Exothermic Welding

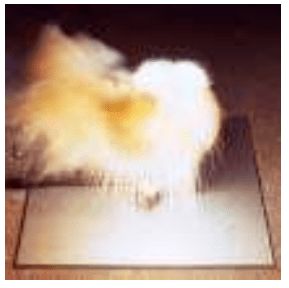

Exothermic welding is a simple, economical method of making permanent, very high quality electrical earthing connections – the exothermic welding process uses the high temperature reaction of copper oxide and aluminium within a semi-permanent graphite mould to form electrical connections mainly between copper to copper or copper to steel.

Exothermic welding requires no outside source of power or heat – the system is also light and portable ideal for field use. Making an exothermic welding joint is a simple procedure which requires a mould, weld powder, handle clamp and exothermic welding tools.

Connections are tolerant to repeated fault currents, highly conductive, permanent and demonstrate excellent corrosion resistance – most exothermic connections have at least twice the cross-sectional area of the earthing conductors being jointed.

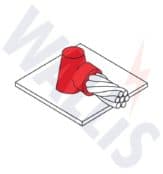

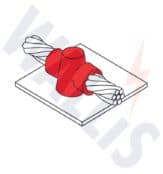

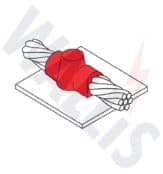

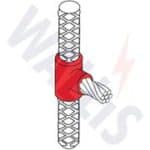

Pictured: Bare copper can be directly attached to rebar using rebar clamps for concrete encasement – here an exothermic welding system was used for this purpose. The concrete that will surround the rebar will act as a buffer, helping to prevent galvanic action from the soil.

- “Steel rebar embedded in concrete has approximately the same potential as copper, thus will not corrode” – IEEE Std. 142-1991 (IEEE Recommended Practice for Grounding of Industrial and Commercial Power Systems)

How to Make an Exothermic Welding Connection

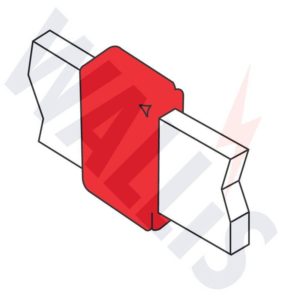

Making an Exothermic Welding Cu-nnect joint is a simple procedure which requires a mould, weld powder, handle clamp and various tools and cleaning accessories as detailed below.

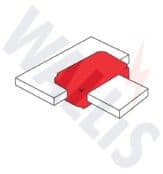

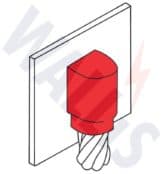

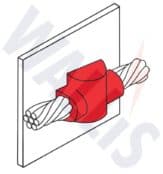

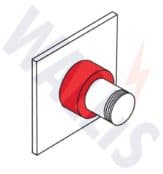

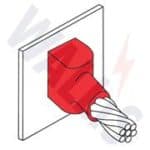

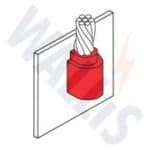

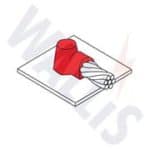

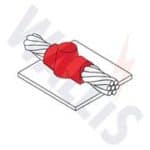

- Position cleaned conductors into exothermic mould after ensuring mould is dry, by pre-heating or making a test joint

- Lock mould with handle clamp and place metal retaining disc in bottom of exothermic welding mould crucible

- Pour weld powder into mould and place small amount of welding powder on edge of mould for easy ignition

- Close mould lid securely

- Ignite starting powder using flint gun

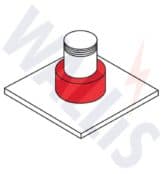

- The exothermic welding reaction occurs – wait several seconds to allow to solidify before opening the mould

- Remove the weld and clean mould carefully before making next connection

|

|

|

|

|

|

The product table below provides an overview of the exothermic welding component parts to enable the jointing and connection of the following:

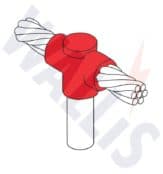

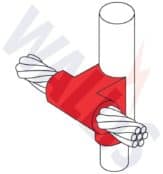

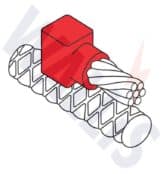

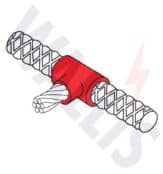

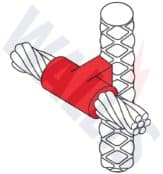

Exothermic Welding Bar to Bar

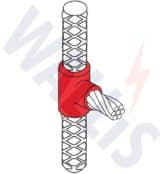

Exothermic Welding Bar To Earth Rod

Exothermic Welding Bar To Steel Surface

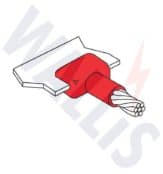

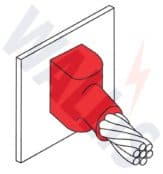

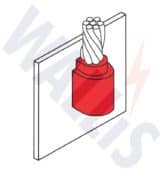

Exothermic Welding Cable To Bar

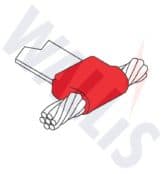

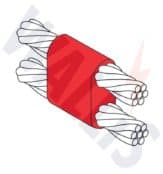

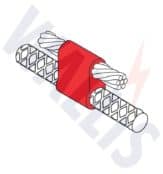

Exothermic Welding Cable To Cable

Exothermic Welding Cable To Earth Rod

Exothermic Welding Cable To Rebar

If connections shown do not meet your requirements please contact Thorne & Derrick. Special custom-made exothermic welding moulds can be produced to suit the earthing application.

| Exothermic Welding Products | |

| BB1 – Bar to Bar |  |

| BB2 – Bar to Bar |  |

| BB3 – Bar to Bar |  |

| BB7 – Bar to Bar |  |

| BB14 – Bar to Bar |  |

| BB41 – Bar to Bar |  |

| BR1 – Bar to Earth Rod |  |

| BR2 – Bar to Earth Rod |  |

| BS1 – Bar to Steel Surface |  |

| BS2 – Bar to Steel Surface |  |

| BS3 – Bar to Steel Surface |  |

| BS4 – Bar to Steel Surface |  |

| CB1 – Cable to Bar |  |

| CB4 – Cable to Bar |  |

| CB5 – Cable to Bar |  |

| CC1 – Cable to Cable |  |

| CC2 – Cable to Cable |  |

| CC4 – Cable to Cable |  |

| CC7 – Cable to Cable |  |

| CC14 – Cable to Cable |  |

| CR1 – Cable to Earth Rod |  |

| CR2 – Cable to Earth Rod |  |

| CR3 – Cable to Earth Rod |  |

| CRE1 – Cable to Rebar |  |

| CRE2 – Cable to Rebar |  |

| CRE3 – Cable to Rebar |  |

| CRE6 – Cable to Rebar |  |

| CRE17 – Cable to Rebar |  |

| CS1 – Cable to Steel Surface |  |

| CS2 – Cable to Steel Surface |  |

| CS3 – Cable to Steel Surface |  |

| CS7 – Cable to Steel Surface |  |

| CS8 – Cable to Steel Surface |  |

| CS9 – Cable to Steel Surface |  |

| CS25 – Cable to Steel Surface |  |

| CS27 – Cable to Steel Surface |  |

| RS1 – Stud to Steel Surface |  |

| RS2 – Stud to Steel Surface |  |

Exothermic Welding Powders

AN Wallis Cu-nnect exothermic welding powders are a high quality mixture of copper oxide and aluminium – the starting powder is compacted at the bottom of each cartridge with the weld metal on top, the starting powder is released by firmly tapping the base of the cartridge.

Exothermic Welding Powders

Exothermic Welding Tools

| AN Wallis Part Ref | Description |

| TCB 001 | Tape Cleaning Brush |

| CCB 001 | Cable Cleaning Brush |

| MCB 001 | Mould Cleaning Brush |

| MCS 001 | Mould Cleaning Scraper |

| FGN 001 | Flint Gun |

| FLT 001 | Replacement Flints |

| DSC 001 | Disc Container |

| DXS 001 | Duxseal Sealing Compound (1lb) |

| PAK 001 | Ceramic Packing |

| BTT 001 | Butane Torch |

| TBX 001 | Welding Toolbox |

| CTK 001 | Cu-nnect Toolkit for Bar Connections. Contains the following: Tape Cleaning Brush (TCB 001) Mould Cleaning Brush (MCB 001) Mould Cleaning Scraper (MCS 001) Flint Gun (FGN 001) |

| CTK 002 | Cu-nnect Toolkit for Cable Connections. Contains the following: Tape Cleaning Brush (TCB 001) Cable Cleaning Brush (CCB 001) Mould Cleaning Brush (MCB 001) Mould Cleaning Scraper (MCS 001) Flint Gun (FGN 001) |

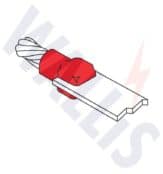

Welding Handle Clamps

A Handle Clamp is required to hold the graphite mould and conductors in place whilst the connection is being made. There are three sizes of handle clamps shown in the table below:

| AN Wallis Part Number | Description |

| HCA 001 | Small Handle Clamp |

| HCC 001 | Medium Handle Clamp |

| HCC 002 | Medium Handle Clamp with Vertical Chain Support |

| HCC 003 | Medium Handle Clamp with Vertical Beam Support |

| HCC 004 | Medium Handle Clamp with Horizontal Chain Support |

| HCD 001 | Large Handle Clamp |

| HCD 002 | Large Handle Clamp with Vertical Chain Support |

| HCD 003 | Large Handle Clamp with Vertical Beam Support |

| HCD 004 | Large Handle Clamp with Horizontal Chain Support |

Handle Clamps

Earthing

Copper electrodes (including earth tapes and rods), conductors, clamps and earth bonding bars provide lightning and transient overvoltage energy with a direct and effective low resistance route from the Earthing & Lightning Protection Systems safely to earth.

See full range of AN Wallis Earthing Products