Cable Pulling & Laying

Cable Drums | Recommended Transport & Storage

January 15th, 2020

Cable Drums

Cable Drums

Even if cable and cable drum look very strong, there are certain rules to follow to avoid damage of the cable and an accompanying impairment of mechanical and electrical characteristics for LV MV HV cables.

Transport & Storage of Cable Drums

It is possible to store cable drums outdoors.

When storage has occurred in heated rooms, a minimum 24-hour acclimatisation period must be observed before installation (possible condensation build-up in the cable!).

For outdoor storage the ground must be even and clean.

Stones or bumps in the ground should be removed or smoothed out.

Damage to the wound goods/cable should be avoided at all costs.

Cables should be secured against accidental rolling away. Under no circumstances should the drum flange of neighbouring cables touch any wound goods.

Cable drums should always be stored and transported standing on both flanges.

They should not be pushed along the ground standing on the flanges. It is possible that the strength of the cable drum would then no longer be guaranteed.

Observe the rolling direction. The arrow printed on the drum flange indicates the rolling direction so that the wound goods do not become loose.

Always uncoil the cable at a tangent, never over the flange, since the torsion thus resulting would damage the cable and laying would not be possible.

Cable Ends

Finally it remains for us to point out the necessity of having faultless cable ends.

Pressure-tight and impermeable cable ends are particularly essential for cables which are not longitudinally water-proof, as well as for cables which are insulated with paper, cellular-PE and foam-skin-PE.

Carelessness in this area can lead to moisture penetration which is accompanied by a drastic deterioration in the electrical transmission rate.

Power failures and expensive replacement work are the result. Pressure-tight and impermeable cable ends can be achieved, for example, through the use of synthetic sealing resin, compressed air sealing stoppers or cable end caps.

Press Release | Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

Further Reading

- Cable Laying | The Importance of Cable Installation Instructions

- How to Prepare Cables To Avoid Cable Damages & Faults

- Cable Pulling | Safe Pulling of Cables Using Motorised Pullers

- Cable Pulling | Safe Pulling of Cables Using Manual Laying

- Installation of Cable Sleeves | Jointing & Splicing Cables

- Installation of Rail Foot Cables

Cable Pulling Equipment

Thorne & Derrick distribute an extensive range of Cable Pulling & Laying Equipment to enable the safe installation of fibre and copper cables within the telecommunications industry. Safely installed cables reduces operational and maintenance requirements to the network and reduced service interruption to telecom cables, wires, ducts, cabinets and exchanges – products include cable spiking tools, conduit rods, cable lubricant, cable socks and rollers.

Cable Laying | The Importance of Cable Installation Instructions

January 14th, 2020

Cable Laying | The Importance of Cable Installation Instructions

Cable Laying

Usually the only people who take any notice of cables and wires are those who work with them. Most of us use the telephone, watch television or surf the Internet without thinking about how the underlying infrastructure, the network of cables, has been assembled.

Cables are rarely heeded; they are ‘simply there’.

General knowledge about cables is equally lacking. Very few people know what high technology is wrapped up in the inconspicuous black, grey or coloured wires. Indoor cables in particular are subjected to heavy handling by the user: office chairs are rolled over telephone connection wires, computer patch cables are trodden on by people or nibbled by their amusing pets.

Outdoor cables are affected by huge differences in temperature and high bending and pulling forces while they are being laid. The thicker the cable the stronger it may appear. However thick as well as thin wires are subject to the same physical conditions and limits.

The following Blogs aim to raise awareness about cables and explain terms such as bending radius, temperature ranges or permissible tension. Furthermore you will find instructions and tips for correct and safe installation.

Parameters

Initially people have the idea, ‘We should/ must modernise or expand our network’.

An engineering consultancy is hired to transform the idea into a feasible plan.

Basic conditions and objectives are decided together with the customer. At the same time many technical parameters must also be considered along with the questions related to infrastructure.

During the realisation phase for the plans numerous trades work closely together. One of these is concerned with the laying of the physical network of wires or cables.

The installation company responsible for laying the cables must heed the following parameters:

- temperature range of the cable,

- bending radius of the cable,

- maximum tension of the cable,

- weight of the cable as well as

- storage and cutting.

Temperature Range

The temperature range of the cable is of great importance for both the user and fitter.

After all the cable is meant to function equally well in cold and hot temperatures. It is particularly during the fitting process that powerful mechanical forces act on the cable. The plastic used serves as the limiting element for the possible temperature range.

At overly warm temperatures the plastic becomes very soft and can change into a thermoplastic state (up to melting point), which causes irreversible changes in the cable.

At very cold temperatures, however, the material stiffens and becomes hard and inflexible. Here, too, irreparable damage can occur.

Tears in the sheath allow dampness and moisture in and impair the transmission rate.

Details about the permissible temperature range during laying and use (following successful fitting) can be found in the information sheets of the cable manufacturer. Since the mechanical strain on the cable in its laid form is significantly less, the permissible temperature range is greater than the range valid for the installation period.

The VDE 0816 gives the following values:

During Cable Laying

PE-sheath, from -20 ° C to + 50 ° C

PVC-sheath, from – 5 ° C to + 50 ° C

Before & After Cable Laying

PE-sheath, from -20 ° C to + 70 ° C

PVC-sheath, from – 5 ° C to + 70 ° C

Cable Bending Radius

Regarding the bending radius we distinguish between multiple and single bending (shaping into the final position). Multiple bending occurs mainly during the laying process.

Cables are laid under tension around deflector rolls. The particular stress of multiple bending lies in the alternating stress on the materials, which can be stretched several times as well as compressed during the laying process. To prevent permanent damage there are prescribed minimum bending radii of, for example, 10 x cable external diameter for multiple bending.

The stress on the material during final bending is not characterised by alternating stress.

The cable is bent into form a final time and stays in this position for the duration of its use. The minimum bending radius in this case is, for example, 7.5 x cable external diameter. During final bending the cable can, therefore, be bent more tightly.

Exact minimum bending radii for specific cables can be found in the information sheets of the cable manufacturer.

Tension

During laying of the cable particular attention must be paid to the maximum possible tension. The cable is very quickly damaged by the use of too much force and must then be replaced. The maximum possible tension depends in the first place on the overall cross section and the tensile strength of the conducting materials used.

For cables with steel tape or copper wire spiral armouring it is the internal copper conductors alone which determine the maximum tension! The armouring has no influence on the maximum tension or can possibly reduce it through additional weight.

For armouring with steel or steel profile wires, however, the tension is determined solely by the steel and steel profile wires.

Cable Weight

The cable weight of larger cable dimensions can take weights of up to more than 9 t/km (without the reel!).

Storage & Cable Cutting

Cables for delivery as well as cut cables must generally be protected against moisture penetration. This best occurs through the use of shrink caps with fusible glue. Loose-fitting caps or temporary measures with plastic adhesive tape are not watertight and are unsuitable.

Moisture penetration leads to corrosion and deterioration of the transmission rate.

If two cable ends are to be connected with a sleeve, this must take place immediately and with protection against moisture and rain. For the period of the sleeve installation an installation tent must be erected.

Press Release | Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

Further Reading

- Cable Drums | Recommended Transport & Storage

- How to Prepare Cables To Avoid Cable Damages & Faults

- Cable Pulling | Safe Pulling of Cables Using Motorised Pullers

- Cable Pulling | Safe Pulling of Cables Using Manual Laying

- Installation of Cable Sleeves | Jointing & Splicing Cables

- Installation of Rail Foot Cables

Cable Pulling Equipment

Thorne & Derrick distribute an extensive range of Cable Pulling & Laying Equipment to enable the safe installation of fibre and copper cables within the telecommunications industry. Safely installed cables reduces operational and maintenance requirements to the network and reduced service interruption to telecom cables, wires, ducts, cabinets and exchanges – products include cable spiking tools, conduit rods, cable lubricant, cable socks and rollers.

Further Reading | Cable Drum Handling & Laying Cables | A Guide from Nexans

Cable Laying & Cable Sleeve Installation | Guidelines by Draka Communications

January 14th, 2020-

uploaded by Chris Dodds - Thorne & Derrick Sales | Marketing Manager

Cable Laying & Cable Sleeve Installation

Draka Communications – part of Draka Holding N.V. situated in Amsterdam – offers a variety of reliable products in copper and fibre optic technology for data transmission and telecommunication.

They have long-term experience and knowledge in the cable and fibre business ensuring their major market position today. Draka Communications can be found in more than 32 countries in Europe, Asia, North and South America.

This series of Blogs focuses on the importance of the correct cable laying, cable pulling and cable sleeve installation and how to avoid damages and faults.

The below Articles will give you some guidance in the laying and installation of outdoor LV MV HV cables.

It is important to note that accuracy during preparation of run, laying of cable and installation of sleeve is crucial as your little additional work is worth it to avoid the cost what may arise in the case of a complaint. It is recommended to choose products from recognised manufacturers and that you have the best conditions for a proper installation.

The below articles containing laying and installation instructions are correct to the best of our knowledge and have resulted from consideration of current and recognised techniques and technologies. They are intended as instructions for the correct laying and installation of outdoor cables.

- Cable Laying | The Importance of Cable Installation Instructions

- Cable Drums | Recommended Transport & Storage

- How to Prepare Cables To Avoid Cable Damages & Faults

- Cable Pulling | Safe Pulling of Cables Using Motorised Pullers

- Cable Pulling | Safe Pulling of Cables Using Manual Laying

- Installation of Cable Sleeves | Jointing & Splicing Cables

- Installation of Rail Foot Cables

Cable Pulling Equipment

Thorne & Derrick distribute an extensive range of Cable Pulling & Laying Equipment to enable the safe installation of fibre and copper cables within the telecommunications industry. Safely installed cables reduces operational and maintenance requirements to the network and reduced service interruption to telecom cables, wires, ducts, cabinets and exchanges – products include cable spiking tools, conduit rods, cable lubricant, cable socks and rollers.

Trace Safe | Which Trace Safe is Best for Your Application?

January 7th, 2020

-

uploaded by Chris Dodds - Thorne & Derrick Sales/Marketing Manager

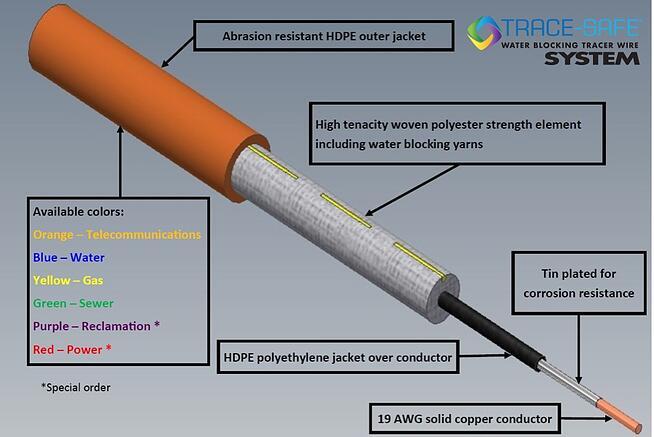

NEPTCO revolutionised the tracer wire market when it introduced Trace Safe, the world’s first tracer wire that incorporated water blocking technology to protect the solid copper conductor from water ingress. There are two distinct products that incorporate many of the same features but there are key differences.

While both products are available in all standard utility colors and have an HDPE outer jacket, water blocking yarns, HDPE wire insulation and a tin coating over the solid copper conductor; the key difference is the strength rating of each product.

Trace Safe gets its strength from the water blocking polyester core that surrounds the solid copper 19 AWG conductor.

The core is made from high tenacity polyester yarns, like those found in car tyres, that are treated with a super absorbent powder.

If the outer jacket is damaged, the super absorbent powders swell up like a baby diaper to prevent any moisture from meeting the solid copper conductor. This helps to ensure a long lasting reliable tracer wire.

Trace-Safe is the only water-blocking tracer wire on the market manufactured by NEPTCO

The amount of core material is the distinguishing difference between the 1800 lb. RT products and 600 lb. TST products. Less core material lowers the cost of the TST products but each product has distinct applications that it is best suited for.

The RT products have an overall rated strength of 1800 lb. and are ideal for horizontal directional drilling applications.

RT products can be attached directly to the drill shaft and pulled back along with the conduit and does not need to go inside the duct. The super tough jacket combined with the 1800 tensile strength means that RT Trace Safe can withstand the rigours and tensions generated during pull back.

The TST products have an overall rated strength of 600 lb. and are ideal open trench, micro trench and nano trenching or can be pulled back alongside dielectric cables inside the duct.

Trace-Safe

Trace Safe is a system which use no strip wire connectors.

Each connector comes with a TST adapter so no matter which wire is used the same connectors will work in any situation.

Trace-Safe and TST adapter

So, which Trace Safe is best for you?

It depends on the application.

For directional drilling applications always choose the RT products, for everything else, the TST products.

For simplicity, some utilities prefer to stock only one wire and choose the RT products because of its universal utility.

However, others are more explicit and will only use RT for directional drilling situations.

Consider the application and be sure to always use the Trace Safe connectors to complete the system.

Further Reading

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

How to Trace & Locate Non-Metallic Underground Gas, Water Sewer Pipelines

January 7th, 2020

Manufacturers of TRACE-SAFE

-

uploaded by Chris Dodds - Thorne & Derrick Sales/Marketing Manager

Water Blocking Utility Locating System

Detecting, Locating & Tracing Underground Pipes

NEPTCO is a global leader in the manufacturing of materials used for the Detection & Pulling of Cables for a wide variety of commercial and industrial applications.

In this Blog, Thorne & Derrick discuss how Trace-Safe provides the ideal solution for all your tracer wire needs including locating non-metallic underground gas and water sewer pipelines.

Trace-Safe® is the only water-blocking tracer wire on the market.

Its unique characteristics protect its solid copper conductor from corrosion. It enables precision locating utilising a 19AWG conductor.

Water blocking reinforced tracer wire for the Trace-safe utility locating system.

Double insulated metallic conductor enables reliable and accurate locating of all-dielectric cables, gas lines, sewer lines or water pipes.

NEPTCO’s cut resistance Trace-Safe® product ensures reliability, locates on frequencies of 9.5, 38, 80, and 512 KHz and outperforms competitive tracer wire products. The product is available in two versions: Trace-Safe and Trace-Safe Trench tracer wires.

Trace-Safe is the strongest tracer wire on the market and eliminates the need to use two or more standard tracer wires for directional drilling applications.

♦ Further Reading Trace Safe | Which Trace Safe is Best for Your Application?

Trace-Safe Water Blocking Tracer Wire System

Features & Benefits

- Water-blocked tracer wire for anti-corrosion

- Four layers of protection to guard against water penetration

- Provides superior locate accuracy for telecom, gas, water, sewer and reclamation applications

- Light-duty and heavy-duty versions available for open trench or directional drilling applications

- Simple to use connectors ensure consistent, reliable splices

- High strength, lightweight and flexible tracing system

- Sequential footage or meter markings

- Passes meter water head test

- Corrosion-resistant conductor compatible with any locating equipment

- Two high density polyethylene jackets

- Abrasion, moisture and UV resistant

- No strip universal connectors ensuring consistent reliable connections every time

Trace-Safe Utility Locating System

Properties

- Break strengths: 1800 and 610lbs (818/181kg) nominal

- RT1800 weight: 20lbs. per 1,000 feet (29 kg/km)

- TST600 weight = 11lbs. per 1,000 feet (16.4kg/km)

- High tenacity polyester fibers with super absorbent powders

- Conductor diameter: .0356″ nominal (19 AWG) (.9mm)

- RT1800 outer jacket thickness = .030″ (.762mm)

- TST600 outer jacket thickness = .025″ (.635mm)

- Inner jacket thickness = .006″ (.152mm)

- Conductor tensile strength: 38,500 psi nominal

- UL 1581 rated to 600 volts CE standards

- Dielectric constant 2.29 @ 1MhZ

Colours available:

Orange – Telecommunications

Red – Telecommunications, (AUS/NZ)

Blue – Water

Yellow – Gas

Green – Sewer

Trace-Safe Water Blocking Tracer Wire System

| Item Number | Product Code | 1800 LB Description | Package | Reel Dimensions | Wt/lbs | Rls/Skid |

| Telecommunications | ||||||

| 44087 | RT1800W | Orange – TRACE-SAFE | 500 ft | Fl. 10.5″ x W 7.75″ | 11 | 45 |

| 42410 | RT1800W | Orange – TRACE-SAFE | 1,000 ft | FI. 12″ x W 12″ | 24 | 36 |

| 44088 | RT1800W | Orange – TRACE-SAFE | 1, 500 ft | FI. 13.25″ x W 17″ | 60 | 18 |

| Gas Transmission & Distribution | ||||||

| 44089 | RT1801W | Yellow – TRACE-SAFE | 500 ft | Fl. 10.5″ x W 7.75″ | 11 | 45 |

| 41741 | RT1801W | Yellow – TRACE-SAFE | 1,000 ft | FI. 12″ x W 12″ | 24 | 36 |

| 44092 | RT1801W | Yellow – TRACE-SAFE | 1,500 ft | FI. 13.25″ x W 17″ | 60 | 18 |

| Water Transmission & Distribution | ||||||

| 44093 | RT1802W | Blue – TRACE-SAFE | 500 ft | Fl. 10.5″ x W 7.75″ | 11 | 45 |

| 41740 | RT1802W | Blue – TRACE-SAFE | 1,000 ft | FI. 12″ x W 12″ | 24 | 36 |

| 44097 | RT1802W | Blue – TRACE-SAFE | 1, 500 ft | FI. 13.25″ x W 17″ | 60 | 18 |

| Sewer | ||||||

| 44098 | RT1803W | Green – TRACE-SAFE | 500 ft | Fl. 10.5″ x W 7.75″ | 11 | 45 |

| 42408 | RT1803W | Green – TRACE-SAFE | 1,000 ft | FI. 12″ x W 12″ | 24 | 36 |

| 44099 | RT1803W | Green – TRACE-SAFE | 1, 500 ft | FI. 13.25″ x W 17″ | 60 | 18 |

| Item Number | Product Code | 400 LB Description | Package | Reel Dimensions | Wt/lbs | Rls/Skid |

| Telecommunications | ||||||

| 61859 | TST600W | Orange – TRACE-SAFE TRENCH | 1,000 ft | Fl. 12 x W 10.25″ | 12 | 36 |

| 61861 | TST600W | Orange – TRACE-SAFE TRENCH | 1,500 ft | Fl. 12 x W 10.25″ | 27 | 36 |

| 62360 | TST600W | Orange – TRACE-SAFE TRENCH | 2,000 ft | Fl. 12 x W 16.25″” | 56 | 18 |

| Gas Transmission & Distribution | ||||||

| 61873 | TST601W | Yellow – TRACE-SAFE TRENCH | 1,000 ft | Fl. 12 x W 10.25″ | 12 | 36 |

| 61875 | TST601W | Yellow – TRACE-SAFE TRENCH | 1,500 ft | Fl. 12 x W 10.25″ | 27 | 36 |

| 62361 | TST601W | Yellow – TRACE-SAFE TRENCH | 2,000 ft | Fl. 12 x W 16.25″” | 56 | 18 |

| Water Transmission & Distribution | ||||||

| 62244 | TST602W | Blue – TRACE-SAFE TRENCH | 1,000 ft | Fl. 12 x W 10.25″ | 12 | 36 |

| 62246 | TST602W | Blue – TRACE-SAFE TRENCH | 1,500 ft | Fl. 12 x W 10.25″ | 27 | 36 |

| 62245 | TST602W | Blue – TRACE-SAFE TRENCH | 2,000 ft | Fl. 12 x W 16.25″” | 56 | 18 |

| Sewer | ||||||

| 62358 | TST603W | Green – TRACE-SAFE TRENCH | 1,000 ft | Fl. 12 x W 10.25″ | 12 | 36 |

| 62357 | TST603W | Green – TRACE-SAFE TRENCH | 1,500 ft | Fl. 12 x W 10.25″ | 27 | 36 |

| 62356 | TST603W | Green – TRACE-SAFE TRENCH | 2, 000 ft | Fl. 12 x W 16.25″” | 56 | 18 |

MULEGLIDE Cable Blowing & Cable Pulling Lubrication

NEPTCO‘s long-lasting silicone cable blowing/pulling lubricant called MULEGLIDE is an ideal LV, MV & HV cable lubricant, available as low-viscosity Underground Cable Blowing Lubricant or MV HV Underground Cable Pulling Lubricant, which allows for swift and safe underground cable installation.

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV