealing Pipes & Cables in the Hazardous Area & Process Industries Using Roxtec

- Whitepaper: Roxtec Multi-Cable Transit Devices

- Whitepaper: Modular Integration of Process Equipment Packages for Oil and Gas Facilities

- Whitepaper | Modular Cable Termination Design By Roxtec

CONTACT US WITH YOUR ENQUIRY

Specialist Distributors of Industrial & Hazardous Area Equipment to provide Power, Heat, Light & Ventilation to the explosive atmospheres and process industries.

Control Panels | Plugs | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Ventilation Fans | Security Access Control

Competitive Prices | Extensive Stocks | Technical Support | Express Delivery

Soil Resistivity | Why & How to Perform Soil Resistivity Surveys

October 19th, 2020

Soil Resistivity Surveys

-

Special thanks to Andy Chaluda Business Development Manager - Technical Services at AN Wallis

The soil resistivity survey by AN Wallis is the first step in ensuring the correct design of an earth electrode system. It is essential that accurate measurements are taken at this stage as this data is used to determine what conductors are required in the finished earthing system to give a safe and suitable design. Corrupt data taken with inadequate test equipment could lead to a vastly over- or under-engineered solution.

Why We Carry Out Soil Resistivity Surveys

To complete an earth electrode system analysis, we need to know what the electrical properties of the ground we intend to install the earthing into.To do this, we would need to complete a soil resistivity survey of the site, or if not directly at the site, a location near to the site on a similar elevation.

How To Perform A Soil Resistivity Survey

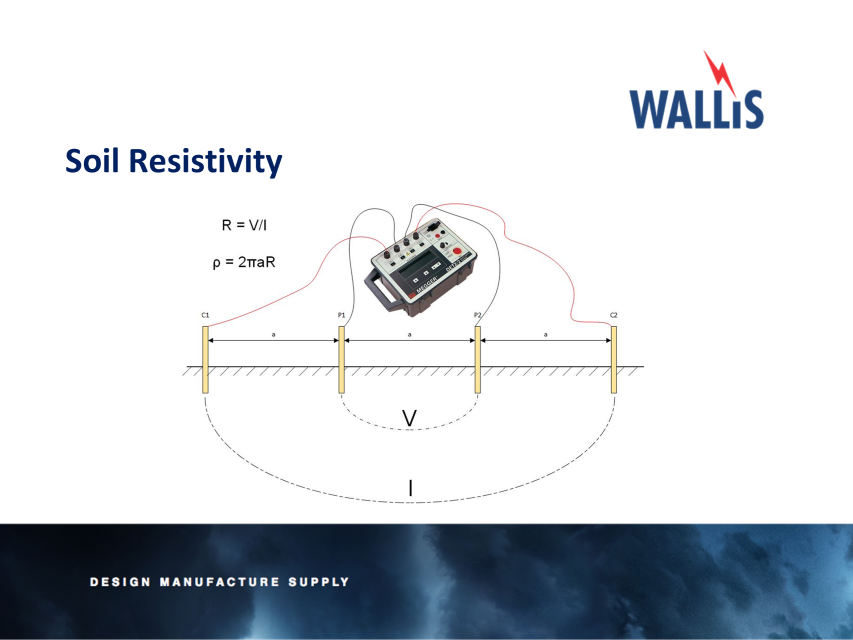

Soil Resistivity

Four probes are inserted into the ground to give a good connection. The four probes are equidistantly spaced apart from one another to the given separation distances, we tend to use the separation distances given in BS EN 50522 as a set value. The distance the probes are spaced apart, dictates the depth into the ground you are testing.

The largest separation distance would normally depend on the size of the proposed substation site, for instance a 5x5m substation may only need to have, for example a 13.5m separation distance, where as a larger substation will need larger separation distances, this would be determined by our Earthing Design professionals when attending site. We must remember that ultimately the surveys will be limited by the land available to us and can therefore take this into account should we not have sufficient space.

It may be possible to compare the derived soil model to the local geology if that is known as shown below:

| Type Of Soil | Soil Resistivity |

| Marshy Soil | 5 to 40 |

| Loam, Clay, Humus | 20 to 200 |

| Sand | 200 to 2,500 |

| Gravel | 2,000 to 3,000 |

| Weathered Rock | Mostly below 1,000 |

| Sandstone | 2,000 to 3,000 |

| Granite | Up to 50,000 |

For instance, in London, we would expect a soil model to be around 20Ω-m, as we know London is in an area of clay. If the values are dissimilar to those shown in the table extracted from BS EN 50522, we may have a problem with our surveys or the land is not natural, such as a landfill site or former quarry.

Once the first survey is complete, further surveys will be completed at different parts of the site until the data gained collates and a ‘clean’ data set is derived.

We are vigilant not to survey near buried metallic objects such as pipelines or parallel to overhead lines, as these may influence the readings taken.

Once the raw data is gained, this is then processed using the CDEGS RESAP software to gain an indicative soil model of the site and therefore completing the Soil Resistivity Survey.

Further Reading

- AN Wallis Earthing & Lightning Protection | ECA Consultant & Specifier Associate

- Earthing | An Introduction To Earthing & Earthing Designs | Part One

- Lightning | An Introduction To Lightning Protection | Networks, Strategy & Systems | Part Two

- Earth Bars | High Specification Copper Earth Bars for Lightning Protection Systems

AN Wallis

The Wallis product range includes copper earth rods (solid copper, copper bond and stainless steel types), earth bars, copper tape, earth clamps and aluminium tapes.

Specialist Distributors: LV, MV & HV Cable Jointing, Substation & Electrical Eqpt

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Earthing & Electrical Equipment – we service UK and global businesses involved in cable installations, substation, overhead line and the installation of medium/high voltage cable joints and terminations at LV, 11kV, 33kV and HV.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Südkabel Training | Cable Terminations 72.5kV – 132kV | Jointer Training Services

October 14th, 2020

Jointer Training MV HV EHV

Sudkabel Terminations

Jointer Training

72.5kV – 132kV Medium & High Voltage Cables

Südkabel are global leaders in manufacturing Extra High Voltage EHV cable joints and cable terminations for XLPE insulated cables also offering an outdoor termination portfolio including the dry type solutions.

The outdoor cable terminations are available between 72.5kV-132kV offering both the self supporting and rigid dry type solution – a Jointer Training Service is also available by contacting Thorne & Derrrick for further information.

➡ The following tables provides an overview of the range of Südkabel Cable Terminations available for the connection, support and sealing of high voltage cables.

Thone & Derrick | Sudkabel Approved Distributor | Joints, Terminations & Connectors | Specification & Supply

|

|

|

|

|

|

|

| EHFVC compound filled composite insulator |

EHFV compound filled porcelain insulator |

EHFVCS pluggable & dry-type gas-filled composite insulator |

EHFS flexible dry-type & gas-free |

EHFSI flexible self-supported dry-type & gas-free |

EHFST self-supported dry-type & gas-free |

|

| Voltage Um | up to 550 kV | up to 550 kV | up to 550 kV | up to 145 kV limited up to 245 kV |

up to 145 kV limited up to 245 kV |

up to 170 kV |

| BIL Û | up to 1550 kV | up to 1550 kV | up to 1550 kV | up to 650 kV | up to 650 kV | up to 750 kV |

| Cross Section | up to 3200 sqmm | up to 3200 sqmm | up to 3200 sqmm | up to 1200 sqmm lager on request |

up to 1200 sqmm lager on request |

up to 1200 sqmm lager on request |

| Creepage Distance |

≥ d / III – heavy IEC 60815 |

≥ d / III – heavy IEC 60815 |

≥ d / III – heavy IEC 60815 |

≥ d / III – heavy IEC 60815 |

≥ d / III – heavy IEC 60815 |

≥ d / III – heavy IEC 60815 |

| Connector | compression or screw connector |

compression or screw connector |

compression or screw connector |

compression or screw connector |

compression or screw connector |

compression or screw connector |

| Suitable for water protection areas |

limited | limited | yes | yes | yes | yes |

| Installation position |

normally ≤ 30° | normally ≤ 30° | arbitrary | normally ≤ 45° resp. upside down ≤ 45° |

arbitrary | normally ≤ 45° |

| Add-ons | OF decoupling rotatable base plate arcing horn PD sensor |

OF decoupling rotatable base plate arcing horn PD sensor |

OF decoupling rotatable base plate arcing horn PD sensor |

OF decoupling | OF decoupling | OF decoupling rotatable base plate arcing horn PD sensor |

About Südkabel

At Südkabel, we are proud of our heritage and everything that has been developed and achieved in Mannheim for more than 100 years. After all, we don’t just produce high quality cables and accessories, but also accomplish pioneering work – particularly in the field of XLPE technology.

This progress is supported by people with a wide range of qualifications and experience. They all distinguish Südkabel’s image. They all drive the company forward and always work in the interest of their customers.

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage cable systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV